1 0 0 0 OA 摩擦切削

- 著者

- 河村 正彌 小川 正義 歌川 正博

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.18, no.213, pp.359-363, 1952-12-05 (Released:2009-06-30)

- 参考文献数

- 3

1 0 0 0 OA プラスチックの溶接

- 著者

- 木村 博

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.31, no.365, pp.447-460, 1965-06-05 (Released:2010-02-16)

- 参考文献数

- 8

1 0 0 0 OA 小型フォーカルプレンカメラ/多軸穿孔機の錐配置装置

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.16, no.185, pp.60-61, 1950 (Released:2009-06-30)

1 0 0 0 OA 画素型プリンタ

- 著者

- 渡辺 昭則

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.40, no.478, pp.969-975, 1974-11-05 (Released:2009-06-30)

- 参考文献数

- 7

1 0 0 0 OA 鉛入黄銅の研究(第1報)

- 著者

- 葉山 房夫

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.20, no.232, pp.240-245, 1954-07-05 (Released:2009-06-30)

Researches on brass containing Pb as the material used for precision mechanism (clock and watch, etc.) have been performed, concerning the machinability for cutting and shearing, the qualities of worked surface, and the wear properties. In the first report the experimental results of the mechanical properties, that is hardness, tensile strength, elongation and shock value are described.

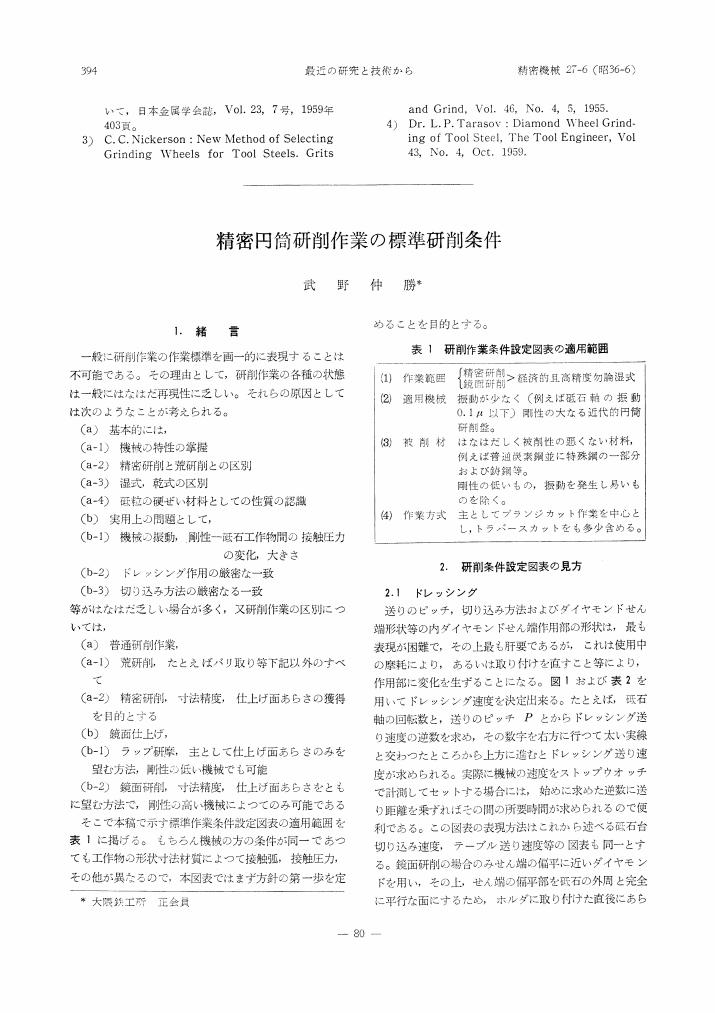

1 0 0 0 OA 精密円筒研削作業の標準研削条件

- 著者

- 武野 仲勝

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.27, no.317, pp.394-398, 1961-06-05 (Released:2009-06-30)

- 参考文献数

- 1

1 0 0 0 OA 三次元切削温度分布の数値解析

- 著者

- 臼井 英治 白樫 高洋 北川 武揚

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.41, no.491, pp.1141-1146, 1975-12-05 (Released:2009-06-30)

- 参考文献数

- 8

- 被引用文献数

- 1 1

The paper proposes an analytical method which enables to predict the temperature distribution in three dimensional metal cutting with single point tool, based only upon orthogonal cutting data. By using the three dimensional cutting model and the energy method presented in the previous paper, it is possible to obtain cutting force and chip formation such as chip flow direction, shear angle and chip shape for the tool of arbitrary shape. An assumption made on the frictional stress distribution on rake face together with the results through the energy method determines the strength of heat sources in the cutting model. The temperature distribution in workpiece, chip and tool is thus obtained through a numerical analysis of the equation involving heat conduction, transfer and generation. The predicted distribution of the temperature on rake face is found to be in good agreement with the distribution measured with a fine, insulated platinum wire embedded in the tool, of which end is exposed on the rake face and makes a thermo-couple with the chip produced.

1 0 0 0 OA 片持はりにおける大たわみの数値計算法

- 著者

- 青木 正義 小高 忠男

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.31, no.368, pp.754-758, 1965-09-05 (Released:2009-06-30)

- 参考文献数

- 7

- 被引用文献数

- 1 1

In many sorts of electronic devices the cantilever leaf springs are widely used, to switch the contact points. In designing such a spring, it is necessary to have an accurate knowledge cncerning to the force-deflection relationship. The large deflection of a cantilever spring has been studied for a long time. And the solution of the deflection is obtained in the form of elliptic integrals. A practical formula is necessary for the practical designing of the spring, for it takes a long time to solve the elliptic integrals numerically.In this paper, firstly, a modulus of the elliptic integrals is derived as a function of a load by introducing thereversion formula. Secondary, the co-ordinates of the loaded point are represented by elliptic functions. Then, the deflections at a loaded point are obtained as a power series of a load.Similarly, the deflection angle at the loaded point and the practical formula of a deflection curve, in the state of large deflection, is also obtained from the exact solution.

1 0 0 0 OA 最近のパッキン展望

- 著者

- 渡辺 武

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.20, no.226, pp.1-7, 1954-01-05 (Released:2009-06-30)

1 0 0 0 OA 関節型ロボットアームの高速化のための運動制御 間欠運動の高速化に関する研究

- 著者

- 神谷 好承 岡部 佐規一 横山 恭男

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.47, no.6, pp.706-711, 1981-06-05 (Released:2009-06-30)

- 参考文献数

- 4

- 被引用文献数

- 1 1

This paper deals with the motion control of a manipulator or an industrial robot arm. Generally speaking, manipulators or industrial robot arms that are constructed by the open-loop articulated kinematic chains are non-linear dynamic systems and the motion equation is described by the coupling dynamic systems between the connecting chains. So it is not easy to control a manipulator or a robot arm for positioning to the desired place at high speed. In this study, for the high speed motion of a robot arm, we tried to adapt the minimum time control to the motion of robot arm that has two articulated kinematic chains, and found the optimal path to move the robot arm from the initial configulation to the final configulation. This optimal path is very similar to the figure of which we move our own arms. And we showed the way to solve the near-minimum-time control for the multi-input and non-linear dynamic system like a robot arm that is constructed by the open-loop articulated kinematic chains.

1 0 0 0 OA 衝撃によるねじの締付け

- 著者

- 玉置 正恭

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.49, no.3, pp.343-347, 1983-03-05 (Released:2009-07-23)

- 参考文献数

- 2

- 被引用文献数

- 1

Few research works have been reported so far on the tightening of bolted joints by means of successive impacts, whereas the impact-wrenching is one of the most practical methods for the tightening of bolted joints. The process of the tightening of bolted joints by means of the swinging hammer is analysed and the theoretical results are compared with the experimental data. The substantial agreements between the theory and the experiment are confirmed. The results are summarized as follows. (1) The clamping force by an impact of the swinging hammer is concerned in the square root of the available energy of the hammer. (2) The increase of clamping force by an impact depends not only on the available energy of the hammer but also the existing clamping force just before the impact and the stiffnesses of the bolt and the clamped parts. (3) The clamping force by successive n impacts is proportional to √n·F1, where F1 is the initial clamping force.

1 0 0 0 OA 偏光形微分干渉顕微鏡の理論と設計製作

- 著者

- 山本 忠昭

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.31, no.371, pp.1008-1015, 1965-12-05 (Released:2009-06-30)

- 参考文献数

- 8

1 0 0 0 OA ベルト研削におけるコンタクトホイールの一選定法

- 著者

- 中島 基雄 井戸 守

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.47, no.11, pp.1373-1377, 1981-11-05 (Released:2009-06-30)

- 参考文献数

- 4

In this paper, under such various conditions as shapes and rubber hardnesses of contact wheels, grinding speeds and settings of cut, the tension acting upon the abrasive belt by means of detecting the electrical signal from a strain gauge passed on the inside of abrasive belt is researched experimentally. Moreover, by using the relation between the tension and depth of cut ratio, it is clarified that a selection method from both the shape of the contact wheel and the most suitable ratio of the effective depth of cut to setting of cut under the various grinding conditions are obtained. The main results obtained are follows. (1) It is impossible to get the shape of the contact wheel which has the most suitable ratio of the effective depth of cut to setting cut from the relation between depth of cut and tangential or normal force acting upon the contact wheel in grinding. However, it makes possible to decide the range between the effective maximum and minimum depth of cut ratio by using the tension and suitable shape of the contact wheel can also be obtained from the effective range mentioned above. (2) Considering the relation between the surface roughness of workpiece and the land height of the contact wheel, the surface finish comes to be bad in the contact wheel giving the suitable depth of cut ratio. However, the shape of the con-tact wheel which has the most effective surface roughness and depth of cut ratio must be decided by this method.

1 0 0 0 OA 歐米に於ける精密機械工業の趨勢

- 著者

- 海老原 敬吉

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.1, no.14, pp.547-558, 1934-11-25 (Released:2010-02-16)

- 参考文献数

- 6

1 0 0 0 OA ステレオ用DDモータの電気的・機械的精度

- 著者

- 佐藤 有司 垂水 賢吉

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.41, no.491, pp.1112-1116, 1975-12-05 (Released:2009-06-30)

- 参考文献数

- 1

1 0 0 0 OA 弁楽器の発音機構

- 著者

- 柳沢 猛 中村 喜十郎 引地 恒夫

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.34, no.402, pp.467-472, 1968-07-05 (Released:2009-06-30)

- 参考文献数

- 1

The sound of a reed-organ, harmonica and accordion has been believed to be made by the surface of a vibrating reed tongue and by the surface of a sound board vibrating from reaction of the tongue vibration. This paper denies this and asserts the following, (1) In the above instruments there is a difference in air pressure with a slot as a boarder, and a very rapid flow of air through the slot. When the tongue closes and opens the slot periodically, the sound is produced by changes in air pressure around the slot.(2) The vibration of the soundboard is also produced by the change in air pressure, but the sound produced by vibration of the soundboad is very weak.

1 0 0 0 OA 超音波振動によるねじのゆるみ 座面の分離現象

- 著者

- 久米原 宏之 丸山 一男 津田 米雄 児玉 正博

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.45, no.540, pp.1492-1496, 1979-12-05 (Released:2009-06-30)

- 参考文献数

- 4

- 被引用文献数

- 1

In order to clarify the self-loosening mechanism of threaded joints which are subjected to ultrasonic vibration in the axial direction, the separating phenomena between the bearing surfaces are investigated experimentally and theoretically. The obtained conclusions are as follows : (1) The theoretical values of the amplitude on the assumption that the bearing surface may begin to separate when the amplitude of vibrational stress on the surfaces reaches the mean compressive stress by tightening force approximately agree with the experimental ones. Then the above-mentioned value, which is called “Critical Amplitude at the Separation between Bearing Surfaces”, is proposed as a criterion of self-loosening of threaded joints. (2) The separation between bearing surfaces is affected by lubricating condition. The critical amplitude with silicone grease is larger than that with machine oil or without lubricant in the range of this experimental conditions.

1 0 0 0 OA 金属の摩耗に関する文献の展望 金属の摩耗に関する文献調査専門委員会報告

- 著者

- 佐藤 健児 菅原 昇 萱場 孝雄 高梨 三郎 松井 正己 武田 信男

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.30, no.352, pp.399-435, 1964-05-05 (Released:2009-10-08)

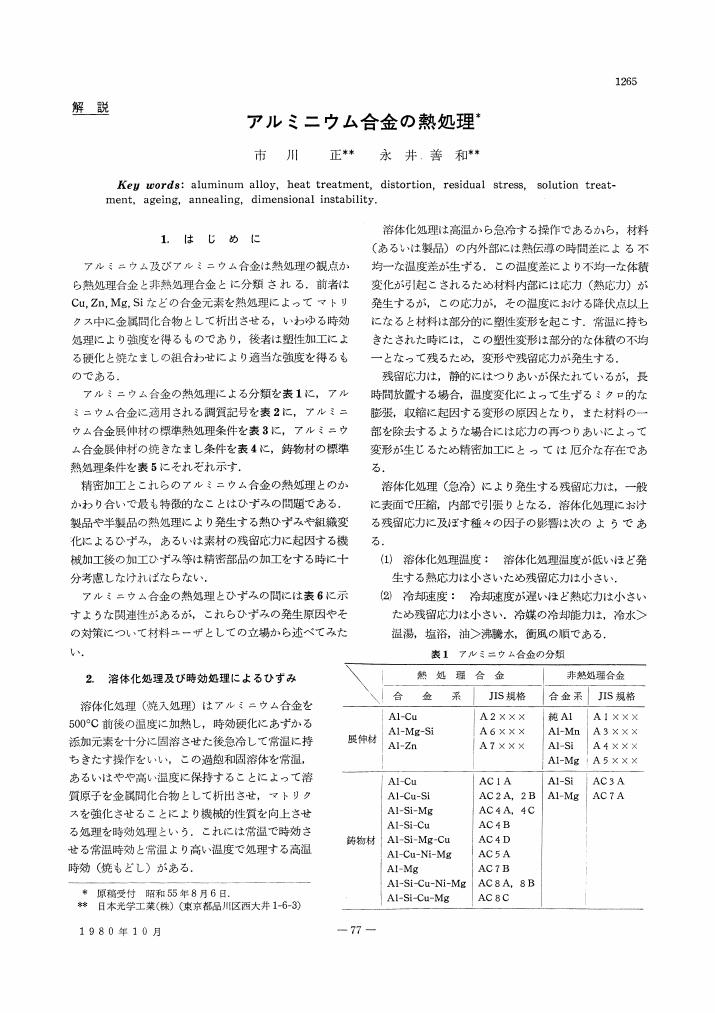

1 0 0 0 OA アルミニウム合金の熱処理

- 著者

- 市川 正 永井 善和

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.46, no.10, pp.1265-1272, 1980 (Released:2009-06-30)

- 参考文献数

- 11

1 0 0 0 OA 温度目盛の現状

- 著者

- 高田 誠二

- 出版者

- 公益社団法人 精密工学会

- 雑誌

- 精密機械 (ISSN:03743543)

- 巻号頁・発行日

- vol.25, no.289, pp.45-49, 1959-02-05 (Released:2009-06-30)