1 0 0 0 樺太に於ける三井鑛山株式會社經營の炭礦現況

- 著者

- 守田 良太耶

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.52, no.615, pp.450-455, 1936

1 0 0 0 OA 北海道に於ける砂金及砂白金に就て

- 著者

- 松本 彬

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.44, no.521, pp.737-745, 1928-09-22 (Released:2011-07-13)

- 被引用文献数

- 1

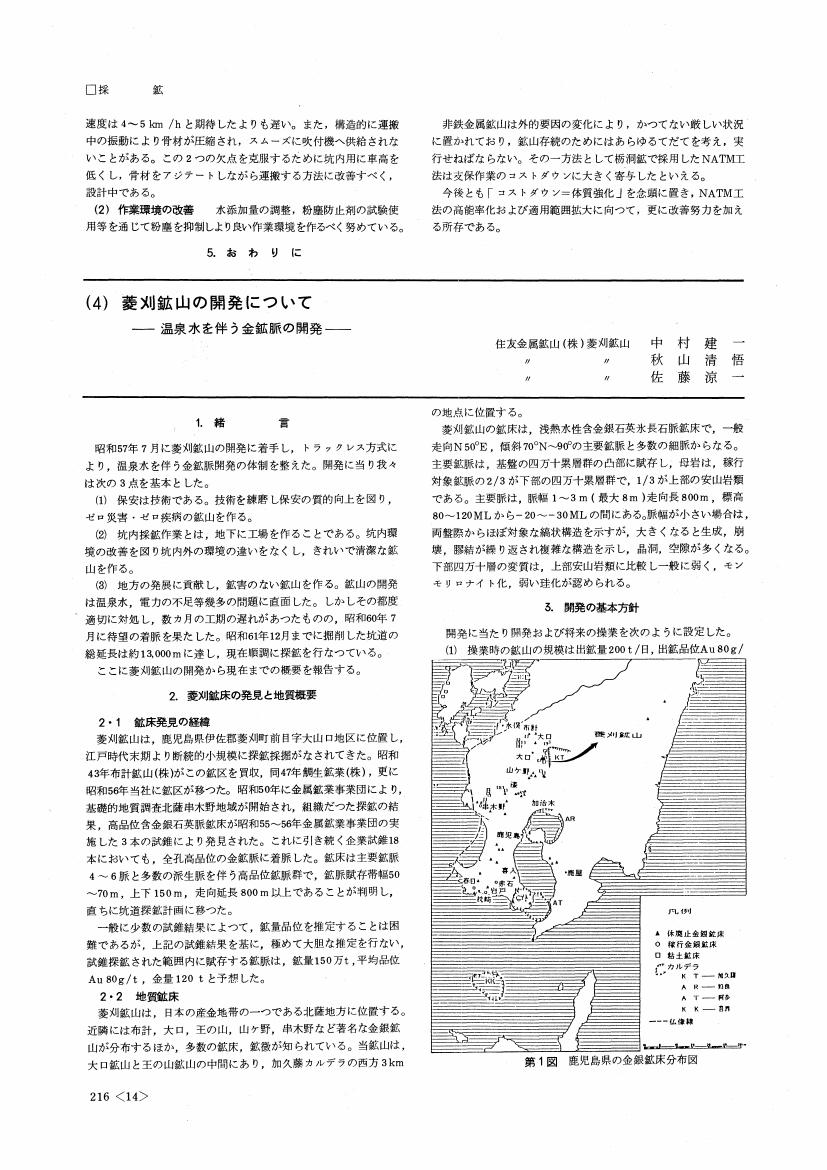

1 0 0 0 OA 菱刈鉱山の開発について 温泉水を伴う金鉱脈の開発

- 著者

- 中村 建一 秋山 清悟 佐藤 涼一

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.103, no.1190, pp.216-222, 1987-04-25 (Released:2011-07-13)

1 0 0 0 加圧浮選法による微細な重晶石-石英および方解石-石英の分離

- 著者

- 吉川 逸治 松岡 功 下飯坂 潤三

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.102, no.1179, pp.295-300, 1986

Applicability of dissolved air flotation (pressure type flotation) for separating ultrafine particles has been investigated using barite-quartz and calcite-quartz mixtures as samples.<BR>In pressure type flotation of barite-quartz mixture, good separation is obtained by the addition of smaller amount of sodium oleate as a collector than in dispersed air flotation (Denver type flotation). On the other hand, in pressure type flotation of calcite-quartz mixture, it is difficult to make calcite selectively float from quartz by adding sodium oleate. This may be explained by the reason that heterocoagulation of calcite and quartz particles can not be prevented under a comparatively static condition in pressure type flotation. However, the separation of calcite from quartz by pressure type flotation is possible when selective flocculation of calcite is achieved by using a polymeric flocculant (Separan AP30) with a dispersant such as sodium hexametaphosphate. The separation of barite-quartz and calcite-quartz mixtures by pressure type flotation is accomplished only at low pulp density below 2 to 3%.

1 0 0 0 加圧浮選法による微細な赤鉄鉱とデイッカイトの分離

- 著者

- 吉川 逸治 松岡 功 下飯坂 潤三

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.102, no.1180, pp.369-373, 1986

The flotation separation of hematite and dickite finer than 2μm has been investigated by using a pressure type and a Denver type flotators.Flotation tests were carried out by activating dickite with calcium chloride, followed by adding sodium oleate as a collector.<BR>In both pressure type and Denver type flotation, the separation of dickite from hematite was not achieved, because the addition of calcium chloride increased the floatability of hematite as well as dickite.However, in the case of the pressure type flotation, dickite could be selectively floated from hematite by adding Proper amounts of Separan AP30 (an anionicpolymeric flocculabt) and sodium oleate in the presence of asmall amount of calcium chloride at pH 8 to11. 5.The selective flotation of dickite from hematite by the pressure type flotation may be explained by the following reasons: the preferential adsorption of calcium species on dickite occurs due to its cation exchangeability in the presence of a small amount of calcium chloride at moderately alkaline pH and then hydrophobic flocs of dickite is formed as the result of the increased adsorption of Separan AP30 and oleate ion on the calcium activated dickite surface.The best separation result was obtained at low pulp density of about 1%.

1 0 0 0 OA 馬鞍山鉱山概況

- 著者

- 西脇 三樹雄

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.81, no.931, pp.981-988, 1965-11-25 (Released:2011-07-13)

- 被引用文献数

- 1

The Ma On Shan Mine, the metamorphic contact iron are deposit, located in Kowloon peninsula, has been operated since 1906. However, in 1952 as the grade of the are was getting gradually low, the Japanese mills refused to take it successively unless the, grade up operations were under control of our company. In 1953 the Mutual Trust Co. Ltd. which is the ownner of the mine asked our company to operate the mine as the joint venture, and the agreement was concluded in that year. The first processing plant having the capacity 120, 000 tons of concentrate per annum, was completed and started its production in 1954. In 1959 the open cast was mined out and the mining site had to be removed into the under ground. At the same time the processing plant was capacitied up partially. In 1963 the 110M adit was driven through. In 1965 the production was raised up to 150, 000 tons of concentrate per annum, and the facilities and equipments of the plant have been increased accordingly.

1 0 0 0 OA ポーランドの鉱業について 訪ポ鉱業研修団の報告

- 著者

- 岡村 宏

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.95, no.1101, pp.829-832, 1979-11-25 (Released:2011-07-13)

1 0 0 0 幌別鑛山の現況

- 著者

- 三崎 復造

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.53, no.625, pp.278-281, 1937

1 0 0 0 OA 鉱物粒子による材料の摩耗

- 著者

- 橋本 建次

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1134, pp.733-740, 1982-08-25 (Released:2011-07-13)

- 参考文献数

- 100

- 被引用文献数

- 2 1

A number of studies have recently been carried out in which the abrasive and erosive wear rate of the materials by the mineral grains was determined. In this paper the effects of various variables on these wear are summarized.M ain contents are as follows:1) Introduction: Difinition of wear, Classification of wear testing methods- three-body sliding friction between loose mineral grains and materials (flat-flat plate and flat-circle plate), two-body sliding friction between materials and minerals (fixed and loose abrasive), rolling and impacting between materials and loose mineral grains (ball or rod mills), rotating of materials in loose mineral grains, impacting of loose mineral grains against materials and impacting of materials against loose mineral grains-, Relations between different testing methods.2) Factors influencing abrasive and erosive wear: Knoop and micro Vickers hardness of minerals and materials, Correlationsbetween wear rate W and hardness ratio (material hardness Hm/mineral hardness Ha)-W∝(Hm/Ha) n-, Wear-resistant factors except hardness- Youngs modulas, tensile strength, fatigue strength, impact strength, etc.-, Effect of mineral grains size while the wear rate are proportional to the grain size, after the critical size (about 10-300 pm) it is almost constant-.3) Wear characteristics: Initial and steady wear processes-in steady wear the wear rate are proportional to sliding distance or impact time-, Influence of velocity V-W∝ Vn, where n value are 0-0.5 in two and three-body sliding friction testing methods, 0.8-1.3 in ball mill, 2-6.5 in testing methods of impacting of loosegrains against materials (metal: 2-3 and non-metal: 3-6.5)-, Influence of impact angle in erosive wear-the ductile materials exhibits maximum wear rate at low impact angle, but the brittle materials produces its maximum at high angle (for example, rubber: 0°, steel: 15-25°, castiron: 40-50°, glass: 90°).

1 0 0 0 選鑛研究會開催の發議

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.44, no.513, pp.82, 1928

1 0 0 0 「ぱありんす」鐵管

- 著者

- 高橋 雄次郎

- 出版者

- The Mining and Materials Processing Institute of Japan

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.17, no.197, pp.414-422, 1901

- 著者

- 杉本 栄佑 幸塚 善作

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.104, no.1200, pp.89-95, 1988

- 被引用文献数

- 2

The present study was done for the purpose of finding any available solid reference electrode for SO<SUB>2</SUB>sensor employingbeta alumina solid electrolyte. In this paper, we tried a few experiments for this sensor using two solid reference electrode, (β+β')-alumina and (α+β)-alumina.<BR>The cells used were as follows: Pt, (β+β')-alumina in air/β'-alumina/Na<SUB>2</SUB>SO<SUB>4</SUB>/SO<SUB>2</SUB>+O<SUB>2</SUB>+SO<SUB>3</SUB>, Pt (1) Pt, (α+β)-alumina in air/β-alumina/Na<SUB>2</SUB>SO<SUB>4</SUB>/SO<SUB>2</SUB>+O<SUB>2</SUB>+SO<SUB>3</SUB>, Pt (1)(11) From the present experiments, the following conclusions were obtained.<BR>1) The constant sodium activities in these solid reference electrodes were maintained for a long duration of the experiment.<BR>2) For both cells, good straight lines were obtained between e.m.f.'s and log Pso2 within the temperature ranges from 933 to 1230 K in the cell (1) and from 932 to 1278 K in the cell (11). Especially, in the (β+β')-alumina solid reference electrode, it was shown that the cell using this electrode could be employed to determine concentrations up to a few ppm of SO<SUB>2</SUB> gases at temperatures of 932 to about 1100 K. Consequently, this (β+β')-alumina mixture is recommended for the solid reference electrode ofSO<SUB>2</SUB> sensor employingβ'-alumina solid electrolyte.<BR>3) From e.m.f.'s of these cells, the activities of Na<SUB>2</SUB>O in β-Al<SUB>2</SUB>O<SUB>3</SUB>+β'-Al<SUB>2</SUB>O<SUB>3</SUB>and α-Al<SUB>2</SUB>O<SUB>3</SUB>+β-Al<SUB>2</SUB>O<SUB>3</SUB>coexistences were respectively calculated by considering thermochemical data and compared with the others.

1 0 0 0 OA 武蔵白岩鉱山

- 著者

- 岡部 恭

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.100, no.1160, pp.993-997, 1984-10-25 (Released:2011-07-13)

Musashi-shiraiwa mine is a underground mining limestone mine which is located at naguri-mura, western part of Saitama prefecture.Annual production of the mine is 170, 000 tons of limestone are and mining method of it is sublevel stopping.This paper describes on the following points(1) Outline of the mine 1) location, 2) development, 3) geology and mineral deposits, 4) motive and changes of adoption for underground mining method(2) Opening 1) pre-surveying, 2) plan of opening, 3) norm for structure of are brock, 4) operation of drifting(3) Mining methods and operation(4) Transportation(5) Ventilation(6) Transmission

1 0 0 0 OA 住友電工伊丹製作所のタングステン精錬

- 著者

- 中尾 智三郎

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.72, no.822, pp.927-932, 1956-12-25 (Released:2011-07-13)

- 参考文献数

- 5

In this paper, some problems such as roasting, crushing, leaching of wolframite and the precipitation, of leached solution are treated. Some fundamental methods for the treating of scheelite are also presented. Though the efficiency of elimination of S and As is very important in the roasting process, it is also necessary to think about the relations between the roasting condition and pulverizing or solubility of elements in the ore. To the mechanism of crushing of wolframite, fundamental theory can he applied, but at the technical case mass effects must be discussed. The leaching efficiency of are depends mostly upon the grain size of are and the quantities of leaching reagents. Impurities in the are are also leached, and then crystallize out, but each impurity has essential beharior in such process. Scheelite can be refined by several technical methods. Decomposition with mineral acid is a ordinay method, but fusion or leaching with soda ash are very interesting methods.

1 0 0 0 OA 海水からマグネシウムの製造

- 著者

- 部坂 恒夫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.84, no.963, pp.954-957, 1968-07-25 (Released:2011-07-13)

1 0 0 0 OA 東芝砂町工場におけるタングステン精錬

- 著者

- 加瀬 薫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.72, no.822, pp.915-918, 1956-12-25 (Released:2011-07-13)

The operation at Sunamachi plant was commenced from 1944, and the output of the metallic tungsten was 7 t per month. The plant was severely destroyed by bombing in March, 1945, but it was reconstructed soon after the war. The present production of metallic tungsten is about 3.5-4.5t per month.The raw material is wolframite and tungsten in it is leached as paratungstic ammonia. The leached solution is thickened to crystallize out the parasalt, and the salt is reduced by the two steps of heating with hydrogen gas. At first it is reduced to blue oxide (W4O11) at the temperature of 410-450°C and then is reduced to metallic state at more higher temperature .

1 0 0 0 OA 北海道, 下川鉱床産鉱石鉱物のコバルト濃度について

- 著者

- 正路 徹也 佐々木 望 金田 博彰 武内 寿久禰

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.96, no.1103, pp.1-6, 1980-01-25 (Released:2011-07-13)

- 参考文献数

- 19

The high grade of cobalt characterizes the deposit of the Shimokawa copper mine which is one of the most famous bedded cupriferous pyrite deposits of Japan. Unfortunately, however, the cobalt has not been recovered, because the concentration of cobalt is difficult. In order to show the distribution of cobalt in the ore, the microscopic observation and the electron microprobe analysis have been carried out. The main ore minerals are pyrite, chalcopyrite, monoclinic pyrrhotite, sphalerite, cobalt pentlandite, and cobaltian mackinawite in the descending order of abundance. Among them, pyrite is the most important carrier of cobalt, and cobalt pentlandite is subordinate. The cobalt of the copper concentrate depends upon the small mingled grains (less than 20μm) of cobalt pentlandite which is closely associated with chalcopyrite. On the other hand, the pyrite concentrate owes its cobalt amount to cobalt-rich pyrite. On the basis of the texture of ore and the crystal form of pyrite, the mode of occurrence of pyrite is divided into seven types as shown in Figs. 1 (a)-(g). The R-type pyrite having a rounded form is the richest in cobalt among them, and contains a average cobalt concentration of 0.8 wt.%.These natures of ore suggest that the cobalt of the coppem concentmate may be recovered as a by-pmoduct of the copper smelting, and that the cobalt of the pyrite concentrate may be recovered as a cobalt concentrate consisting of R-type pyrite.

1 0 0 0 OA 金貨の製造 附古今東西の金貨の要項

- 著者

- 廣瀬 亜夫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.49, no.578, pp.510-520, 1933-06-22 (Released:2011-07-13)

In this paper the author deals with the gold coins with special reference to the Japanese specification of the gold coinage.With detailed explanation the following items are treated on the gold coins:(1) the Japanese regulation of coinage, (2) history of the coinage institution, (3) production, (4) weight and grade, (5) course of coinage ration, (6) amelioration of irregular brittleness of gold bullion, (7) gold coins in olden times and (8) table of the gold coinage in countries of the world.

1 0 0 0 OA 岩手県における珪石・粘土資源とその利用

- 著者

- 佐藤 昌暉

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.83, no.946, pp.341-345, 1967-02-25 (Released:2011-07-13)

1 0 0 0 OA 爆薬の薬径と爆力について

- 著者

- 福山 郁生

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.71, no.801, pp.131-133, 1955-03-25 (Released:2011-07-13)