- 著者

- Yuki Tampa Kosuke Takagi Shohei Ueki Motoki Ohta Yoji Mine Kazuki Takashima

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.62, no.8, pp.1741-1749, 2022-08-15 (Released:2022-08-18)

- 参考文献数

- 27

- 被引用文献数

- 3

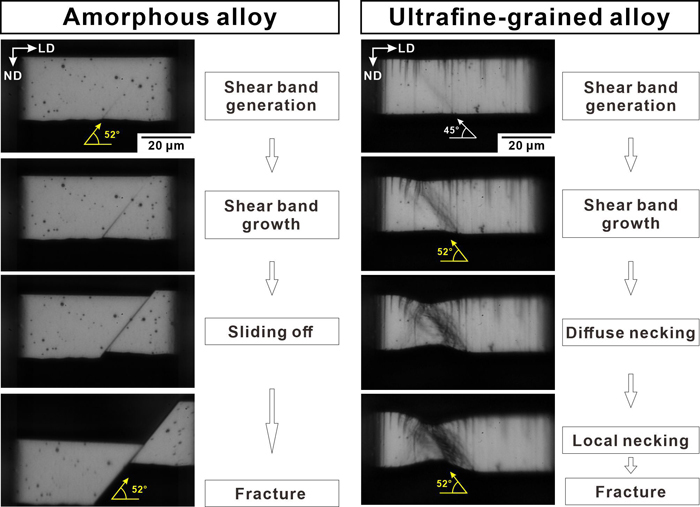

Micro-tensile tests were employed to clarify the post-plastic-instability behavior in the shear fractures of specimens with the dimensions of 18×25×50 µm3 made from iron-based amorphous (AM) and ultrafine-grained (UFG) alloys. The AM specimen yielded by localized shear bands with an inclination angle of ~52° with respect to the loading axis, followed by sliding off almost throughout the entire specimen thickness. Micro-tensile and micro-shearing tests revealed that the Mohr failure envelope of the AM specimens could be described by a quadratic equation rather than a linear equation. Therefore, the sliding-off process is assisted by the applied normal stress, which suggests that it is caused by free-volume coalescence. For the UFG specimen, yielding set in by shear band formation with an inclination angle of ~45° with respect to the loading axis, following the Tresca criterion. Necking after shear band diffusion formed a triaxial stress state, which resulted in a final shear fracture plane via void coalescence in the UFG specimens. Voids formed along the intersection of the primary shear bands with secondary shear bands during the necking process. This indicates that the deviation of the shear fracture plane in the UFG specimen was determined by the strain development process. A comparison of the post-plastic-instability behavior between the AM and UFG specimens suggests that the external control of triaxial stress conditions is key to improving the formability of AM specimens.