2 0 0 0 傾斜圧延において介在物が内部割れに及ぼす影響

- 著者

- 山根 康嗣 下田 一宗 黒田 浩一 梶川 翔平 久保木 孝

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.62, no.720, pp.1-7, 2021 (Released:2021-01-25)

- 参考文献数

- 25

This paper discusses the effect of inclusions on internal fracture in skew rolling. The prediction of internal fractures is crucial given that internal fractures cause loss of product strength and are difficult to detect. Our previous report, published in 2019, proposed a new ductile fracture criterion that considers the effect of shear stress on void coalescence in a cylindrical coordinate system. This paper covers the following three points: (1) the evaluation of the hot workability of materials with different inclusions in tensile testing, (2) the relationship between the hot workability and the damage value determined using the proposed criterion, and (3) the effect of inclusions on void evolution in skew rolling. Given that the critical damage value decreased with decreasing hot workability, internal fractures are more likely to occur in a material that contains numerous large inclusions. The experimental results led to the hypotheses that the plastic strain nucleates the voids originating from inclusions and that shear stress allows the voids to coalesce. This study has demonstrated that decreasing the diameter and number density of inclusions is effective toward suppressing internal fractures.

2 0 0 0 自転車用フレームのチューブフォーミング技術

- 著者

- 轟 寛

- 出版者

- 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.40, no.459, pp.300-304, 1999-04

2 0 0 0 OA ビッカース硬さ試験におけるDLC-Si被膜の損傷挙動

- 著者

- 窪田 寛之 王 志剛 土屋 能成 谷口 幸典

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.48, no.562, pp.1017-1021, 2007 (Released:2007-11-26)

- 参考文献数

- 8

- 被引用文献数

- 2 1

To investigate the damage behavior of DLC (diamond-like carbon)-Si coating under high contact pressure, a series of experiments were carried out using the Vicker's hardness test. As substrate materials, alloy tool steel (SKD11) and high speed tool steel (SKH51) were used. In order to investigate the effect of coating thickness on coating damage, DLC-Si coatings with two thicknesses of 2.1μm and 4.0μm were prepared on SKD11. Coating damage was observed from the coating and cross-section surfaces. From observation of the coating surface, the indentation shapes of DLC-Si-coated tools were able to be sorted into 3 main types in terms of macroscopic coating damage level. For indentation shape type I, which shows no marked damage but a cross mark caused by the Vicker's indenter, cross-sectional observation was carried out, and a crack parallel to the coating surface was observed in all the DLC-Si coatings. It is inferred that the parallel crack in the coatings was generated by a force from the compressive residual stress of the coating.

1 0 0 0 薄肉銅円管の回転引曲げ加工における工具形状の影響

- 著者

- 梶川 翔平 荒木 聖人 渡辺 雅人 崩岡 久敏 土屋 昭則 久保木 孝

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.64, no.750, pp.123-128, 2023 (Released:2023-07-25)

- 参考文献数

- 15

The small diameter bending of thin-walled copper tubes which are used for heat exchanger is desired to reduce the size and weight of products. In this study, a series of experiments were conducted to investigate appropriate tool shapes, such as that of a mandrel, for preventing wrinkling, cracking and flattening in rotary draw bending. A C1220 tube with a diameter of 7 mm and a thickness of 0.21 mm was used in the experiments. The bending radius was twice the tube diameter. Plug and ball mandrels were used. The effects of the mandrel position, the mandrel shape, and the clearance between the tube and the mandrel were investigated. As a result, moving the mandrel position forward prevented wrinkling and flattening, but moving the mandrel position excessively caused cracking. The mandrel position at which the wrinkle and crack occurred varied depending on the mandrel shape and clearance. By optimizing the tool shape, wrinkling and cracking were prevented, and flatness was reduced to less than 15% for the plug mandrel and 5% for the ball mandrel.

1 0 0 0 拡管型抽伸加工における成形性に及ぼすプラグ半角の影響

- 著者

- 張 世良 川口 光 久保木 孝 赤坂 勇 寺下 雄三 秋山 雅義 梶川 翔平

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.63, no.743, pp.174-179, 2022 (Released:2022-12-25)

- 参考文献数

- 9

- 被引用文献数

- 2

In the present paper, we describe a tube drawing method with diameter expansion for the effectively formation of thin-walled tubes. The proposed method makes the tube thickness easier to reduce than the conventional method, because the tube wall stretches biaxially in the axial and hoop directions. The effects of the plug half-angle on the forming limit, drawing load, thickness reduction, the precision of the inner diameter, and the strength of the formed tube were investigated by a series of experiments and finite element method (FEM) analysis. As a result, the forming limit was the highest at a plug half-angle α of 36˚, and then the maximum thickness reduction ratio γ max of 32 % was obtained by increasing the expansion ratio. In addition, the thickness reduction ratio increased with the plug half-angle owing to the increase in drawing load. On the other hand, the dimensional precision of the tube inner diameter deteriorated with the increase in plug half-angle because of an overshoot of the tube wall, indicating a gap between the tube wall and the plug. The effect of the plug half-angle on the strength was small, while elongation changed with the plug half-angle. The above results suggest that the plug half-angle should be selected appropriately to obtain the target dimension and mechanical properties.

- 著者

- 柳田 明

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.56, no.656, pp.784, 2015

1 0 0 0 OA バウシンガー効果活用による自動車部品の寸法精度変動低減技術の開発

- 著者

- 飛田 隼佑 新宮 豊久 山﨑 雄司 平本 治郎

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.60, no.701, pp.155-160, 2019 (Released:2019-06-25)

- 参考文献数

- 17

- 被引用文献数

- 3 5

Dimensional scattering is a severe problem in press forming of ultrahigh-strength steels (UHSS), because of material strength scattering in mass production. In this study, camber back which occurs in longitudinally curved parts was focused on and a new forming method whereby dimensional scattering of camber back can be suppressed by the Bauschinger effect was developed. The new method consists of two processes. In the 1st process, a blank is formed to with a small radius of curvature compared with the 2nd-process radius of curvature. In the 2nd process, the 1st-formed part is formed to a large radius of curvature compared with the 1st-process radius of curvature. Then the Bauschinger effect works to decrease the amount of camber back. The new method was applied to a hat-shaped model of 590, 980, and 1180 MPagrade steels, where the radius of curvature in the longitudinal direction was 1600 mm. The experimental results showed that the difference in the amount of camber back between 590 MPa and 1180 MPa steels formed by the developed method decreased 95 % compared with the case of the conventional method.

1 0 0 0 OA 焼嵌めで構成された圧延用補強ロールに生じる残留曲がり生成メカニズムの解明

- 著者

- 野田 尚昭 佐野 義一 高瀬 康 下田 祐太朗 張 国偉

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.58, no.672, pp.66-71, 2017 (Released:2017-01-24)

- 参考文献数

- 15

- 被引用文献数

- 4 8

First, back-up rolls for rolling require toughness, particularly in the shaft portion, and high-hardness in the sleeve portion. The back-up rolls are classified into two types; one is a single-solid type, and the other is a shrink-fitted construction type consisting of a sleeve and an arbor. The shrink-fitted back up roll has several advantages, for example, different materials can be chosen and the arbor can be reused by replacing the damaged sleeve. Therefore, the shrinkfitted back-up rolls are economical. However, residual deflection becomes a major problem for the shrink-fitted back-up roll. Elucidating the mechanism of the occurrence of residual deflection and devising countermeasures are important issues. Unfortunately conducting a real experiment is difficult because of much time and huge cost. In this paper, we reproduce this phenomenon by elastic FEM analysis, establish a simulation method, and elucidate the mechanism behind underlying residual deflection.

- 著者

- 肥沼 康太 山中 晃徳 渡邊 育夢 桑原 利彦

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.61, no.709, pp.48-55, 2020 (Released:2020-02-25)

- 参考文献数

- 31

- 被引用文献数

- 1

Deformation of an aluminum alloy sheet is affected by its underlying crystallographic texture and has been widely studied by the crystal plasticity finite element method (CPFEM). The numerical material test based on the CPFEM allows us to quantitatively estimate the stress-strain curve and the Lankford value (r-value), which depend on the texture of aluminum alloy sheets. However, in the use of the numerical material test as a means of optimizing the texture to design aluminum alloys, the CPFEM is computationally expensive. We propose a methodology for rapidly estimating the stress -strain curve and r-value of aluminum alloy sheets using deep learning with a neural network. We train the neural network with synthetic texture and stress-strain curves calculated by the numerical material test. To capture the features of synthetic texture from a {111} pole figure image, the neural network incorporates a convolution neural network. Using the trained neural network, we can estimate the uniaxial stress-strain curve and the in-plane anisotropy of the r-value for various textures that contain Cube and S components. The results indicate that the neural network trained with the results of the numerical material test is a promising methodology for rapidly estimating the deformation of aluminum alloy sheets.

1 0 0 0 塑性加工解析に必要なソフトウエアスキル②最適化ソフト

- 著者

- 高橋 進

- 出版者

- The Japan Society for Technology of Plasticity

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.56, no.651, pp.300-304, 2015

1 0 0 0 OA 荷重制御による高精度曲げ加工

- 著者

- 柴田 隆浩 金 英俊 小山 純一 久保木 孝 村田 眞

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.53, no.612, pp.64-68, 2012 (Released:2012-01-25)

- 参考文献数

- 8

- 被引用文献数

- 1

Recently, the adjustment of working conditions in a manufacturing process is indispensable for realizing manufacturing accuracy in the V bending of a sheet metal. This adjustment is called "Trial Processing", and is a factor for lowing productivity. Therefore, "Trial Processing Free", a method that can obtain accuracy within tolerance but without the adjustment, is required. In the V bending of a sheet metal, there are two types of bending process, i.e., (i) air bending and (ii) bottom bending, using two types of punch control, i.e., (a) stroke control and (b) force control. In this research, a series of analysis and experiments were carried out to clarify that (ii) bottom bending with (b) force control is most appropriate for achieving Trial Processing Free. It was also established that bottom bending at an appropriately controlled force can absorb the effect of uncontrollable factors such as the dispersion of thickness and material properties of sheet metals and bend sheets within a certain tolerance, because the bending angle is stable even in a very wide range of bending forces. This bending method with force control was called the "FCSS (Force Control to Sweet Spot) method" and the advantage of this new process was verified experimentally.

1 0 0 0 振動付加による蛇腹容器の成形:— 両面しごき加工の研究 IV —

- 著者

- 青木 隆行 宮内 邦雄 西村 光彦 中村 和彦

- 出版者

- The Japan Society for Technology of Plasticity

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.48, no.555, pp.308-312, 2007

- 被引用文献数

- 1

A both-sided ironing process for simultaneous ironing of the outer and inner wall surfaces of deeply drawn cans has been developed successfully. The new process produces ring grooves in the can wall by vibrating the inner die along the ironing direction. The up-and-down motion of the inner die changes the ironing condition between the inner die and the outer die to continuously form ring grooves in the wall of ironed cans. The frequency of the vibration of the both-sided ironing process is set at about 4∼6 c⁄min. The profile of ring grooves in the ironed can wall is found to be influenced by the height difference between the outer and inner dies and the amplitude of the vibration. In particular, the greater the amplitude of vibration, the greater the depth of the ring grooves. The bent part of the ring grooves formed by the both-sided ironing process using vibration is the unique point of lowest strength. An ironed can with ring grooves in the wall can be easily squashed by a relatively small force.

1 0 0 0 OA プリハードン鋼におけるバニシ加工条件の検討

- 著者

- 森 茂樹 石橋 佑貴也 永野 善己 小川 秀夫

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.49, no.564, pp.71-75, 2008 (Released:2008-01-30)

- 参考文献数

- 8

- 被引用文献数

- 1

In the surface finishing of high-hardness materials such as die materials, it is common for a polishing process to be used. If burnishing is feasible for the surface finishing of a die using a CAD/CAM system and a machining center, it will become a useful working method for the following reasons: (1) reduction of the time required to make work arrangements, (2) improvement of the precision of shape and dimensions, and (3) improvement of the mechanical properties of the surfaces. In this paper, the relationships between working conditions and surface roughness are examined when the finish burnishing of a die material is carried out. The burnishing experiments were performed on prehardened steel with a SiC ceramic ball having a 9.525 mm diameter. Under the conditions of a burnishing force of 400 N and a pitch of 0.195 mm, finish burnishing was performed on a milled surface having a roughness of Ra1.4 μm, and a mirror surface having a roughness of Ra0.1 μm was obtained. In addition, in the case of the product having a free curved surface, a good mirror surface was obtained.

1 0 0 0 せん断加工等に関する研究と学会活動への貢献

- 著者

- 銘苅 春榮

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.50, no.587, pp.1118-1119, 2015 (Released:2016-07-23)

1 0 0 0 国際ジャーナルに通用する英語論文執筆のすすめ

- 著者

- ステンソン ウイリアム D.

- 出版者

- The Japan Society for Technology of Plasticity

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.51, no.597, pp.937-943, 2010-10-25

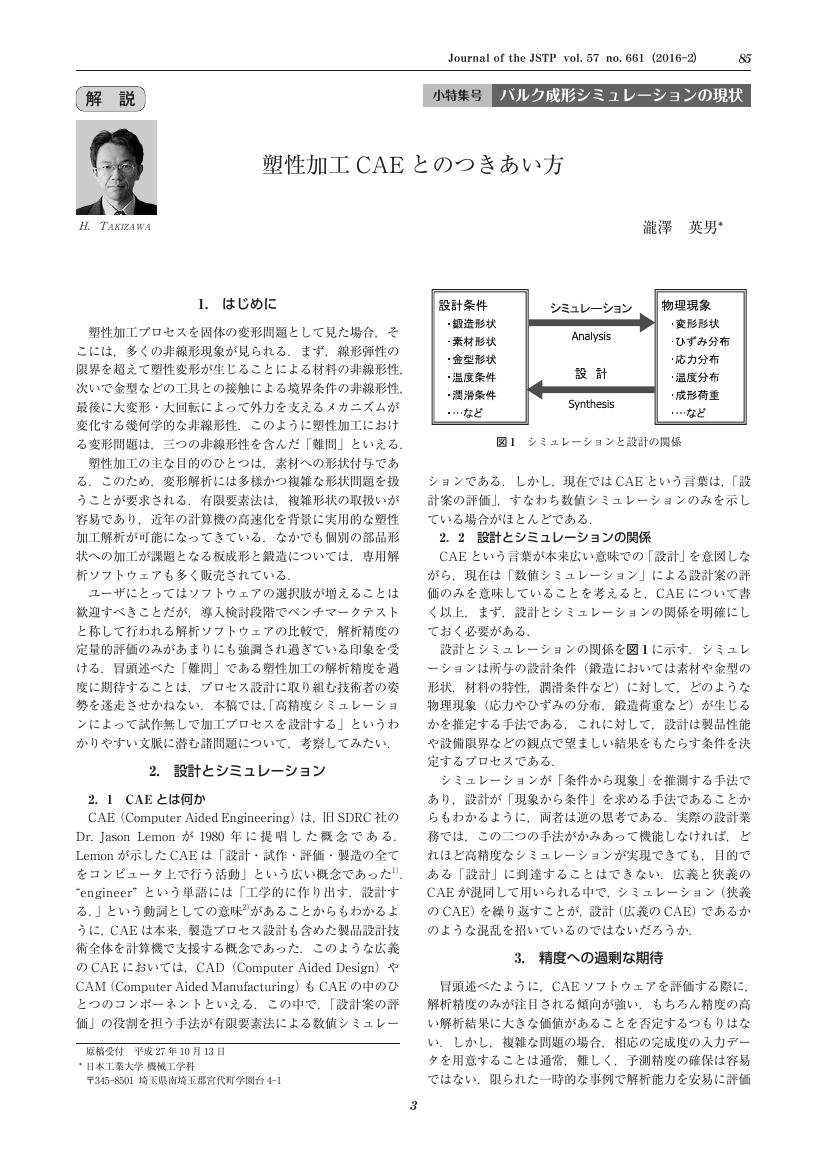

1 0 0 0 塑性加工CAEとのつきあい方

- 著者

- 瀧澤 英男

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.57, no.661, pp.85-89, 2016 (Released:2016-02-25)

- 参考文献数

- 8

1 0 0 0 グローバル化時代における日本のものづくりへの提言

- 著者

- 木村 昌平

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.55, no.641, pp.489-490, 2014

- 被引用文献数

- 3

1 0 0 0 外国特許の基礎知識

- 著者

- 今江 敏夫

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.55, no.642, pp.611-611, 2014 (Released:2014-08-06)

1 0 0 0 OA ワールドクラスのCNC 転造機とダイス製作技術

- 著者

- 株式会社 ニッセー

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.54, no.624, pp.46-46, 2013 (Released:2013-04-02)

- 著者

- 高木 知弘 山中 晃徳

- 出版者

- 一般社団法人 日本塑性加工学会

- 雑誌

- 塑性と加工 (ISSN:00381586)

- 巻号頁・発行日

- vol.54, no.633, pp.906-910, 2013 (Released:2013-11-06)

- 参考文献数

- 69

- 被引用文献数

- 2