- 著者

- Reon Ando Takashi Matsuno Tomoko Matsuda Norio Yamashita Hideo Yokota Kenta Goto Ikumu Watanabe

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.61, no.1, pp.473-480, 2021-01-15 (Released:2021-01-16)

- 参考文献数

- 21

- 被引用文献数

- 3

Herein, we investigated the local preliminary hardening of ferrite near the ferrite–martensite interfaces in a dual-phase (DP) steel. Geometrically necessary dislocations (GNDs), generated due to interfacial misfit between different phases, may cause preliminary hardening of ferrite around such interfaces. However, for nano-hardness distribution, the hardened zone was not evidently detected by scattering measurement. Thus, we factorized nano-hardness scattering to estimate the actual ferrite hardness near ferrite–martensite interfaces.First, nano-hardness was measured around a martensite island using a conical nano-indenter in the DP steel containing 10% martensite by volume. Taking into account the scattering, the nano-hardness measurement converged to the hardness of ferrite, exceeding the distance corresponding to the nano-indenter radius. Thus, a preliminary hardening zone was not detected. Subsequently, the surface of the nano-indented microstructure was polished and observed using scanning electron microscopy (SEM) by analyzing electron back scattering diffraction (EBSD). This analysis confirmed the presence of the nano-indented microstructure under ferrite. Moreover, it established that the majority of the irregularly higher nano-hardness was caused by the buried martensite under ferrite. The value of the kernel average misorientation (KAM), which is proportional to the GND density for other irregularly higher nano-hardness points, was higher for the nano-indented microstructure as compared to that of the buried martensite. On the other hand, the ferrite was expanded under the nano-indented points for the majority of the irregularly lower nano-hardness, with some exceptions. Further, soft martensite was observed to induce irregularly lower nano-hardness locally around the interface.

- 著者

- Kohta Koenuma Akinori Yamanaka Ikumu Watanabe Toshihiko Kuwabara

- 出版者

- The Japan Institute of Metals and Materials

- 雑誌

- MATERIALS TRANSACTIONS (ISSN:13459678)

- 巻号頁・発行日

- vol.61, no.12, pp.2276-2283, 2020-12-01 (Released:2020-11-25)

- 参考文献数

- 31

- 被引用文献数

- 13

The deformation of an aluminum alloy sheet is affected by its underlying crystallographic texture and has been extensively studied using the crystal plasticity finite element method (CPFEM). Numerical material test based on the CPFEM enables the quantitative estimation of the stress-strain curve and Lankford value (r-value), which depend upon the texture of aluminum alloy sheets. However, the application of CPFEM-based numerical material test to the optimization of aluminum alloy texture is computationally expensive. In this paper, we propose a method for rapidly estimating the stress-strain curves and r-values of aluminum alloy sheets using deep learning with a neural network. We train the neural network with the synthetic crystallographic texture and stress-strain curves calculated through the numerical material tests. To capture the features of synthetic texture from a {111} pole-figure image, the neural network incorporates a convolution neural network. Using the trained neural network, we estimate the uniaxial stress-strain curve and in-plane anisotropy of the r-value for various textures that contain Cube and S components. The results indicate that the application of a neural network trained with the results of numerical material test is a promising method for rapidly estimating the deformation of aluminum alloy sheets. This Paper was Originally Published in Japanese in J. JSTP 61 (2020) 48–55.

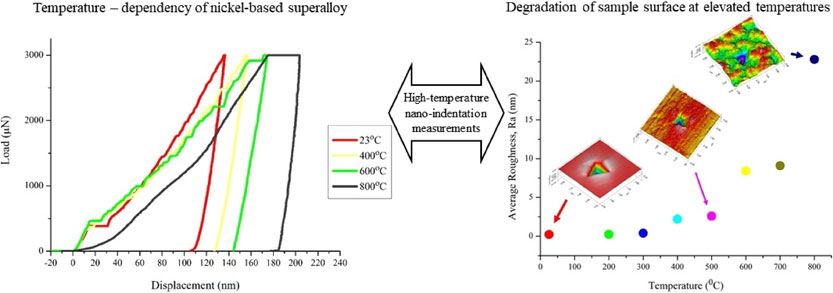

1 0 0 0 OA Nano-Indentation Measurement for Heat Resistant Alloys at Elevated Temperatures in Inert Atmosphere

- 著者

- Jovana Ruzic Ikumu Watanabe Kenta Goto Takahito Ohmura

- 出版者

- The Japan Institute of Metals and Materials

- 雑誌

- MATERIALS TRANSACTIONS (ISSN:13459678)

- 巻号頁・発行日

- vol.60, no.8, pp.1411-1415, 2019-08-01 (Released:2019-07-25)

- 参考文献数

- 22

- 被引用文献数

- 10

A new approach of nano-indentation measurements at elevated temperatures has been developed to evaluate a temperature-dependent mechanical behavior of heat resistant alloys on a submicron scale, where the measurement is conducted in an inert atmosphere to prevent the surface oxidation of a sample and heat an indenter passively. The developed approach enables us to perform nano-indentation testing with a diamond indenter in the temperature range of 23∼800°C. The developed approach has been applied to gamma single-phase single-crystal of a nickel-based superalloy. Then the degradations of the sample surface and the indenter tip have been discussed in this case.