452 0 0 0 OA 銅より線と黄銅端子圧着部の力学的作用

- 著者

- 藤巻 裕彦 鷹合 徹也 佐野 一仁

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.13, no.4, pp.550-555, 1995-11-05 (Released:2009-06-12)

- 参考文献数

- 3

- 被引用文献数

- 2 3

Crimping mechanism between the stranded copper wires and brass terminals was investigated in terms of repulsion force acting on crimp terminations by way of the stranded wires. The repulsion force was estimated from the load-displacement curves recorded during the crimping process. We obtained the results as follows;(1) Repulsion forces, which were based on the elastic deformation of the strand composing wires, are observed between the stranded wires and crimp terminals.(2) The repulsion forces have a peak value at the compression ratio of 27% in the crimp terminations.(3) The suitable conditions of the contact resistance and the crimping strength are secured under the conditions of the peak value of the repulsion forces.

52 0 0 0 OA 2 深海潜水調査船の定期点検とメンテナンスについて

- 著者

- 脇田 典英 井上 和也

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.65, no.2, pp.141-142, 1996-03-05 (Released:2011-08-05)

- 参考文献数

- 4

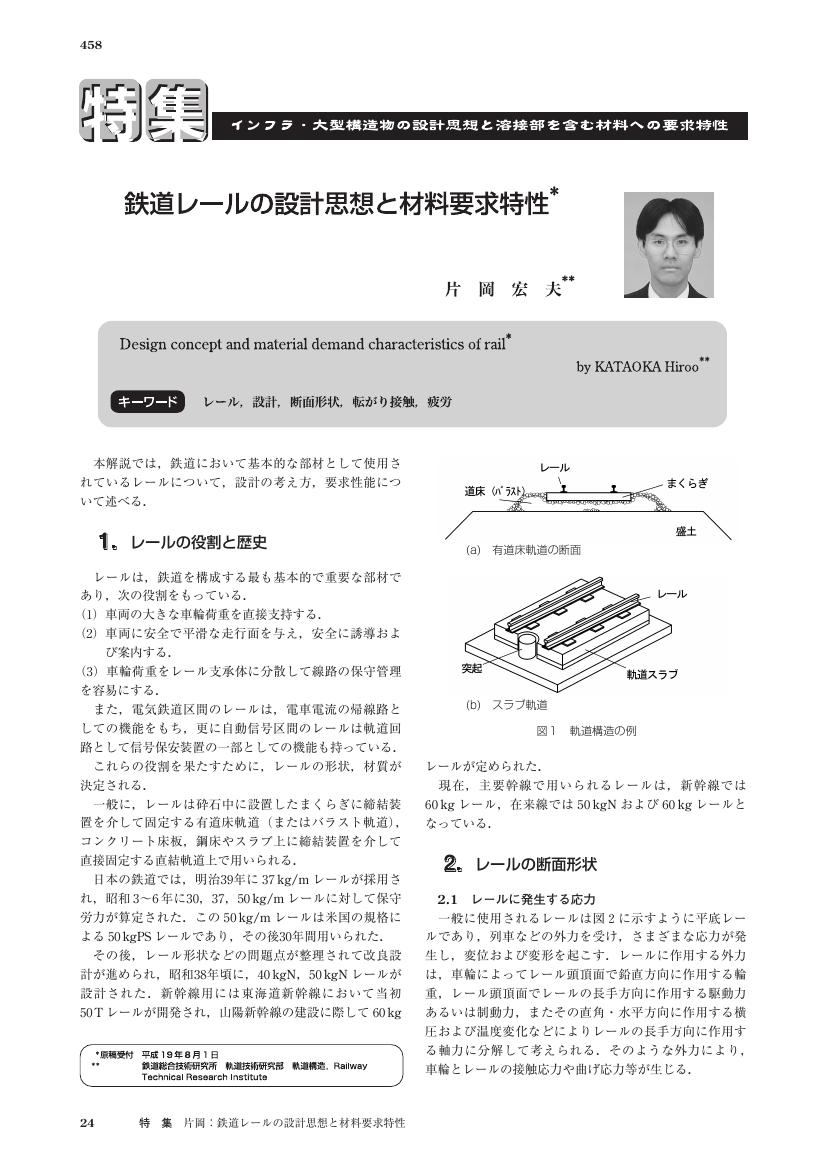

35 0 0 0 OA 鉄道レールの設計思想と材料要求特性

- 著者

- 片岡 宏夫

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.76, no.6, pp.458-461, 2007 (Released:2012-02-20)

- 参考文献数

- 5

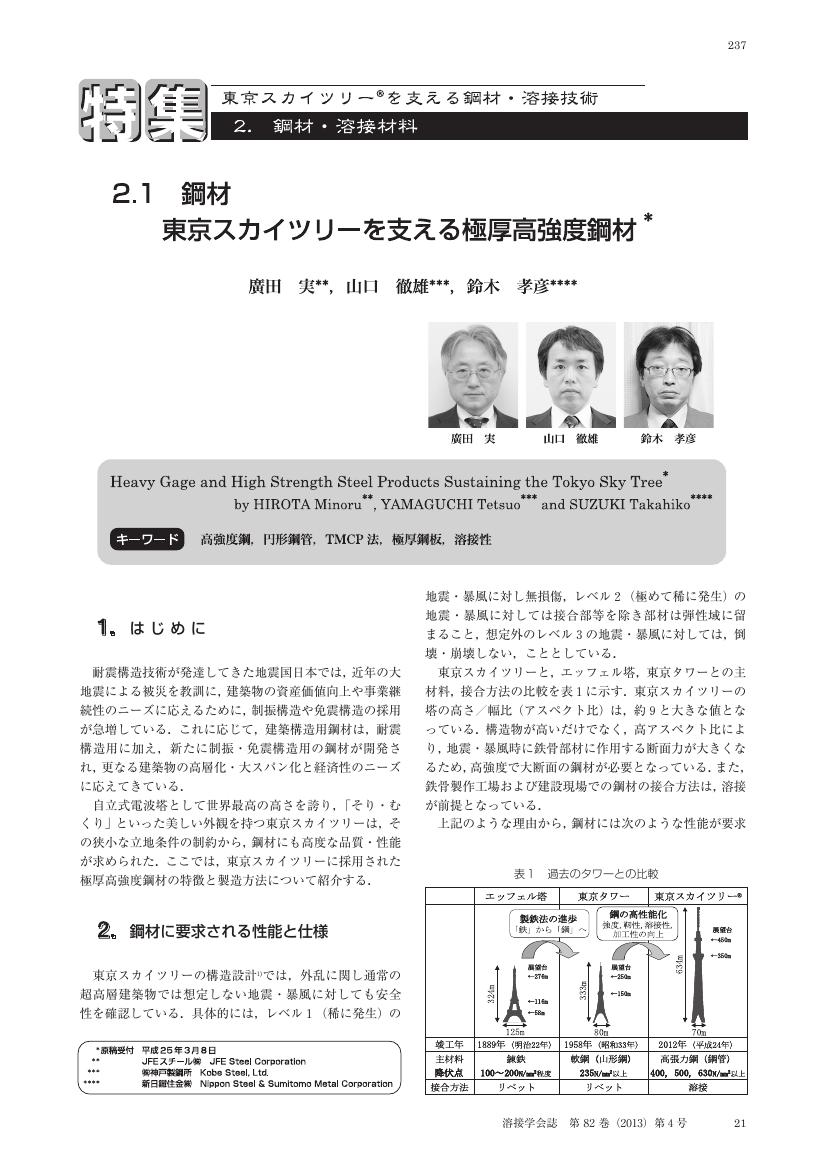

8 0 0 0 2.1 鋼材 東京スカイツリーを支える極厚高強度鋼材

- 著者

- 廣田 実 山口 徹雄 鈴木 孝彦

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.82, no.4, pp.237-240, 2013 (Released:2015-04-09)

- 参考文献数

- 6

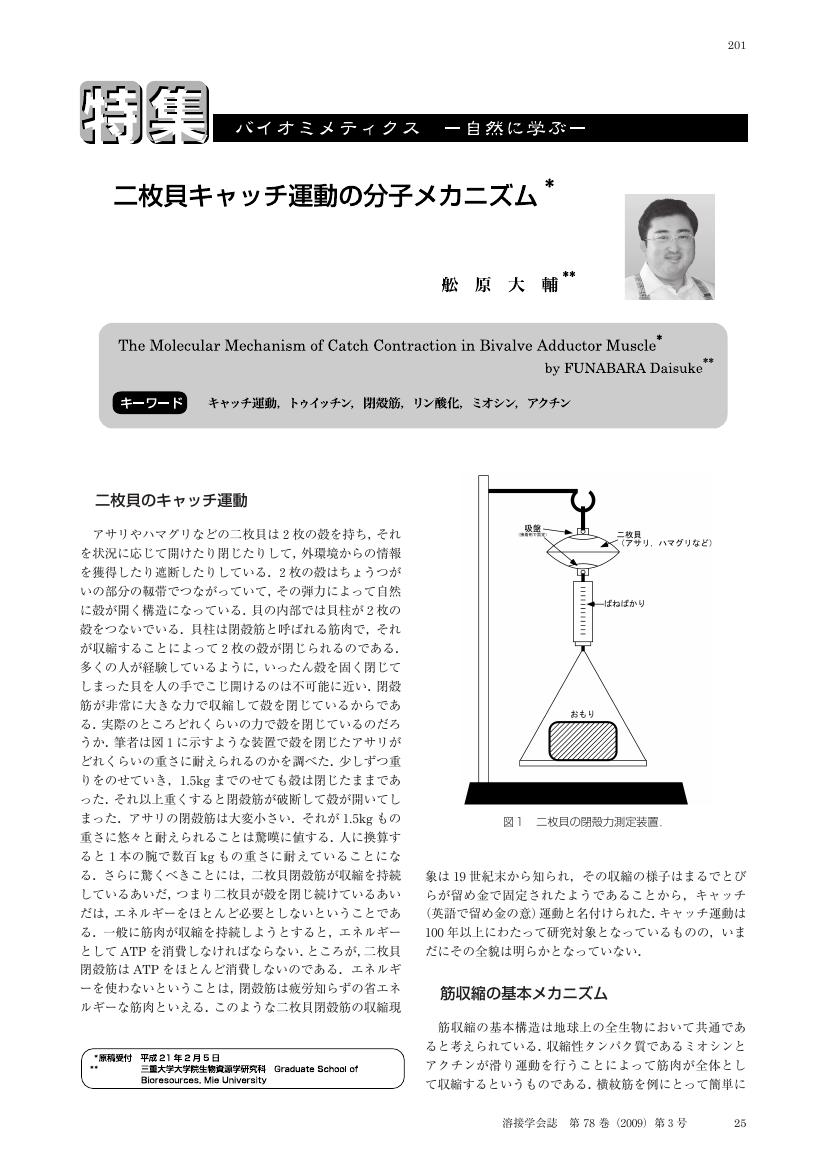

7 0 0 0 OA 二枚貝キャッチ運動の分子メカニズム

- 著者

- 舩原 大輔

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.78, no.3, pp.201-205, 2009 (Released:2014-02-12)

- 参考文献数

- 5

6 0 0 0 OA 特殊鋼板の熔接手記(I)

- 著者

- 手塚 敬三

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.17, no.4, pp.156-159, 1948 (Released:2009-06-12)

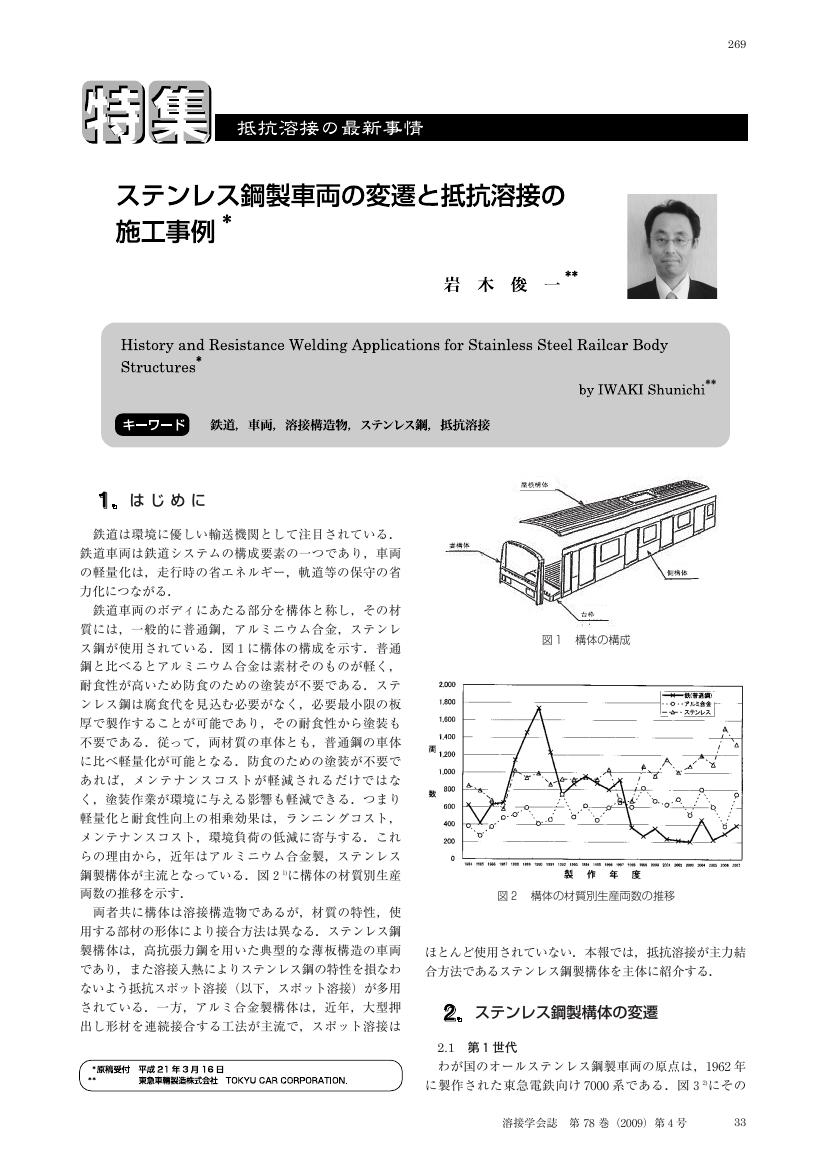

6 0 0 0 OA ステンレス鋼製車両の変遷と抵抗溶接の施工事例

- 著者

- 岩木 俊一

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.78, no.4, pp.269-273, 2009 (Released:2014-02-12)

- 参考文献数

- 7

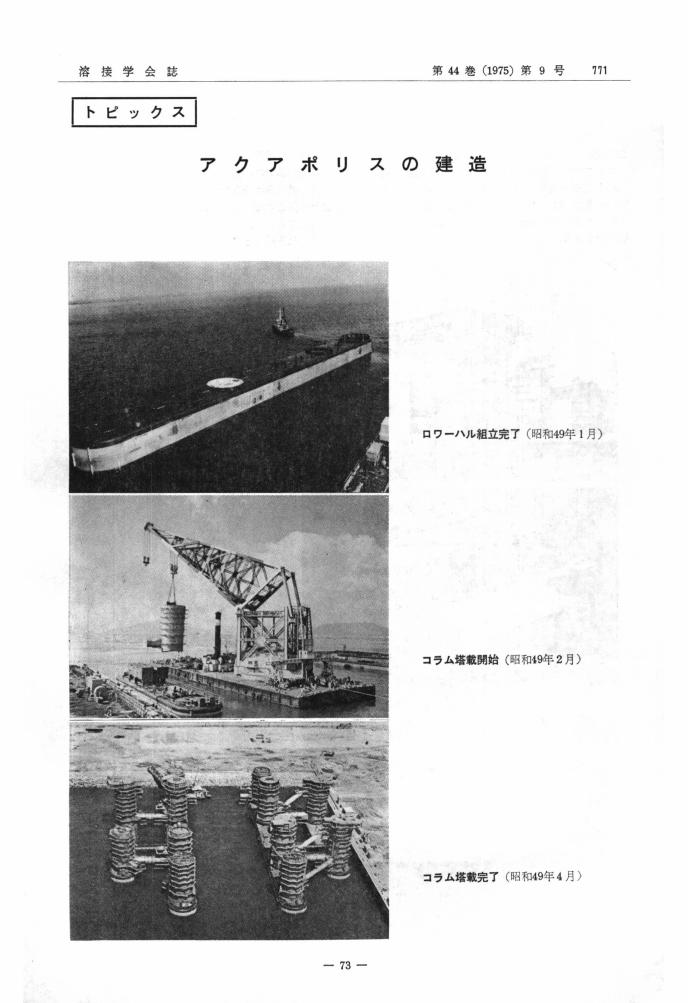

6 0 0 0 OA トピックス・アクアポリスの建造

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.44, no.9, pp.771-773, 1975-09-05 (Released:2011-08-05)

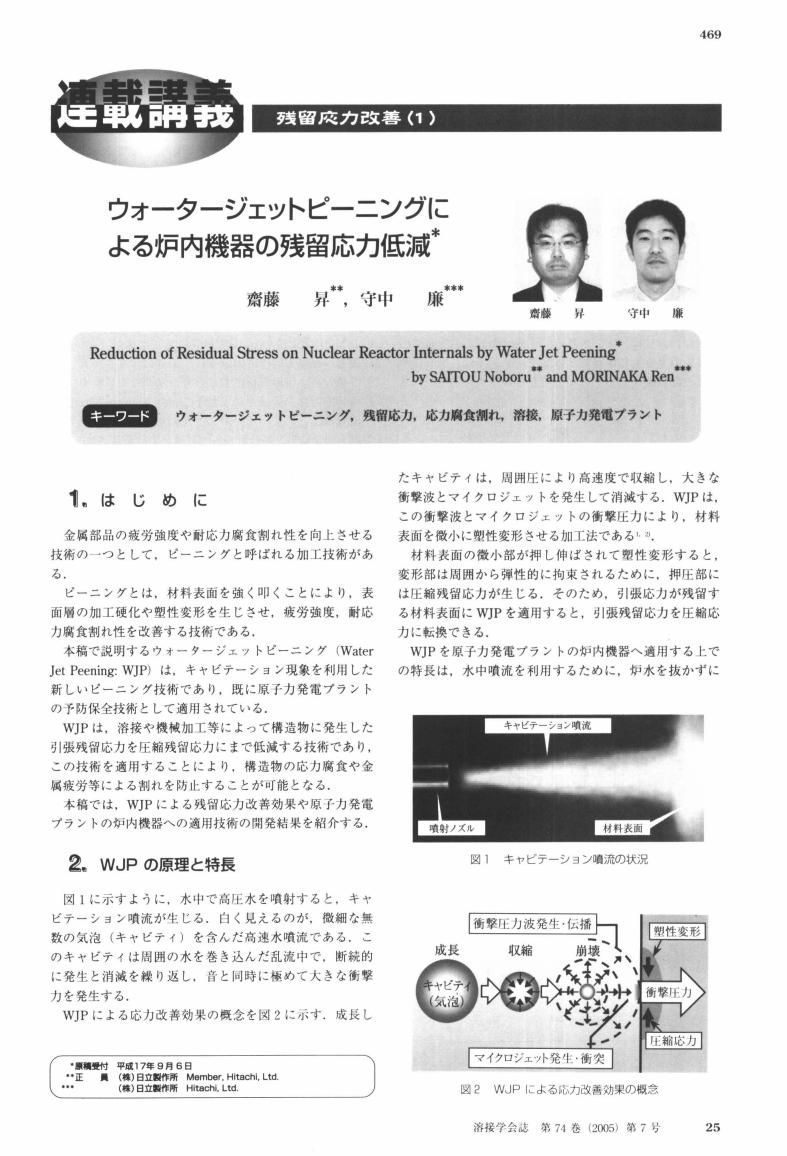

6 0 0 0 OA ウォータージェットピーニングによる炉内機器の残留応力低減

- 著者

- 齋藤 昇 守中 廉

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.74, no.7, pp.469-472, 2005-10-05 (Released:2011-08-05)

- 参考文献数

- 4

- 被引用文献数

- 1

5 0 0 0 OA 日本における原子力発電所の建設に伴う溶接の諸問題

- 著者

- 橋本 宇一 木原 博 安藤 良夫

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.33, no.4, pp.357-363, 1964-04-25 (Released:2011-08-05)

The first nuclear power station in Japan (Advanced Calder Hall type, 166 MW electric) is now under construction at Tokaimura.Construction of several new nuclear power stations will begin within a few years and also building project of the first nuclear powered ship (6500 G.T.) has been started in 1963.Al-killed steel plates 8094 mm thick were manually welded for Tokai reactor pressure vessel and its steam raising units were constructed with 5474 mm thick boiler plates using both submerged arc and manual welding. JPDR is a small BWR (12.5 MW electric), and the inner surface of its pressure vessel was stainless steel cladded by submerged arc process.Researches on the welding of the nuclear reactor have been extensively carried out by Japan Welding Engineering Society and also each industrial plant is doing its own researches. The study on the effect of irradiation on the properties of materials has been just started.

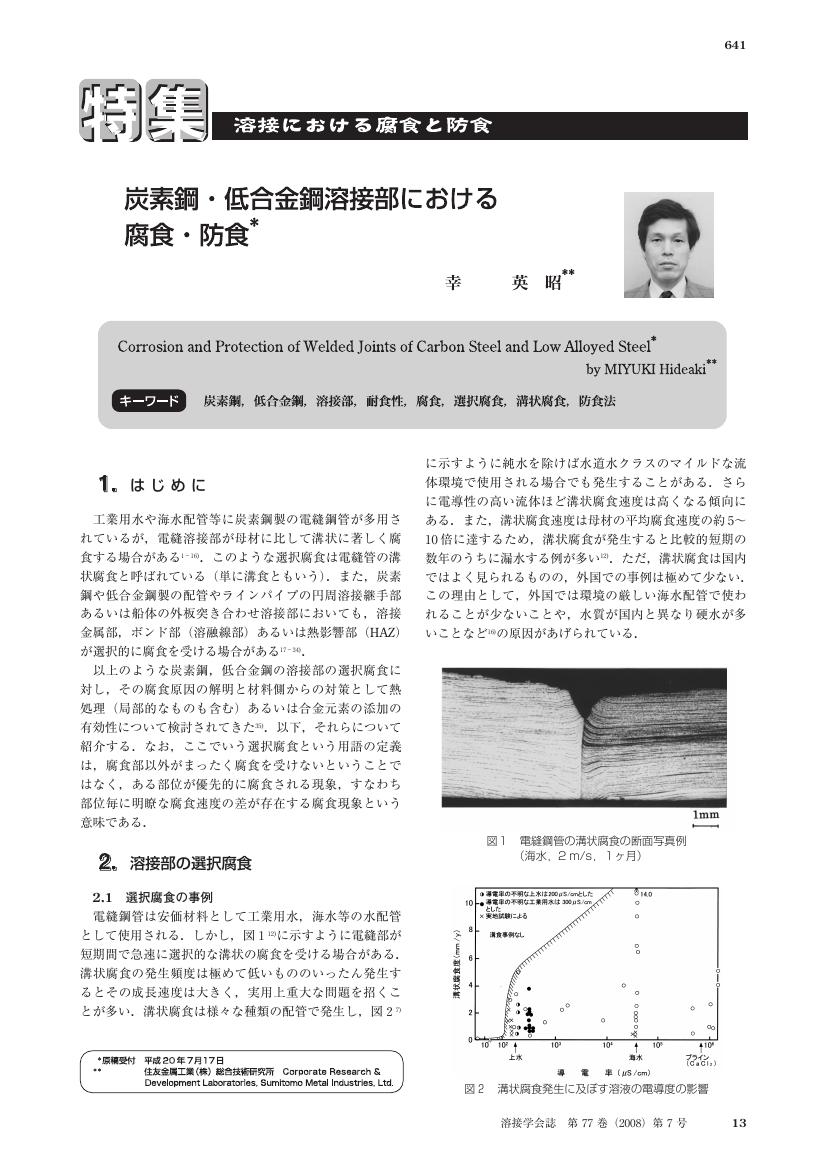

4 0 0 0 OA 炭素鋼・低合金鋼溶接部における腐食・防食

- 著者

- 幸 英昭

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.77, no.7, pp.641-645, 2008 (Released:2012-10-05)

- 参考文献数

- 36

- 被引用文献数

- 2 1 2

4 0 0 0 OA インタビュー -溶接タマゴ-

- 著者

- ZHOU Qiaofeng

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.86, no.3, pp.192-194, 2017 (Released:2017-04-15)

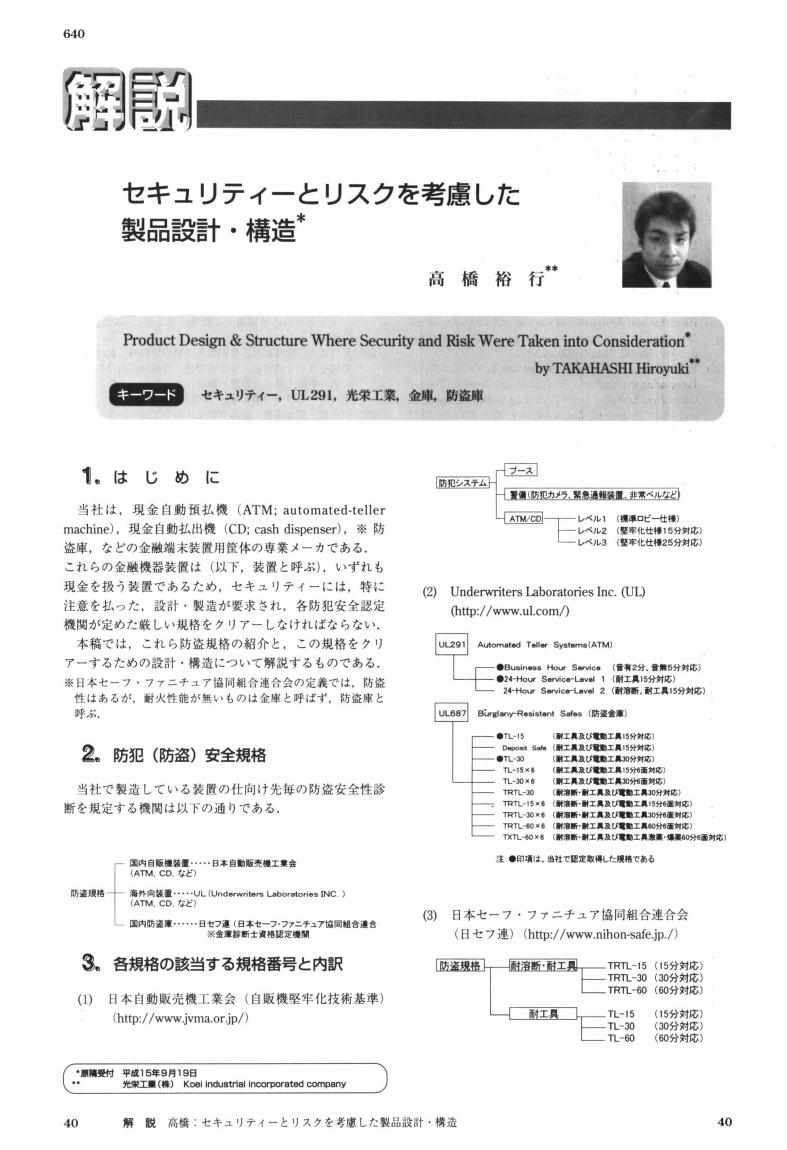

4 0 0 0 OA セキュリティーとりスクを考慮した製品設計・構造

- 著者

- 高橋 裕行

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.72, no.8, pp.640-643, 2003-12-05 (Released:2011-08-05)

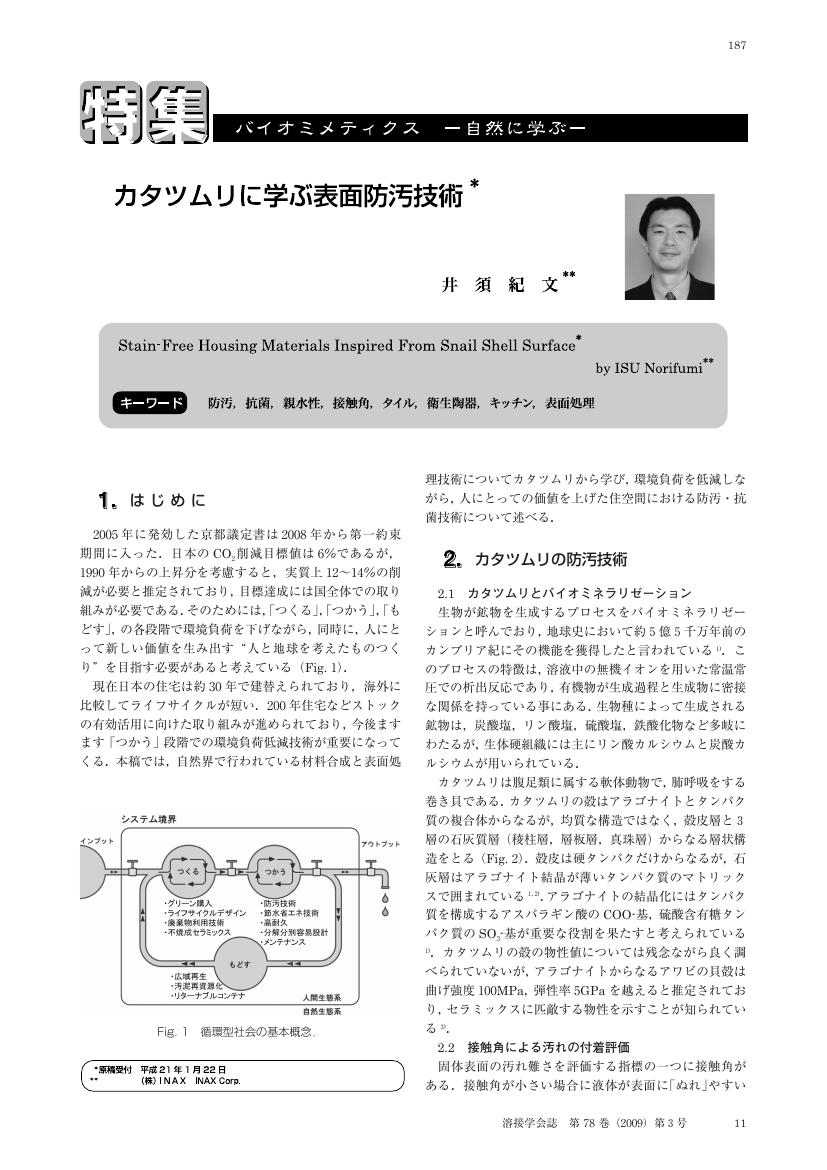

4 0 0 0 OA カタツムリに学ぶ表面防汚技術

- 著者

- 井須 紀文

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.78, no.3, pp.187-190, 2009 (Released:2014-02-12)

- 参考文献数

- 10

- 被引用文献数

- 4 7

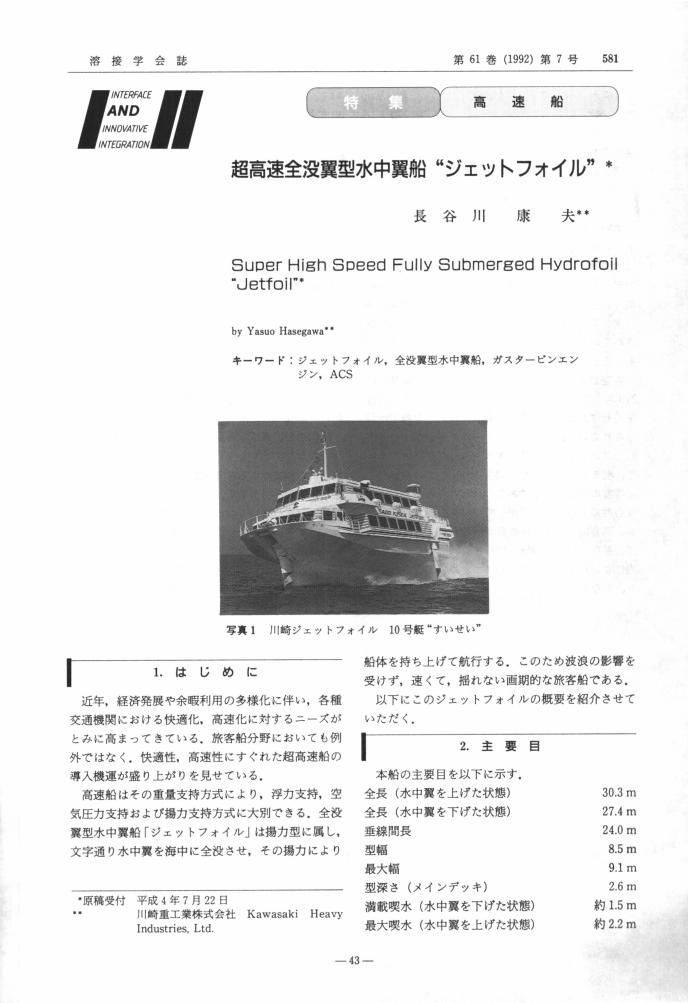

3 0 0 0 OA 超高速全没翼型水中翼船"ジェットフォイル"

- 著者

- 長谷川 康夫

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.61, no.7, pp.581-586, 1992-10-05 (Released:2011-08-05)

- 参考文献数

- 4

- 被引用文献数

- 1

3 0 0 0 OA 横浜ランドマークタワーの構造設計

- 著者

- 山崎 真司

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.61, no.2, pp.107-112, 1992-03-05 (Released:2011-08-05)

- 参考文献数

- 1

- 被引用文献数

- 2

3 0 0 0 OA 製造業発展の担い手は溶接

- 著者

- 高野 元太

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.81, no.8, pp.633-635, 2012 (Released:2015-02-05)

- 参考文献数

- 1

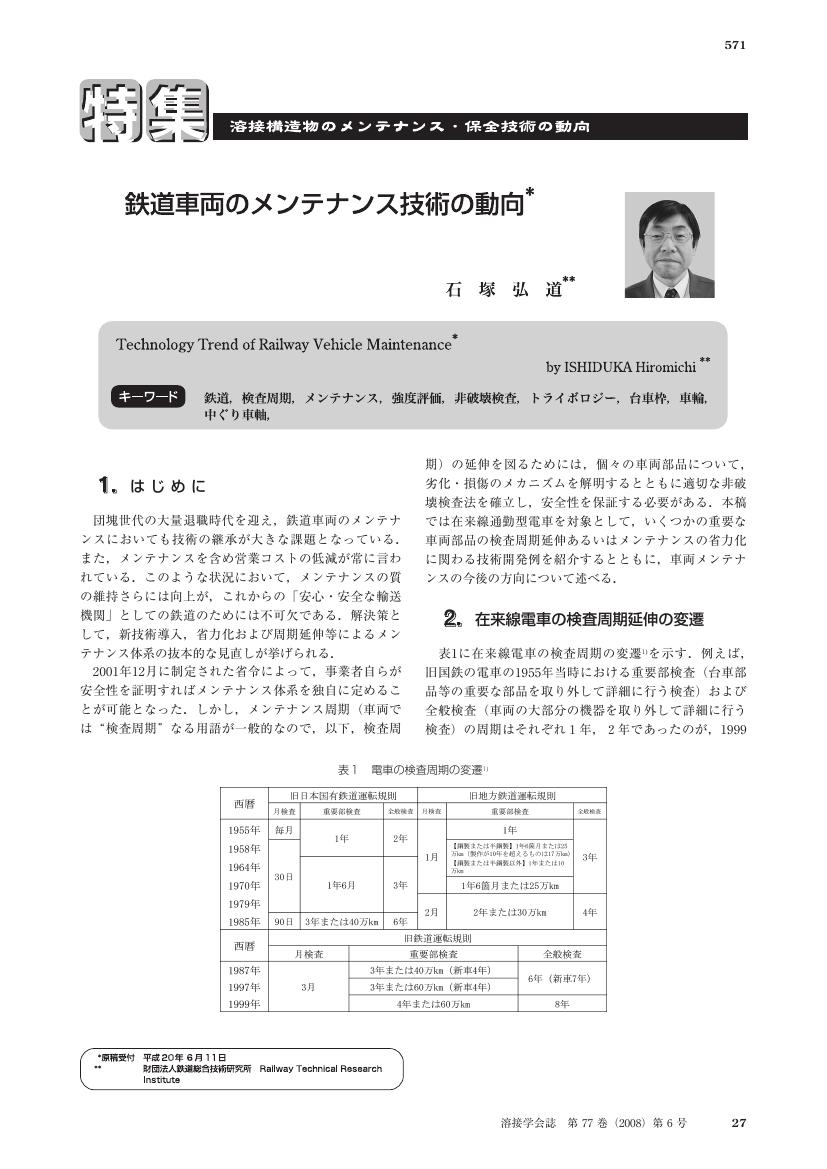

3 0 0 0 OA 鉄道車両のメンテナンス技術の動向

- 著者

- 石塚 弘道

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.77, no.6, pp.571-575, 2008 (Released:2012-10-05)

- 参考文献数

- 8

- 被引用文献数

- 2

- 著者

- 児玉 真二 椙浦 一輝 中西 省太 坂井 大介 辻村 吉寛 田中 学 MURPHY Anthony B.

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.31, no.1, pp.80-87, 2013 (Released:2013-04-17)

- 参考文献数

- 11

- 被引用文献数

- 1 1

The influences of welding condition on the atmospheric nitrogen mixing into the arc plasma in helium GTA welding was analyzed by numerical simulations. In order to evaluate the effects of the convection flow and the diffusion on the nitrogen mixing phenomenon, the distributions of the Peclet number was used. Elongation of the electrode length has low impact on the decrease of shielding gas concentration because the convection flow becomes dominant in this area which indicates higher Peclet numbers. Meanwhile, the nitrogen diffusion increases in the plasma area with the temperature of about 10,000K, so that elongation of the arc length leads to a remarkable decrease of shielding gas concentration. Additionally, the impact of convection flow increases in the arc center area where high-velocity plasma jet exists, and the shielding gas concentration tends to rise owing to higher welding current in the condition of sufficient shielding gas flow rate.

3 0 0 0 OA 水中におけるプラズマ溶接(第2報)

- 著者

- 蓮井 淳 衣川 純一 菅 泰雄

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.42, no.1, pp.18-28, 1973-01-25 (Released:2011-08-05)

- 参考文献数

- 1

A new underwater plasma welding process has been developed. In this process, viscous liquid is used in place of shielding gas to protect the part being welded from the surrounding water and to stabilize plasma arc.Welding experiments are done by using steel for welded structure of 6 mm in thickness and it is ascertained that this process can be put to practical use.Main results are summarized as follows:(1) Water glass is used as a typical viscous liquid.(2) Water glass shielding for the part being welded has a marked effect on stabilization of underwater plasma arc.(3) Water glass shielding has an effect on heat insulating of the part being welded and lowers the solidification rate of molten metal. Owing to this feature, the weld metal does not include a blowhole and the maximum hardness of the heat-affected zone adjacent to the bond is lowered considerably.(4) The weld resulting from this process has excellent mechanical properties, and especially its ductility and notch toughness can be improved remarkably, compared with those of the weld resulting from nonshielding.(5) Coefficient of viscosity and flow (feeding) rate of shielding water glass should be selected properly. However, the proper range of combinations of viscosity and flow rate may be relatively wide.