1 0 0 0 OA ターボ動力工学 (その3)

- 著者

- 刑部 真弘

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.36, no.6, pp.375-383, 2001-06-01 (Released:2010-05-31)

- 参考文献数

- 20

1 0 0 0 OA 低硫黄燃料油の製造方法と品質

- 著者

- 林 利昭

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.50, no.3, pp.341-346, 2015-05-01 (Released:2016-11-22)

1 0 0 0 OA 三菱ハイブリッドSOxスクラバーの紹介 - 舶用燃料の硫黄分規制の代替手段として

- 著者

- 深谷 一郎

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.50, no.3, pp.332-335, 2015-05-01 (Released:2016-11-22)

1 0 0 0 OA 低圧ガス噴射式2ストローク・ガスエンジンの開発

- 著者

- 廣瀬 孝行 増田 裕 山田 剛 梅本 義幸

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.49, no.1, pp.7-12, 2014-01-01 (Released:2015-07-07)

- 参考文献数

- 7

- 被引用文献数

- 1

1 0 0 0 OA 停止性能推定における主機・プロペラ遊転期間の影響について

- 著者

- 高木 道雄

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.38, no.10, pp.688-695, 2003-10-01 (Released:2010-05-31)

- 参考文献数

- 1

Through the past studies, it has been pointed out that the duration of free rotating period of propulsion shafting system may affect the stopping ability of the ships. However, in the studies of predicting stopping ability of the ships, more specifically in the predicting stopping distances of the ships, it is a common practice to treat the free rotating period as a certain fixed length of time, or to neglect as it is short.It may be one of the reasons why current simplified and practical predicting methods of stopping ability sometimes show greater deviations between the prediction and the actual result.In order to solve such problems, at this time, the duration of free rotating period have been assessed for actual data of the ships with diesel main propulsion engines to grasp current situation, the scenario of free rotating of propulsion shafting system has been considered, and based on which how the free rotating period affects the stopping ability has been considered.In addition, possible predicting method taking essential feature of free rotating of propulsion shafting system into account based on practical and reasonable approximation has been considered, using which trail calculations have been carried out on the sample data of 132 vessels. Deviations between predictions and actual results have been improved compared with conventional method.

1 0 0 0 海水潤滑ゴム軸受における軸スリーブ損傷の研究―第2報

- 著者

- 吉川 文隆 内田 幸宏 藤田 健二 矢野 昭彦 川添 強 佐田 裕之

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.43, no.2, pp.258-264, 2008

- 被引用文献数

- 1

The previous report described the corrosive wear on propeller shaft sleeves, made of bronze, in seawater-lubricated stem tube bearings. Accompanying is the occurrence of craters on the sleeve surface due to the action of erosion corrosion. As a countermeasure, based on the mechanism, this second report will provide the development of a catholic protection bearing, what prevents corrosion of the sleeve surface and reduces wear. Using anodes installed in some of the water channel grooves of the rubber bearings, this method is characterized by intermittent protection at best, and protection conditions were investigated by means of fundamental testing and using bearings of 140mm in diameter. As a result, a current density of 8A/m<SUP>2</SUP> was found to protect the sleeve from corrosive wear. Cathodically protected bearings were also applied to bearings of 500mm in diameter and equipped for a ferry vessel. The results are presented here in terms of bearing design, trial running, and successful reduction of wear during actual in-service use.

1 0 0 0 OA 有害廃棄物の越境移動の規制 -日本の輸出規制に焦点をあてて

- 著者

- 鶴田 順

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.48, no.1, pp.44-47, 2013-01-01 (Released:2014-02-28)

- 参考文献数

- 6

1 0 0 0 OA 海水中気泡群の終端速度に関する研究

- 著者

- 吉田 昭仁 久郷 信俊 石田 憲治 佐藤 圭司 黒田 真生

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.38, no.10, pp.696-702, 2003-10-01 (Released:2010-05-31)

- 参考文献数

- 6

Most of industrial plants such petrochemical plant, LNG plant, and power plant, usually use water for the process cooling. Especially, in a large industrial plant, a large amount of seawater is used as the cooling media, and finally discharged to sea area through a seawater discharge basin.The seawater discharge basin has a weir to keep the sufficient backpressure of the seawater cooling system. In the seawater discharge basin, the seawater overflows the weir and falls down into the seawater flow at the downstream of weir. Then, the air is entrained into the seawater at the downstream of weir due to the waterfall flow and air bubbles with various sizes and shapes are generated in seawater.From the viewpoint of an environmental conservation, it is often required to eliminate air bubbles contained in cooling seawater discharged from industrial plants to sea area. There is a de-aeration chamber as a technology to separate these bubbles from the discharged seawater.To perform the optimum design of the de-aeration chamber, it is important to grasp the volume and size distribution of air bubbles generated in the seawater by the waterfall flow at the weir, and a terminal velocity of air bubbles rising in seawater.Therefore, in this study, the terminal velocities of any bubble in swarm of air bubbles rising in stagnant seawater, were measured in the region of low void fraction.

- 著者

- 石原 孟

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.50, no.1, pp.14-19, 2015-01-01 (Released:2016-01-27)

- 参考文献数

- 5

- 被引用文献数

- 2

- 著者

- 小松 正夫 太田 真 熊本 均 伊藤 弘人

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.50, no.1, pp.20-23, 2015-01-01 (Released:2016-01-27)

- 参考文献数

- 11

- 著者

- 北小路 結花

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.50, no.1, pp.24-29, 2015-01-01 (Released:2016-01-27)

- 参考文献数

- 1

1 0 0 0 OA 高EGR直接噴射式ディーゼル機関における燃焼過程の化学動力学モデルに基づく3次元数値解析

- 著者

- 脇坂 知行 藤本 英史 松川 洋介 高田 洋吾

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.43, no.6, pp.971-976, 2008-11-01 (Released:2010-05-31)

- 参考文献数

- 10

- 被引用文献数

- 2

The purpose of this study is to establish a practical method based on a chemical kinetic model for three-dimensional numerical analysis of the combustion process in direct-injection diesel engines. For saving computational time, a reduced elementary reaction scheme for diesel fuel was constructed. The basis was the Golovitchev detailed elementary reaction scheme. Using an original engine combustion simulation code GTT-CHEM along with the reduced elementary reaction scheme, the combustion process was three-dimensionally analyzed in a direct-injection diesel engine with high-EGR ratios.As a result, the combustion process and NO emission were quantitatively predicted by estimating the initial gas state and the initial composition appropriately. The emission tendency of soot was reasonably assessed by means of φ-T maps.

1 0 0 0 海洋最深部を探査する小型無人探査機ABISMOの開発と将来

- 著者

- 井上 朝哉 Aabo Kjeld

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- Marine engineering : journal of the Japan Institution of Marine Engineering = マリンエンジニアリング : 日本マリンエンジニアリング学会誌 (ISSN:13461427)

- 巻号頁・発行日

- vol.43, no.4, pp.531-534, 2008-07-01

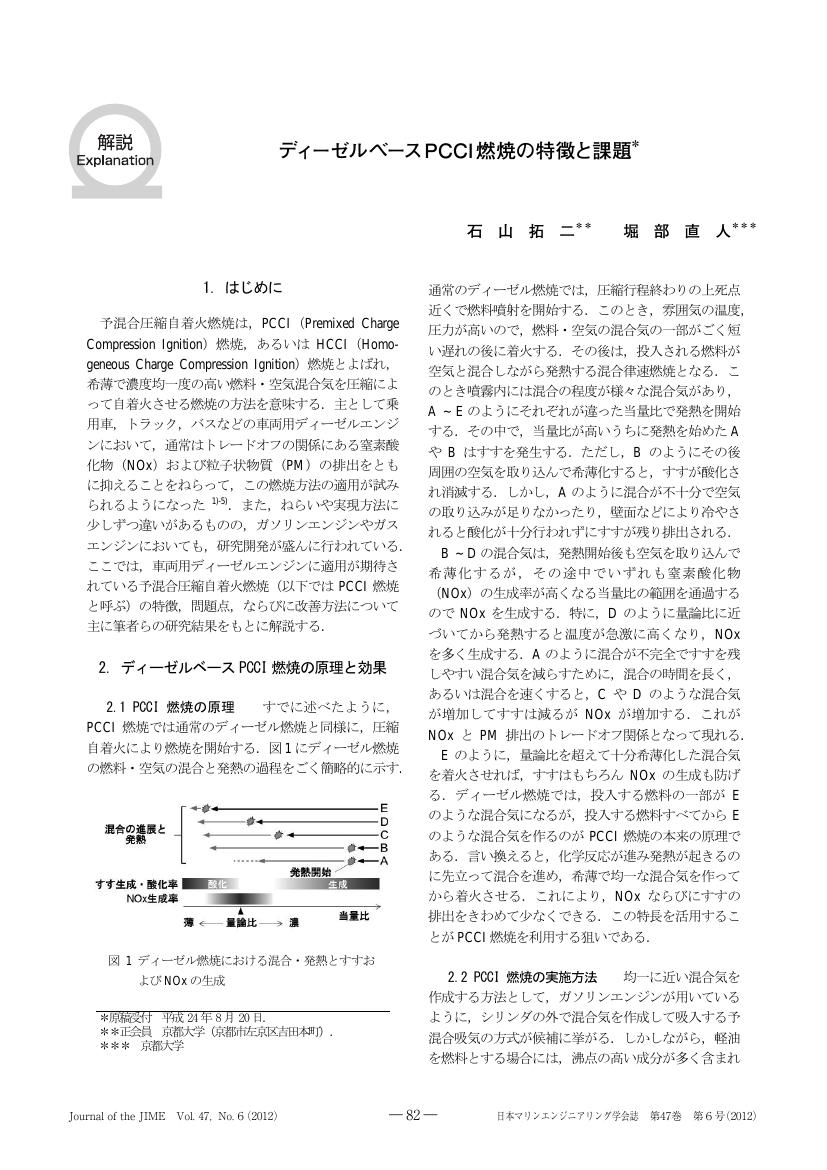

1 0 0 0 OA ディーゼルベース PCCI 燃焼の特徴と課題

- 著者

- 石山 拓二 堀部 直人

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.47, no.6, pp.859-864, 2012-11-01 (Released:2013-12-26)

- 参考文献数

- 24

- 被引用文献数

- 1 4

1 0 0 0 OA 舶用プロペラのCFD解析

- 著者

- 川村 隆文

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.48, no.5, pp.623-628, 2013-09-01 (Released:2014-09-02)

- 参考文献数

- 17

1 0 0 0 OA Java/JavaScript

- 著者

- 春海 和佳

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.36, no.12, pp.1016-1017, 2001-12-01 (Released:2010-05-31)

1 0 0 0 OA にっぽん丸の搭載機器について

- 著者

- 火置 将一

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.47, no.2, pp.203-207, 2012-03-01 (Released:2013-10-30)

1 0 0 0 OA 特集号「張り巡らされるセンサー・計測技術」によせて

- 著者

- 木船 弘康

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.46, no.2, pp.180-180, 2011 (Released:2013-10-23)

1 0 0 0 OA 「ちきゅう」の運航体制

- 著者

- 堀江 典弘

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.40, no.2, pp.155-158, 2005-03-01 (Released:2010-05-31)

- 著者

- 西尾 澄人

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- マリンエンジニアリング (ISSN:13461427)

- 巻号頁・発行日

- vol.51, no.1, pp.61-65, 2016

- 被引用文献数

- 1