5 0 0 0 OA 核分裂生成物の利用

- 著者

- 木村 毅一

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.5, no.39, pp.770-773, 1956-12-15 (Released:2009-05-26)

- 参考文献数

- 36

3 0 0 0 OA Dywidag工法による嵐山橋の設計,施工について

- 著者

- 中島 儀八 今井 勤 小田 純夫

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.8, no.69, pp.519-527, 1959-06-15 (Released:2009-07-09)

3 0 0 0 OA ワイセンベルク効果について

- 著者

- 田村 幹雄 倉田 道夫 小高 忠男 山本 三三三

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.6, no.43, pp.227-231, 1957-04-15 (Released:2009-07-09)

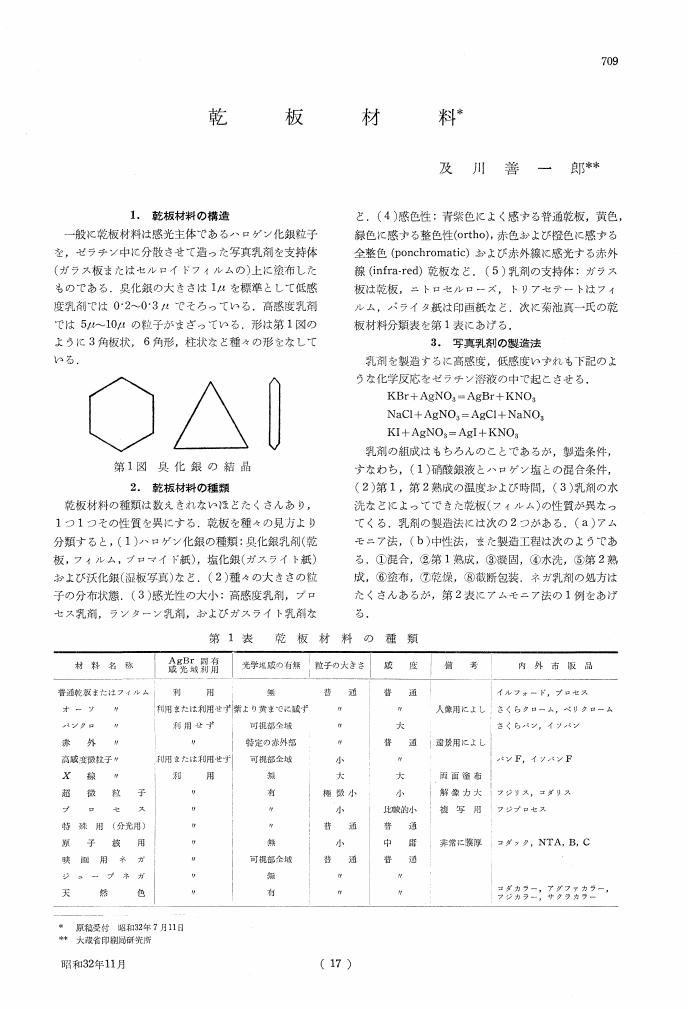

2 0 0 0 OA 乾板材料

- 著者

- 及川 善一郎

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.6, no.50, pp.709-716, 1957-11-15 (Released:2009-05-26)

- 参考文献数

- 8

2 0 0 0 OA ジルコニウム合金の圧縮クリープ

- 著者

- 西原 正夫 西原 守 山本 俊二

- 出版者

- 社団法人日本材料学会

- 雑誌

- 材料試験 : journal of the Japan Society for Testing Materials (ISSN:03727971)

- 巻号頁・発行日

- vol.10, no.90, pp.168-173, 1961-03-15

Compression-creep data for zircaloy 2, Mo-Cu-Zr alloy and 18-8 stainless steel were obtained at room temperature, 250℃, 316℃ (600゜F) and 450℃ for a period of 100 hours. Zircaloy 2 and Mo-Cu-Zr alloy were casted respectively as ingot by the consumable-electrode double-arc melting. The test specimens were machined from a bar obtained from the ingot by forging, and annealed at 700℃ (Zircaloy 2) and 750℃ (Mo-Cu-Zr alloy) for 1 hour in vacuum furnace. The test equipment for compression creep is the conventional tension creep machine with a fixture consisted of two yokes which convert tensile loading into compressive loading. The fixture used is of the similar type to the one developed at the Westinghouse Research Laboratory by M.J. Manjoine. The compression-specimen which has a diameter of 12 mm and an overall length of 36 mm was compressed between two seats, the ends of the specimen and of the seats being ground and lapped. The relative displacement of the yokes was measured by dial gauge extensometer as a measure of the strain in the specimen. For checking the magnitude of instantaneous strain in creep tests, short-time tension and compression tests were made for zircaloy 2 and Mo-Cu-Zr alloy at 316℃ by using the test equipment above-mentioned. The continuous loading was given by moving a running weight sliding on the loading lever arm of the creep machine. Although at room temperature zircaloy 2 and Mo-Cu-Zr alloy have smaller instantaneous and creep strain in comparison with 18-8 stainless steel which displays appreciable creep at room temperature, they tend to have poorer creep resistance at higher temperatures, and the steady-state creep component becomes conspicuous for Mo-Cu-Zr alloy at 316℃ and for zircaloy 2 at 450℃. The creep strength of Mo-Cu-Zr alloy at 450℃ is stronger than that of zircaloy 2 when the stress level is below 17 kg/mm^2. Comparison of tension-creep and compression-creep properties for Mo-Cu-Zr alloy (at 316℃ and 450℃) show that the alloy has poorer resistance in compression than in tension within a certain limit of stress, above which an effect of decrease of stress resulted from the increase of cross-section of a compression specimen would appear. The similar phenomena for S 816 and nimonic 90 at 1600゜F have been reported by L.A. Yerkovich. This difference in creep-resistance may partly be explained by the anomalous variation of the stress-strain relationship in tension and compression. But it should be taken into account as well that the bedding-down of the ends of compression-specimen and the anisotropic effects in the resistance to deformation produced in the process of preparing the test specimen are related to the difference in creep-resistance, although in our experiment the bedding-down of the compression specimen was minimized by lapping the ends of compression specimen.

2 0 0 0 OA 湿板材料に関して

- 著者

- 伊東 亮次

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.6, no.50, pp.702-708, 1957-11-15 (Released:2009-05-26)

- 参考文献数

- 5

1 0 0 0 OA 遮蔽用構築材料としてのセメント・コンクリート

- 著者

- 岡田 清

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.5, no.39, pp.743-748, 1956-12-15 (Released:2009-05-26)

- 参考文献数

- 13

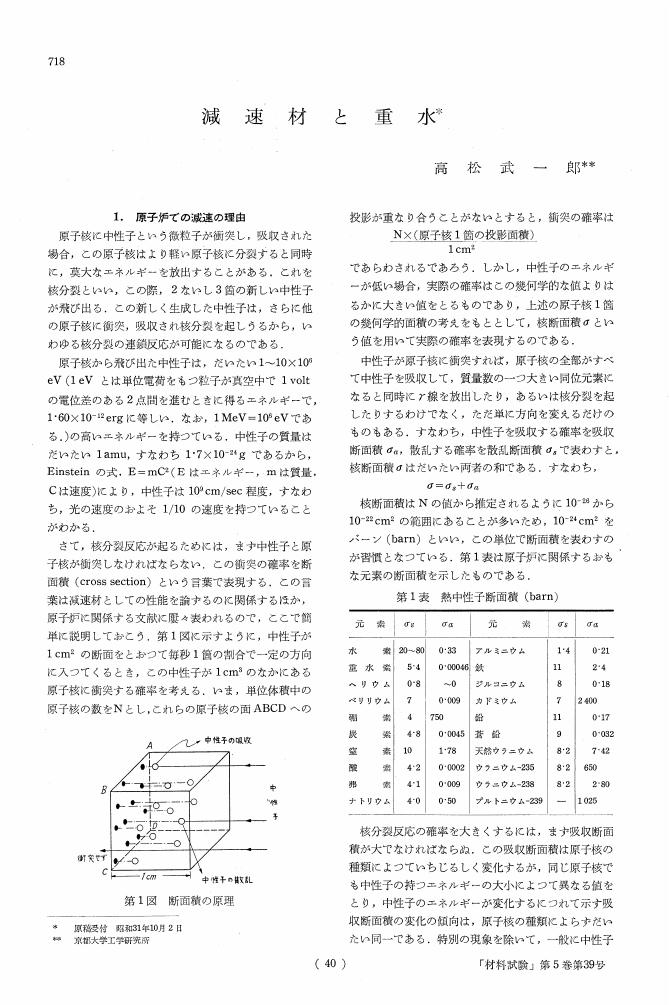

1 0 0 0 OA 減速材と重水

- 著者

- 高松 武一郎

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.5, no.39, pp.718-725, 1956-12-15 (Released:2009-05-26)

1 0 0 0 OA 螢光塗料

- 著者

- 滝沢 達児

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.8, no.64, pp.47-52, 1959-01-15 (Released:2009-05-26)

- 参考文献数

- 5

1 0 0 0 OA 木材接着剤

- 著者

- 新保 正樹

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.7, no.60, pp.474-480, 1958-09-15 (Released:2009-05-26)

- 参考文献数

- 11

1 0 0 0 OA 押込硬度の圧こんについて

- 著者

- 財満 鎭雄

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.5, no.37, pp.584-586, 1956-10-15 (Released:2009-05-26)

- 参考文献数

- 4

- 被引用文献数

- 1 1

The measuring error of the depression has a large influence upon the hardness which is calculated by the area of depression.The author studied the surface indented by Brinel, Vickers and Knoop depressions using Ogoshi Surface Roughness Tester, and found that for the same metal the piling-up was almost constant regardless of the applied weight and the measuring error, i. e. the error of hardness, differs with the metal. It was also found that there was a slight piling-up in the diagonal of Vickers depression but no piling up in the major diagonal of Knoop depression.

1 0 0 0 OA 木材接着剤の耐久性

- 著者

- 菅野 蓑作

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.10, no.98, pp.850-854, 1961-11-15 (Released:2009-05-26)

- 参考文献数

- 20

- 被引用文献数

- 1 1

- 著者

- 上田 太郎 朝倉 健二

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.9, no.78, pp.192-199, 1960

This investigation was planned for researching the effect of the repeated stress upon the longitudinal residual stress existing in the cold drawn carbon steel wire. For the specimen, 0.65% carbon steel wires drawn with 60% and 80% reductions were used, and the diameter of these wires was 1.3mm.<BR>For the measurement of the longitudinal residual stresses existing in these fine steel wires, the present writers adopted the mechanical method and electro-magnetic method.<BR>Hunter fatigue testing machine was used in this investigation, and from S-N curves of these wires the fatigue limit stress and three stresses over the fatigue limit were chosen as the repeated stress to research the behavior of residual stress. The fatigue test specimens were taken out from the fatigue testing machine at 10<SUP>7</SUP> and 10<SUP>6</SUP> cycles for the fatigue limit stress and at the number of cycle just before the break down cycle for each stress over the fatigue limit, and then the specimens for measurement of residual stress were cut out from the middle part of these fatigue test specimens. The distributions of longitudinal residual stresses of these specimens subjected to the repeated stresses were measured and those were compared with that of the standard specimen not subjected to the repeated stress.<BR>From the results obtained by this investigation, it was made clear that if the longitudinal tensile residual stress existing in the outer part of the wire was about 20-30kg/mm<SUP>2</SUP>, the distribution of longitudinal residual stress of the cold drawn steel wire was little affected by the repeated stress under rotating bending over the fatigue limit, and that which is equal to the fatigue limit, either.

1 0 0 0 OA 粉末冶金工業の発展の歴史と現状

- 著者

- 渡辺 孝章

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.11, no.105, pp.352-357, 1962-06-15 (Released:2009-05-26)

- 参考文献数

- 21

- 被引用文献数

- 1 1

1 0 0 0 OA 木材の老化 建築古材について

- 著者

- 小原 二郎

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.10, no.98, pp.894-899, 1961-11-15 (Released:2009-05-26)

- 被引用文献数

- 2 2

1 0 0 0 OA ロックラ-PCパイプの試験結果

- 著者

- 木村 恵雄

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.11, no.111, pp.781-785, 1962-12-15 (Released:2009-05-26)

- 参考文献数

- 1

NIPPON ROCLA PIPE CO. has been producing noncylinder prestressed concrete pipes since the fall of 1961. One of the products which has 1200mm inner diameter and is designed for the inner pressure of 13.0kg/cm2 was tested hydrostatically and under the external load.The results of test obtained are as follows:(1) Under the hydrostatic pressure up to 12.0kg/cm2, there was no leakage on outer surface of the pipe and at rubber joints.As the capacity of the bulkhead of the machine was not sufficiently large, the test up to 13.0kg/cm2 pressure was given up.(2) Under the external load up to 8.25 tons per meter (total load of 33.0 tons), could no visible crack was found at any point of the pipe.From analyses about the stress and measured strain on concrete surface at the end of the pipe, the prestress in the core concrete was supposed to be as much as the designed value, and the flexural strength of the concrete to be sufficient.

1 0 0 0 OA 原子炉用金属材料

- 著者

- 篠田 軍治

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.5, no.39, pp.738-742, 1956-12-15 (Released:2009-05-26)

- 参考文献数

- 14

1 0 0 0 OA 粘土-水系の性質

- 著者

- 奥田 進

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.11, no.109, pp.581-587, 1962-10-15 (Released:2009-05-26)

- 参考文献数

- 25

1 0 0 0 OA 加熱されたコンクリートの物理的性質の変化

- 著者

- 原田 有

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.6, no.40, pp.15-19, 1957-01-15 (Released:2009-07-09)

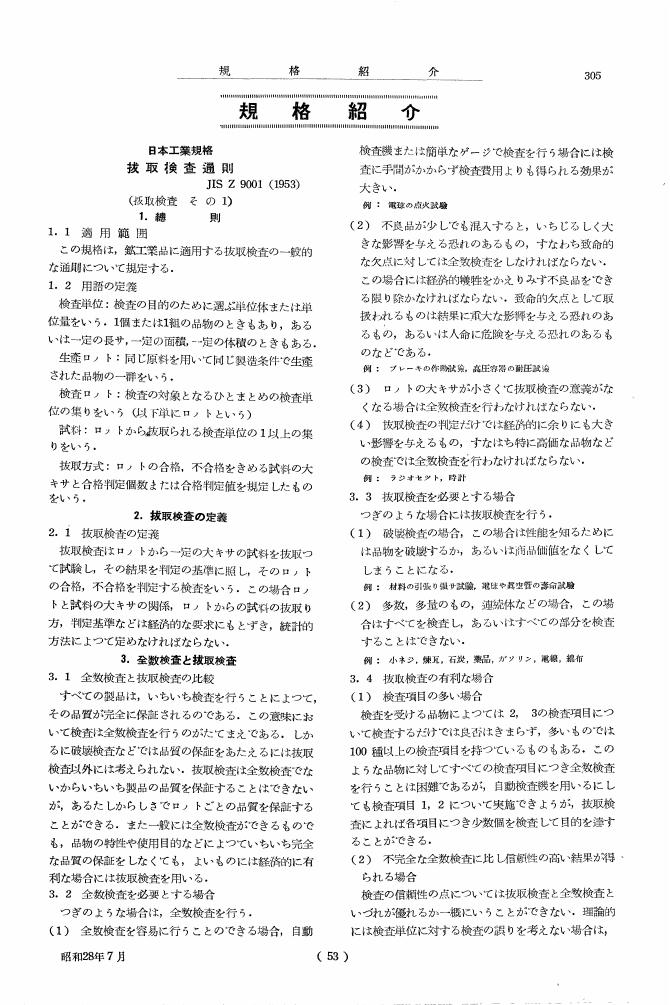

1 0 0 0 OA 規格紹介

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.2, no.7, pp.305-316, 1953-07-01 (Released:2009-05-26)