75 0 0 0 OA 航空發動機用曲軸鋼の撰定竝に其將來に就て

- 著者

- 高瀬 孝次

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.22, no.2, pp.107-120, 1936-02-25 (Released:2009-07-09)

Owing to the marked increase of aero-engine power, number of revolution, compression ratio, etc., crankshaft should inevitably biar the vibrational and duplicated over-stresses. The crankshaft should, therefore, not only be of the best chemical composition, most properly heat-treated, the latest metallurgical procedure being applied, but also of the most perfect design, in addition to the minimum weight and size.The writer has published a part of this investigation in the "Tetsu To Hagane" Vol. XIX, No.4 In this paper, in order to select the most suitable steel for the future, the notch effect in regard to the endurance properties and the influence of heat-treatment of these steels have been investigated.An investigation of crankshaft steel on the relation between the mechanical test results and the endurance properties by fatigue test have also been executed, and the writer has introduced a new method for determing the endurance limit in stead of laborious fatigue test.As a conclusion, the writer has suggested future requirements for the aero-engine crankshaft steel, considering all the facts above mentioned.

31 0 0 0 OA 小型たたら炉による鋼製錬機構

- 著者

- 永田 和宏

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.84, no.10, pp.715-720, 1998 (Released:2009-06-19)

- 参考文献数

- 7

- 被引用文献数

- 8 9

Tatara was used to be a traditional process to produce solid steel, so called "Kera", and/or liquid pig iron, so called "Zuku", from iron sand and charcoal using the box type furnace with blowing cold air intermittently. A modified Tatara furnace has been examined on the production mechanisms of "Kera". Temeratures and oxygen partial pressures in the furnace were measured by means of thermocouples and oxygen sensors with solid electrolyte of zirconia. Iron sand and a piece of "Kera" produced in the bottom of furnace were sampled and analyzed chemically or by a electron probe micro analyser. Iron sand is reduced above tuyere and absorbs carbon on fired charcoals in front of the tuyere at about 1350°C. Many small balls of liquid steel with different carbon content were found in molten slag pool of FeO-saturated silica, so-called "Noro", and cohere each other to grow into a bloom. The characteristics of Tatara steelmaking process are low temperature for carbon absorption of steel at about 1350°C, high oxygen potential in the molten slag of FeO-saturated silica and hypo-eutectic carbon content in steel.

18 0 0 0 OA AMS-炭素14年代測定法が明らかにした日本の鉄の歴史

- 著者

- 藤尾 慎一郎

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.91, no.1, pp.11-15, 2005-01-01 (Released:2009-06-19)

- 参考文献数

- 12

- 被引用文献数

- 3 2

This paper focuses on the influence what the AMS-carbon 14 age method attains to the history of the iron in the Japanese Islands.The research team in National Museum of Japanese History makes a clear that the Yayoi period began in 10 Cen. cal BC. However, there was a problem in this.It is iron. If the Yayoi period has started in the 10th Cen. BC, it means that the ironware in Japanese Islands had spread early rather than it spreads in China.The research team reexamined the ironware excavated from Magarita site in the Fukuoka Pref. considered to be the oldest ironware in Japan. Consequently, the excavation situation was indefinite and it turned out that we cannot specify the time to belong.Furthermore, 36 ironwares in the initial and early Yayoi were also already found by that time cannot be specified except for two points. Therefore, it turned out that Japanese ironware appeared in the 3rd century of B.C. What does this mean?Although it had been thought that the beginning of agriculture in Japan and the appearance of ironware were simultaneous, it turned out that agriculture has appeared early about in 700 years. Therefore, it became clear that agriculture of Japan started at the Stone Age.

17 0 0 0 OA 装甲鈑製造についての回顧録

- 著者

- 佐々川 清

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.53, no.9, pp.1119-1129, 1967-08-01 (Released:2010-10-12)

- 著者

- Tomotaka Sasada Amartuvshin Chunag

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.54, no.5, pp.1017-1023, 2014-05-15 (Released:2014-06-12)

- 参考文献数

- 11

- 被引用文献数

- 3 15

The first archeological evidence in Mongolia of an iron-smelting site has been discovered at Khustyn Bulag. This site belongs to the Xiongnu age (209BCE-155CE). The Xiongnu was the first Nomadic Empire in east Eurasia. Our excavation area was quite small but contained many interesting structures (smelting furnaces, calciners or roasters of iron ore, and slag disposal pits) and artifacts (a few pieces of pottery of Xiongnu age, many clay tuyeres and slag, stone hammers and stone anvil). We could categorize the furnaces into three types, but all of them had slag pits. In addition, several clay tuyeres were used at each furnace. These characteristics of iron smelting are related not to China but to South Siberia. We also performed metallurgical and mineralogical analyses on the slag, clarified the processes of direct steel-making, roasting of iron ore (Magnetite), and found the iron mine that supplied ore to the site. We consider our research results sufficient to undertake a comparative study on Eurasia scale. This iron-smelting technology was introduced into ancient Mongolia from the West through the Steppe-Taiga area and was adjusted and locally developed (or originally), even though iron production was in conflict with the traditional nomadic life-style of the ancient Mongolians. We will continue our research, to clarify the interesting process that led nomadic society to produce political system and establish a nomadic state.

14 0 0 0 OA 日本刀の鍛錬性に及ぼす南蛮鉄のリン含有量の影響

- 著者

- 鈴木 卓夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.90, no.1, pp.43-47, 2004-01-01 (Released:2009-05-29)

- 参考文献数

- 10

- 被引用文献数

- 2 2

Nanban-tetsu is a steel which was imported into Japan by Portuguese or Spanish merchant ships in the end of Muromachi period (1392-1573). The steel was produced in India and called "Wootz steel". Nanban-tetsu steel was shaped in some forms of a gourd called "Hyotan", a oval called "Koban", a square timber called "Saijo", a semi-cylinder called "Tajo" and others. In 1613, one of the Japanese sword smith, Echizen Yasutsugu 1, first produced a sword using Nanban-tetsu steel. Since then, many sword smiths who lived in Echizen area (Fukui Prefecture) had used Nanban-tetsu steel as a material of Japanese swords. The steels produced using the "Nittoho-Tatara" furnace in Shimane prefecture has been examined by forge-welding as a function of phosphor content in the steels. It is concluded that "Hyotan" shaped Nanban-tetsu steel is not good for forging, "Saijo" shaped Nanban-tetsu steel is good for forging, "Koban"-shaped one is difficult to forgeweld and "Tajo"-shaped one is intermediate.

8 0 0 0 OA New Materials for High Speed Railway Vehicle

- 著者

- Yasufumi SUZUKI

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- Tetsu-to-Hagane (ISSN:00211575)

- 巻号頁・発行日

- vol.79, no.8, pp.N568-N575, 1993-08-01 (Released:2009-06-30)

- 参考文献数

- 13

- 被引用文献数

- 4

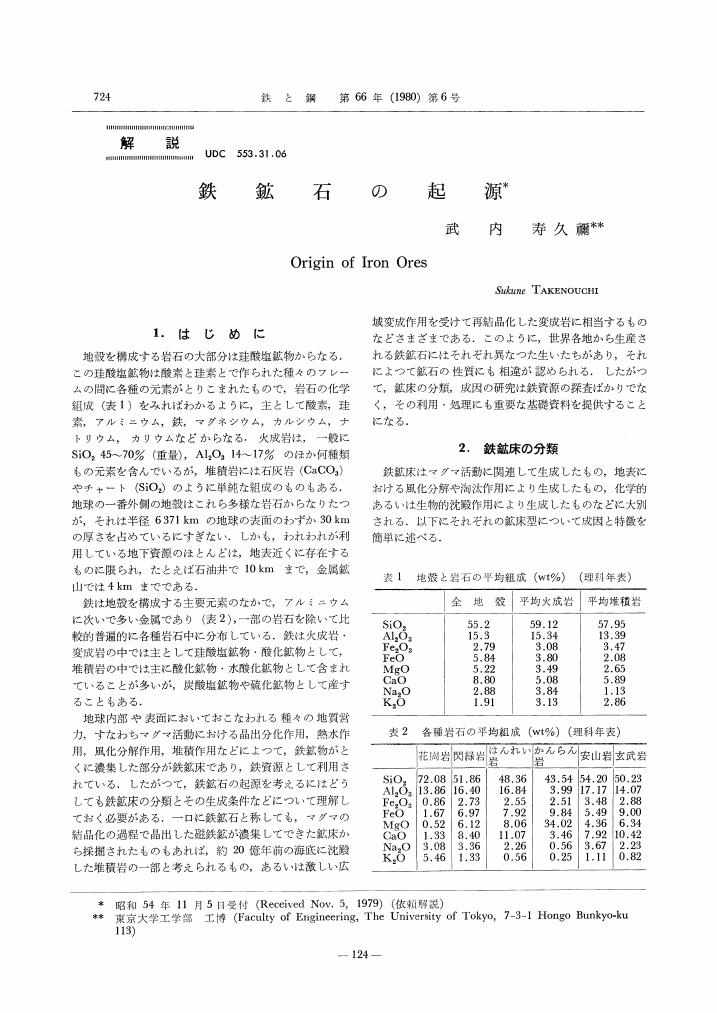

7 0 0 0 OA 鉄鉱石の起源

- 著者

- 武内 寿久禰

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.66, no.6, pp.724-729, 1980-05-01 (Released:2009-06-19)

- 被引用文献数

- 2 5

5 0 0 0 OA わが国における製鉄技術の歴史

- 著者

- 舘 充

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.91, no.1, pp.2-10, 2005-01-01 (Released:2010-01-19)

- 参考文献数

- 35

- 被引用文献数

- 5 7

Iron making from iron sand in Chugoku district began soon after the introduction of iron ore smelting by the low shaft box-type furnace in the middle of the sixth century and it rapidly spread all over the country, but Chugoku district continued to be the center of its progress. The process consistently developed throughout the ancient and the medieval times towards more elevated furnace temperature by means of increased furnace volume, improved underground facilities for moisture elimination and increased blowing capacity of bellows. The development resulted in the birth of Tatara as the finally-evolved box-furnace on the one hand and in the change of the chief product of smelting from lumpy mixture of metal with slag or a large metal block involving some slag to molten pig iron (Zuku) on th other hand. The priority production of Zuku led to the invention of the two-stage refining process for its conversion into wrought iron (Ohkaji) in the 17th century. Zuku-making by Tatara and refining by Ohkaji formed Japanese indirect wrought iron making system.Metal block (Kera), which was formed in Zuku making from a sort of iron sand hard to fuse (Masa) compared with another sort of iron sand (Akome), proved to contain about 50% parts of steel high in carbon content, which, naturally, were taken out by hammering after the rough crushing by falling-weight methd.Because of economical disadvantages mainly due to inefficiency of iron sand smelting, Japanese indirect iron making system could not survive after 1923 in spite of several successes in developing new iron making process of blast furnace-type. However Tatara is preserved as a technical heritage and is still operated several times a year for direct steel making through Kera.

- 著者

- Yoshikazu Matsuoka Tatsuya Iwasaki Nobuo Nakada Toshihiro Tsuchiyama Setsuo Takaki

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.53, no.7, pp.1224-1230, 2013 (Released:2013-08-20)

- 参考文献数

- 14

- 被引用文献数

- 139 174

In order to clarify the grain size dependence of mechanical stability of austenite, deformation-induced martensitic transformation behavior was investigated on uniaxial tensile deformation in a metastable austenitic stainless steel (Fe–16%Cr–10%Ni) with the grain size controlled from 1 to 80 μm. In addition, crystallographic characteristics of deformation-induced martensite were analyzed by means of the EBSD (electron backscattering diffraction) method to discuss the variant selection rule. It was found that mechanical stability of austenite is independent of its grain size, although thermal stability of austenite is remarkably increased by grain refinement. Some special martensite variants tend to be selected in an austenite grain on the deformation-induced martensitic transformation (near single-variant transformation), and this results in the formation of a texture along tensile direction. This suggests that the most advantageous variants are selected in the deformation-induced martensitic transformation to release tensile strain and leads to the grain size independence of mechanical stability of austenite.

5 0 0 0 OA 明治期の海軍工廠における特殊鋼製造とたたら鉄

- 著者

- 渡辺 ともみ

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.91, no.1, pp.108-115, 2005-01-01 (Released:2010-01-18)

- 参考文献数

- 41

The traditional steel manufacturing (Tatara) of Japan which developed in the early modern times fell into the decline in the Meiji Period. On the other hand, because it is being made by reducing iron sand with charcoal, the amount of phosphorus and sulfur of Tatara iron is low. Therefore it was adopted as a raw material of the alloy steel at Naval Arsenal of the Meiji latter period. The purpose of the main subject is to explain that process.The quality which the navy demanded was limited to the speck of the low phosphorus. Then, the navy never tried to admit the cost which corresponded with that quality. The makers of Tatara iron had efforts to cope with a naval requirement. But, they had to give up their Tatara business suddenly. That was because naval warship manufacture stopped observing Washington disarmament treaty. They advanced all together to charcoal industry after that.

5 0 0 0 OA 日本刀の冶金学的研究

- 著者

- 谷村 〓

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.3, pp.497-507, 1981-03-01 (Released:2010-01-19)

- 参考文献数

- 8

- 被引用文献数

- 5 3

5 0 0 0 OA Online Prediction of Hot Metal Temperature Using Transient Model and Moving Horizon Estimation

- 著者

- Yoshinari Hashimoto Yoshitaka Sawa Manabu Kano

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.59, no.9, pp.1534-1544, 2019-09-15 (Released:2019-09-15)

- 参考文献数

- 27

- 被引用文献数

- 1 9

Precise control of hot metal temperature (HMT) is crucial for achieving stable operation of a blast furnace, but it is difficult due to the sluggish dynamics caused by the huge heat capacity. To cope with such difficulty, this work aims at developing a method that can predict future HMT by adopting moving horizon estimation (MHE) based on a one-dimensional transient model. MHE is useful to successively adjust model parameters so that the undesirable influence of past disturbances on the prediction is minimized. The real application result demonstrated that the root mean square error (RMSE) of HMT of eight-hour-ahead prediction was only 11.6°C. The high-performance prediction enables operators to realize the efficient operation of the blast furnace.

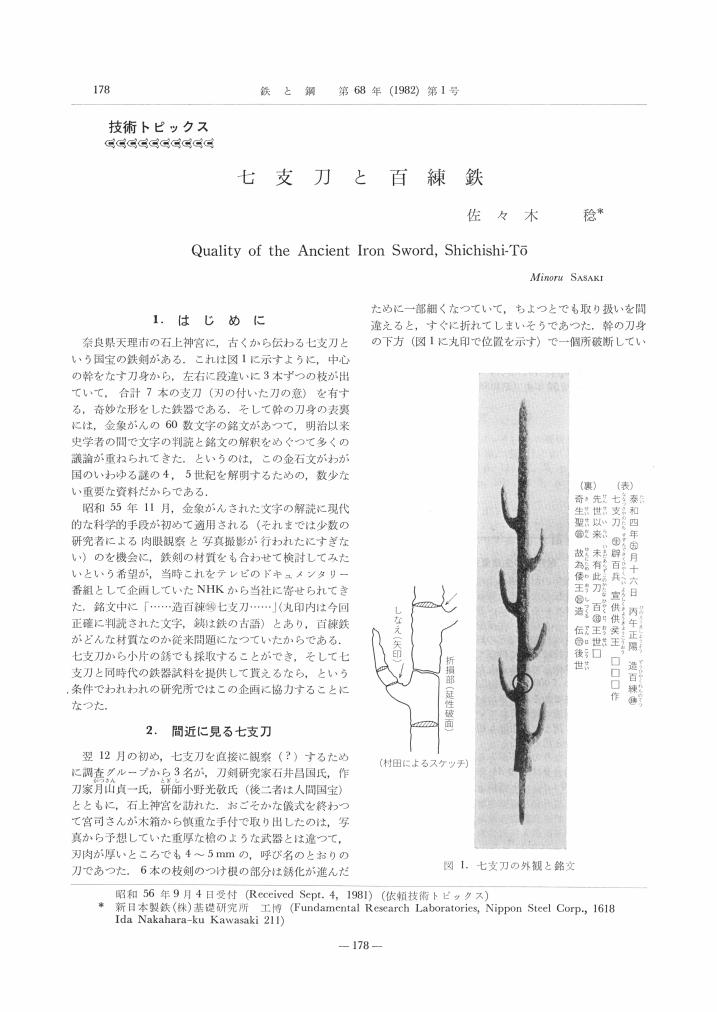

4 0 0 0 OA 七支刀と百練鉄

- 著者

- 佐々木 稔

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.68, no.1, pp.178-184, 1982-01-01 (Released:2010-01-19)

- 参考文献数

- 6

- 被引用文献数

- 2

4 0 0 0 OA 鋼材の火花試驗に關する研究1)(第1報)

- 著者

- 三島 徳七 三橋 鐵太郎

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.28, no.2, pp.117-136, 1942-02-25 (Released:2009-07-09)

- 参考文献数

- 49

Die Schleiffunken der allen Stahlsorten haben kenzeichnende Merkmale. Die Funkenprobe bildet daher ein einfaches und weitverbreitetes Mittel zur Feststellung der Werkstoffzusammensetzung und zur Vermeidung von Werkstoffvermischung.Ein Teil dieser Arbeit, über den hier berichtet wurde, sollte Genauigkeit dieser Funkeprobe fur C-Stähle, auch die Zusammenhang zwischen die Funkenformen und die Menge der speziellen Elementen, wie Ni, Cr, Mn, Si, feststellen.In Fe-C-Mn Legierungen befindet sich ein schwerfunkbares Gebiet. Die Abhängigkeit von der Härte und dieser Schwerfunkbarkeit wurde nicht festgestellt.Karbide im Gusseisen ist immer schwerfunkbar, welches nach Graphitisation beim Ausglü hen wieder wesentlich funkbar wird. Das Gleiche wird auch im Cr-Gusseisen festgestellt, welches in Abhängigkeit von der steigernden Al Gehalten allmählich schwerfunkbar wird.Das Gefüge der amerikanischen handelsübrigen nichtfunkbaren Legierungen, die zu Ni-Cr-und Fe-W-Cr-VLegierungen (z.B. 18-4-1 Typus) gehören, besteht aus Austenit und Karbide.

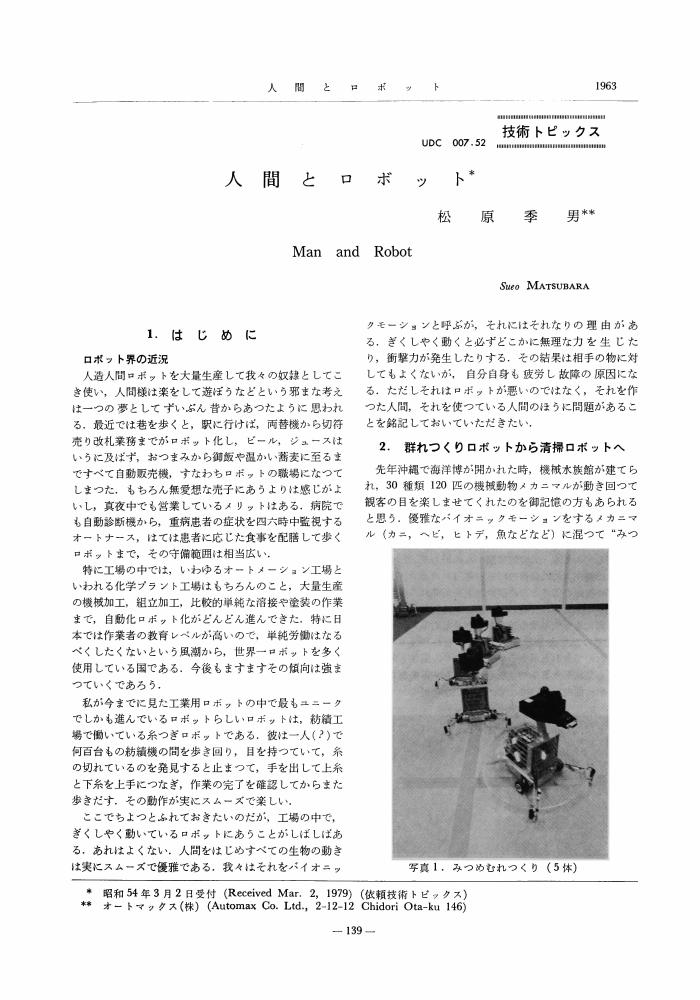

4 0 0 0 OA 人間とロボット

- 著者

- 松原 季男

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.65, no.13, pp.1963-1971, 1979-11-01 (Released:2010-02-22)

4 0 0 0 OA 戦時中のジェット・エンジン事始め

- 著者

- 永野 治

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.64, no.5, pp.659-663, 1978-04-01 (Released:2010-02-22)

- 被引用文献数

- 3 4

4 0 0 0 OA 支那事變に於ける日本刀の威力

- 著者

- 蒔田 宗次

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.24, no.12, pp.1106-1112, 1938-12-25 (Released:2009-07-09)

Participated in work of the party engaging specially in the repair of Japanese swords in the front, the author observed the superiority of Japanese swords in the light of the present Sino-Japanese fighting.It is a well-acknowledged fact that the Japanese sword has an excellent sharpness. Its splendid effect has invariably been shown in action at the present crisis, there being many instances to be quoted from numerous exploits in the actural occasions.A large number of Japanese swords being used in the front, sword makers are naturally very busy at present.We know the physical effect of the Japanese sword from its sharpness as well as the user's skill. Besides the most important matter is our strong faith for the Japanese sword. Consequentty, the mental effect of it against the enemy is very powerful with the action of the "Japanese spirit" in it.Therefore, we observe the Japanese sword not only materially but also spiritually. In short, the Japanese sword is considered to be a spiritual material, which stands to guard strongly and to prosper eternally the Land of Our Mikado.

3 0 0 0 OA スチールハウス実住宅における軽量形鋼の耐食性寿命予測

- 著者

- 鹿毛 勇 坂本 義仁 高阪 廣作 藤田 栄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.89, no.1, pp.188-195, 2003-01-01 (Released:2009-05-29)

- 参考文献数

- 26

- 被引用文献数

- 4 4

Atmospheric corrosion on the inhabited steel framed house was investigated with Fe-Ag galvanic type atmospheric corrosion monitoring (ACM) sensors. As the environmental conditions, temperature, humidity and currents of the ACM sensors were continuously measured in several parts of the house for five years. Corrosion rates of hot-dip galvanized steel sheet, Zn-5%Al coated steel and 55%Al-Zn coated steel for the light gauge steels were also determined on the basis of exposure tests. Service life of the galvanized steels and dew condensation in the house were discussed.Amount of deposited sea salt influences the corrosion resistance of the coated steels. Under the indoor conditions of the inhabited house, the amount of deposited sea salt was negligibly small. It is difficult to evaluate the corrosion resistance of coated steel sheets using convenient corrosion tests because of too much sea salt.

3 0 0 0 OA ブラジルの木炭製鉄

- 著者

- 谷口 良一 芹沢 保文

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.68, no.15, pp.2086-2094, 1982-11-01 (Released:2009-06-19)

- 参考文献数

- 10

- 被引用文献数

- 3 3