37 0 0 0 OA 複合材料の吸脱湿変形評価

- 著者

- 神谷 友裕 水谷 忠均

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.66, no.4, pp.275-281, 2017-04-15 (Released:2017-04-20)

- 参考文献数

- 23

- 被引用文献数

- 1

35 0 0 0 OA 日本刀の刀身モデルの衝撃応答

- 著者

- 臺丸谷 政志 小林 秀敏

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.60, no.7, pp.668-673, 2011-07-15 (Released:2011-07-20)

- 参考文献数

- 12

- 被引用文献数

- 1

The Japanese sword is interesting not only from the viewpoint of traditional crafts of arts, but also from the aspect of modern science and technology because the way of making and its functionality as a weapon are really consistent with modern science. The present study is concerned with the joint between tohshin (blade) and tsuka (hilt) of the sword. Only one mekugi-take (retaining peg made of bamboo) with about 5mm in diameter holds Nakago (tang) in the hilt. However the slender mekugi might not be broken, even in the case of violent sword-fighting. This fact has been historically demonstrated in many battles by Japanese swords. In this study, using a Japanese sword model, it is examined theoretically and experimentally why a mekugi used in Japanese swords might not be broken from the viewpoint of impact engineering. Consequently, it is presumed that such a strong force as breaking mekugi-take does not act on it, because of the location of mekugi-ana (a hole for mekugi) in the tang, which has been made by following the traditional code of swordsmiths.

18 0 0 0 OA 日本刀に息づく科学と技術

- 著者

- 井上 達雄

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.66, no.11, pp.804-810, 2017-11-15 (Released:2017-11-20)

- 参考文献数

- 10

- 被引用文献数

- 1

15 0 0 0 OA 板谷産ゼオライトの窒素選択吸着による富酸素空気の製造

- 著者

- 高坂 彬夫 松田 良弘

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.28, no.312, pp.794-797, 1979-09-15 (Released:2009-06-03)

- 参考文献数

- 11

- 被引用文献数

- 2 3

An investigation was made on the method of concentrating oxygen in air under the gauge pressure of 0∼3g/cm2 at a normal temperature by using Itaya-zeolite composed mainly of clinoptilolite.Approximately 50 volume % of oxygen-concentrated air could be obtained by a two-cylinder small-sized pressure swing device. Though Itaya-zeolite has less adsorbing power of nitrogen than the molecular sieve 5A or 4A, it will be useful for oxygen-enriched air in the fields such as waste water treatment and medical attendance.

12 0 0 0 OA ポリマーコンクリートの研究,開発の現状と動向

- 著者

- 大濱 嘉彦

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.36, no.406, pp.679-689, 1987-07-15 (Released:2009-06-03)

- 参考文献数

- 74

- 被引用文献数

- 1 1

10 0 0 0 OA 各種特殊鋼およびアルミニウム合金の弾性係数の温度依存の実験式

- 著者

- 竹内 洋一郎 野田 直剛 小森 茂 入交 裕 北川 俊治

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.26, no.282, pp.210-214, 1977-03-15 (Released:2009-06-03)

- 参考文献数

- 6

- 被引用文献数

- 8 7

The ultrasonic wave reflection method has been used to determine the elastic constants, Young's modulus, shear modulus, and Poisson's ratio of various steels and aluminium alloys in the temperature range from room temperature to 800°C. It was found that the both elastic moduli tend to decrease with the rise of temperature. Poisson's ratio, however, shows no significant difference among the materials with temperature and there is a slight increase with rise of temperature. The data were successfully represented by the empirical formulae in the form of exponential function of temperature. They are very convenient expressions for the analyses of thermal stress problems.

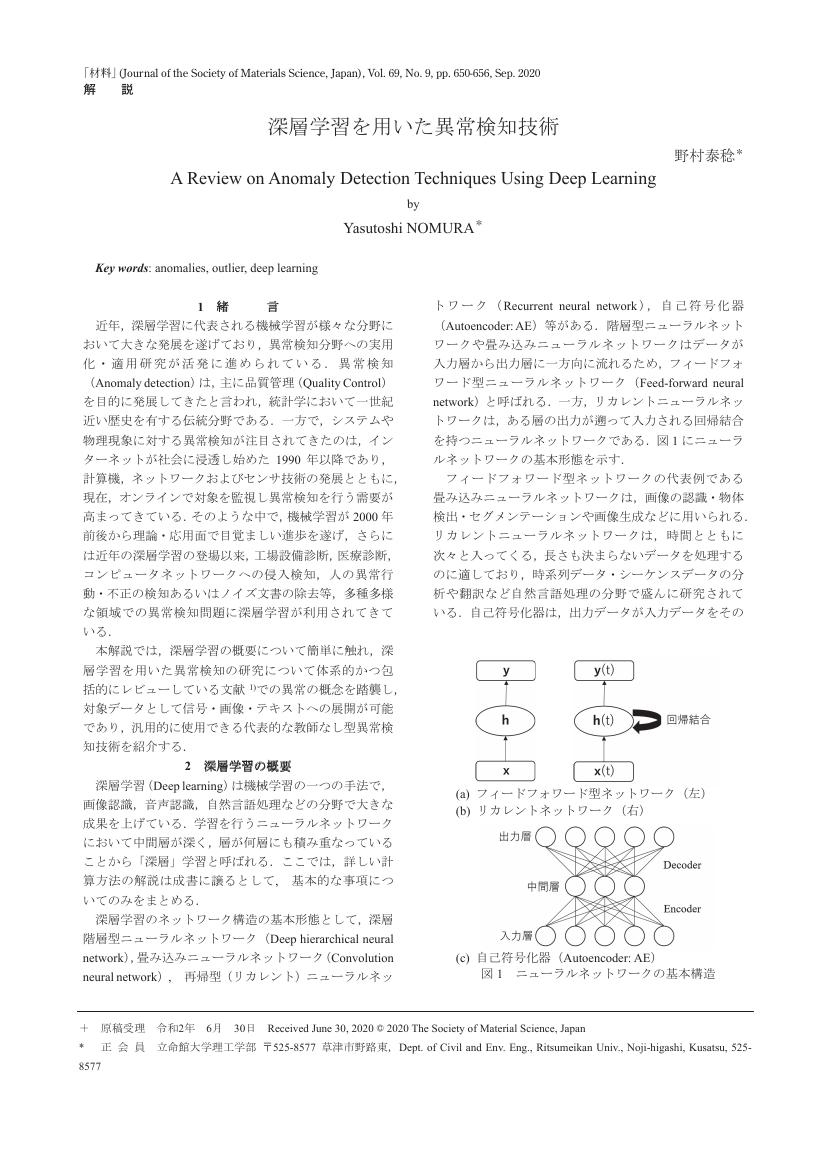

7 0 0 0 OA 深層学習を用いた異常検知技術

- 著者

- 野村 泰捻

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.69, no.9, pp.650-656, 2020-09-15 (Released:2020-09-20)

- 参考文献数

- 13

- 被引用文献数

- 1 3

6 0 0 0 OA 日本刀の焼入れにおける焼刃土の効果

- 著者

- 上原 拓也 井上 達雄

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.44, no.498, pp.309-315, 1995-03-15 (Released:2009-06-03)

- 参考文献数

- 19

- 被引用文献数

- 4 9

The quenching process of a Japanese sword is simulated by a CAE system “HEARTS” developed by one of the authors. The system is available to consider the coupling effect among metallurgical change due to phase transformation, temperature and inelastic stress/strain.In the quenching process of the Japanese sword, a special kind of clay is pasted on the surface to control the heat transfer coefficient between metal and water. The dependence of the coefficient on the thickness of clay and also the surface temperature is experimentally evaluated first by using a cylindrical rod of silver. The results show a relatively higher value with thin-pasted clay than that without clay at a high temperature range. The data are then applied to simulate the variation of temperature coupled with the structural change from austenite to martensite and pearlite as well as the variation of stress. It gives an attractive result that the sword is bent two times to the direction opposite to the normal shape due to the complicated time difference between martensitic and pearlitic transformation and thermal contraction. The simulated results of residual stress distributions are compared with the measured data by X-ray diffraction technique.

6 0 0 0 OA スクロースとクエン酸を混合した木材粉末の押出し加工による円管成形

- 著者

- 鈴本 雄也 梶川 翔平 久保木 孝

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.70, no.12, pp.912-917, 2021-12-15 (Released:2021-12-20)

- 参考文献数

- 10

Wood materials are attracting attention as an alternative material to plastics for solving environmental problems, such as sea microplastic. An effective wood processing method should be developed for producing products with various shapes, which leads to an effective use of the wood. This paper proposed extrusion of the wood powder mixed with a natural binder composed of sucrose and citric acid, which effectively forms products with same cross-sectional shape in the extruding direction. Circular tube was extruded in this experiment. It was important to solidify the wood powder inside an extrusion die for molding the tube without cracks and fracture. Therefore, influence of the extrusion die length, the punch speed and the heating temperature, which concern solidification with cooling, were investigated for improving the dimensional accuracy and the mechanical property of the tube. At first, the fracture of the molded product was prevented by setting an appropriate die length. High punch speed caused the tube expansion due to insufficient cooling before extruding, while low punch speed caused the fracture due to long time heating. Density and strength of the molded product increased with the decrease in the temperature, although the cracks easily occurred on the tube surface under the low temperature of 140°C. The tube surface state became smooth by setting the molding temperature to 160 or 180°C. From the above results, the circular tube, which has good dimensional accuracy and mechanical property, was molded by controlling the extruding condition.

6 0 0 0 OA スポール破壊条件の研究

- 著者

- 浅田 和雄 高橋 浩昭 高橋 尚志

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.41, no.468, pp.1396-1402, 1992-09-15 (Released:2009-06-03)

- 参考文献数

- 7

When a projectile with high velocity impacts onto a target, several fracture modes (such as spall fracture, plug fracture, penetration fracture and so forth) appear in the target. Therefore, in order to identify an impact fracture strength of materials, a particular type of impact experiments should be undertaken. For example, an impact experiment for flying plate is suitable to determine the spall fracture strength. Different impact conditions, however, may bring in different fracture strength even for the same target material. For the purpose of clarifying perforation dynamics (mechanism) by means of computer code, it is necessary to provide a unified fracture condition which enables to explain all modes of spall fracture, plug fracture and penetration fracture. Under this fracture condition, fracture takes place when the strain has attained its critical value, which may be affected by pressure and temperature.In the present study, the unified fracture condition was examined through comparison between the back surface velocity of flying plate impact experiment and the velocity calculated from computer code by using Ni-Cr-Mo steel (SNCM-630 steel). The computer code used here was that of one-dimensional large deformation stress wave propagation by finite-difference-method. The experimental results and computer code results were well in accord with each other, confirming the applicability of the unified fracture condition to perforation dynamics.

5 0 0 0 OA 核分裂生成物の利用

- 著者

- 木村 毅一

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料試験 (ISSN:03727971)

- 巻号頁・発行日

- vol.5, no.39, pp.770-773, 1956-12-15 (Released:2009-05-26)

- 参考文献数

- 36

5 0 0 0 OA 羽田空港D滑走路建設工事における長期的な圧密沈下予測について

- 著者

- 水野 健太 渡部 要一 小林 正樹 野口 孝俊 青木 康哲 山本 隆信 高橋 充

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.61, no.1, pp.78-84, 2012-01-15 (Released:2012-01-20)

- 参考文献数

- 9

In the construction of the D-runway in Tokyo International Airport (Haneda Airport), “the settlement prediction and management system (HSAP)” which can efficiently evaluate the consolidation settlement of artificial reclamation was developed. The reclamation history data base which reflected the actual construction until July, 2009 and the reclamation plan after that was made. The actual measurement and the calculation value were compared and the various consolidation parameters were identified. Moreover, the long-term consolidation test and constant strain rate consolidation test were executed, and the secondary consolidation parameter was set based on the isotache model's concept. Based on the prediction result of the residual consolidation settlement, the filling height of the D-runway at the start of in-service period was decided to be 0.70m, which is required from the aviation operation.

5 0 0 0 OA 逆問題の解析手法

- 著者

- 久保 司郎

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.41, no.470, pp.1595-1604, 1992-11-15 (Released:2009-06-03)

- 参考文献数

- 72

- 被引用文献数

- 4

5 0 0 0 OA 最近の疲労破壊による航空機事故と疲労基準改訂案

- 著者

- 藤原 源吉

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.45, no.1, pp.2-8, 1996-01-15 (Released:2009-06-03)

- 参考文献数

- 10

This article describes the findings of research for some recent transport airplane's accidents related to fatigue cracks. One is a B747SR's accident due to crack initiating at the fastener holes (to say Multiple-Site Damage). The other describes the crash of UAL's DC10-10 (N1819U), in Sioux City, Iowa, U. S. A., on July 19, 1989, which experienced a catastrophic failure of the No. 2 tail-mounted engine during cruise flight. The third explains the in flight separation of the No. 2 engine and engine pylon from B747-100F, shortly after departure from Anchorage International Airport, Anchorage, Alaska, on March 31, 1993. As a result of investigation for B747-100F's accident, National Transportation Safety Board made some important recommendations (One is to amend the design load requirements of Title 14 Code of Federal Regulations Part 25 to consider multiple axis loads encountered during severe turbulence) to the Federal Aviation Administration. Also, current aging airplane service data have identified that there are more cracked airplanes with increasing fleet edge, and possibly several fatigue cracks in some of the cracked airplanes. Especialy, MSD helped focus the attention of the aeronautical field on the problems of operating an aging transport airplanes. Therefore, FAA proposed to rivise the Advisory Circular No. 25·571-1A (Damage tolerance and fatigue evaluation of structure) on 3/5/1986. This article describes one operator's viewpoint on the means to maintain the safety of aircraft structures in consideration of the revised structural fatigue evaluation standards.

5 0 0 0 OA 疲労の基礎と実機疲労設計の最新動向 2.発電機器の疲労設計における最近の動向

- 著者

- 菅田 淳 齊藤 和宏

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.59, no.2, pp.171-177, 2010-02-15 (Released:2010-02-19)

- 参考文献数

- 27

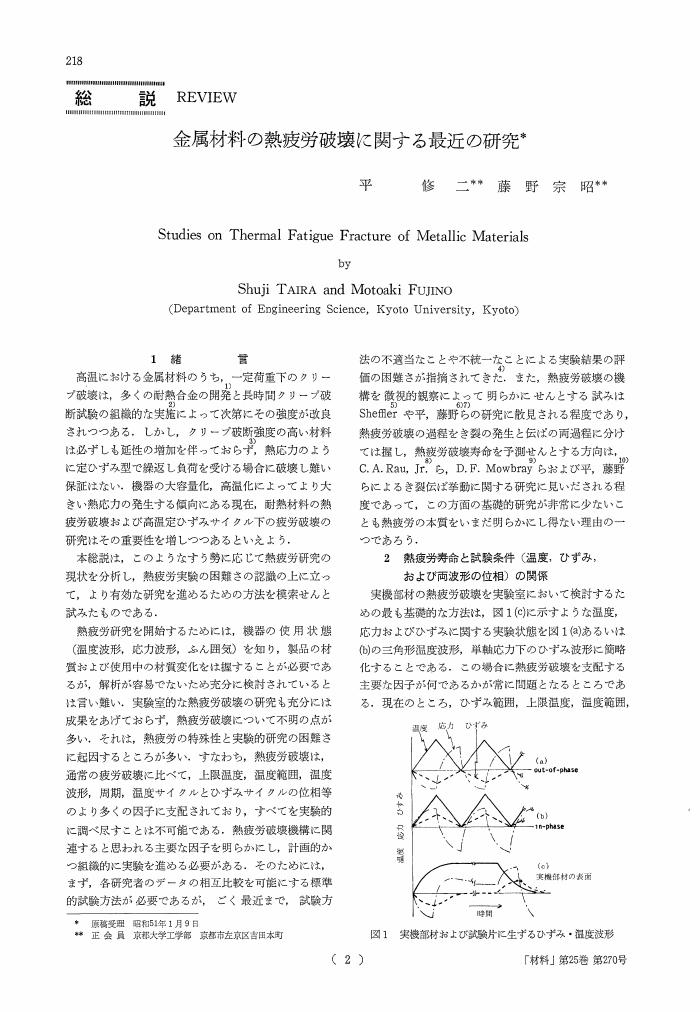

4 0 0 0 OA 金属材料の熱疲労破壊に関する最近の研究

- 著者

- 平 修二 藤野 宗昭

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.25, no.270, pp.218-229, 1976-03-15 (Released:2009-06-03)

- 参考文献数

- 55

- 被引用文献数

- 6 6

4 0 0 0 OA 急冷と準安定平衡

- 著者

- 新宮 秀夫 鈴木 亮輔 石原 慶一

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.33, no.366, pp.239-245, 1984-03-15 (Released:2009-06-03)

- 参考文献数

- 22

- 被引用文献数

- 1 2

3 0 0 0 OA ガラスと金属の接着機構 (I)

- 著者

- 池田 豊

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.17, no.180, pp.783-792, 1968-09-15 (Released:2009-06-03)

- 参考文献数

- 68

- 被引用文献数

- 1 1

3 0 0 0 悪夢のようなクリスマスイブ前夜

- 著者

- 金子 健太郎

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.68, no.9, pp.731-732, 2019

3 0 0 0 OA 石炭灰による土地造成の問題点

- 著者

- 三木 五三郎

- 出版者

- 公益社団法人 日本材料学会

- 雑誌

- 材料 (ISSN:05145163)

- 巻号頁・発行日

- vol.19, no.205, pp.900-904, 1970-10-15 (Released:2009-07-09)

Special attention must be paid to the fill construction where coal ashes are used because they have particular geotechnical properties.Coal ashes are sandy coarse silt and have no plasticity. They have such small specific gravity as 2.1. Compacted coal ashes have strong shearing resistance at the optimum moisture content, but loose coal ashes have the risk of liquefaction when they are saturated.In Hisasue valley in Kawasaki city, an extensive flow slide of fill construction where coal ashes were used occurred in June, 1965. The fill consisted of loose dumping ashes and it collapsed just when it had been saturated by the seeping groundwater to the critical state.In Hodogaya in Yokohama city, a large fill construction has been built with coal ashes with special attention paid to the drainage of groundwater and to the compaction of fill material. The work has proved a success.