2 0 0 0 OA 石油貯槽の経年損傷と寿命予測

- 著者

- 亀井 浅道

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.29, no.1, pp.20-28, 1991-01-25 (Released:2010-08-05)

- 参考文献数

- 2

In order to prevent leakage accidents in a oil storage tank, it is important to be acquainted with the state of deterioration. Unless the tank is maintained properly, estimation of the life may be indispensable to avoid accidents. In this paper, the life is defined as time necessary for a deepest corrosion pit on a steel plate to penetrate through the thickness.Method to predict the life are shown on the bases of statistics. Some data on corrosion rate of bottom plates are reviewed and a new interpretation about scattered values appeared in such data is introduced, which will be useful to estimate the reliability of predicted life. Extremal statistics is also reviewed to estimate the maximum corrosion depth on the outer surface of bottm plate and an usage of double exponential distribution is shown in an example for life prediction.

2 0 0 0 OA 有限要素法の流体力学への応用

- 著者

- 川原 睦人

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.12, no.3, pp.151-156, 1974-05-25 (Released:2010-08-05)

- 参考文献数

- 14

2 0 0 0 OA 自緊処理を施した超高圧圧力容器材料の破壊じん性特性

- 著者

- 岩舘 忠雄 田中 泰彦 竹俣 裕行

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.23, no.6, pp.286-293, 1985-11-25 (Released:2010-08-05)

- 参考文献数

- 2

The high pressure reactors are sometimes autofrettaged to have the life elongated which is based on the highly compressive residual stress near the bore surface. In this study, to evaluate the material degradation based on the autofrettaged strain, the effect of autofrettage on the fracture toughness behavior was investigated using the 3.5% Ni-Cr-Mo-V steels.(1) When the prestrain increases, the fracture toughness decreases, especially in the higher yield strength steel. The decrease of the fracture toughness of the material was observed in the prestrain range larger than 5 percent for the about 1000MPa yield strength steel and than 2 percent for the about 1150 MPa yield strength steel.(2) The material resistance to ductile fracture, that is, tearing modulus TJ decreases in the same prestrain ranges as those of the fracture toughness.(3) However, the autofrettaged material taken out of the actual pressure reactor shows no decrease of the fracture toughness and the tearing modulus which is caused by the small amount of the prestrain, less than about 1 percent even in the 100 percent autofrettaged reactors.

1 0 0 0 OA 316系ステンレス鋼の高圧水素環境脆化特性におよぼすNiおよびCr量の影響

- 著者

- 藤井 秀樹 大宮 慎一

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.47, no.2, pp.85-94, 2009-03-25 (Released:2009-04-27)

- 参考文献数

- 11

- 被引用文献数

- 2

To accelerate the construction of hydrogen energy society featuring fuel cell vehicles by enlarging the kinds of materials safely used in hydrogen circumstances in addition to JIS SUS316L, several steels having Ni contents lower than SUS316L and Cr contents equivalent to SUS316L are prepared and their tensile properties in high pressure gaseous hydrogen are investigated at room temperature and -40°C. [Ni]+0. 35[Cr] ([Ni] and [Cr] are their concentrations in mass%) is proposed as an indicator to properly indicate whether hydrogen environmental embrittlement (HEE) occurs or not in45MPa hydrogen gas at both temperatures. HEE is basically related to strain-induced martensite having bcc crystallographic structure. However, there are some steels which do not exhibit any significant HEE although noticeable amount of martensite phase forms. In this case, HEE mainly occurs at the later stage of deformation just before fracture. Steels containing more than 12mass% Ni including SUS316L do not show HEE if there is not serious segregation of alloying elements such as Ni, Cr, Mo. It is also indicated that SUS316 probably do not show HEE if more than 12mass% Ni is contained. Furthermore, steels having Ni content close to 10mass%, which corresponds to the lower limit of the standard of JIS SUS316 and AISI 316L, have considerably higher resistance against HEE compared to SUS304 based steels although HEE occurs at the late stage of deformation. It may be possible for them to be used in high pressure hydrogen circumstances if temperature range at which they are used is fully taken into account and small level of HEE is acceptable.

1 0 0 0 OA 熱間静水圧加圧装置

- 著者

- 西原 正夫 井上 陽一

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.22, no.1, pp.50-55, 1984-01-25 (Released:2010-08-05)

- 参考文献数

- 6

1 0 0 0 OA 10,000m 級無人探査機「かいこう」システムの開発 水深11,000mへの挑戦

- 著者

- 和田 一育

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.36, no.4, pp.194-202, 1998-07-25 (Released:2010-08-05)

- 参考文献数

- 3

Japan Marine Science and Technology Center has been constructing for the development of the 11, 000m depth class ROV “KAIKO” system. The final sea trial of full depth diving carried out on March at Mariana Trench. The “KAIKO” went down to the 2m altitude from the bottom, and cruised the 10, 909m depth. But, the data communication link was interrupted. We thoroughly investigated the cause of the trouble by postponing the sea trial. We pinpointed the problem and were improved on the secondary cable. The sea trial were restarted in February 1995, and the “KAIKO” touched the bottom of the trench.

1 0 0 0 OA 原子力配管設計手法の概要 主として安全設計の立場から

- 著者

- 石井 正則 沖 禎三郎

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.13, no.3, pp.150-158, 1975-05-25 (Released:2010-08-05)

- 参考文献数

- 6

1 0 0 0 OA 最近のエネルギー貯槽関連事故報告

- 著者

- 吉田 聖一

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.49, no.5, pp.232-240, 2011-09-25 (Released:2012-09-25)

- 参考文献数

- 6

- 被引用文献数

- 13

1 0 0 0 OA 水素社会 水素サプライチェーン•マネージメント

- 著者

- 坂口 順一 国分 紀之

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.42, no.3, pp.121-129, 2004 (Released:2004-09-15)

- 参考文献数

- 8

- 被引用文献数

- 2

Hydrogen energy system is one of the solutions for the global issue of greenhouse gases emission. The hydrogen supply chain system i. e. manufacturing, transportation and storage shall be discussed for the development of hydrogen Society. From this standpoint, thermal efficiency and CO2 emission of both hydrogen energy system and fossil energy system are evaluated in the “Well to Wheel” and “Well to Bus”.

1 0 0 0 OA 石油精製プラントにおける材料経年劣化

- 著者

- 川野 浩二

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.54, no.3, pp.133-137, 2016-05-25 (Released:2016-06-21)

- 参考文献数

- 5

石油精製プラントは稼動後40年以上を経過するプラントが多くなり, 設備健全性維持の観点より, その時間依存性の劣化について検討する必要性が高まってきている。ここでは, 実際のプラントで長時間使用された材料 (SUS405) での経年劣化調査結果を紹介する。

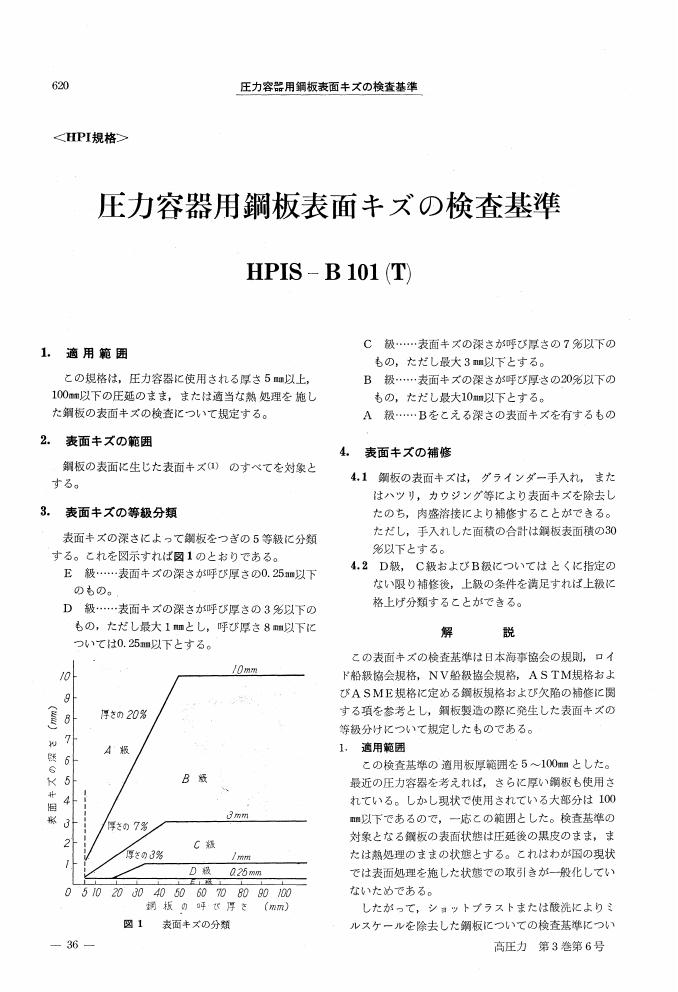

1 0 0 0 OA 圧力容器用鋼板表面キズの検査基準HPIS-B 101 (T)

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 高圧力 (ISSN:21851662)

- 巻号頁・発行日

- vol.3, no.6, pp.620-627, 1965-11-25 (Released:2010-08-05)

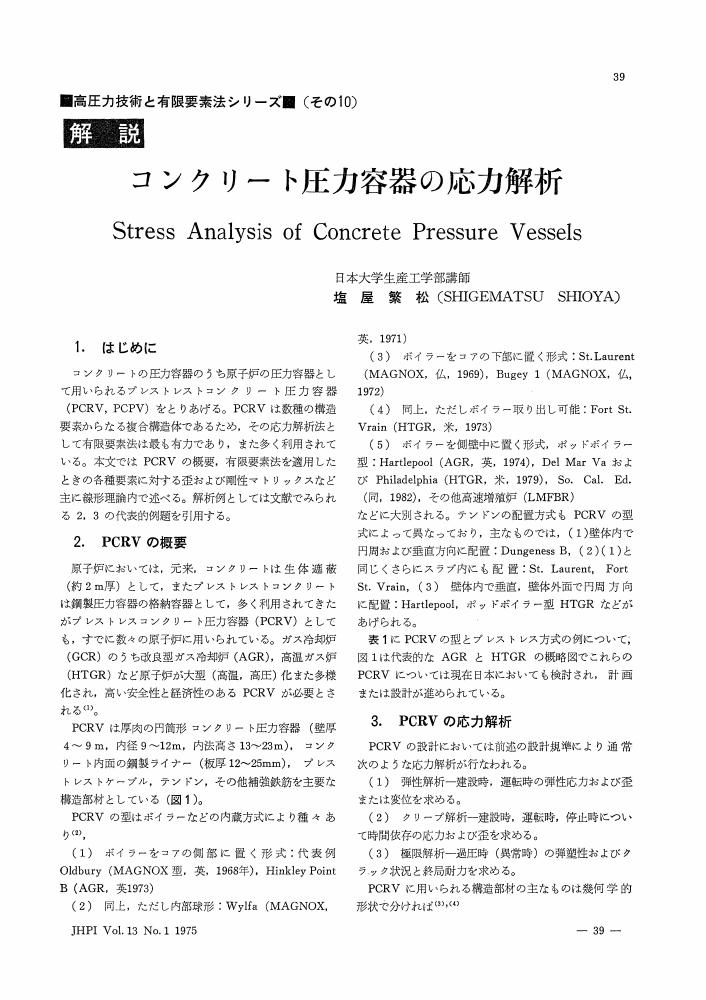

1 0 0 0 OA コンクリート圧力容器の応力解析

- 著者

- 塩屋 繁松

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.13, no.1, pp.39-48, 1975-01-25 (Released:2010-08-05)

- 参考文献数

- 16

1 0 0 0 OA 石油タンクのオーバル振動の固有振動数に及ぼすウインドガーダーの影響

- 著者

- 吉田 聖一

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.57, no.1, pp.13-23, 2019 (Released:2019-02-28)

- 参考文献数

- 10

The current seismic design codes of aboveground oil storage tanks (ASTs) are conducted based on the beam-type vibration with circumferential wave numberm=1. The oval-type vibration withm≥2 in which shell plate vibrates in a petal shape due to local mass and stiffness, initial imperfection or nonlinear vibration occurs in ASTs. The initial stress due to hydrostatic pressure was reported to increase the natural frequency in highm range by several studies. The circumferential tensile stress on shell plates caused by hydrostatic pressure increases the stiffness and as a result the natural frequency is also increased. Wind girders are installed to the shell plates in ASTs for the prevention of buckling by wind pressure. The wind girder which is a ring stiffener increases the stiffness of the shell plate. In this paper, the natural frequency of the oval-type vibration in a large sized AST is analyzed and the effect of the wind girder on natural frequency is studied. The method is the free vibration analysis by axisymmetric finite element method considering coupled vibration of internal liquid and tank.

1 0 0 0 OA 真空容器材料としてのステンレス鋼とアルミニウム合金

- 著者

- 石川 雄一

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.36, no.6, pp.442-452, 1998-11-25 (Released:2010-08-05)

- 参考文献数

- 18

- 被引用文献数

- 1

1 0 0 0 OA 東北地方太平洋沖地震による石油タンクのスロッシング被害と長周期地震動

- 著者

- 座間 信作 畑山 健 西 晴樹 山田 實

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.51, no.1, pp.4-10, 2013-01-25 (Released:2013-07-15)

- 参考文献数

- 3

The 2011 off the Pacific coast of Tohoku Earthquake (Mw9. 0) occurred on 11 March2011 caused various damage to oil storage tanks in wide area. At Sakata, Niigata, Kashima and Tokyo Bay area, we found damage due to the liquid sloshing excited by the long-period ground motions such as sinking of floating roofs, failure of pontoons, deformation of gauge poles, leakage of oil onto the floating decks, and so on. Many strong motion records were obtained in and around tank sites and their velocity response spectra Sv in the long-period range hardly exceed the regulation in the Fire Service Law at all. Therefore, the floating roofs reinforced in compliance with the technical standard of the Fire Service Law revised in consideration of the damage in the 2003 Tokachi-oki earthquake suffered no severe damage. On the other hand, unreinforced floating roof of a tank located in the Tokyo Bay area sank after 3 days of the event because of the failure of pontoons by the liquid sloshing, although Sv near the tank is not more than 100cm⁄s in the previous regulation.

1 0 0 0 OA 構造物の耐震設計

- 著者

- 梅村 魁

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 高圧力 (ISSN:21851662)

- 巻号頁・発行日

- vol.4, no.2, pp.703-710, 1966-03-25 (Released:2010-08-05)

- 参考文献数

- 6

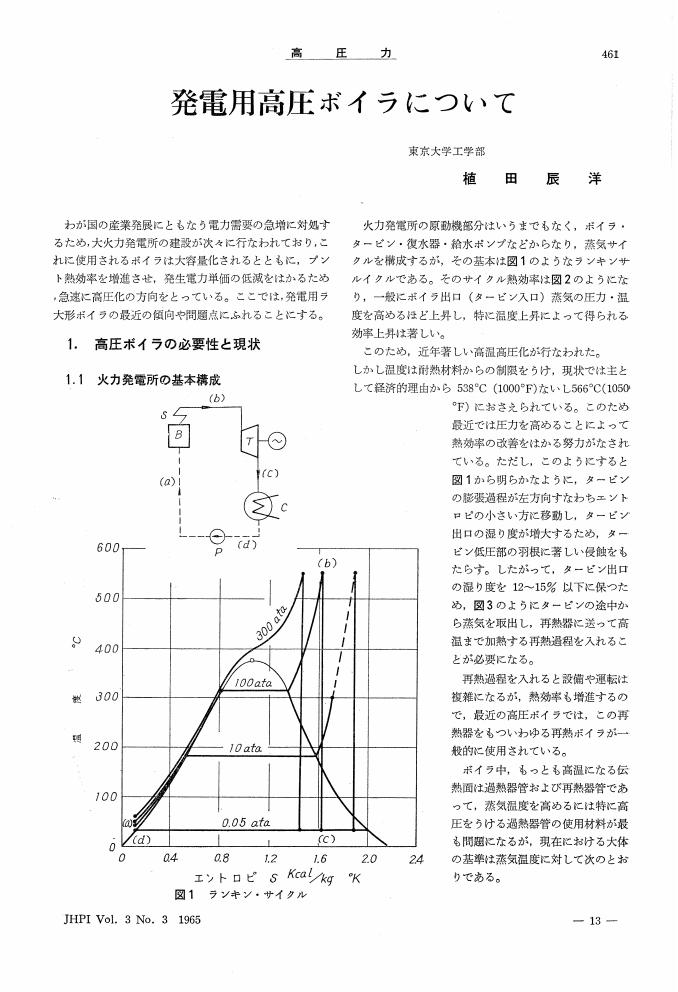

1 0 0 0 OA 発電用高圧ボイラについて

- 著者

- 植田 辰洋

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 高圧力 (ISSN:21851662)

- 巻号頁・発行日

- vol.3, no.3, pp.461-467, 1965-05-25 (Released:2010-08-05)

- 参考文献数

- 15

1 0 0 0 OA 水素環境下における金属系構造材料の機械的性質

- 著者

- 藤井 秀樹

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.42, no.3, pp.154-161, 2004 (Released:2004-09-15)

- 参考文献数

- 5

Activities of Cryogenic Materials Working Group (Task 10) in the WE-NET program are introduced with emphasizing on mechanical properties of metallic structural materials used in liquid hydrogen and compressed gaseous hydrogen. Regarding the evaluation of properties in liquid hydrogen, mechanical tests were conducted mainly using the newly designed and installed facilities for mechanical testing in liquid hydrogen. Austenitic stainless steel plates of 5mm in thickness and their welds processed with TIG, MIG and FSW showed excellent mechanical properties at cryogenic temperatures, while the thicker weld metals processed with multi-layer deposition sometimes exhibited lower toughness in cryogenic circumstances. Regarding gaseous hydrogen, SUS304L showed clear hydrogen environmental embrittlement (HEE) even at room temperature, while SUS316L showed no HEE at room temperature although some ductility decrease was recognized at low temperatures. All kinds of steels tested, including plain steel, low-alloyed steels and stainless steels, exhibited considerable hydrogen absorption when the specimens were exposed at 54°C for 1000h in compressed hydrogen gas at 27MPa pressure. In case of stainless steels, plastic deformation at room temperature enhanced this tendency.

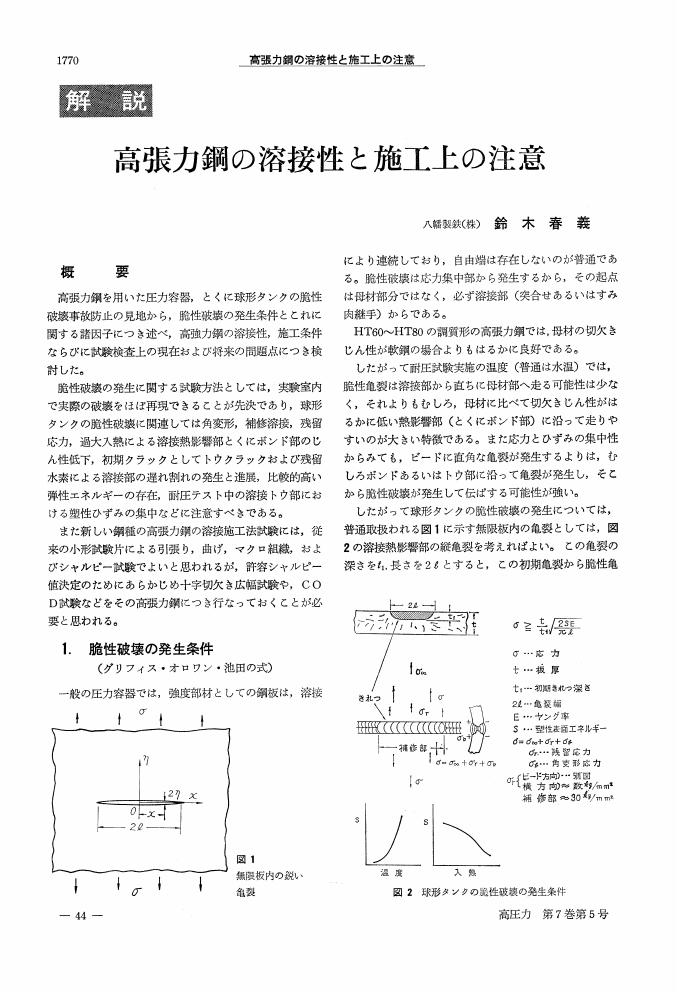

1 0 0 0 OA 高張力鋼の溶接性と施工上の注意

- 著者

- 鈴木 春義

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 高圧力 (ISSN:21851662)

- 巻号頁・発行日

- vol.7, no.5, pp.1770-1778, 1969-09-25 (Released:2010-08-05)

- 参考文献数

- 14

1 0 0 0 OA 最近の石油タンク爆発事故から考察する放爆構造

- 著者

- 吉田 聖一

- 出版者

- 一般社団法人 日本高圧力技術協会

- 雑誌

- 圧力技術 (ISSN:03870154)

- 巻号頁・発行日

- vol.47, no.6, pp.378-385, 2009-11-25 (Released:2011-01-24)

- 参考文献数

- 8

- 被引用文献数

- 2

Two tank explosions simultaneously occurred at a salt water disposal facility in Lamesa, Texas on May 15, 2009. One tank launched as a skyrocket, and the roof plate separated and flew in the other tank at the explosion. The frangible roof joint is designed so that the strength of the sidewall-to-roof joint is weaker than that of the sidewall-to-bottom joint under overpressurization in aboveground oil storage tanks. This rule did not perform as intended in the tank which launched. This paper presents a consideration on the frangible roof joint design due to the tank explosion.