1 0 0 0 OA 炭鉱の水力化に関する研究

- 著者

- 渡邊 慶輝

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.83, no.951, pp.895-901, 1967-07-25 (Released:2011-07-13)

Since 1961 a series of tests for hydraulic mechanization of coal mine has been made by the Coal Mining Research Centre, Japan. And at the first trial in Meiho colliery it was succeeded in constructing a hydraulic model mine in which all mining processes such as getting, loading and tranportation of coal are carried out hydraulically. During the trial many problems to solve were found, but this new method proved of practical use. Thereafter trials were made at 12 coal mines, and several of those mines have adopted this new method commercially. Now 100, 000 tons/month of coal is produced by hydraulic mining in Japan.The productivity of hydraulic coal mining largely depends on the strength of coal. While in SSR the strength of coal is expressed by Protojakonow's index f1, in Japan friability index FD is used generally. And it was found that there is a relation of f1·FD=32. The pressure of water necessary to a hydraulic monitor P is expressed as a function of coal strength in the form P=K 1600/FD. K is a factor of fissures in a coal seam and is 1-1.3.Equipments for hydraulic mining have been much improved during trials. Above all efficiency of a hydraulic monitor has been raised.When hydraulic mining, commonly a monitor requires 2-3 m3/min water of 50-150 kg/cm2. Further tests of mining with higher pressure 200-400 kg/cm2 but smaller quantity of water 60-360 1/min were made. But this is applicable only to very friable coal. Now we are trying to combine the high pressure water jet with usual mining-or boring-machineries for the purpose of increasing their performances.There are two ways of hydraulic transportation. One way is pumping coal through a pump and another way is feeding coal into a pipeline with a coal feeder. Both ways were tested. The higher the lifting head of a pump becomes, the more the rotating part of the pump wears. Consequentry for high head hydraulic transportation a multi-pipe type coal feeder was invented. And the first trials of it was made at Yoshima colliery. The results revealed that it had the tranporting capacity of 100 t/h registering volume concentration 20%. Now the trial is continued at Sunagawa colliery. 256, 000 tons of coal were transported from the begining of last year up to March this year.

1 0 0 0 OA クロール法による金属チタン製造工程の合理化

- 著者

- 八木 節男

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.79, no.901, pp.477-484, 1963-07-25 (Released:2011-07-13)

- 参考文献数

- 7

TOHO Titanium Co. erected 20 T per month plant of titanium sponge in 1953 and developed it to 150 T per month within 4 years.But the price of titanium has fallen down year by year and the demand for it decreased since 1957. So we have endeavoured cut down the production cost.The methods of rationalization are as follows:1) Improvement of the operation of chlorinato- and recovery of TiO2 from its waste.2) Simplification of TiCl4 purification.3) Diminution of magnesiuem losses at the reduction process and others.4) The reduction of production cost of magnesium by the rationalization of its electrolytic plant.With these above and other several improvements. we have been able to reduce the production cost of titanium sponge about 20% during these 4 years.

1 0 0 0 OA 坑道火災の性状と拡大防止

- 著者

- 松隈 喜総 清正 稔 井清 武弘 鈴木 忠

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.93, no.1076, pp.659-663, 1977-10-25 (Released:2011-09-13)

- 参考文献数

- 8

1 0 0 0 OA 三井美唄炭礦の機械採炭に就て

- 著者

- 安部 貞次

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.52, no.620, pp.924-932, 1936-12-22 (Released:2011-07-13)

The contents described in this paper are detailed descriptions of working face at the present condition, and describe the method of increasing the out put of one face, at Mitui Bibai Colliery.

1 0 0 0 OA 3m以上の厚層一段採掘における移動式組立枠払について

- 著者

- 若林 寿雄

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.79, no.901, pp.457-464, 1963-07-25 (Released:2011-07-13)

- 被引用文献数

- 1

The working face at Miike coal mine have been removed into the thick seam area over 3 meter gradually since 1950-1951. To work this seam throughly, several mining methods were investigated, then the slicing system was applied in Mikawa pit, while self advancing powerd roof support was introduced to Miyaura pit.It had been generally believed that the working height of long wall face in low dip was up to nearly 2.8 meter, however, after extensive examinations, we had developed the self advancing support using mighty hydraulic props of higher yielding load, there by we have succeed in getting coal seam over 3 meter throughly at same time.

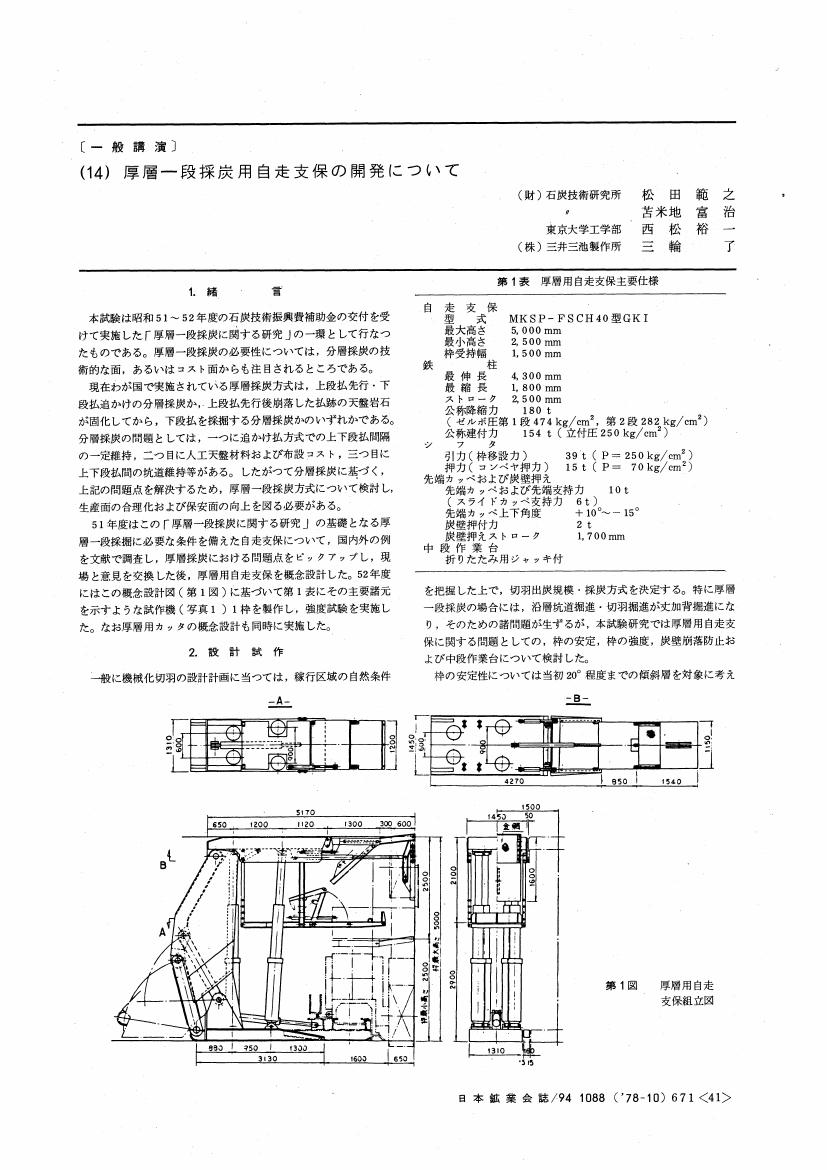

1 0 0 0 OA 厚層一段採炭用自走支保の開発について

- 著者

- 松田 範之 苫米地 富治 西松 裕一 三輪 了

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1088, pp.671-674, 1978-10-25 (Released:2011-07-13)

1 0 0 0 OA グライトホーベルの実績について

- 著者

- 岩橋 恵 山本 敏雄

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.84, no.965, pp.1388-1391, 1968-09-25 (Released:2011-07-13)

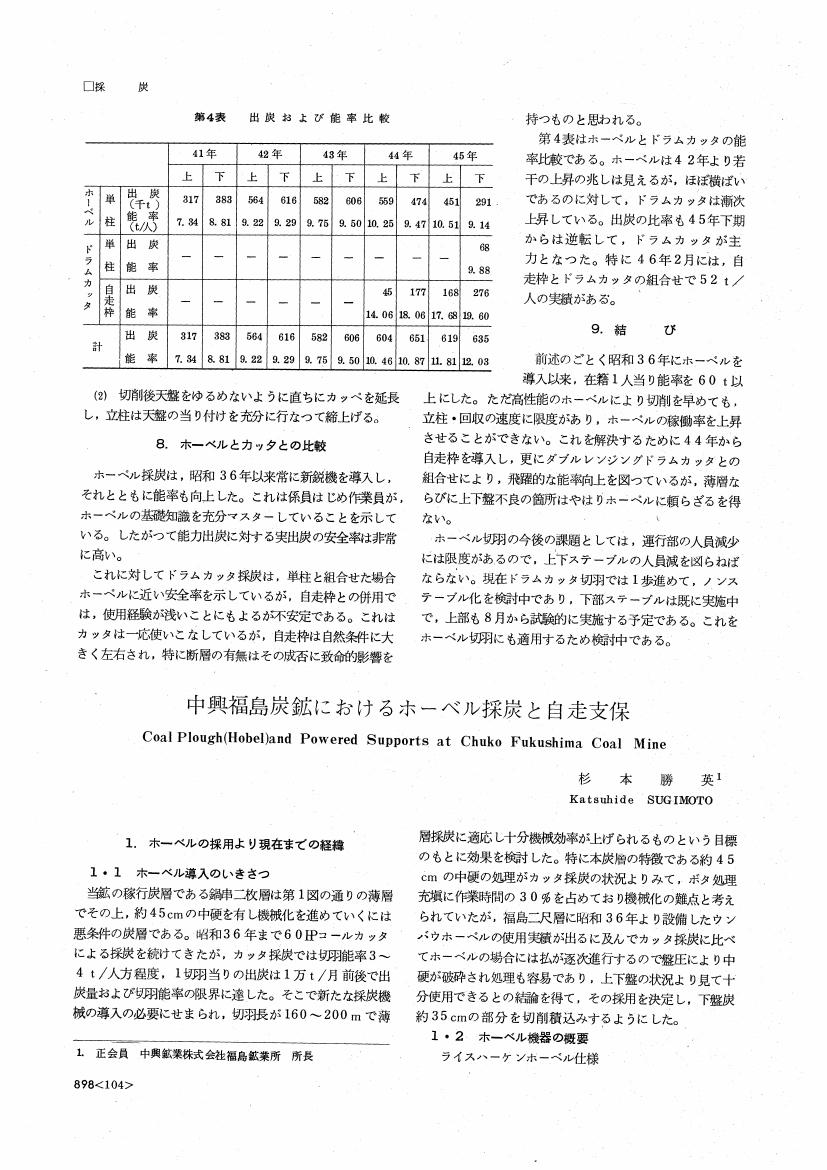

1 0 0 0 OA 中興福島炭鉱におけるホーベル採炭と自走支保

- 著者

- 杉本 勝英

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.87, no.1005, pp.898-902, 1971-11-25 (Released:2011-07-13)

1 0 0 0 OA 三井砂川炭鉱の深部採掘における技術改革

- 著者

- 大塚 泰二朗

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.96, no.1110, pp.507-513, 1980-08-25 (Released:2011-07-13)

Mitsui Sunagawa Mine is situated northern part of Ishikari coal field in Hokkaido and produces 1.1 million clean coal tonnes per year.The Sunagawa Mine first started in 1914, has produced for 65 years. It is mining five steeply dipping seams (50-70 deg.). Mining blocks are located at 900m below surface now, and further new blocks at 1, 000m are being prepared.After years of technical innovations on deep mining and safety methods to overcome severe conditions-gas emission, gas outburst, spontaneous combustion, and earth pressure-hydraulic mining has proved to be a safe and economical method of coal extraction since 1964.In general, mining blocks deepen in short period, roadways to be maintained lengthen and finally main structure is very complicated at steep dipping coal mines. A new return shaft of 900 m was sunk at Sunagawa Mine in 1979 to shorten the sustaining roadways and to make the main structure simple and steady.The hydraulic mining has been shown to provide benefits in safety and improved productivity, comparing to the conventional mechanical mines in thefl at seams.

- 著者

- 松本 広市

- 出版者

- 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.102, no.1184, pp.p669-672, 1986-10

1 0 0 0 OA 奈良県五代松鉱床におけるスカルンの産状

- 著者

- 宮石 修 李 勇 港 種雄

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.96, no.1113, pp.789-794, 1980-11-25 (Released:2011-07-13)

- 参考文献数

- 9

The Goyomatsu magnetite skarn deposit consists of large and small irregular massive bodies interlayered in upper Chichibu formations (limestone, sandstone, slate etc.), which have been metamorphosed by Miocene Omine acidic rocks (granodiorite).On the basis of mineralogic observations and thermodynamic data, the principal conditions of formation of the skarns have been determined. Results are as follows:1) Field evidence reveals that in the deposit hedenbergite is predominant in and near the granodiorite, and andradite is predominant in and near the limestone. This contrasting occurrence appears to show that the μO2 in the limestone gradually increased away from the granodiorite-limestone contact, assuming these skarns were formed at nearly the same stage.2) Generally, andradite rarely coexists with actinolite in skarns. This field evidence iswell in agreement with thermodynamic data, which shows that the andradite+actinolite phase cannot be a stable assemblage at constant temperature and pressure asseen in Fig. 3.3) Fig. 3 suggests that in general, under constant μCO2 conditions, the following mineral zonation formed with increasing μO2: zones of hedenbergite+actinolite, hedenbergite+andradite, and andradite, respectively. However primary assemblages of hedenbergite+actinolite havenot been observed. On this point, we need more detailed examinations.4) It is also found that in the skarns, hedenbergite has sometimes altered into aggregates of actinolite, calcite and quartz. Assuming constant temperature and pressure it can be interpreted that such alteration was caused by an increase in μCO2 at low μO2 environments.

1 0 0 0 OA 青銅・燐青鋼屑の電解分離に關する研究

- 著者

- 徳永 惇 栗林 祿郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.60, no.709, pp.180-184, 1944-05-22 (Released:2011-07-13)

筆者等は先般來各種銅合金屑の電解による分離再生に關する研究を行ひ好結果を得、黄銅屑、青銅屑、白銅屑の電解分離に關する研究報文は既に本會誌に發表したが其後青銅・燐青銅の電解分離の研究實績が得らるるに至つたので茲に其の大要を報告する。青銅を陽極として電解する場合陽極中の錫を陰極に入らしめない様にするのに如何なる條件を選べきかを特に追求しi) 電解液の温度を50~55℃程度に高く保つ事。ii) 電解液物中のH2SO4を30g/L. 程度以下に保つ事。iii) 陽極中に少く共10%程度のZnを含ましめ陽極の分極法防止劑として働かしむる事。等が最も緊要な條件であり、此等の條件を満足せしむれば陽極中に5~10%或はそれ以上のSnを含む場合でも陰極中に入るSnを0.005%以下に抑壓する事が出来る。燐青銅を陽極とする場合は陽極中の燐が液中に入り燐酸錫の疎水性沈澱を作りSnを液相又は膠質懸濁相から除去するから陰極銅の品位は益々良好となる。燐酸曹達を液中に投じても此の好結果が得られる。

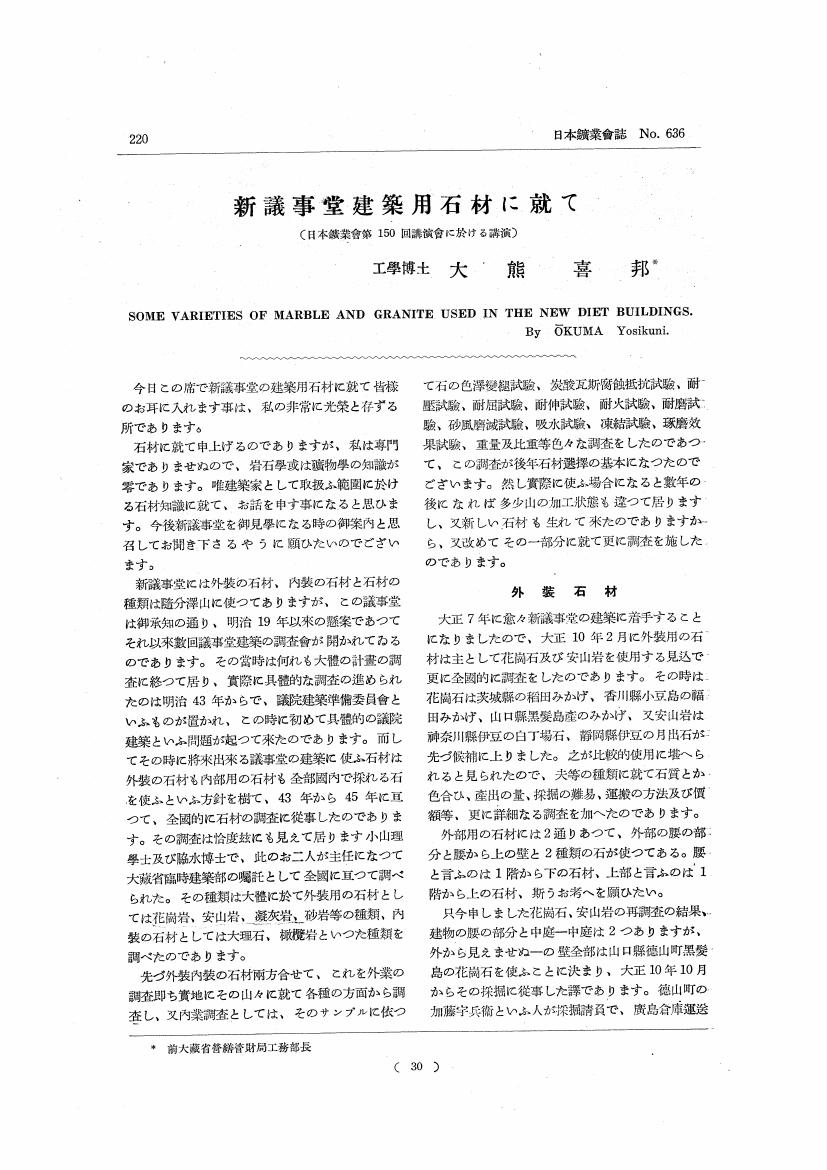

1 0 0 0 OA 新議事堂建築用石材に就て

- 著者

- 大熊 喜邦

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.54, no.636, pp.220-226, 1938 (Released:2011-07-13)