4 0 0 0 OA 機械特性とリサイクル性に優れたカーボン強化マグネシウム合金の開発

2 0 0 0 OA マグネシウム合金の新しい陽極酸化処理

- 著者

- 日野 実 村上 浩二 西條 充司 金谷 輝人

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.58, no.12, pp.767-767, 2007 (Released:2008-08-01)

- 参考文献数

- 28

- 被引用文献数

- 10 11

1 0 0 0 OA A5052-H14およびA2017-T4アルミニウム合金の疲労特性に及ぼす表面処理の影響

- 著者

- 城戸 竜太 桑野 亮一 日野 実 村山 敬祐 黒坂 成吾 小田 幸典 堀川 敬太郎 金谷 輝人

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.84, no.3, pp.74-79, 2020-03-01 (Released:2020-02-25)

- 参考文献数

- 11

- 被引用文献数

- 1 1

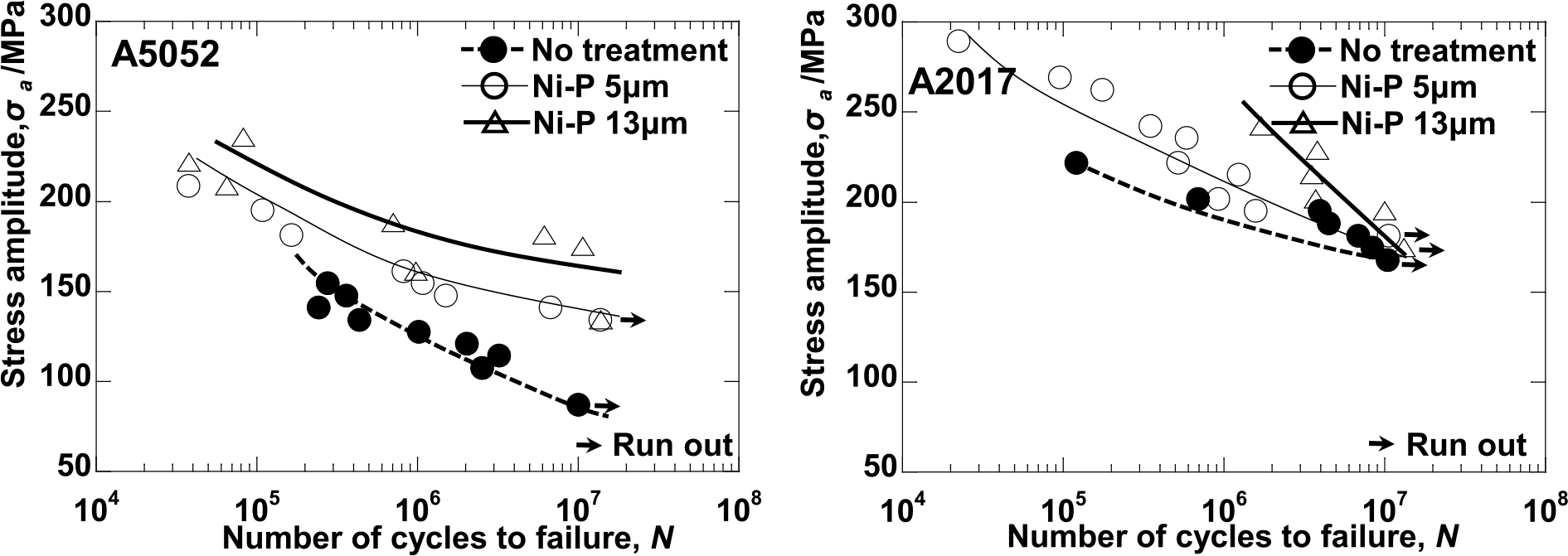

In this study, the effect of anodization and electroless Ni-P plating on the fatigue strength of commercial A5052-H14 and A2017-T4 aluminum alloys was investigated. The coated aluminum alloys were tested using a rotary bending fatigue testing machine. Anodization led to a slight increase in the fatigue strength of the A2017-T4 alloy of approximately 10% because of the suppression of the generation of fatigue crack, and anodization with a 5-µm thickness for A5052-H14 also led to a slight increase in the fatigue strength. However, anodization with a 20-µm thickness for A5052-H14 led to reduced fatigue strength because of the pits that formed in the film. In addition, electroless Ni-P plating drastically improved the fatigue strength of the A5052-H14 alloy by suppressing the generation of fatigue crack.It also improved the fatigue strength of the A2017-T4 alloy in the high-stress region. However, the fatigue strength in the low-stress region was the same as that of the non-coated specimens.This fatigue strength should have originated from the hydrogen embrittlement by the hydrogen introduced into the specimen during the plating.

1 0 0 0 マグネシウム合金の新しい陽極酸化処理

- 著者

- 日野 実 村上 浩二 西條 充司 金谷 輝人

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 = The Journal of the Surface Finishing Society of Japan (ISSN:09151869)

- 巻号頁・発行日

- vol.58, no.12, pp.767-773, 2007-12-01

- 参考文献数

- 27

- 被引用文献数

- 6 11

1 0 0 0 OA Al-Zn合金のスピノーダル温度の上下におけるG.P.ゾーンの形成, 成長について

- 著者

- 太田 陸奥雄 金谷 輝人 山田 益男 榊原 精

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.29, no.8, pp.315-321, 1979-08-30 (Released:2008-10-30)

- 参考文献数

- 27

- 被引用文献数

- 3 3

Measurements of electrical resistivity and intensity of small-angle X-ray scattering and transmission electron microscopy were made on several compositions of Al-Zn alloys. G. P. zones are formed above the spinodal temperature in the nucleation-and-growth mechanism. The nucleus has a critical size for growth. This size becomes larger when aged at higher temperatures. The G. P. zones formed in this mechanism distribute broadly, but those formed by the spinodal decomposition do closely. The number of G. P. zones is much larger in the latter case (127°C) than that in the former (132°C). The spinodal temperatures estimated for Al-10.0, 12.5, 15.0 and 20.0wt% Zn alloys are 90-95°, 105-110°, 125-130° and 170-180°C respectively. The critical temperatures below which G. P. zones are observed in these alloys are 105-115°, 125-135°, 150-160° and 200-210°C respectively.

1 0 0 0 OA インサート材を用いた異種材料間のレーザ接合技術の開発

- 著者

- 水戸岡 豊 山田 功作 永田 員也 日野 実 金谷 輝人

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.54, no.1, pp.24-26, 2015 (Released:2015-01-01)

- 参考文献数

- 5

- 著者

- 日野 実 村上 浩二 水戸岡 豊 平松 実 西山 俊一 細川 和幸 金谷 輝人

- 出版者

- The Surface Finishing Society of Japan

- 雑誌

- 表面技術 = The Journal of the Surface Finishing Society of Japan (ISSN:09151869)

- 巻号頁・発行日

- vol.58, no.8, pp.476-481, 2007-08-01

- 被引用文献数

- 1 3

This study examined the effects of alloying elements on zincate treatment and adhesion of electroless Ni-P coating onto various aluminum alloy substrate. Surface morphology of zinc deposition from the single zincate treatment and its adhesion were changed, depending on the alloying element. The zinc deposition from the double zincate treatment became thinly uniform, and the adhesion between aluminum alloy substrate and Ni-P coating was improved irrespective of the alloying element. However, the adhesion of A7075P aluminum alloy was inferior to that of other alloys.