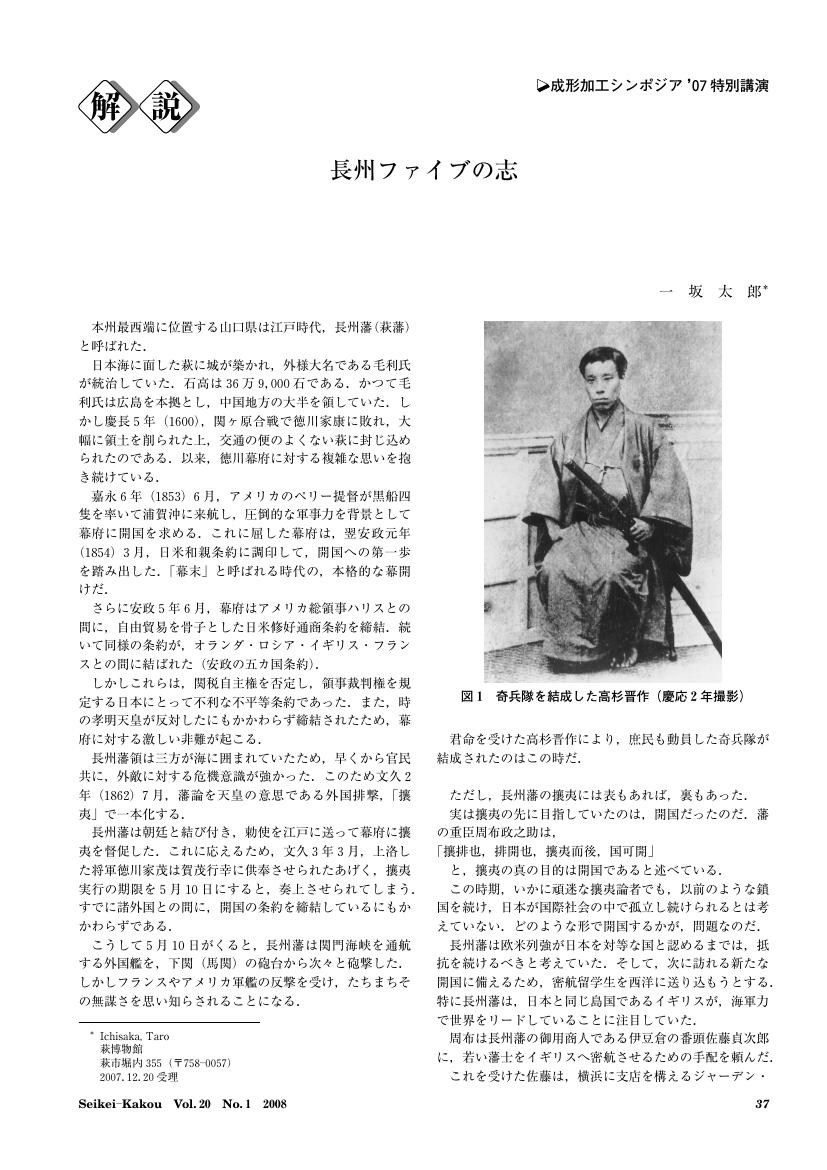

46 0 0 0 OA 長州ファイブの志

- 著者

- 一坂 太郎

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.20, no.1, pp.37-40, 2008-01-20 (Released:2021-02-25)

9 0 0 0 3 D 研究でワクワクしよう!

- 著者

- 古川 英光

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.34, no.8, pp.279, 2022-07-20 (Released:2022-08-20)

7 0 0 0 OA ナイロン46樹脂

- 著者

- 西嶋 清明 弘中 克彦

- 出版者

- The Japan Society of Polymer Processing

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.5, no.9, pp.603-609, 1993-09-20 (Released:2009-11-18)

- 参考文献数

- 5

4 0 0 0 OA サウジアラビアに暮らして

- 著者

- 城本 征治

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.27, no.8, pp.341-343, 2015-07-20 (Released:2020-11-30)

3 0 0 0 OA 未来の人工物を支える全樹脂電池

- 著者

- 堀江 英明

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.31, no.10, pp.378-381, 2019-09-20 (Released:2020-11-30)

- 参考文献数

- 1

2 0 0 0 OA アメリカ通信 (6) ; 日米就職状況比較

- 著者

- 大塚 隆英

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.23, no.3, pp.170-171, 2011-02-20 (Released:2021-01-25)

2 0 0 0 OA リポソームが初めて化粧品になった日

- 著者

- 荒金 久美

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.30, no.6, pp.246-247, 2018-05-20 (Released:2020-08-25)

2 0 0 0 OA 射出成形 CAE における AI 技術の応用

- 著者

- 山田 高光

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.32, no.3, pp.74-77, 2020-02-20 (Released:2020-03-20)

- 参考文献数

- 6

1 1 0 0 OA ものづくりに貢献する 3 次元射出成形 CAE システム“3 D TIMON”

- 著者

- 末吉 耕平

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.24, no.6, pp.321, 2012-05-20 (Released:2020-12-25)

- 参考文献数

- 1

1 0 0 0 OA 射出成形品に生ずる物性値分布の予測手法の検討(3)

- 著者

- 瀬戸 雅宏 寺倉 祐二 佐々木 幹夫 山部 昌

- 出版者

- The Japan Society of Polymer Processing

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.15, no.2, pp.148-154, 2003-02-20 (Released:2009-11-18)

- 参考文献数

- 11

- 被引用文献数

- 10 3

The material properties within injection molded products may display a distribution or anisotropy due to the influence of the resin flow velocity distribution profile and the cooling rate during the injection molding process. As a result, the products may warp. From the standpoint of production efficiency, it is very important to predict such warpage prior to the injection molding process, and injection molding CAE tools are widely used at present to conduct warpage analyses.Warpage analysis techniques currently available do not provide sufficient accuracy because they cannot predict the distribution of material properties that occurs in the interior of injection molded products. This is especially true for thick injection molded products, which display a large distribution of material properties across their thicknesses. As that distribution is thought to affect warpage substantially, the accuracy of the warpage analysis presumably declines even further.In this research, a thick flat plate was injection molded from a medium density crystalline polyethylene material, and the distribution of the thermal expansion coefficient was measured along the thickness of the molded part. The molecular orientation ratio and crystallinity were also measured and their correlation was examined in order to investigate a method for predicting the thermal expansion coefficient distribution. The results revealed that the thermal expansion coefficient displayed a large variation and anisotropy in the thickness direction and that the distribution correlated with the crystallinity. Moreover, using the thermal expansion coefficient data obtained by these measurements, a material property database was created for use in conducting warpage analyses that take account of the distribution of material properties along the thickness of injection molded products. A multi-layer analysis model was then used in an effort to improve warpage analysis accuracy. The results indicated that warpage analysis accuracy was improved, which shows that a multi-layer model that takes account of the distribution of material properties is effective in conducting more accurate warpage analyses.

1 0 0 0 OA 成形用金型へのシボ加工技術について

- 著者

- 渡邊 豊彦

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.23, no.11, pp.654-658, 2011-10-20 (Released:2021-01-25)

1 0 0 0 OA ポリプロピレンのせん断誘起結晶化に及ぼす繊維状結晶核剤の影響

- 著者

- Khunanya Janchai 井上 貴博 岩崎 祥平 木田 拓充 山口 政之

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.35, no.9, pp.318-323, 2023-08-20 (Released:2023-09-20)

- 参考文献数

- 38

We investigated the effect of shear history on the crystallization behavior of isotactic polypropylene (PP) containing a fibrous nucleating agent, i.e., 1, 3 : 2, 4-bis-o-(4-methylbenzylidene)-Dsorbitol (MDBS), using a polarized optical microscope attached with a parallel-plate shear device. The addition of MDBS greatly enhanced the crystallization temperature of PP with an accelerated crystallization rate. Although shear history applied during cooling barely affected the crystallization temperature for the sample containing MDBS, it greatly enhanced the PP orientation, even with a low shear rate. This was attributed to the formation of a pseudo shish-kebab structure, in which MDBS acted as the shish. It was also found that the addition of MDBS reduced the amount of β -form crystals, while PP without MDBS exhibited β -form crystals after applying an appropriate shear history.

1 0 0 0 OA 液体自動充填システムとヒートシール

- 著者

- 二瀬 克規

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.13, no.10, pp.660-664, 2001-10-20 (Released:2022-02-01)

- 参考文献数

- 9

- 被引用文献数

- 2

1 0 0 0 OA 倉敷芸術科学大学 産業科学技術学部 機能物質化学科

- 著者

- 岡田 賢治

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.12, no.11, pp.722-724, 2000-11-20 (Released:2022-11-01)

- 参考文献数

- 5

1 0 0 0 OA ゴムの摩擦・摩耗

- 著者

- 網野 直也

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.30, no.4, pp.150-154, 2018-03-20 (Released:2020-08-25)

- 参考文献数

- 35

1 0 0 0 OA 樹脂サッシのデザインを決めるもの

- 著者

- 村上 敦亮 高田 和規

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.33, no.12, pp.429-433, 2021-11-20 (Released:2021-12-20)

- 参考文献数

- 4

1 0 0 0 OA 太陽電池の最新動向

- 著者

- 池上 和志

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.32, no.6, pp.202-205, 2020-05-20 (Released:2020-06-20)

- 参考文献数

- 6

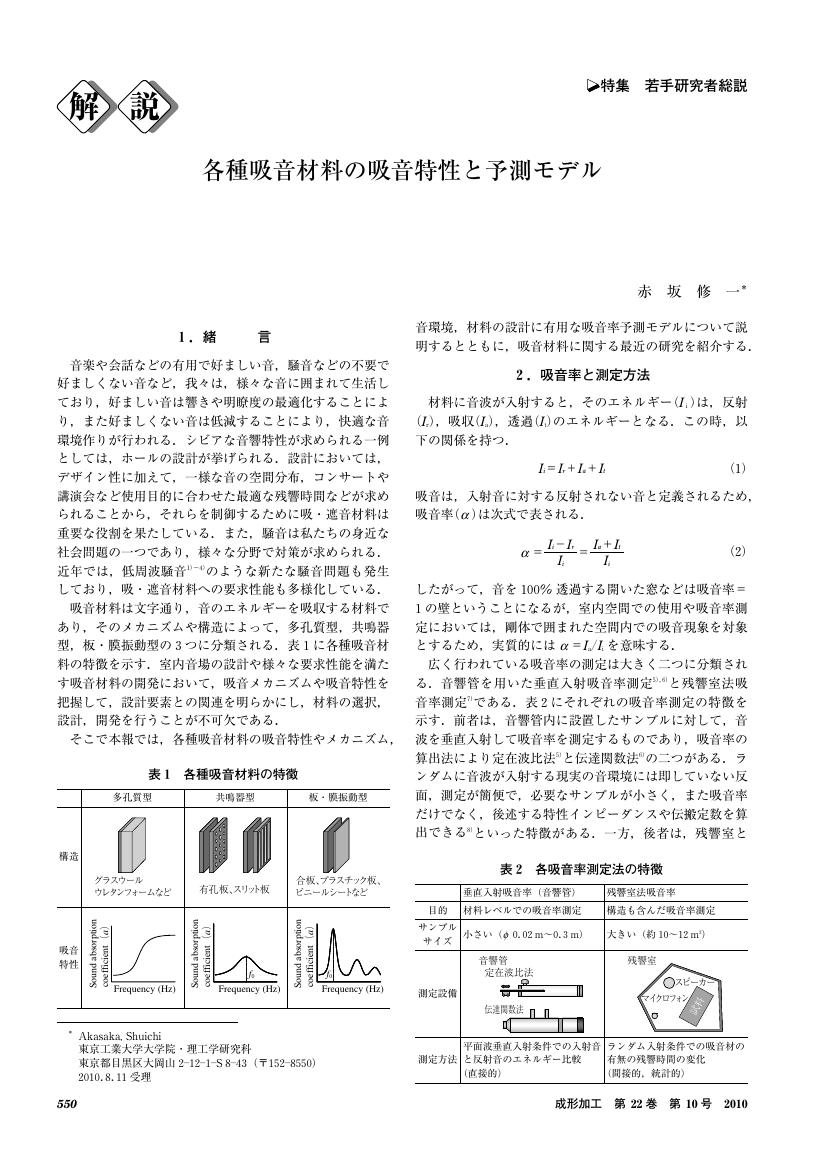

1 0 0 0 OA 各種吸音材料の吸音特性と予測モデル

- 著者

- 赤坂 修一

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.22, no.10, pp.550-555, 2010-09-20 (Released:2021-01-25)

- 参考文献数

- 41

1 0 0 0 OA カーボンナノチューブを添加したポリエチレンのシシカバブ構造形成に及ぼす加熱延伸の影響

- 著者

- 西川 理穂 山口 政之

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.34, no.1, pp.25-28, 2021-12-20 (Released:2022-01-22)

- 参考文献数

- 17

We investigated the structure and properties of extruded high-density polyethylene (HDPE) containing 03. wt.% of multi-walled carbon nanotubes (CNTs). It was found from differential scanning calorimetry measurements that the CNT addition raised the crystallization temperature of HDPE, suggesting that CNT acts as a nucleating agent for HDPE. Furthermore, two-dimensional X-ray diffraction measurements revealed that the CNT addition greatly enhanced the chain orientation of HDPE in the extruded strand, which was pronounced by melt-stretching after passing through the die. CNTs orientated parallel to the flow direction behave like extended chain crystals, and thus accelerate the formation of shish-kebab structure. As a result, the tensile modulus was enhanced by the CNT addition, which was pronounced especially in the high temperature region.

1 0 0 0 OA ポリマー成形加工へのインフォマティクス適用

- 著者

- 茂本 勇

- 出版者

- 一般社団法人 プラスチック成形加工学会

- 雑誌

- 成形加工 (ISSN:09154027)

- 巻号頁・発行日

- vol.32, no.2, pp.48-51, 2020-01-20 (Released:2020-02-20)

- 参考文献数

- 32