1 0 0 0 OA 坑道火災の性状と拡大防止

- 著者

- 松隈 喜総 清正 稔 井清 武弘 鈴木 忠

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.93, no.1076, pp.659-663, 1977-10-25 (Released:2011-09-13)

- 参考文献数

- 8

1 0 0 0 OA 3m以上の厚層一段採掘における移動式組立枠払について

- 著者

- 若林 寿雄

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.79, no.901, pp.457-464, 1963-07-25 (Released:2011-07-13)

- 被引用文献数

- 1

The working face at Miike coal mine have been removed into the thick seam area over 3 meter gradually since 1950-1951. To work this seam throughly, several mining methods were investigated, then the slicing system was applied in Mikawa pit, while self advancing powerd roof support was introduced to Miyaura pit.It had been generally believed that the working height of long wall face in low dip was up to nearly 2.8 meter, however, after extensive examinations, we had developed the self advancing support using mighty hydraulic props of higher yielding load, there by we have succeed in getting coal seam over 3 meter throughly at same time.

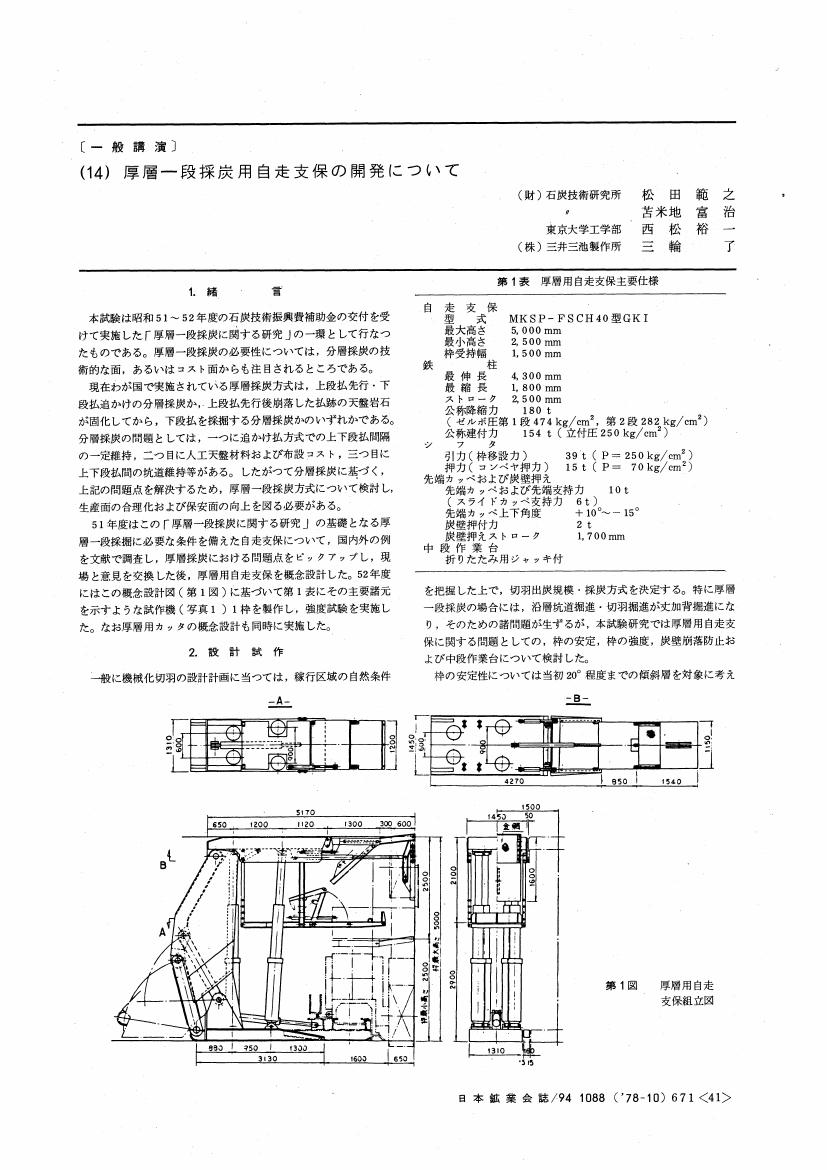

1 0 0 0 OA 厚層一段採炭用自走支保の開発について

- 著者

- 松田 範之 苫米地 富治 西松 裕一 三輪 了

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1088, pp.671-674, 1978-10-25 (Released:2011-07-13)

1 0 0 0 OA グライトホーベルの実績について

- 著者

- 岩橋 恵 山本 敏雄

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.84, no.965, pp.1388-1391, 1968-09-25 (Released:2011-07-13)

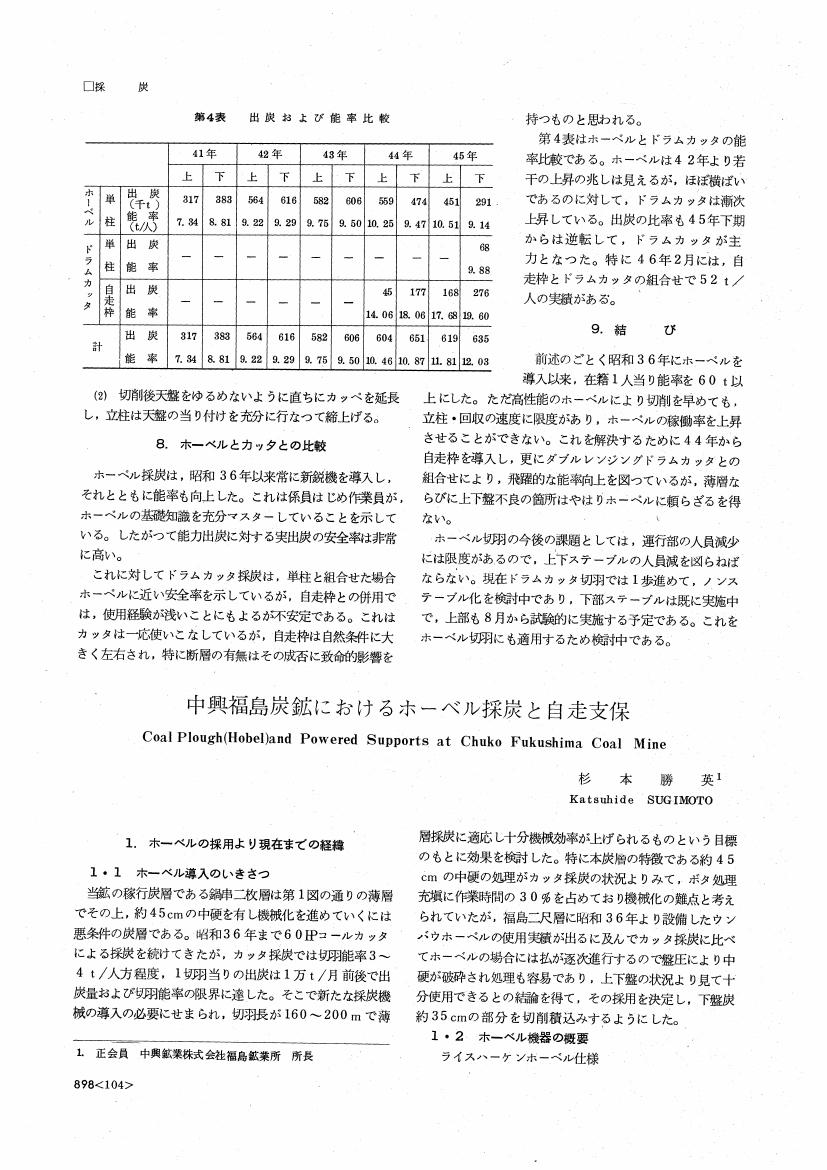

1 0 0 0 OA 中興福島炭鉱におけるホーベル採炭と自走支保

- 著者

- 杉本 勝英

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.87, no.1005, pp.898-902, 1971-11-25 (Released:2011-07-13)

1 0 0 0 OA 三井砂川炭鉱の深部採掘における技術改革

- 著者

- 大塚 泰二朗

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.96, no.1110, pp.507-513, 1980-08-25 (Released:2011-07-13)

Mitsui Sunagawa Mine is situated northern part of Ishikari coal field in Hokkaido and produces 1.1 million clean coal tonnes per year.The Sunagawa Mine first started in 1914, has produced for 65 years. It is mining five steeply dipping seams (50-70 deg.). Mining blocks are located at 900m below surface now, and further new blocks at 1, 000m are being prepared.After years of technical innovations on deep mining and safety methods to overcome severe conditions-gas emission, gas outburst, spontaneous combustion, and earth pressure-hydraulic mining has proved to be a safe and economical method of coal extraction since 1964.In general, mining blocks deepen in short period, roadways to be maintained lengthen and finally main structure is very complicated at steep dipping coal mines. A new return shaft of 900 m was sunk at Sunagawa Mine in 1979 to shorten the sustaining roadways and to make the main structure simple and steady.The hydraulic mining has been shown to provide benefits in safety and improved productivity, comparing to the conventional mechanical mines in thefl at seams.

- 著者

- 松本 広市

- 出版者

- 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.102, no.1184, pp.p669-672, 1986-10

1 0 0 0 OA 奈良県五代松鉱床におけるスカルンの産状

- 著者

- 宮石 修 李 勇 港 種雄

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.96, no.1113, pp.789-794, 1980-11-25 (Released:2011-07-13)

- 参考文献数

- 9

The Goyomatsu magnetite skarn deposit consists of large and small irregular massive bodies interlayered in upper Chichibu formations (limestone, sandstone, slate etc.), which have been metamorphosed by Miocene Omine acidic rocks (granodiorite).On the basis of mineralogic observations and thermodynamic data, the principal conditions of formation of the skarns have been determined. Results are as follows:1) Field evidence reveals that in the deposit hedenbergite is predominant in and near the granodiorite, and andradite is predominant in and near the limestone. This contrasting occurrence appears to show that the μO2 in the limestone gradually increased away from the granodiorite-limestone contact, assuming these skarns were formed at nearly the same stage.2) Generally, andradite rarely coexists with actinolite in skarns. This field evidence iswell in agreement with thermodynamic data, which shows that the andradite+actinolite phase cannot be a stable assemblage at constant temperature and pressure asseen in Fig. 3.3) Fig. 3 suggests that in general, under constant μCO2 conditions, the following mineral zonation formed with increasing μO2: zones of hedenbergite+actinolite, hedenbergite+andradite, and andradite, respectively. However primary assemblages of hedenbergite+actinolite havenot been observed. On this point, we need more detailed examinations.4) It is also found that in the skarns, hedenbergite has sometimes altered into aggregates of actinolite, calcite and quartz. Assuming constant temperature and pressure it can be interpreted that such alteration was caused by an increase in μCO2 at low μO2 environments.