1 0 0 0 OA 八戸製錬所の亜鉛・鉛製錬

- 著者

- 一ノ瀬 幸夫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.97, no.1122, pp.676-680, 1981-08-25 (Released:2011-07-13)

Hachinohe Smelting Company was established on Feb. 1st, 1967 as a joint toll smelter to take advantage of the Imperial Smelting Process to treat mixed and complex ores, especially some concentrates from “black ore” in Tohoku district of Japan and concentrates from Huanzala Mine in Peru. The Hachinohe ISF plant was commissioned in Feb., 1967, and has beensu ccessfully operating with excellent performances.The Smelter Complex consists of sinter plant, acid plant, furnace plant, and zinc refinery. The sinter plant employs the Lurgi type sintering machine, while acid is produced in Lurgi type double contact acid plant. Some parts of crude zinc producedb y the ISF is further refined by its own reflux ing refining plant. Bullion is shipped without refining.Since the, operation commencement, various improvements and modifications have been constantly applied to make the plant competitive, emphasizing the theme of “conservation and recovery of energy”. A typical example of the efforts is incorporation of power generator which utilizes waste heat of the furnace off-gas. Now the plant is trying to further strengthen its ability to cope with low production.rate forced by current unfavorable situations surrounding zinc industry

- 著者

- 加藤 與五郎 武井 武

- 出版者

- The Mining and Materials Processing Institute of Japan

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.46, no.539, pp.167-176, 1930

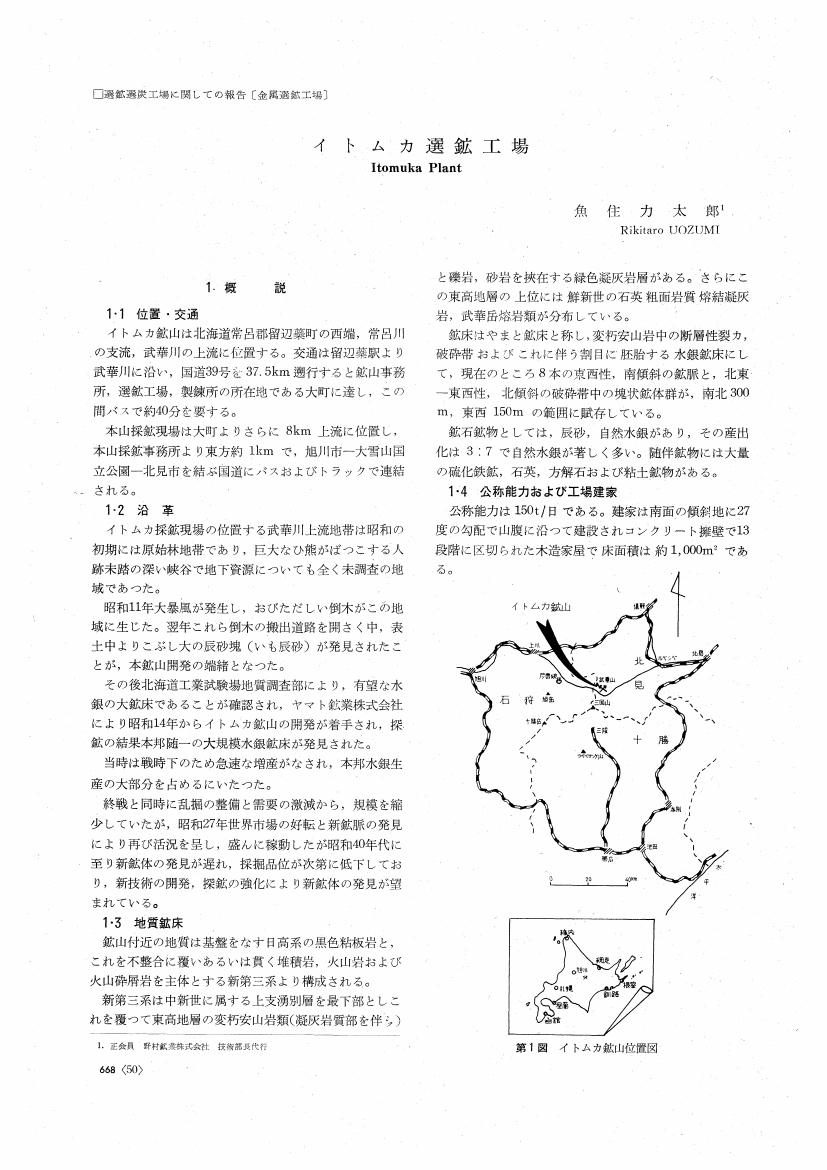

1 0 0 0 OA イトムカ選鉱工場

- 著者

- 魚住 力太郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.86, no.991, pp.668-672, 1970-10-25 (Released:2011-07-13)

1 0 0 0 OA イトムカ鉱山の採鉱法

- 著者

- 吉田 邦久 川口 修

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.73, no.832, pp.785-787, 1957-10-25 (Released:2011-07-13)

The deposits of this mine lie in or along the faults as replacement and impregnation. So, generally speaking, it is very difficult to distinguish the boundaries between ore bodies and country rocks. Moreover, the both sides of ore bodies are very brittle due to shearing stress and alteration of rock. Therefore, timbering and filling with waste rock are necessary in stoping. Until recently the over land flatback filled stoping had been used, but the slushers has been adopted in filled stopes, since June 1956, to raise the efficiency of stoping. The results of slushers in filled stopes have been a great success.

1 0 0 0 OA 下部立坑開さく工事について

- 著者

- 植野 泰治 中村 建一 尾藤 邦治

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.92, no.1058, pp.236-239, 1976-04-25 (Released:2011-07-13)

1 0 0 0 OA 三菱美唄新選炭工場の計画と概要

- 著者

- 今井 清 高崎 達也

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.77, no.879, pp.807-811, 1961-09-25 (Released:2011-07-13)

According to the increasing output plan, construction of the new coal preparation plant of 400 tons per hour in capacity had been projected at Mitsubishi-Bibai Colliery, Hokkaido. The new plant construction was started in February 1960 and was put in operation in June 1961. For the purpose of high efficiency in cleaning and accurate stability in coal quality, the new plant adopted Drewboy dense-medium separators for, coarse coal and a feldspar bed-jig for fine coal.This paper describes chiefly the fundamental elements and some problems involved in the design of the new plant as well as its outlines.

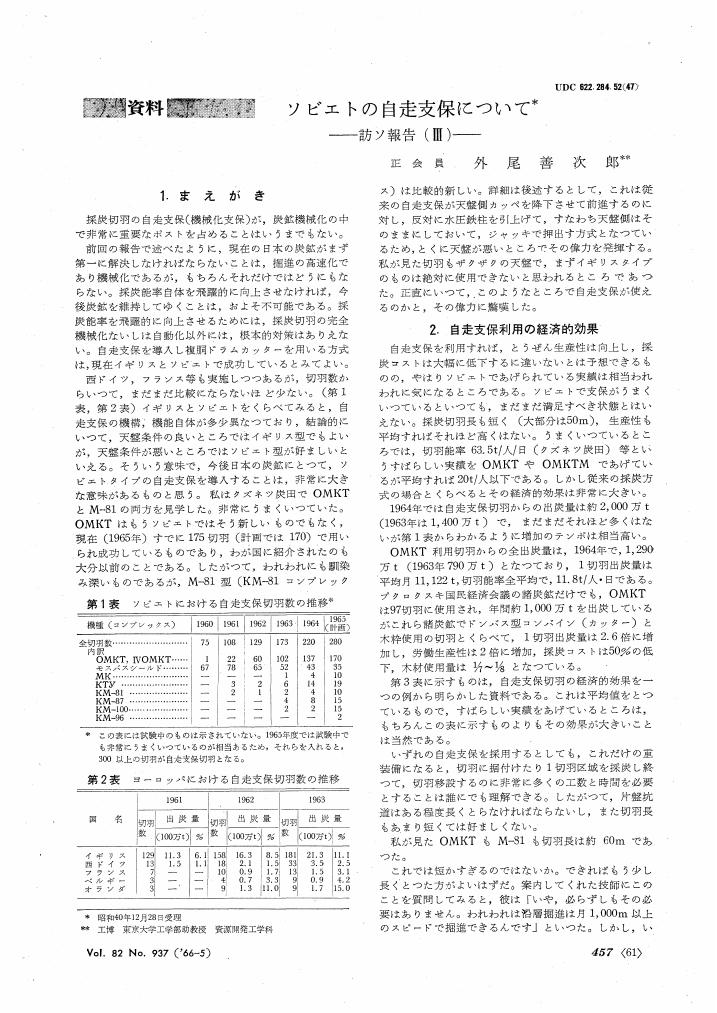

1 0 0 0 OA ソビエトの自走支保について

- 著者

- 外尾 善次郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.82, no.937, pp.457-468, 1966-05-25 (Released:2011-07-13)

1 0 0 0 OA ソビエトにおける急傾斜採炭機

- 著者

- 外尾 善次郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.82, no.938, pp.533-542, 1966-06-25 (Released:2011-07-13)

1 0 0 0 OA ソビエトの沿層掘進機について

- 著者

- 外尾 善次郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.82, no.936, pp.365-373, 1966-04-25 (Released:2011-07-13)

1 0 0 0 OA 花岡鉱山松峰坑

- 著者

- 浅海 宣慶 大槻 晃義

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.100, no.1160, pp.900-904, 1984-10-25 (Released:2011-07-13)

Matsumine deposit, located in the northern part of Odate basin, Akita Prefecture, is a large scale Kuroko deposit. This deposit was discovered in 1963. The development work was started in July 1964, and the production was started in October 1966, at the rate of 20, 000 tons/month. Current production rate is 40, 000 tons/month, and it is the largest copper supplier in Japan.The Kuroko generally consists of black ore, yellow ore (cupriferous pyrite ore) and siliceous ore. The black ore (Kuroko) is a black coloured ore consisting mainly of sphalerite, garena and barite, and rich in gold and silver, too. The yellow ore is a yellow massive powdery ore comprising mainly chalcopyrite and pyrite. The siliceous ore which is rich in silica is divided into two types, one containing considerable amount of chalcopyrite and pyrite, and the other with a high sphalerite content.The mining method applied is “The underhand cut and fill with artificial roofing”. Once a unit block of ore is mined out in a stope, iron reinforcing bars are laid on the floor, and a 15 percent cemented mortar mixed with mill tailings and volcanic ash is pumped over the bars up to 0.6 meter thickness. Then, the space above the layer is filled with the 3 percent cemented sand slime. This reinforced mortar serves as an artificial roof when ores below are mined next. In 1982, the conventional battery locomotive and tub system was partly replaced by the trackless system with L. H. D.

1 0 0 0 OA 採炭

- 著者

- 伊木 正二 服部 三郎 田島 一幸 神野 哲一 広部 亮一郎 肥田野 親男 安達 六郎 神谷 国輝 平塚 欣蔵 宮崎 義一 紫雲 千鶴雄 大渡 介一郎 石本 強 小島 鴻次郎 佐藤 喜輔 野上 辰之助 山口 哲二 久保 正明 原 俊郎 白水 護 稲永 守 永江 光夫 徳原 光信 御厨 美年 坪田 督之助 斎藤 義博 渡辺 尚三

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.74, no.843, pp.585-640, 1958-09-25 (Released:2011-07-13)

- 参考文献数

- 10

As in about ten years the new mining machines and technics were imported, the mining method in Japan were changed remarkably.Natural condition of coal seam in Japan (1956)Working depth (Average) 334.7m(Maximum) 836mAverage thickness of seam 1.71mAverage thickness of coal 1.31mOutput from coal face 48.281Mill. t.About 65% of output is worked by longwall method. About 36% of output is gotten by blasting, and 36% by coal picks in coal face, but coal cutters are used pretly well. Hobels are used in Emukae, Takashima, Kogayama and Mitsubishi-Bibai. 55% of output is conveyed Panzer conveyor at coal face.Hydraulic stowing is carried out at Onoura and pneumatic stowing is used at Yamano, Akabira and Sakito coal mines. Slicing method for thick seam is carried out at Hojo and Takashima coal mines.We must decrease the number of coal faces in one pit and increase the output per one coal face, and use the practical working time effectively.

1 0 0 0 OA ストリッピング・スクレーパによる薄層採炭について

- 著者

- 石川 健次

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.69, no.784, pp.419-421, 1953-10-25 (Released:2011-07-13)

The coal seam of Shikamachi coal mine, belonging to Hokusho district in Sasebo coal field, is thin, from 0.35 to 0.5 meter high, and soft. The coal of which is called strongly caking coal.Before, the stripping scraper was employed, hand-digging had been held only.We investigated and tested practicaly the stripping scraper as the mining machine that can be applied to the above conditional seam.Now we have used it practically.In this report, we describe simply about the following articles.1. Mechamizm of the stripping scraper.2. The state of operation in faces.3. The results.4. Comparison of efficiency between stripping scraper and hand-digging.

1 0 0 0 OA 太平洋炭鉱におけるローカル運搬諸問題に対する一連の改善

- 著者

- 坂田 元

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.104, no.1208, pp.662-665, 1988-10-25 (Released:2011-07-13)

1 0 0 0 OA (7) 太平洋炭鉱のローカルの人員輸送について

- 著者

- 清水 彰

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.103, no.1196, pp.620-621, 1987-10-25 (Released:2011-07-13)

1 0 0 0 OA (10) 幌内炭鉱における斜坑用マンリフトの開発経緯

- 著者

- 坂田 純一 葛西 禎一 進藤 孝一

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.103, no.1196, pp.630-634, 1987-10-25 (Released:2011-07-13)

1 0 0 0 OA 深部化に対応する骨格構造若返り工事としての芦別斜坑工事概要とその効果

- 著者

- 塚本 慶四郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.99, no.1147, pp.745-747, 1983-09-25 (Released:2011-07-13)

1 0 0 0 OA 密閉容器中におけるメタンガスの爆発跡ガスと爆圧について

- 著者

- 石浜 渉 岡田 寿徳 広田 豊彦 菊地 昭

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.80, no.915, pp.816-817, 1964-09-10 (Released:2011-07-13)

1 0 0 0 OA 三井砂川炭鉱の深部採掘について

- 著者

- 西田 昌利

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.99, no.1146, pp.667-671, 1983-08-25 (Released:2011-07-13)

Sunagawa Colliery has managed to solve many difficult problems since 1914 and the technical innovation took place in 1964 when the colliery employed hydraulic mining. Subsequently, the hydraulic mining has been steadily improved widening the range of its application. The colliery is now working steeply inclined seams at the depth of 900 to 1000 meters below surface. The author intends to introduce parts of the results successfully practiced in the deep mining at Sunagawa Colliery.

1 0 0 0 OA 炭鉱の水力化に関する研究

- 著者

- 渡邊 慶輝

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.83, no.951, pp.895-901, 1967-07-25 (Released:2011-07-13)

Since 1961 a series of tests for hydraulic mechanization of coal mine has been made by the Coal Mining Research Centre, Japan. And at the first trial in Meiho colliery it was succeeded in constructing a hydraulic model mine in which all mining processes such as getting, loading and tranportation of coal are carried out hydraulically. During the trial many problems to solve were found, but this new method proved of practical use. Thereafter trials were made at 12 coal mines, and several of those mines have adopted this new method commercially. Now 100, 000 tons/month of coal is produced by hydraulic mining in Japan.The productivity of hydraulic coal mining largely depends on the strength of coal. While in SSR the strength of coal is expressed by Protojakonow's index f1, in Japan friability index FD is used generally. And it was found that there is a relation of f1·FD=32. The pressure of water necessary to a hydraulic monitor P is expressed as a function of coal strength in the form P=K 1600/FD. K is a factor of fissures in a coal seam and is 1-1.3.Equipments for hydraulic mining have been much improved during trials. Above all efficiency of a hydraulic monitor has been raised.When hydraulic mining, commonly a monitor requires 2-3 m3/min water of 50-150 kg/cm2. Further tests of mining with higher pressure 200-400 kg/cm2 but smaller quantity of water 60-360 1/min were made. But this is applicable only to very friable coal. Now we are trying to combine the high pressure water jet with usual mining-or boring-machineries for the purpose of increasing their performances.There are two ways of hydraulic transportation. One way is pumping coal through a pump and another way is feeding coal into a pipeline with a coal feeder. Both ways were tested. The higher the lifting head of a pump becomes, the more the rotating part of the pump wears. Consequentry for high head hydraulic transportation a multi-pipe type coal feeder was invented. And the first trials of it was made at Yoshima colliery. The results revealed that it had the tranporting capacity of 100 t/h registering volume concentration 20%. Now the trial is continued at Sunagawa colliery. 256, 000 tons of coal were transported from the begining of last year up to March this year.

1 0 0 0 OA クロール法による金属チタン製造工程の合理化

- 著者

- 八木 節男

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.79, no.901, pp.477-484, 1963-07-25 (Released:2011-07-13)

- 参考文献数

- 7

TOHO Titanium Co. erected 20 T per month plant of titanium sponge in 1953 and developed it to 150 T per month within 4 years.But the price of titanium has fallen down year by year and the demand for it decreased since 1957. So we have endeavoured cut down the production cost.The methods of rationalization are as follows:1) Improvement of the operation of chlorinato- and recovery of TiO2 from its waste.2) Simplification of TiCl4 purification.3) Diminution of magnesiuem losses at the reduction process and others.4) The reduction of production cost of magnesium by the rationalization of its electrolytic plant.With these above and other several improvements. we have been able to reduce the production cost of titanium sponge about 20% during these 4 years.