2 0 0 0 OA 緊急脱出用酸素マスク (PEBA PE-3M) の概要

- 著者

- 山本 雅則

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1136, pp.997-999, 1982-10-25 (Released:2011-07-13)

- 被引用文献数

- 2

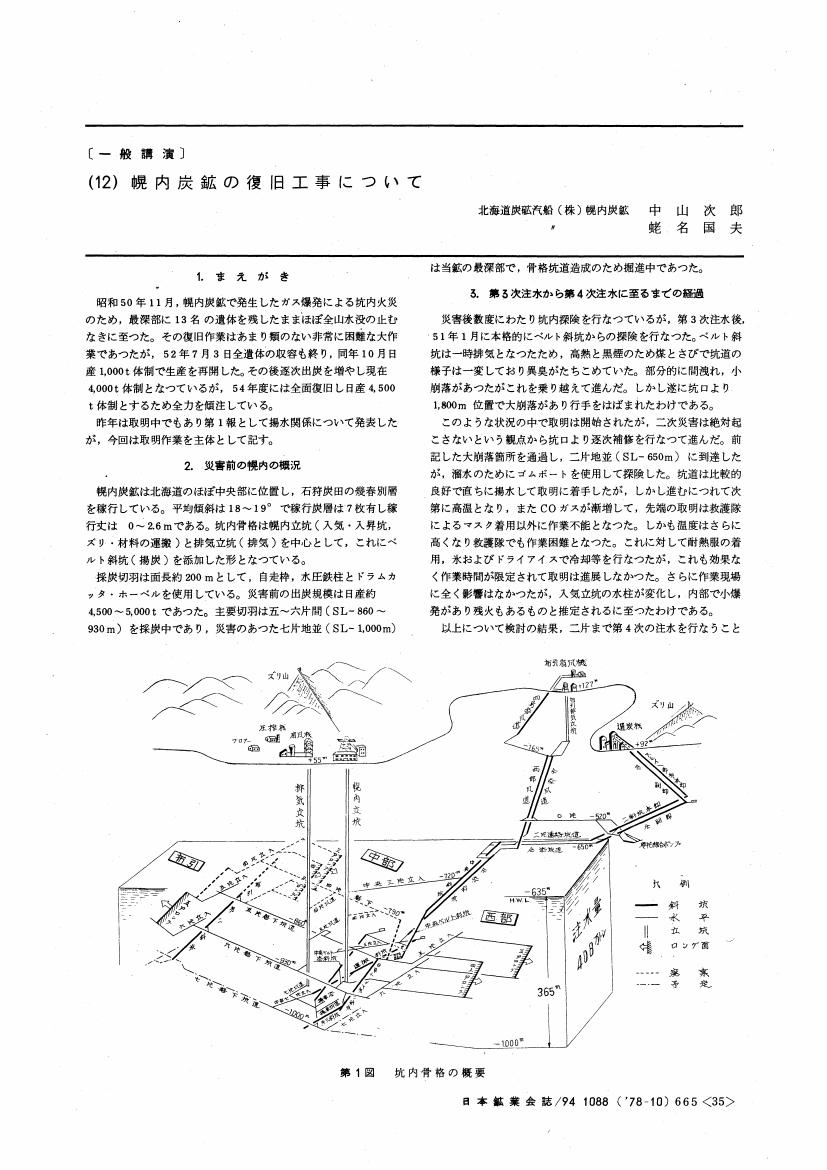

2 0 0 0 OA 幌内炭鉱の復旧工事について

- 著者

- 中山 次郎 蛯名 国夫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1088, pp.665-668, 1978-10-25 (Released:2011-07-13)

2 0 0 0 OA 分岐管式給炭装置を用いた石炭の水力輸送に関する研究

- 著者

- 渡辺 慶輝

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.82, no.936, pp.333-341, 1966-04-25 (Released:2011-07-13)

- 参考文献数

- 19

The results of fundamental experiments revealed that the coal filled in a pipe was moved by low water pressure, and it flowed in a pipeline with little delay when velocity of stream exceeded 3.5m/s. According to these results a multi-pipe type coal feeder was invented. It consists of several parallel long lock chambers which are branched from a delivery pipe of a high pressure pump. And they have approximately the same diameter of the conveying pipe. One of these is fed coal and water mixture by means of a low pressure sand pump. After this, the mixture is pushed into the conveying pipe by the high pressure water. This process is repeated one after another, and coal is transported continuously.The auther produced a hand-operated model of this coal feeder for laboratory tests, then made its valves act automatically. The practical tests of this feeder was carried out at Yoshima colliery. 20.000t of coal was transported by 7 in. pipeline with it. The test results revealed that it had the transporting capacity of 100t/h, registering the volume concentration 20% Now the test is continued on commercial basis at Sunagawa colliery. The transportation height is 490m and the length of pipeline 2, 046m. There automatic control of concentration of coal in the pipeline is attemped to economize the transportation cost.

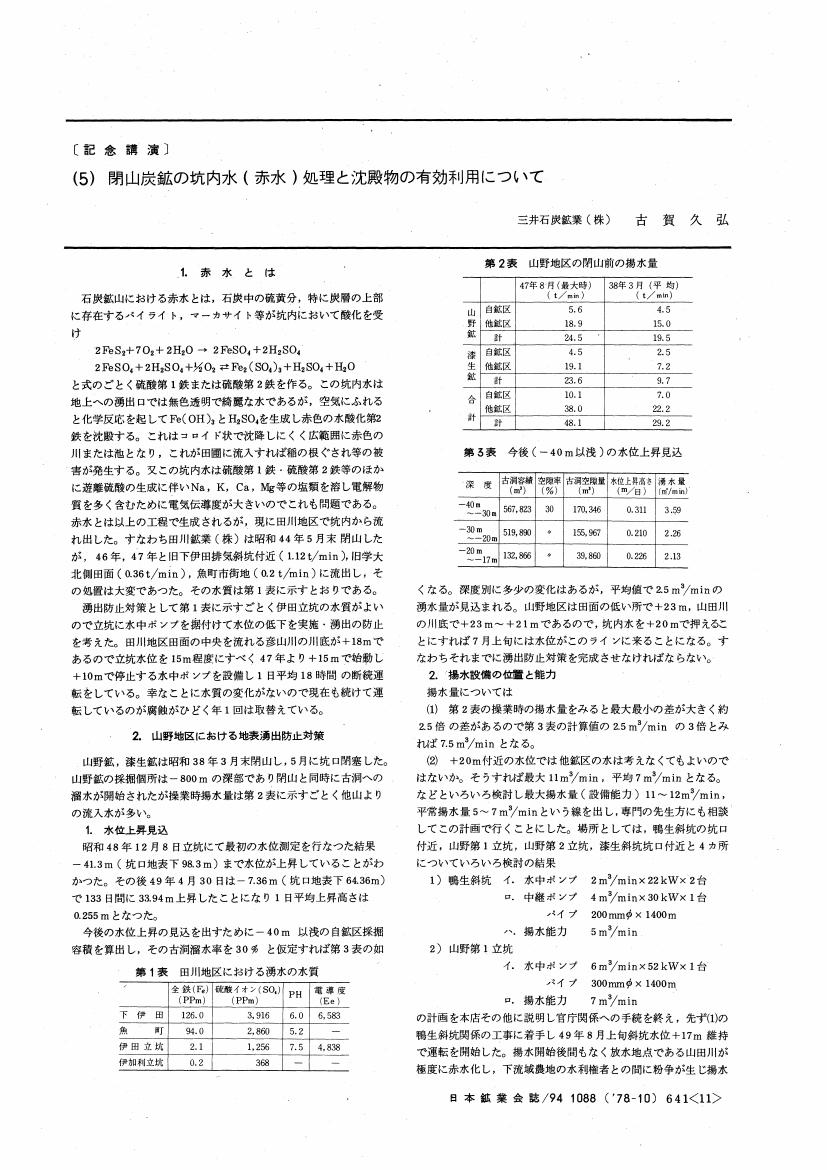

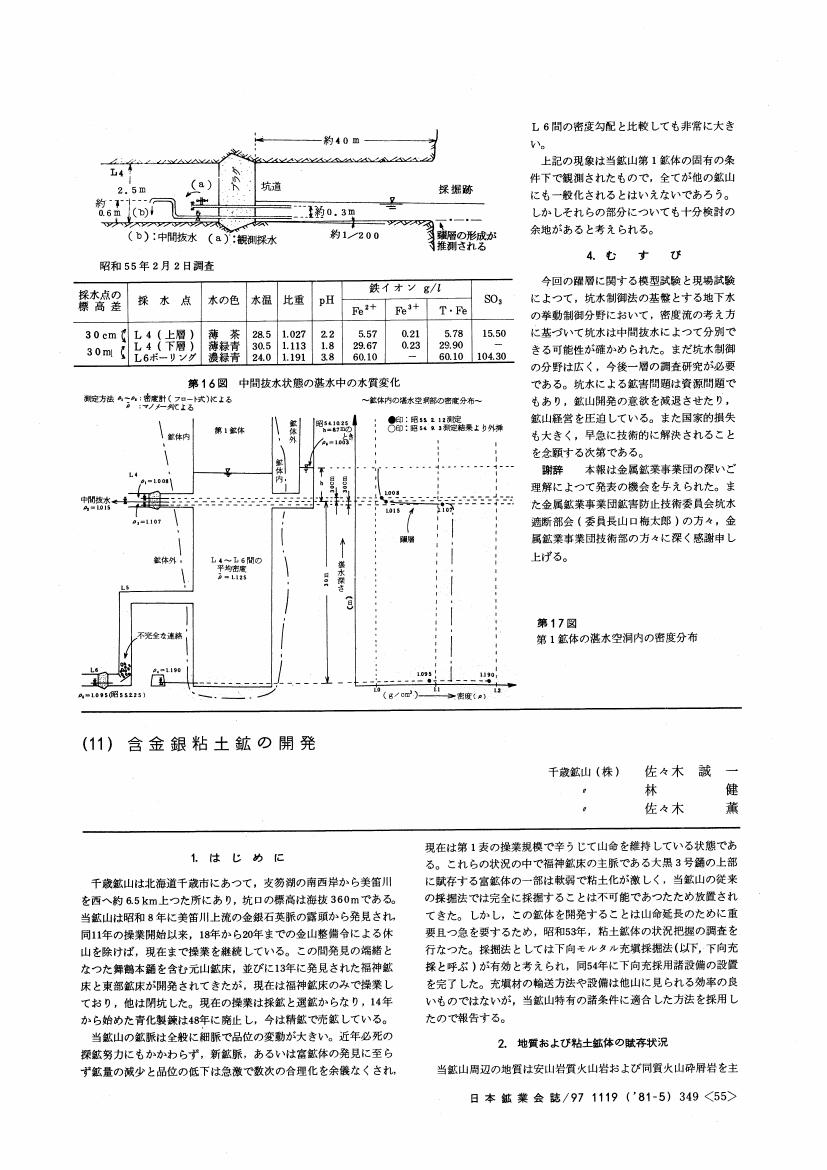

2 0 0 0 OA 閉山炭鉱の坑内水 (赤水) 処理と沈殿物の有効利用について

- 著者

- 古賀 久弘

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1088, pp.641-645, 1978-10-25 (Released:2011-07-13)

1 0 0 0 OA 含金銀粘土鉱の開発

- 著者

- 佐々木 誠一 林 健 佐々木 薫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.97, no.1119, pp.349-353, 1981-05-25 (Released:2011-07-13)

1 0 0 0 OA 亜鉛製錬副産物からのガリウム, インジウムの回収

- 著者

- 阿部 秀来

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1133, pp.561-565, 1982-07-25 (Released:2011-07-13)

- 被引用文献数

- 2 1

The trace amounts of gallium and indium are contained in the Black Ore type of deposits distributed at Hokuroku area in Akita. Gallium and indium tend to be concentrated into the zinc concentrates through mineral processing.Dowa Mining Co., Ltd. began to examine the recovering process of gallium and indium in 1963 whengallium was given attention as raw material of semi-conductor, and studied manysided technique to recover both metals fromthe by-product of zinc refinery. Our gallium and indium recovery process is characterized by the zinc residue treatmentprocess of The lijima Zinc Refinery of Akita Zinc Co., Ltd. which is very useful to concentrate both metals, and also by thesolvent extraction process to separate gallium and indium from the sulfuric acid solution.Considering how to solve the problem derived from the application of the technique to the plantoperation, gallium recovering plant was constructed in Kosaka Smelter of Dowa Mining Co., Ltd. simultaneously with theconstruction of Iijima Zinc Refinery.Operation started in January 1972, and is producing high quality gallium and indium. Though only 40kg/m ofmetallic gallium and some indium hydroxides were produced when started, now 180kg gallium and 250kg indium areproduced every month.

1 0 0 0 OA 酸化銅鉱の回収

- 著者

- 若松 貴英

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1134, pp.687-693, 1982-08-25 (Released:2011-07-13)

- 参考文献数

- 38

A number of approaches to the treatment of oxidized copper have been proposed. The principal methods for copper recovery from oxidized are have included leaching, sulfidization flotation, leach-precipitation-flotation, segregation, and leachsolvent extraction-electrowinning. In this paper the basic science and performance of some of the techniques for oxidized copper processing are briefly reviewed. Further, recent trends in the fundamental investigations concerning oxidized copper processing are summarized.

1 0 0 0 OA 沸石化凝灰岩の加熱発泡性 (I) 未利用岩石資源の利用に関する研究 (第2報)

- 著者

- 小野寺 嘉郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.100, no.1152, pp.67-72, 1984-02-25 (Released:2011-07-13)

- 参考文献数

- 28

The bloating properties of sedimentary zeolites existing enormously in Green Tuff region of our country were investigated. Pelletized bodies (9-12mm diameter) prepared from pulverized zeolites were fired in the range of 900-1350°C. Then physicochemical properties, such as specific gravity, water absorption, crushing strength etc., of the pellets were measured. Moreover, 38 mixtures prepared from mordenite tuff, silica, alumina and ferric oxide were fired in order to make clear the optimum bloating range in chemical compositions.The results obtained are summarized as follows;In many cases, air dried pellets had high crushing strength enough to permit the firing by rotary kiln. Pellets started to bloat at temperatures above 1150°C and the bloating extent increased with raising the temperature. Most of the pellets fired at higher temperature than 1100°C were impervious and their specific gravity was about 2.3-0.4. Crushing strength of the fired pelletes whose specific gravity were about 1.2-1.3 were in the range of 120-170kg, and it was about 2 times that of artificial light weight aggregates commercially produced. By the results of X-ray analysis, chemical and thermal analysis, it was guessed that a common gas-forming component in sedimentary zeolites concerning with the bloating was ferric oxide.From the firing tests of the above-mentioned mixtures, the optimum contents of silica, alumina and flux for the bloating were ascertained to be in the range of 60-70%, 10-25% and 10-20%, respectively.

1 0 0 0 OA 大谷鉱山

- 著者

- 宮地 正人

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.83, no.956, pp.1619-1621, 1967-12-25 (Released:2011-07-13)

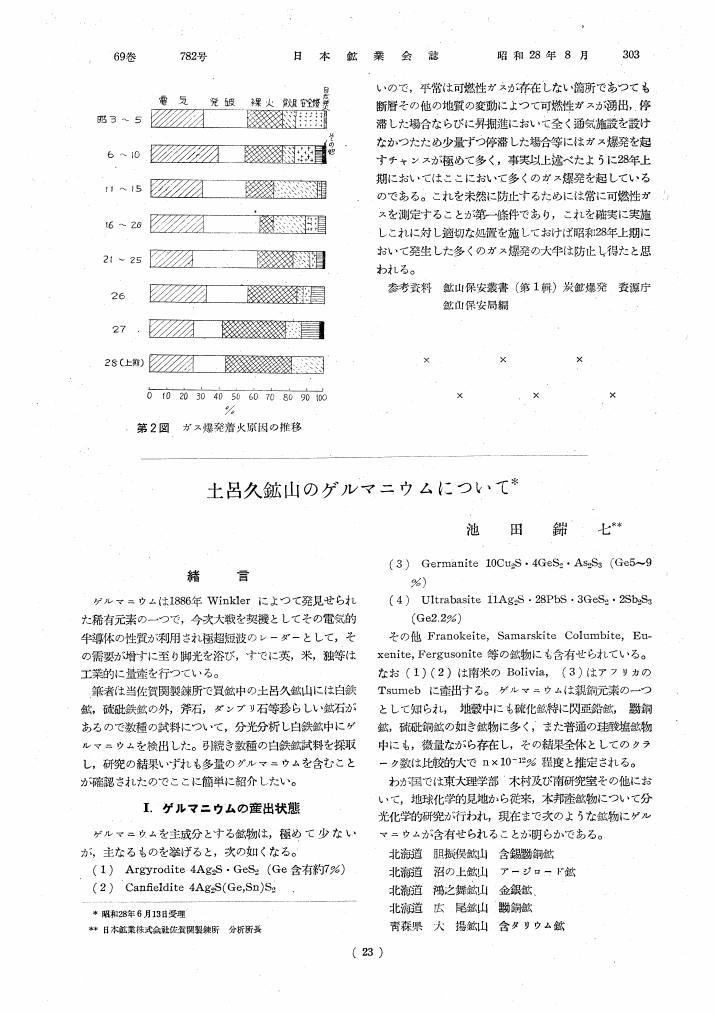

1 0 0 0 OA 土呂久鉱山のゲルマニウムについて

- 著者

- 池田 錦七

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.69, no.782, pp.303-305, 1953-08-25 (Released:2011-07-13)

- 参考文献数

- 8

1 0 0 0 OA 日本碍子におけるベリリウム製錬

- 著者

- 永井 敏郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.84, no.963, pp.986-988, 1968-07-25 (Released:2011-07-13)

1 0 0 0 OA 野呂景義先生揮毫の「山神社」扁額 釜石市沢桧川流域の高炉によせて

- 著者

- 岡田 広吉 加藤 清一

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.92, no.1064, pp.685-688, 1976-10-25 (Released:2011-07-13)

- 参考文献数

- 24

1 0 0 0 OA わが国の2, 3のドロマイトの化学組成および結晶構造の偏僑

- 著者

- 今井 直哉 山崎 純夫 森 正章

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.84, no.959, pp.205-206, 1968-03-25 (Released:2011-07-13)

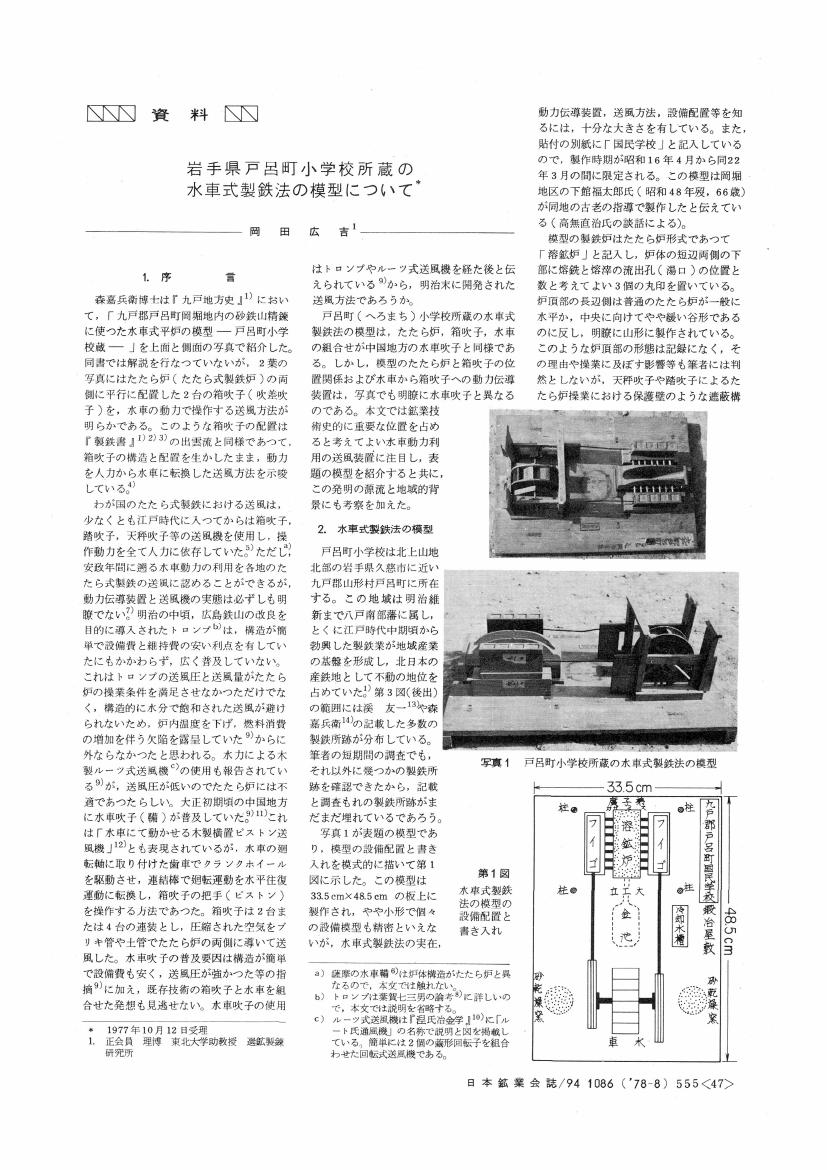

1 0 0 0 OA 岩手県戸呂町小学校所蔵の水車式製鉄法の模型について

- 著者

- 岡田 広吉

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1086, pp.555-558, 1978-08-25 (Released:2011-07-13)

- 参考文献数

- 25

1 0 0 0 OA 釈迦内鉱山

- 著者

- 岡本 明夫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.100, no.1160, pp.913-917, 1984-10-25 (Released:2011-07-13)

(1) 名称釈迦内鉱山株式会社釈迦内鉱山(2) 所在地秋田県大館市釈迦内字二ツ森三八郵便番号017電話0186 (48) 2141(3) 鉱種金, 銀, 銅, 鉛, 亜鉛, 硫化鉄鉱, 重晶石, 石こう(4) 位置・交通釈迦内鉱山は, 秋田県大館市釈迦内字二ツ森38に事務所があり, 奥羽本線大館駅より国道7号線を北に約5kmの地点にある。(第1図)(5) 地形・気候本鉱山は大館盆地北端部に位置し, 局部的に石英安山岩体よりなる丘陵が点在するほか, 概して平担であり, 地表の多くは耕作地となつている。気候的には寒冷であり, 11月末-3月初旬は降雪期であるが, 積雪量は1m前後である。

1 0 0 0 OA 対馬国貢銀記とその製錬法

- 著者

- 吾妻 潔

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.91, no.1051, pp.607-609, 1975-09-25 (Released:2011-07-13)

- 参考文献数

- 15

1 0 0 0 OA 神岡・鹿間選鉱工場における閉回路粉砕のシミュレーション

- 著者

- 村上 義雄 山口 寿々男 伊東 賢治 大坪 泰典

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.101, no.1164, pp.67-73, 1985-02-25 (Released:2011-07-13)

- 参考文献数

- 7

- 被引用文献数

- 1 1

Through analysis of the data obtained from the plant test in the Kamioka-Shikama concentrator, which includes a 2, 700mm dia.×3, 600mm length rod mill and a 3, 900mm dia.×5, 700mm length ball mill in a closed circuit with 2 or 3 hydrocyclones of 600mm in diameter, a comminution mathematical model has been deduced from making use of a selection function under the assumption of plug flow material transport. ln the rod mill, the said selection function “s (x) =Kx” is 1.871×10-4x0.7151 (s-1) and that in the ball mill is 1, 179×10-5x0.9891 (s-1).As a cyclone classification-model, the logarithmic cumulative normal distribution function has been found to give a best fit to the true partition curve. Several regression equations for the prediction of the fraction of water β, separation size D50, and the sharpness of σ separation a have been made up as the functions of the feed to the cyclone. Combining the mill models with those regression classification models, many simulations have been carried out to find out the most accurate cyclone model to be applied for simulating the real operation.Making use of the optimum models, the comminution in the mills and classification in the cyclones have been simulated in a wide range of operating conditions to obtain information on the conditions of the plant. The results of the simulations indicate that it is possible to gain higher throughput in the mill-cyclone circuit without changing the characteristics of the cyclone overflow (i. e. the feed to the flotation circuit).

1 0 0 0 OA 松尾鉱山の硫黄製錬

- 著者

- 国枝 鋭二

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.84, no.963, pp.935-939, 1968-07-25 (Released:2011-07-13)

1 0 0 0 OA 炭鉱における不発雷管 (流管) 検出について

- 著者

- 山田 正幸 馬場 文夫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.73, no.834, pp.861-865, 1957-12-25 (Released:2011-07-13)

In the most recent we have been interested in keep away from an explosion accident by the misfired detonstors. In this paper we shall report on the electronic metal detection.The metal detector is build around some form of mutual-inductance bridge employing a symmetrical coil arrangement which is bed by a suitable oscillator. The presence of a metallic particle in the A. C. electro-magnetic field which links the coils disturbs the original field pattern for which the bridge was balanced. The resulting bridge unbalance current is amplified and made to operate a warning or rejection device.

1 0 0 0 OA (2) 幌内炭鉱における傾斜層の機械化採炭技術について (第2報)

- 著者

- 上水 昇平

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.103, no.1196, pp.605-608, 1987-10-25 (Released:2011-07-13)