1 0 0 0 日本初のジェット機「橘花」と松根油

- 著者

- 石田 憲治

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- Marine engineering : journal of the Japan Institution of Marine Engineering = マリンエンジニアリング : 日本マリンエンジニアリング学会誌 (ISSN:13461427)

- 巻号頁・発行日

- vol.41, no.1, pp.62-65, 2006-01-01

- 参考文献数

- 6

1 0 0 0 OA 沈船からの油流出問題と流出事故の環境影響評価

- 著者

- 黒田 貴子 原 正一

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.42, no.5, pp.794-799, 2007-09-01 (Released:2010-05-31)

- 参考文献数

- 6

1 0 0 0 OA 海事教育機関における人材育成の現状と課題 - 船員不足と教官不足

- 著者

- 引間 俊雄

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.52, no.6, pp.750-755, 2017-11-01 (Released:2018-03-07)

- 参考文献数

- 13

1 0 0 0 OA 深海底リアルタイム観測ネットワークの構築

- 著者

- 川口 勝義

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.44, no.1, pp.58-63, 2009 (Released:2012-02-29)

- 参考文献数

- 5

- 被引用文献数

- 1

1 0 0 0 OA 川崎重工業の舶用再熱蒸気タービン推進プラントについて

- 著者

- 半田 昌平 吉川 洋平

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.51, no.6, pp.755-760, 2016-11-01 (Released:2018-01-01)

- 参考文献数

- 5

1 0 0 0 OA ディーゼル重量車における排出ガス規制と対応技術の推移

- 著者

- 鈴木 央一

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.49, no.6, pp.776-781, 2014-11-01 (Released:2015-12-16)

- 参考文献数

- 2

- 被引用文献数

- 1 2

1 0 0 0 OA タンデム型(ハイブリッド型)電気推進船

- 著者

- 加納 敏幸 今澄 敏夫

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.46, no.1, pp.38-43, 2011 (Released:2013-10-23)

- 参考文献数

- 9

The Super Eco-Ship Project was conducted by the National Maritime Research Institute of Japan (NMRI) as a national project from April, 2001, under the Ministry of Land, Infrastructure and Transport. It aims at achieving the ship with environment friendliness and economical benefit. The Super Eco-Ship has high propulsion efficiency by contra-rotating propeller (CRP) effect. The high propulsive efficiency due to the combination with the optimum hull design and podded propulsion system enables the reduction of CO2 compared with the conventional ship. In addition, the podded propulsion system enables drastically superior manoeuvrability and flexible control system in ship operation as well as high propulsive efficiency. NMRI developed, cooperated with ship owner Ube Shipping & Logistics, LTD., the modified buttock flow hull form equipped with one podded propulsion system close behind the conventional propulsion system for Cement Tanker “KOZAN MARU”. This paper introduced history on Research & Development of The Super Eco-Ship Project and described the Hybrid type’s Electric Podded Propulsion Cement Tanker.

- 著者

- 田頭 剛 水野 拓哉

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.48, no.6, pp.791-796, 2013-11-01 (Released:2014-11-01)

- 参考文献数

- 5

1 0 0 0 OA 舶用潤滑油の性能と評価

- 著者

- 竹島 茂樹

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.45, no.1, pp.44-50, 2010 (Released:2012-11-23)

- 参考文献数

- 5

1 0 0 0 OA 日本郵船歴史博物館・日本郵船氷川丸

- 著者

- 遠藤 あかね

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.53, no.1, pp.109-113, 2018-01-01 (Released:2018-03-14)

- 参考文献数

- 11

1 0 0 0 日本郵船歴史博物館・日本郵船氷川丸

- 著者

- 遠藤 あかね

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.53, no.1, pp.109-113, 2018

1 0 0 0 OA 舶用ガスタービンコンバインドサイクルのシステム検討

- 著者

- 安達 雅樹 岸 武行 樽井 真一

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.50, no.4, pp.502-509, 2015-07-01 (Released:2016-11-26)

- 参考文献数

- 22

- 被引用文献数

- 1 1

Combined cycle is often called as the hybrid power generation system composed of a gas turbine and a steam turbine where the steam turbine is powered by exhaust gas heat from the gas turbine. Emission control requirement of the exhaust gas and the fuel oil price forecast have induced to choose the liquefied natural gas (LNG) as alternative to fuel oil, which offers more options of marine power source including the combined cycle. This paper reviews technologies related to the marine LNG-fueled combined cycle, primarily: working fluid, exhaust gas heat exchanger, and compact steam prime mover. The case study of the marine combined cycle is also proposed, in which the working fluid is set to water, exhaust gas heat exchanger is set to hi-finned tube heat exchanger and compact steam prime mover is set to hi-speed radial turbine. Supposing the gas turbine with rated power of 22,370kW, operating at 100% of power with 40% efficiency, and steam turbine with 80% efficiency; steam condition at the exit of the heat exchanger is 0.3MPa and 573K to gain larger expansion ratio in the steam turbine and more total output of the combined cycle. The case study predicted 3,381kW output by two-stages of the radial steam turbine and 44.06% total efficiency of this combined cycle.

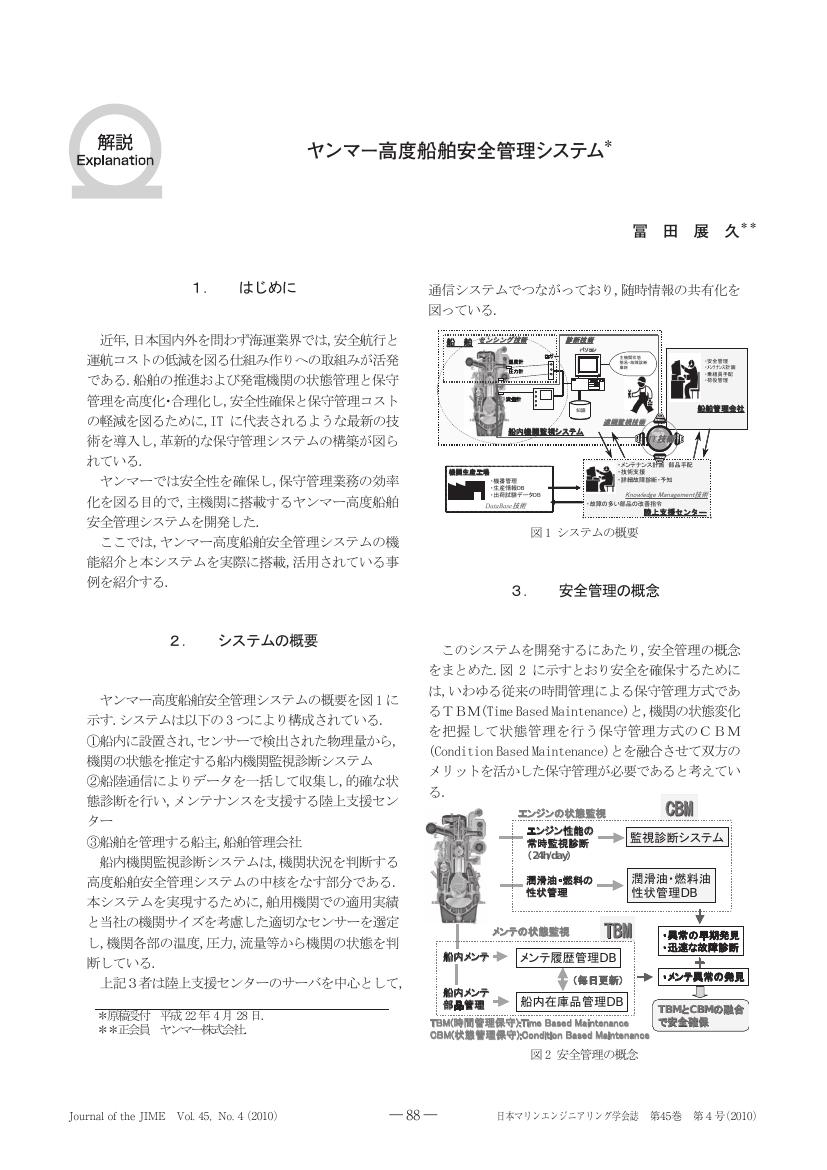

1 0 0 0 OA ヤンマー高度船舶安全管理システム

- 著者

- 冨田 展久

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.45, no.4, pp.525-529, 2010 (Released:2013-03-09)

- 参考文献数

- 1

1 0 0 0 OA バイオディーゼル燃料の製造方法と利用の現状

- 著者

- 岡田 正史

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.47, no.1, pp.45-50, 2012-01-01 (Released:2013-10-26)

- 参考文献数

- 1

Bio-Diesel Fuel is an alternative fuel for gas oil and has been widely introduced as one method to reduce carbon dioxide emissions. In Japan, bio-diesel produced from waste cooking oil is commonly used. One of the largest facilities is in Kyoto city which has a 5000L/day production capacity and supplies garbage collection trucks and city buses with fuel it produces. Taking this facility as example, the outline of the bio-diesel production process is introduced. In addition, production costs and the CO2 reducing effect the bio-diesel is quantitatively estimated. The cost estimation shows that the biodiesel can be produced for almost the same price as gas oil if tax is excluded. Moreover, CO2 emission is estimated to decrease by 2.0kg for every liter of bio-diesel utilized as alternative fuel.

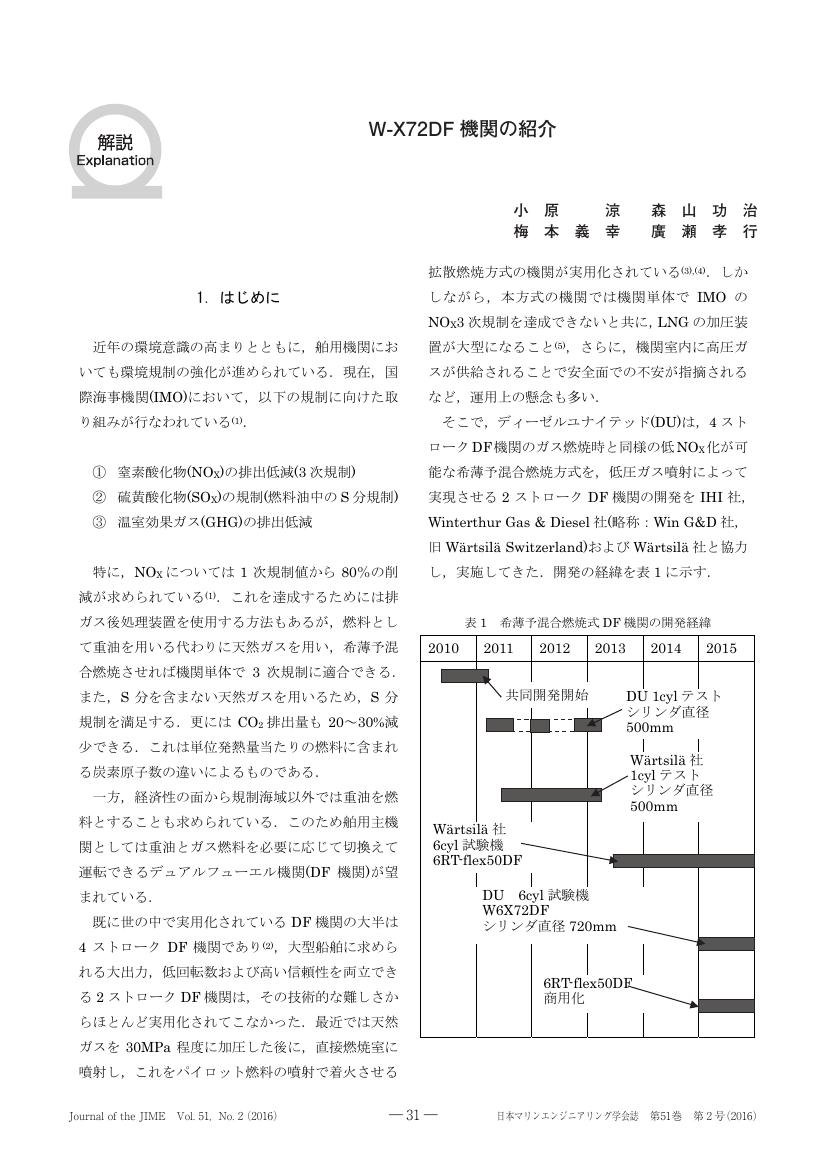

1 0 0 0 OA W-X72DF機関の紹介

- 著者

- 小原 涼 森山 功治 梅本 義幸 廣瀬 孝行

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.51, no.2, pp.163-167, 2016-03-01 (Released:2017-03-01)

- 参考文献数

- 8

1 0 0 0 OA ガス焚き低速ディーゼル機関「ME-GI」の紹介

- 著者

- 田渕 隆平 渕上 孝 難波 浩一 和田 裕太郎 辻 康之

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.51, no.2, pp.153-158, 2016-03-01 (Released:2017-03-01)

- 参考文献数

- 6

1 0 0 0 OA 超低燃費型船底防汚塗料による船体抵抗の低減技術

- 著者

- 島田 守

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.48, no.3, pp.288-293, 2013-05-01 (Released:2014-06-10)

- 参考文献数

- 8

- 著者

- 伊藤 聡史 志摩 政幸 菅原 隆志 地引 達弘 秋田 秀樹 雨澤 弘機 大貫 晃

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.45, no.2, pp.269-275, 2010 (Released:2012-12-06)

- 参考文献数

- 8

- 被引用文献数

- 2 6

A basic study on the development of sliding materials which can be used in seawater is made in this paper. As well known, stainless steel and titanium alloy are both fine anti-corrosive materials in seawater, but these are easily worn as resulting from corrosive type of wear in seawater. In order to overcome the disadvantage silicon (Si) particles were embedded into the surface layers of them, by applying the rubbing treatment process which was developed by the authors. The wear tests were done in artificial seawater by using the reciprocating wear apparatus. The results show that the coefficient of frictions are not so improved, but wear resistant properties are improved, especially for Si treated stainless steel mated by the same substrate material. Based on the results the wear mechanism of the developed materials is discussed.

- 著者

- 遠藤 健斗 Wong Yue Him 野方 靖行 小黒-岡野 美枝子 岡野 桂樹

- 出版者

- 日本マリンエンジニアリング学会

- 雑誌

- Marine engineering : journal of the Japan Institute of Marine Engineering = マリンエンジニアリング :日本マリンエンジニアリング学会誌 (ISSN:13461427)

- 巻号頁・発行日

- vol.52, no.1, pp.19-24,図巻頭3-4, 2017-01

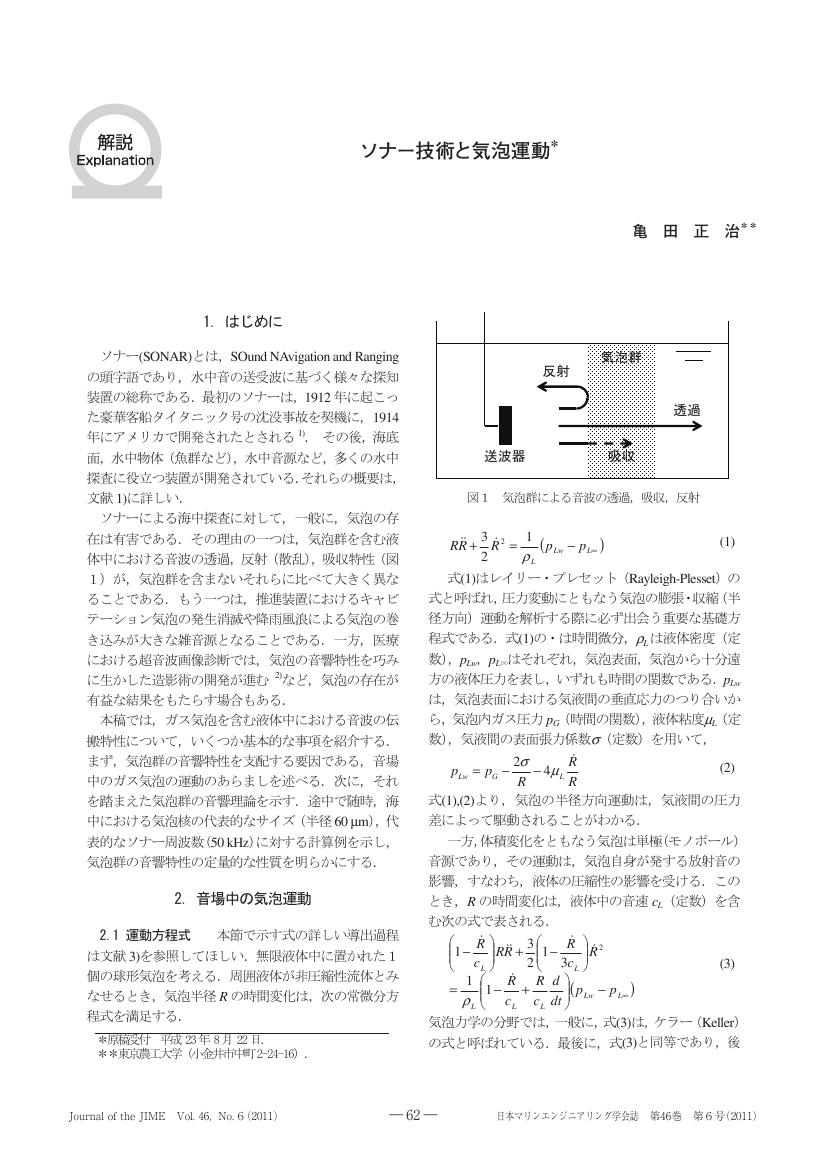

1 0 0 0 OA ソナー技術と気泡運動

- 著者

- 亀田 正治

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.46, no.6, pp.867-872, 2011 (Released:2013-10-23)

- 参考文献数

- 18