2 0 0 0 OA 開坑

- 著者

- 外尾 善次郎 小出 治彦 幡谷 敬二 文蔵 良 橋谷田 次郎 尾石 照雄 酒井 証

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.74, no.843, pp.535-552, 1958-09-25 (Released:2011-07-13)

Underground working place in coal mine in Japan became dipper and dipper, and we can not product coal so efficiently with our mining system, so called “inclined sys em.”In order to more efficiently product coal, many people recognized, it is necessary to adapt the mining system in Europe, for instance in Germany and France, namelly so called “horizontal system”.It is said, the translation from the inclined system to horizontal system is for our coal mine in Japan very urgent and important problem.After War, many shafts were already excavated for the above mentioned purpose. As we know in Japan, many superior shaft sinking technic in Europe especially in Germany was introduced and technic in Japan was also very improved. But it is not yet so gut as in Europe. Till today many mechanization and rationalization was achieved, for instance, mechanization of loading (Adaption of Greifer) and rationalization of working system etc. Sinking speed in Japan is about 40-50m, in Europe. about 50-70m per month. In U. S. S. R, it is said, they excavated per month 241.1m.From now ono we must force to achieve the mechanization of not only loading, but bohring, walling as in U. S. S. R. and also the rationalization of working-system and cycle.

2 0 0 0 OA 産炭地発電について

- 著者

- 西山 孝

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.88, no.1015, pp.572-575, 1972-09-25 (Released:2011-07-13)

- 参考文献数

- 4

2 0 0 0 OA 墨洋丸沈没の原因に就て

- 著者

- 氷上 克之

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.58, no.687, pp.458-459, 1942-07-22 (Released:2011-07-13)

墨洋丸沈没後直ちに北米合衆國の保險業者は各荷主に對して保險金を仕拂ひたる處なれども、一方當保險業者は引續き日本郵船會社を相手取り北米合衆國の法廷に損害賠償の訴訟を提出せり。即ち自然發火の危險性ある銅精鑛と共に棉花其の他の貨物を積載し、銅精鑛の自然發熟の爲本船を沈没に至らしめ、從つて他の貨物をも損失せしめたるは、船會社其の責を負ふべきなりとの理由に基くものなり。其の要求する賠償金額は邦貨にして約110萬圓にして、國家非常の時に際し外貨にてかゝる多額の金を仕拂ふことは實に大なる損失なるを深く憂ひ、郵船本社の外、關係者に於て有利に導かんと苦心努力したれども、當初に於ては殆ど勝算なく深く焦慮したる處なり。然るに時偶々、筆者等の銅精鑛の發熱性及び其の防止法の研究もやうやく進捗したるを以て、其の研究報告と本文に示す墨洋丸沈没原因に關する考察を、參考として、北米合衆國法廷に提出したる處、状態は急に我に有利に好轉し、遂に多額の外貨の流失なく、無事決着を見たるは誠に欣快の至りなり。即ち本文に示す如く、墨洋丸乗組員の當時取りたる應急處置(漲水)は麻袋等の有機物が燻り居たるを消火せんとして行ひたるものにて保險法規上何等の手落なく、然るに結果より見てそれが適當ならざりしに依り沈没にまで至りたるものにて、全く從來銅精鑛の發熟に對する研究もなく、其の知識も不明なりしに基因するものにて、其の責任を會社が負ふべき要なきを強調せしものなり。此處に當時の報文を其儘示し、參考に供さんとす。

2 0 0 0 OA 摘録

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.80, no.919, pp.1176-1188, 1964-12-25 (Released:2011-07-13)

2 0 0 0 OA 卸向厚層用ダブルレンジングドラムカッタについて

- 著者

- 沢田 仁 佐藤 祐治

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.95, no.1099, pp.611-615, 1979-09-25 (Released:2011-07-13)

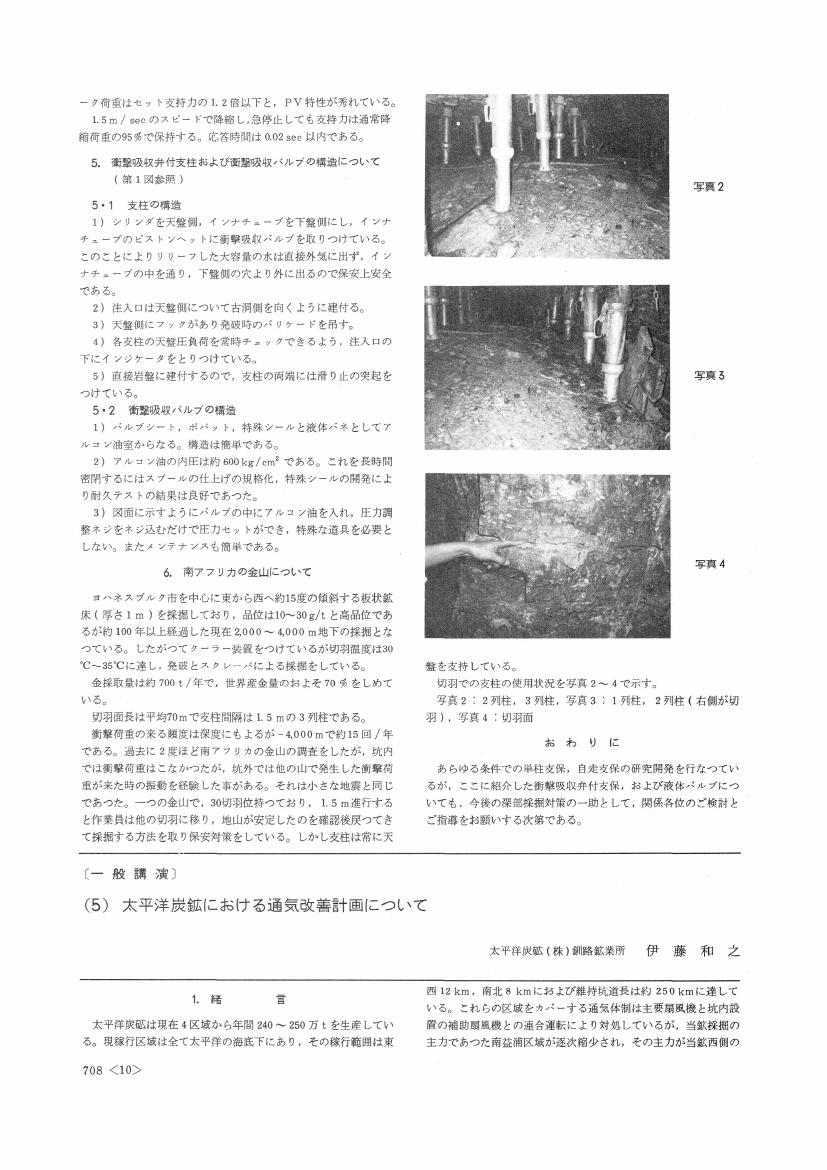

2 0 0 0 OA 太平洋炭鉱における通気改善計画について

- 著者

- 伊藤 和之

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.100, no.1159, pp.708-711, 1984-09-25 (Released:2011-07-13)

2 0 0 0 OA 非常制動時の立坑巻索の振動実測とその理論的解析

- 著者

- 会田 俊夫 石橋 重遠 佐進 進

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.78, no.887, pp.377-384, 1962-05-25 (Released:2011-07-13)

- 参考文献数

- 2

In this paper we have studied the characteristics of the vibration of winding ropes in vertical shafts when the drums are braked in an emergency, measuring the vibration and analying the measured results by the theoretical methods published in our former paper.Some results we have obtained through our researches are as follows;1) The maximum vibration of a winding rope in a vertical shaft when the drum is braked in an emergency can safely be estimated to be 1.3 times as large as the maximum acceleration of the winding drum.2) The shock absorber is hardly effective for reducing the vibration of a winding rope in an emergency braking.3) We find that the length of a winding rope has nothing to do with its vibration in a shaft.

2 0 0 0 OA 炭鉱の立坑ライニングの応力の測定

- 著者

- 平松 良雄 岡 行俊

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.76, no.866, pp.543-548, 1960-08-25 (Released:2011-07-13)

- 参考文献数

- 5

For the purpose of contributing to the design of shaft linings, especially of coal mines, the authors have attempted to measure the stress in the shaft linings in several coal mines in Japan with the photoelastic apparatus contrived by them.The results show that the lining in a solid ground is generally subjected to but a low stress, but sometimes to a stress about 30kg/cm2, that in a crushed ground the lining is subjected to a medium or high stress fluctuating, and that in a loose ground there appears such an earth pressure acting on the outer surface of the lining that may be estimated by the formula of the soil pressure.

2 0 0 0 OA ラヂュウムの鑛石よりラヂュウムを抽出する方法

- 著者

- T、K

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.32, no.373, pp.270-272, 1916-03-22 (Released:2011-07-13)

2 0 0 0 OA 緊急脱出用酸素マスク (PEBA PE-3M) の概要

- 著者

- 山本 雅則

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1136, pp.997-999, 1982-10-25 (Released:2011-07-13)

- 被引用文献数

- 2

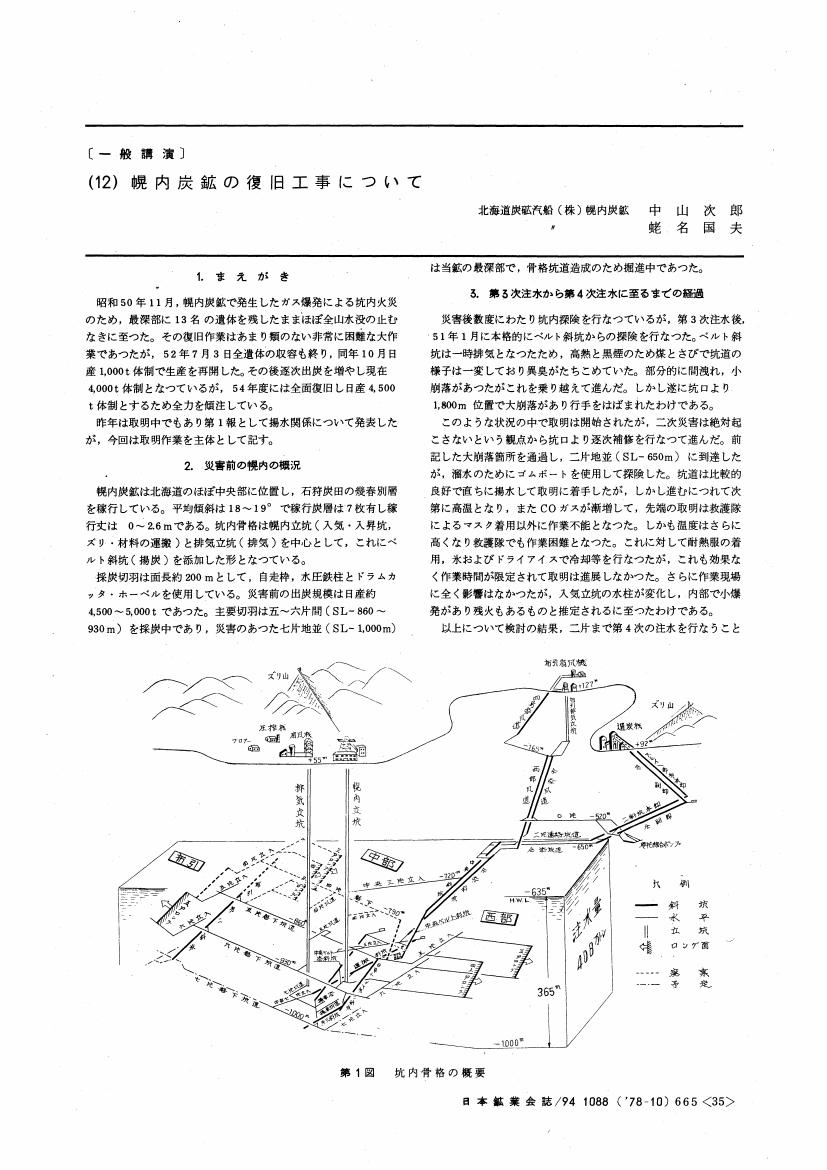

2 0 0 0 OA 幌内炭鉱の復旧工事について

- 著者

- 中山 次郎 蛯名 国夫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1088, pp.665-668, 1978-10-25 (Released:2011-07-13)

2 0 0 0 OA 三菱美唄炭鉱におけるストコ及びカーゴット採炭について

- 著者

- 矢野 隆二

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.68, no.770, pp.347-352, 1952-08-25 (Released:2011-07-13)

“Stoco” and “Cargot” are the same principle as “Cardox”. In the Bibai Coal Mine “Stoco” was tested for the first time July 1949 and “Cargot” August 1950. In these tests, we found many imperfect points, and then we have made the effects to improve these points. Now, these tools are used practically in this Coal Mine.This report contains the progress improving the mechanism of these tools and results of the coal getting by these tools.

2 0 0 0 OA 分岐管式給炭装置を用いた石炭の水力輸送に関する研究

- 著者

- 渡辺 慶輝

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.82, no.936, pp.333-341, 1966-04-25 (Released:2011-07-13)

- 参考文献数

- 19

The results of fundamental experiments revealed that the coal filled in a pipe was moved by low water pressure, and it flowed in a pipeline with little delay when velocity of stream exceeded 3.5m/s. According to these results a multi-pipe type coal feeder was invented. It consists of several parallel long lock chambers which are branched from a delivery pipe of a high pressure pump. And they have approximately the same diameter of the conveying pipe. One of these is fed coal and water mixture by means of a low pressure sand pump. After this, the mixture is pushed into the conveying pipe by the high pressure water. This process is repeated one after another, and coal is transported continuously.The auther produced a hand-operated model of this coal feeder for laboratory tests, then made its valves act automatically. The practical tests of this feeder was carried out at Yoshima colliery. 20.000t of coal was transported by 7 in. pipeline with it. The test results revealed that it had the transporting capacity of 100t/h, registering the volume concentration 20% Now the test is continued on commercial basis at Sunagawa colliery. The transportation height is 490m and the length of pipeline 2, 046m. There automatic control of concentration of coal in the pipeline is attemped to economize the transportation cost.

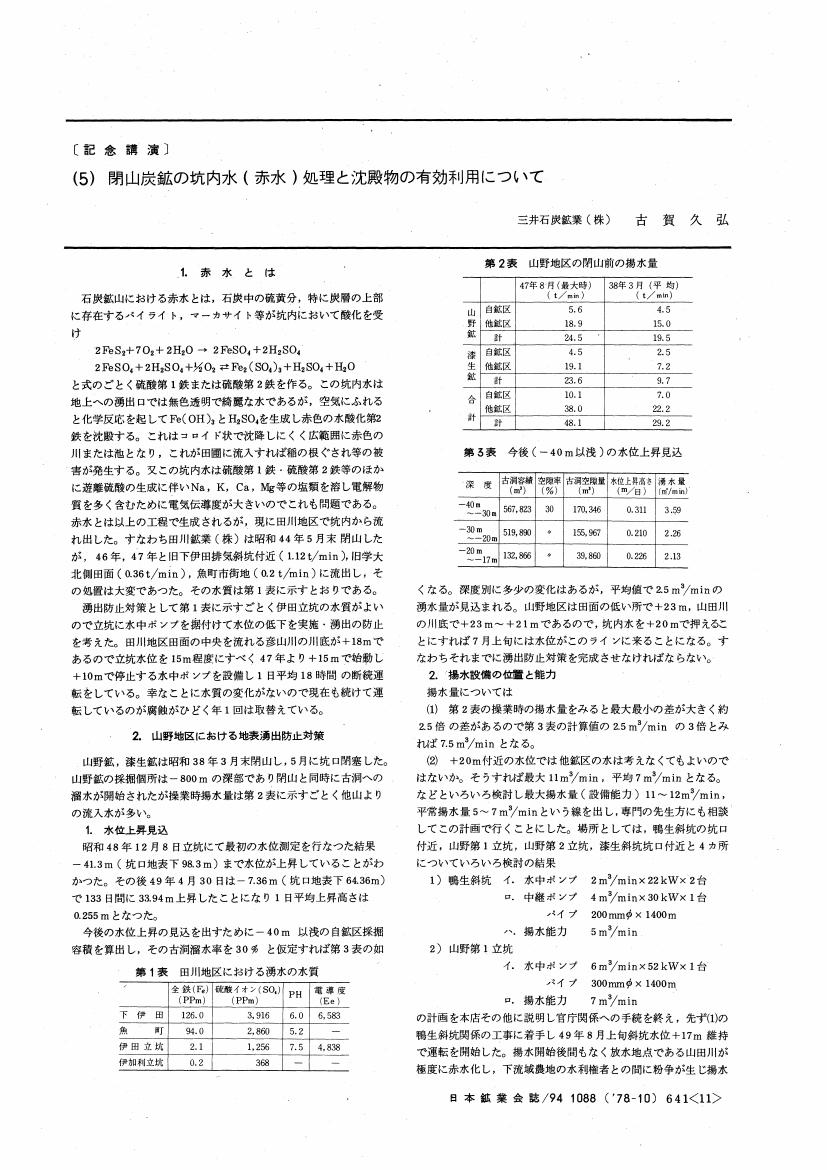

2 0 0 0 OA 閉山炭鉱の坑内水 (赤水) 処理と沈殿物の有効利用について

- 著者

- 古賀 久弘

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1088, pp.641-645, 1978-10-25 (Released:2011-07-13)

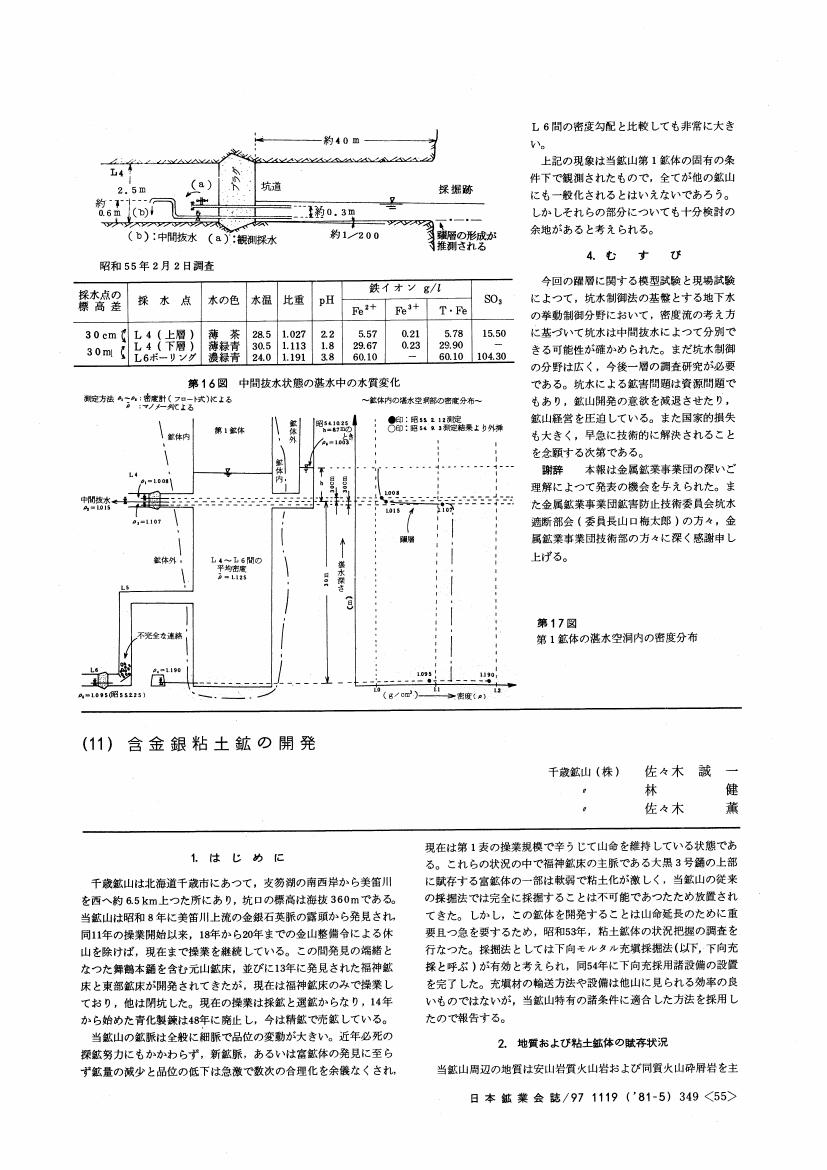

1 0 0 0 OA 含金銀粘土鉱の開発

- 著者

- 佐々木 誠一 林 健 佐々木 薫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.97, no.1119, pp.349-353, 1981-05-25 (Released:2011-07-13)

1 0 0 0 OA 基隆炭礦の現況に就て

- 著者

- 池部 龍生

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.51, no.606, pp.651-658, 1935-10-22 (Released:2011-07-13)

1 0 0 0 OA 第16回採鑛研究會記録

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.60, no.710, pp.205-229, 1944-06-22 (Released:2011-07-13)

1 0 0 0 OA 亜鉛製錬副産物からのガリウム, インジウムの回収

- 著者

- 阿部 秀来

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1133, pp.561-565, 1982-07-25 (Released:2011-07-13)

- 被引用文献数

- 2 1

The trace amounts of gallium and indium are contained in the Black Ore type of deposits distributed at Hokuroku area in Akita. Gallium and indium tend to be concentrated into the zinc concentrates through mineral processing.Dowa Mining Co., Ltd. began to examine the recovering process of gallium and indium in 1963 whengallium was given attention as raw material of semi-conductor, and studied manysided technique to recover both metals fromthe by-product of zinc refinery. Our gallium and indium recovery process is characterized by the zinc residue treatmentprocess of The lijima Zinc Refinery of Akita Zinc Co., Ltd. which is very useful to concentrate both metals, and also by thesolvent extraction process to separate gallium and indium from the sulfuric acid solution.Considering how to solve the problem derived from the application of the technique to the plantoperation, gallium recovering plant was constructed in Kosaka Smelter of Dowa Mining Co., Ltd. simultaneously with theconstruction of Iijima Zinc Refinery.Operation started in January 1972, and is producing high quality gallium and indium. Though only 40kg/m ofmetallic gallium and some indium hydroxides were produced when started, now 180kg gallium and 250kg indium areproduced every month.

1 0 0 0 OA 酸化銅鉱の回収

- 著者

- 若松 貴英

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1134, pp.687-693, 1982-08-25 (Released:2011-07-13)

- 参考文献数

- 38

A number of approaches to the treatment of oxidized copper have been proposed. The principal methods for copper recovery from oxidized are have included leaching, sulfidization flotation, leach-precipitation-flotation, segregation, and leachsolvent extraction-electrowinning. In this paper the basic science and performance of some of the techniques for oxidized copper processing are briefly reviewed. Further, recent trends in the fundamental investigations concerning oxidized copper processing are summarized.

1 0 0 0 OA 沸石化凝灰岩の加熱発泡性 (I) 未利用岩石資源の利用に関する研究 (第2報)

- 著者

- 小野寺 嘉郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.100, no.1152, pp.67-72, 1984-02-25 (Released:2011-07-13)

- 参考文献数

- 28

The bloating properties of sedimentary zeolites existing enormously in Green Tuff region of our country were investigated. Pelletized bodies (9-12mm diameter) prepared from pulverized zeolites were fired in the range of 900-1350°C. Then physicochemical properties, such as specific gravity, water absorption, crushing strength etc., of the pellets were measured. Moreover, 38 mixtures prepared from mordenite tuff, silica, alumina and ferric oxide were fired in order to make clear the optimum bloating range in chemical compositions.The results obtained are summarized as follows;In many cases, air dried pellets had high crushing strength enough to permit the firing by rotary kiln. Pellets started to bloat at temperatures above 1150°C and the bloating extent increased with raising the temperature. Most of the pellets fired at higher temperature than 1100°C were impervious and their specific gravity was about 2.3-0.4. Crushing strength of the fired pelletes whose specific gravity were about 1.2-1.3 were in the range of 120-170kg, and it was about 2 times that of artificial light weight aggregates commercially produced. By the results of X-ray analysis, chemical and thermal analysis, it was guessed that a common gas-forming component in sedimentary zeolites concerning with the bloating was ferric oxide.From the firing tests of the above-mentioned mixtures, the optimum contents of silica, alumina and flux for the bloating were ascertained to be in the range of 60-70%, 10-25% and 10-20%, respectively.