1 0 0 0 OA NC切削加工による高速鋳型作製技術

- 著者

- 岩田 靖 岩堀 弘昭 内藤 国雄 大庫 和孝

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.75, no.12, pp.870-874, 2003-12-25 (Released:2015-01-07)

- 参考文献数

- 3

A sand block was developed for direct machining with a numerical contorol machine. The sand block has a cutting resistance of 30N which is as small as 1/300 that of steel block. Especially, sand blocks made of fine spherical particles have better dischargeability and dimensional accuracy, thus providing excellent machinability. Direct machining of a sand block reduces molding time. For example, it takes merely four hours to complete the mold for the cylinder head cover of an automobile engine.

1 0 0 0 OA 日本におけるダイカストの歴史

- 著者

- 西 直美

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.78, no.4, pp.199-206, 2006-04-25 (Released:2015-01-10)

- 参考文献数

- 12

- 被引用文献数

- 1

1 0 0 0 OA 新材料と先駆者たち

- 著者

- 木村 康夫

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.69, no.11, pp.947-950, 1997-11-25 (Released:2014-12-18)

- 参考文献数

- 19

- 被引用文献数

- 1

- 著者

- 吉井 武輝 古田 将吾 小林 正和 三浦 博己

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.93, no.10, pp.604-611, 2021-10-25 (Released:2021-11-01)

- 参考文献数

- 10

Image-based finite element (FE) simulation, based on images of a model built with 3D images obtained by synchrotron radiation nano-tomography, was performed to investigate the point of preferential damage on Si particles in the early stage of tensile deformation in Al-10%Si casting alloys. By reproducing stress concentration on Si particles with the FE simulation, the effects of particle parameters such as (1) particle size, (2) particle orientation to loading direction, and (3) particle shape on damage were evaluated. Nano-tomography observation suggested that the parameters influence damage. The increasing rate of maximum hydrostatic stress differed depending on the Si particle size. Larger particles showed rapid increment in stress, suggesting that preferential damage may occur in large particles at an early stage of tensile deformation. In the study on the influence of particle orientation, particles whose longitudinal direction are more or less parallel to the tensile direction tend to also show rapid increment in stress. However, the most rapid development of the maximum hydrostatic stress was observed in particles possessing small Gaussian curvature which corresponds to severe necking. Comparisons of particles having specific parameters with damaging behavior revealed that the most influential parameter of particles on stress concentration was particle shape possessing necking.

1 0 0 0 OA 球状黒鉛鋳鉄における接種の役割

- 著者

- 鹿毛 秀彦

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.74, no.9, pp.601-604, 2002-09-25 (Released:2015-01-07)

- 参考文献数

- 2

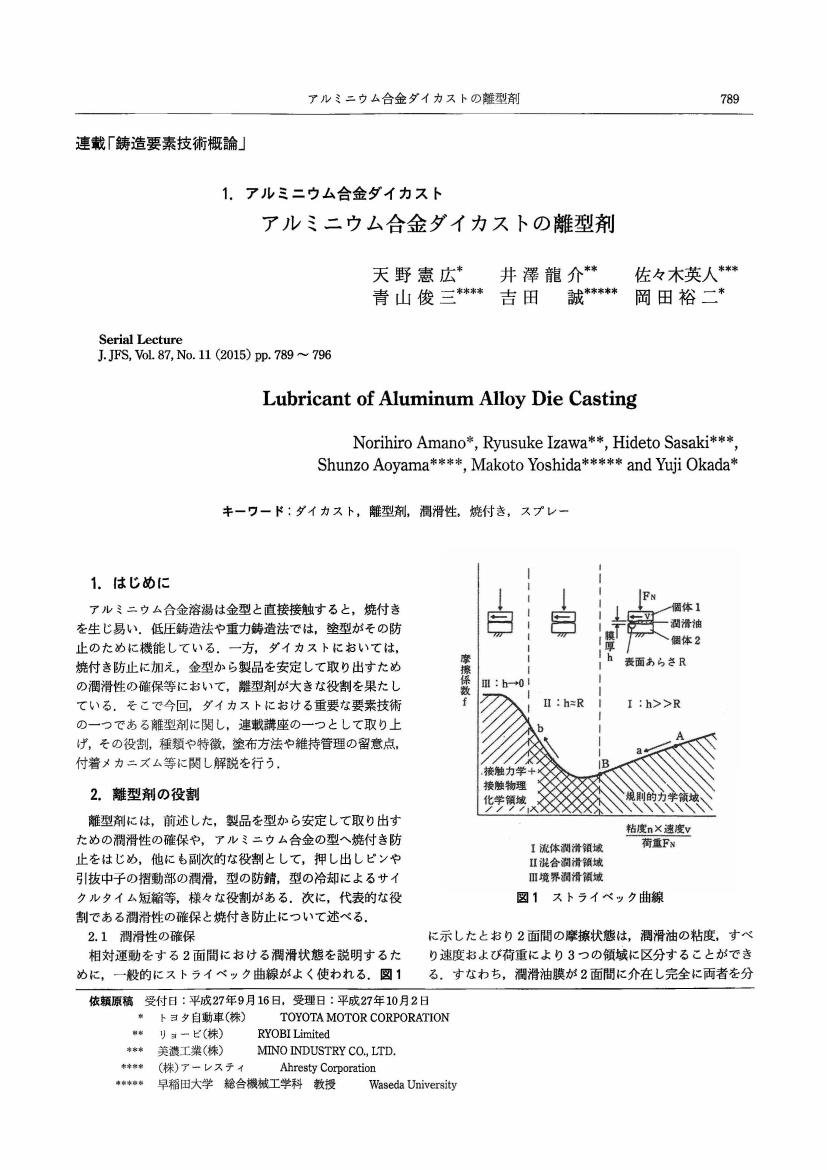

1 0 0 0 OA アルミニウム合金ダイカストの離型剤

- 著者

- 天野 憲広 井澤 龍介 佐々木 英人 青山 俊三 吉田 誠 岡田 裕二

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.87, no.11, pp.789-796, 2015-11-25 (Released:2020-01-01)

- 参考文献数

- 11

1 0 0 0 OA 二輪車設計から見たダイカスト技術の課題

- 著者

- 山縣 裕

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.79, no.5, pp.251-258, 2007-05-25 (Released:2015-01-13)

- 参考文献数

- 28

- 被引用文献数

- 1

- 著者

- 小林 正和 杉浦 協司 竹下 裕市 戸田 裕之

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.86, no.3, pp.209-215, 2014

<p> The feasibility of applying the fluidized bed furnace to the solution and aging treatments of aluminum alloys was assessed by examining concerns such as the efficiency of heat treatments and delay of quenching, together with its merits such as the shortening of heat treatment and the possibility of high temperature heat treatments.</p><p> It was concluded that this method realizes high efficiency of heat treatments, which is comparable to that attainable with the combination of a salt bath and oil bath. By suppressing the delay time within 20 to 30sec. after the removal of works from the fluidized bed furnace, no degradation in mechanical properties occurs. The allowable delay time is dependent on the work size. The solution treatment time can be shortened to 60min. or below. Good mechanical properties were obtained even with a short solution treatment time of 15min. depending on the size and thickness of the work. This also enables suppression of pore growth at the same time. In addition, high temperature heat treatment at around ternary eutectic temperatures was realized by precise temperature control, thereby realizing superior mechanical properties and shorter heat treatment time.</p>

- 著者

- 田辺 郁 茂木 徹一 マリア エレナ ロベルト

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.75, no.7, pp.474-478, 2003

In order to demonstrate the superiority of granular grain structure for thixocasting materials, semisolid samples with granular and dendrite structures were cast into a permanent mold by a punch. The test piece consisting of granular crystals revealed that the punch power was less than 1 kN until three quarters of the casting process. In contrast, the structure consisting of dendrite crystals revealed that the punch power was greater than 8 kN until one quarter of the casting process, and the power increased as the casting process proceeded. Granular grains of primary α aluminum surrounded by liquid phase could be easily moved into the die cavity, since the liquid phase acted as a lubricant. However, with test piece consisting of dendrite crystals, the liquid phase only moved at the first stage and the deformation resistance increased.

1 0 0 0 OA ダイエットはサイエンス

- 著者

- 西 直美

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.86, no.3, pp.266-267, 2014-03-25 (Released:2019-01-01)

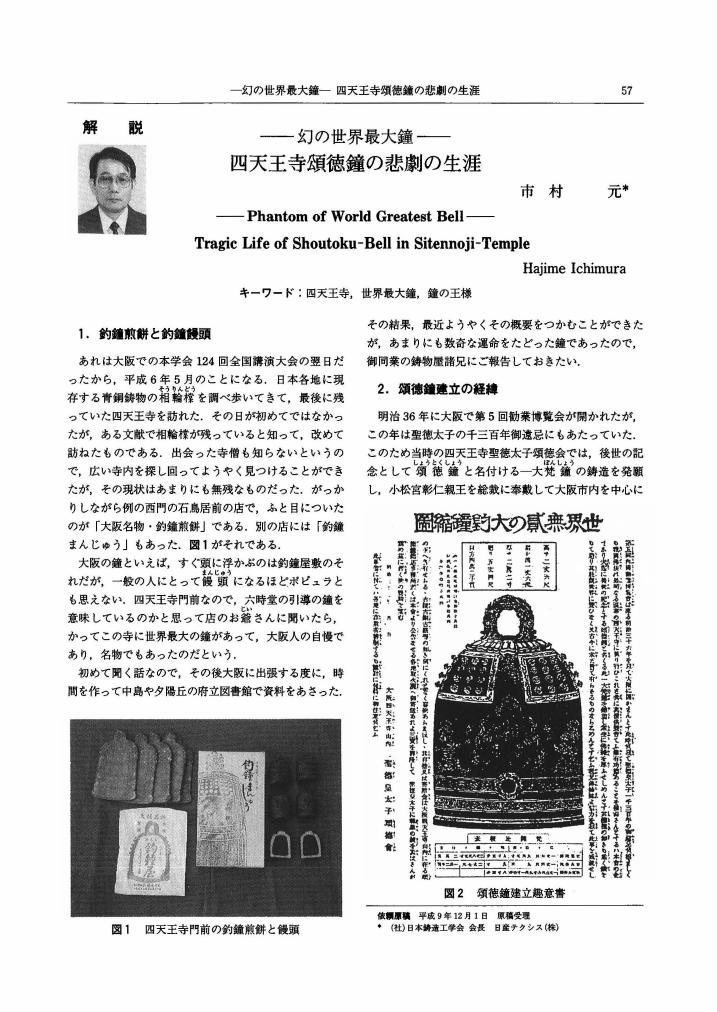

1 0 0 0 OA ―幻の世界最大鐘― 四天王寺頌徳鐘の悲劇の生涯

- 著者

- 市村 元

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.70, no.1, pp.57-62, 1998-01-25 (Released:2014-12-18)

1 0 0 0 OA IX. 我が国の工業用精密鋳造の初期から現在までのいくつかの話題

- 著者

- 錦織 徳郎

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.72, no.12, pp.835-839, 2000-12-25 (Released:2014-12-18)

1 0 0 0 OA 銅合金鋳物の歴史

- 著者

- 岡根 利光

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.6, pp.381-385, 2013-06-25 (Released:2018-01-01)

- 参考文献数

- 14

1 0 0 0 溶融堆積法により作製した角筒積層材の形状制御

- 著者

- 大石 郁 森本 貴幸 水本 将之 香川 明男

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.76, no.7, pp.582-587, 2004

Al-4 mass%Cu alloy was melted in a quartz tube with a small nozzle at the bottom. By pressing the melt surface with argon gas pressure of 0.12 to 0.13 MPa, the alloy melt flowed out through the nozzle onto the copper substrate and was rapidly solidified. A rectangular tube specimen was formed by moving the sub. strate in the X-Y horizontal directions and downwards simultaneously. <br> With increasing the moving speed of the substrate, the thickness of one layer deposited reduced and the spacing between eutectics in the interdendritic regions increased, while the width of the castings remained almost constant. With increasing the number of layers, the cooling rate was decreased, and the weldability between the layers improved. Under optimum conditions, a coexisting solid-liquid region was formed between the layers, resulting in smooth side surface of the castings due to the surface tension of the liquid phase in the region.

1 0 0 0 OA 日本の鉄仏の成立とその鋳造方法

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.69, no.9, pp.767-774, 1997-09-25 (Released:2014-12-18)

- 参考文献数

- 19

- 被引用文献数

- 4

1 0 0 0 OA 高真空ダイカスト法による自動車車体用大型薄肉高延性部品の開発

- 著者

- 浅井 宏一 大杉 泰夫 八下田 健次

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.82, no.12, pp.819-826, 2010-12-25 (Released:2015-04-21)

- 参考文献数

- 3

1 0 0 0 OA 鉄鋳物の歴史 (3)

- 著者

- 中江 秀雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.7, pp.452-462, 2013-07-25 (Released:2018-01-01)

- 参考文献数

- 40

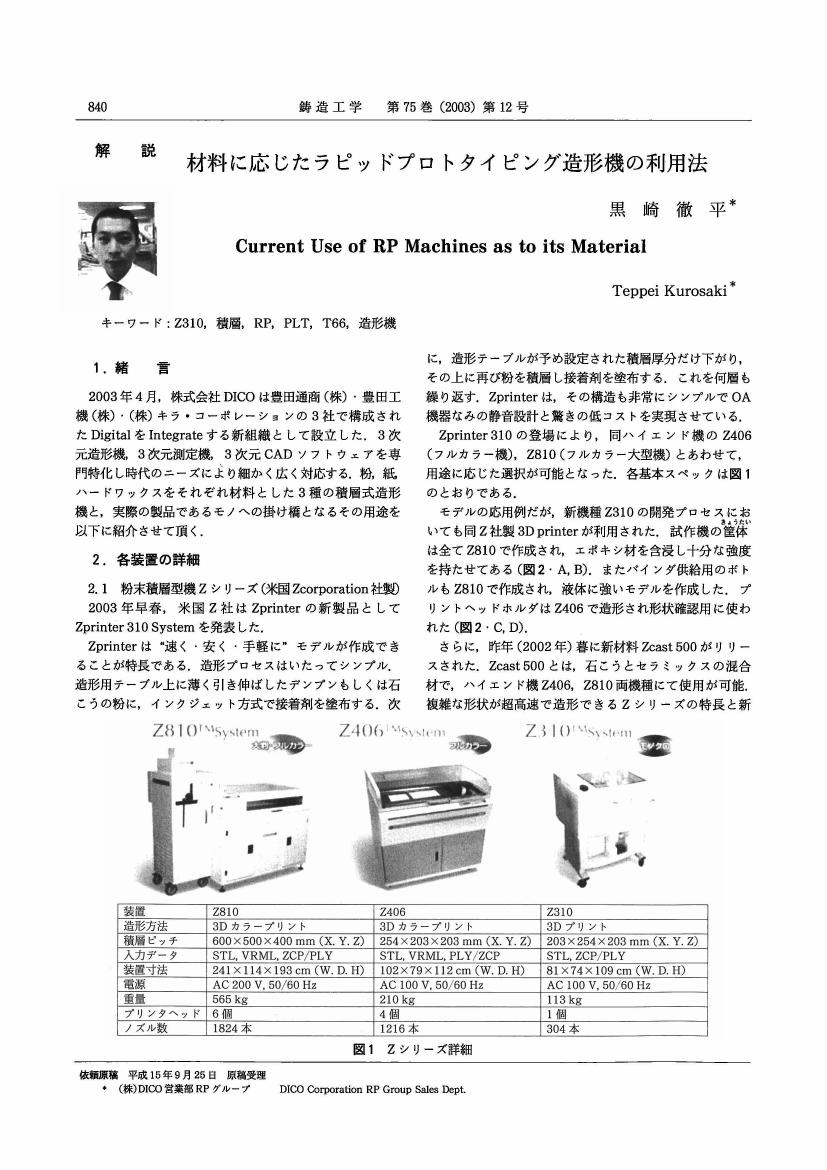

1 0 0 0 OA 材料に応じたラピッドプロトタイピング造形機の利用法

- 著者

- 黒崎 徹平

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.75, no.12, pp.840-845, 2003-12-25 (Released:2015-01-07)

- 被引用文献数

- 1

1 0 0 0 OA 鋳鉄における硬さと各種機械的性質の関係

- 著者

- 菅野 利猛 丸山 善久

- 出版者

- Japan Foundry Engineering Society

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.77, no.12, pp.833-840, 2005-12-25 (Released:2011-02-01)

- 参考文献数

- 29

- 被引用文献数

- 1

Since cast iron is a compound material of steel and graphite, its mechanical properties change according to the amount, form and distribution of the graphite. In this paper, the effects of graphite on the mechanical properties were kept constant. That is, the eutectic graphitization ability (EGA) in gray cast iron was limited to approximately 50%, and in the case of spheroidal graphite cast iron, the nodularity was maintained above 80%. This paper presents a method of determining the mechanical properties from the hardness. First, the relationship between hardness and tensile strength was established and then the relationship between tensile strength and various mechanical properties was determined. From the data thus obtained it was possible to determine the various mechanical properties only from the hardness.

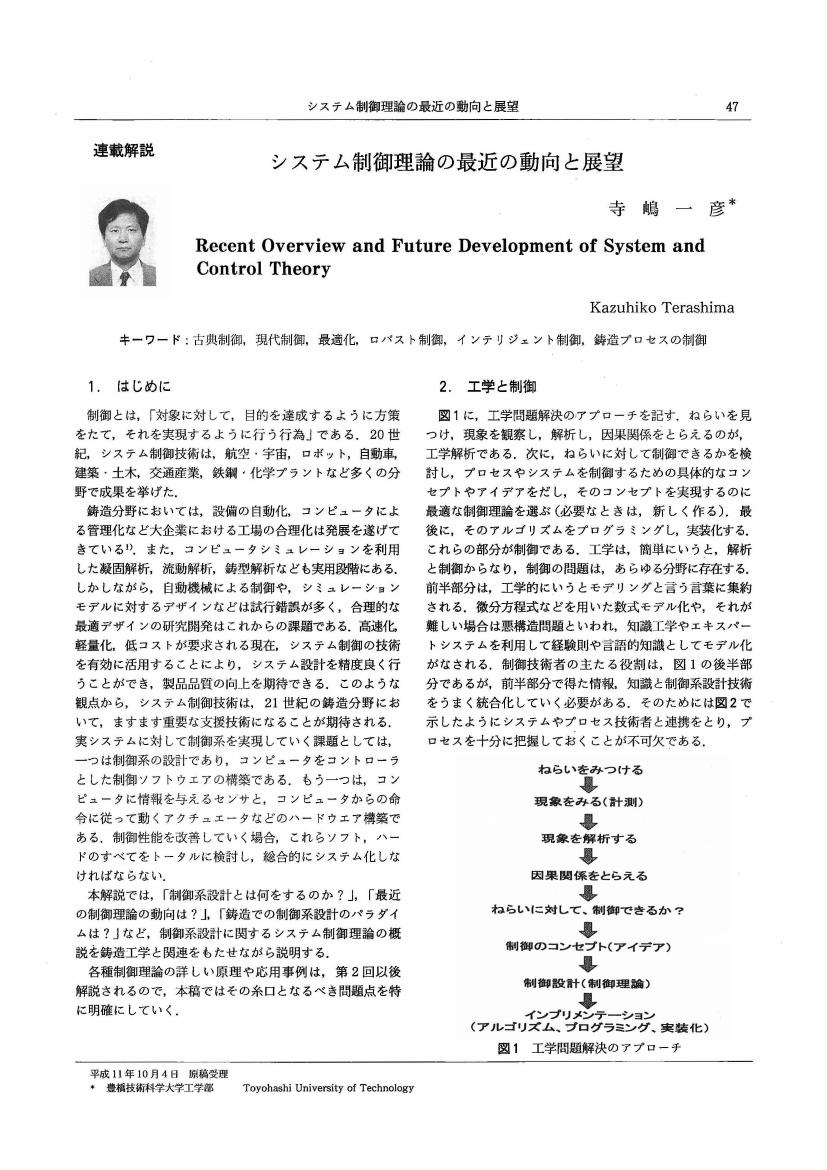

1 0 0 0 OA システム制御理論の最近の動向と展望

- 著者

- 寺嶋 一彦

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.72, no.1, pp.47-56, 2000-01-25 (Released:2014-12-18)

- 参考文献数

- 31

- 被引用文献数

- 3