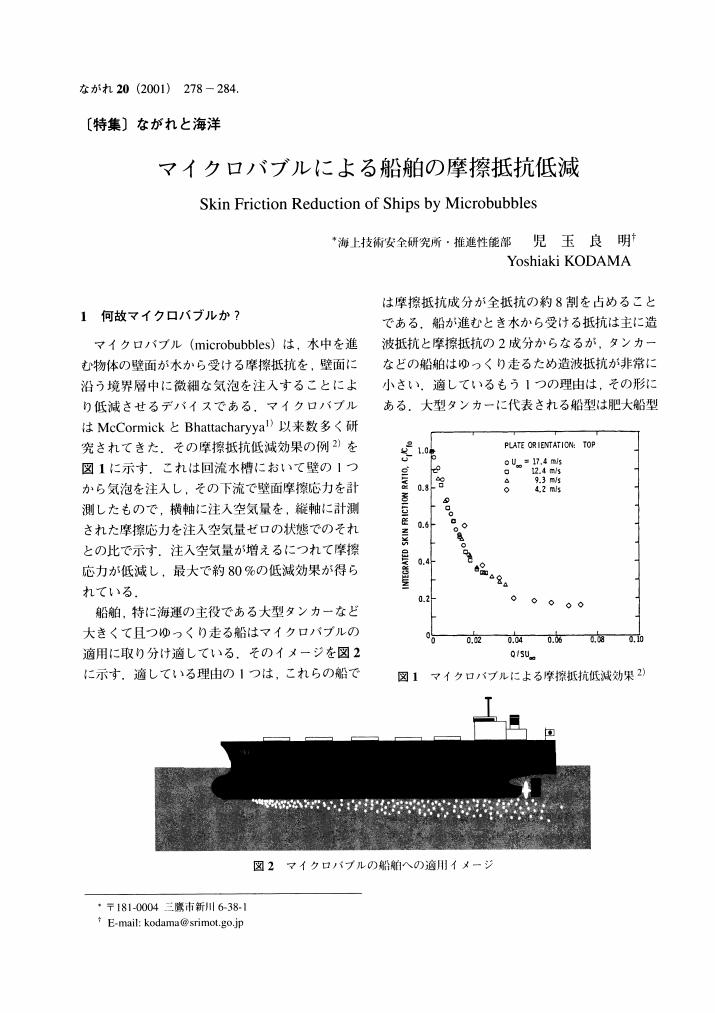

2 0 0 0 OA マイクロバブルによる船舶の摩擦抵抗低減

- 著者

- 児玉 良明

- 出版者

- 社団法人 日本流体力学会

- 雑誌

- 日本流体力学会誌「ながれ」 (ISSN:02863154)

- 巻号頁・発行日

- vol.20, no.4, pp.278-284, 2001-08-25 (Released:2011-03-07)

- 参考文献数

- 8

- 被引用文献数

- 1

2 0 0 0 OA 青雲丸を用いたマイクロバブルの摩擦抵抗低減実船実験

- 著者

- 児玉 良明 角川 明 高橋 孝仁 石川 暁 川北 千春 金川 健 戸田 保幸 加藤 洋治 地本 晶彦 山下 和春 永松 哲朗

- 出版者

- The Japan Society of Naval Architects and Ocean Engineers

- 雑誌

- 日本造船学会論文集 (ISSN:05148499)

- 巻号頁・発行日

- vol.2002, no.192, pp.1-13, 2002 (Released:2007-05-30)

- 参考文献数

- 17

- 被引用文献数

- 5 2

This paper is the first half of the report on the study on microbubbles carried out by the SR239 project of the Shipbuilding Research Association of Japan, and describes the preparatory study for the full-scale experiment using a 116m-long ship. In the present study, first the skin friction reduction effect by microbubbles was investigated including the use of an array-of-holes plate for bubble generation, the effects of streamwise pressure gradient, surface curvature, and vertical plate, the sea-water effect, and the effect of bubble size. Bubble generators for the full-scale experiment were designed and built, and a preliminary injection experiment was carried out. Two new measuring devices for the full-scale experiment were developed; they are skin friction sensors and local void ratio sensors. Microbubble experiments were carried out in a 400m-long towing tank using a 50m-long flat plate ship, in order to obtain the scale effect data and to confirm the validity of the new devices for the full-scale experiment. The use of adhesives to fix measurement devices and cables on the hull surface was tested and established. The hydrodynamic fairing of the cables was also tested and established. Finally, a preliminary microbubble experiment using a small ship was carried out and the bubble behavior was observed.

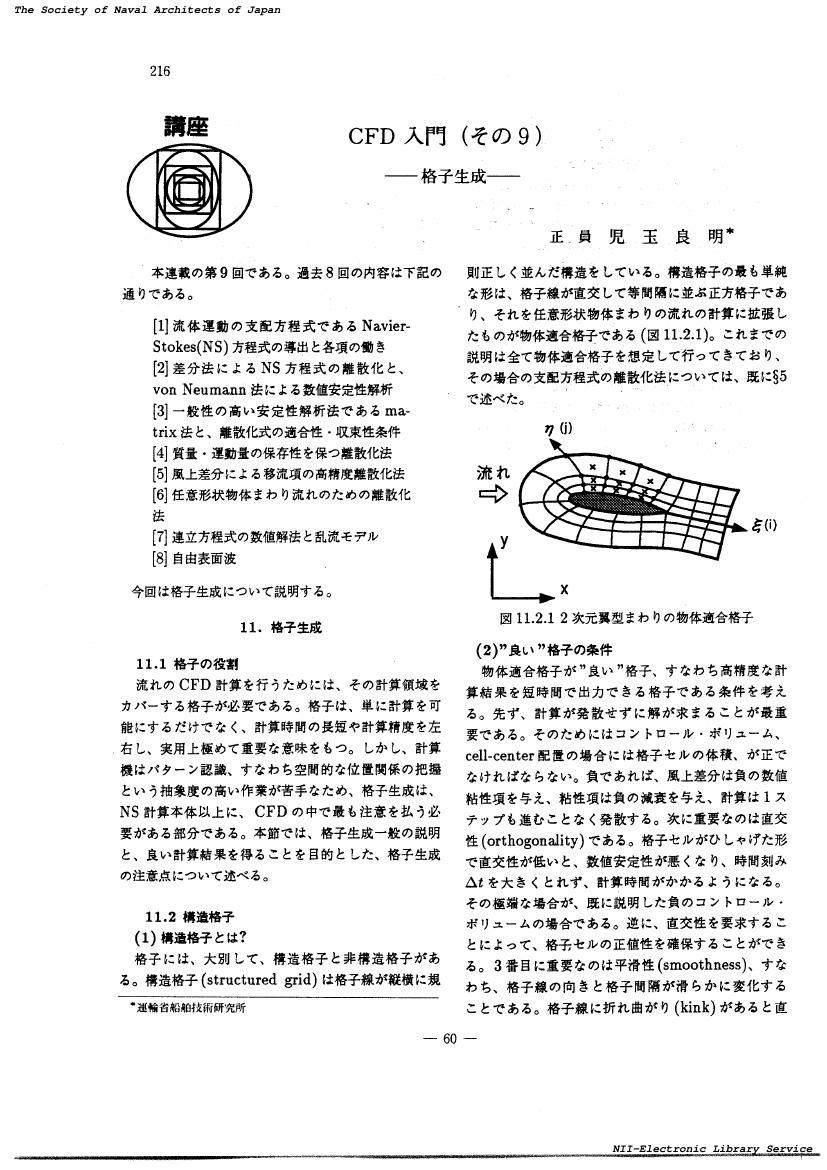

1 0 0 0 OA 格子生成(<講座>CDF入門(その9))

- 著者

- 児玉 良明

- 出版者

- 公益社団法人 日本船舶海洋工学会

- 雑誌

- Techno marine 日本造船学会誌 (ISSN:09168699)

- 巻号頁・発行日

- vol.813, pp.216-221, 1997 (Released:2018-03-01)

1 0 0 0 OA 船舶の摩擦抵抗低減デバイスとしてのマイクロバブルの研究動向

- 著者

- 児玉 良明 高橋 孝仁 牧野 雅彦 北川 石英 堀 利文

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.39, no.3, pp.192-196, 2004-03-01 (Released:2010-05-31)

- 参考文献数

- 15

- 著者

- 永松 哲郎 児玉 良明 角川 明 高井 通雄 村上 恭二 石川 暁 上入佐 光 荻原 誠功 吉田 有希 鈴木 敏夫 戸田 保幸 加藤 洋治 池本 晶彦 山谷 周二 芋生 秀作 山下 和春

- 出版者

- 公益社団法人日本船舶海洋工学会

- 雑誌

- 日本造船学会論文集 (ISSN:05148499)

- 巻号頁・発行日

- no.192, pp.15-28, 2002-12

- 参考文献数

- 11

- 被引用文献数

- 7 12

This paper is the second half of the report on the study on microbubbles carried out by the SR239 project of the Shipbuilding Research Association of Japan, and describes the full-scale experiment using "SEIUN MARU", a 116m-long training ship that belongs to the Institute for Sea Training. Using numerical analysis and the experimental data obtained in the preparatory study described in the first half of the report, the net energy saving of SEIUN MARU by microbubbles at 14kts was estimated to be 2%. In the full-scale experiment, the trajectory of the generated bubbles was observed using underwater TV cameras and was found to shift more upward than predicted. The local skin friction was measured at several locations on the hull surface, and the skin friction increase as well as decrease by the bubbles was measured. The local void ratio was measured at one point on the hull surface, and the bubbles were found to travel slightly away from the hull surface. The change of the ship speed and shaft horsepower by microbubbles was measured, and the decrease or increase of engine power at constant ship speed was analyzed. In the most cases of the experiment the ship speed decreased by the bubble injection, mainly due to the increase of ship resistance and the decrease of propeller efficiency caused by the bubbles going into the working propeller. But, by carefully choosing the bubble injection location and thus avoiding the bubble entrainment into the propeller, the 3% power saving at a constant speed of 14kts was obtained. By taking into account the power needed to inject bubbles against hydrostatic pressure due to water depth at the injection point, this corresponds to the net power saving of 2%. Thus the net power saving by microbubbles was measured on a full-scale ship for the first time in the world.

- 著者

- 児玉 良明

- 出版者

- 公益社団法人日本船舶海洋工学会

- 雑誌

- 日本造船学会論文集 (ISSN:05148499)

- 巻号頁・発行日

- no.172, pp.147-155, 1992-12

- 被引用文献数

- 16 6

A globally conservative NS solver for flow past a ship hull has been developed. It uses a 3rd-order accurate upwind differencing of the preprocessing (MUSCL) type for inviscid terms, in which the non -uniformity of grid spacing is taken into account. Using the solver, the drag of a fiat plate at zero incidence was computed in the Reynolds number range R_e=4.0 × 10^5 to R_e=4.0 × 10^7. The dependence of the drag on the degree of clustering of grid points was checked. The computed drag agreed with the Schoenherr value within 4%. An appropriate criterion for the minimum grid spacing Δ_<min> adjacent to solid wall with this particular scheme seems to be Δ_<min>=0.005/√<R_e>. Then the drag of the Series 60 (C_B=0.6) ship hull with the double model assumption was computed in the same Reynolds number range using grids with various Δ_<min> and various degree of clustering toward bow and stem. Although the computed drag values showed some scattering among different grids, the results with the smallest Δ_<min> agreed well with the measured values throughout the Reynolds number range.