81 0 0 0 OA 亜共晶Al-Si系合金におけるPと改良処理

- 著者

- 森中 真行

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.8, pp.508-516, 2013-08-25 (Released:2018-01-01)

- 参考文献数

- 65

12 0 0 0 OA 鋳鉄砲の歴史と技術問題

- 著者

- 新井 宏

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.76, no.7, pp.599-606, 2004-07-25 (Released:2015-01-10)

- 参考文献数

- 13

5 0 0 0 OA 明治時代の鋳鉄鋳物

- 著者

- 中江 秀雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 全国講演大会講演概要集 第166回全国講演大会講演概要集 (ISSN:18805388)

- 巻号頁・発行日

- pp.3-4, 2015 (Released:2017-02-01)

- 参考文献数

- 4

5 0 0 0 OA 近代科学導入までの鋳物の歴史と技術

- 著者

- 石野 亨

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳物 (ISSN:00214396)

- 巻号頁・発行日

- vol.67, no.2, pp.118-123, 1995-02-25 (Released:2015-01-21)

- 参考文献数

- 25

5 0 0 0 OA 高燐鋳鉄制輪子の耐磨耗性の研究

- 著者

- 中井 実 斎藤 省三 岡林 邦夫

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳物 (ISSN:00214396)

- 巻号頁・発行日

- vol.32, no.11, pp.765-772, 1960-11-25 (Released:2012-10-30)

- 参考文献数

- 8

Not a small amount is spent on the brake shoes in the expenditures of railway maintenance. And great efforts have been made to cut down this expense. As a result of adapting High Phosphorus Cast Iron Brake Shoes, Kinki Nippon Railway Company has succeeded in cutting down much of the cost, by prolonging its life more than 45% in the year 1959 as compared with that of 1951. This reprot shows the following two points which prove the superiority of High Phosphorus Brake Shoes. These results were obtained both by actual car tests and by laboratorial test. 1. It is possible to say that High Phosporus Cast Iron Brake Shoes of Kinki Nippon Railway Co. specification of about H.B.250 wear almost 20% less than most widely used Low Phosphorus Brake Shoes of about H.B.220. 2. When the effect on the wear of tire wheels is considered, it is also possible to say that when Low Phosphorus Cast Iron Brake Shoes are used, the degree of wear runs parallel with the hardness of the material. But when High Phosphorus Cast Iron Brake Shoes are used no tendency as mentioned above can be found, and it is also made clear that the use of High Phosphorus Cast Iron Brake Shoes is good for both wheels and Brake Shoes.

4 0 0 0 OA 幕末の鋳物の大砲 (補遺)

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.77, no.12, pp.857-862, 2005-12-25 (Released:2015-01-10)

- 参考文献数

- 27

4 0 0 0 OA 国際単位系 (SI) よもやまばなし

- 著者

- 土岐 光

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳物 (ISSN:00214396)

- 巻号頁・発行日

- vol.61, no.2, pp.116-120, 1989-02-25 (Released:2015-01-27)

- 参考文献数

- 3

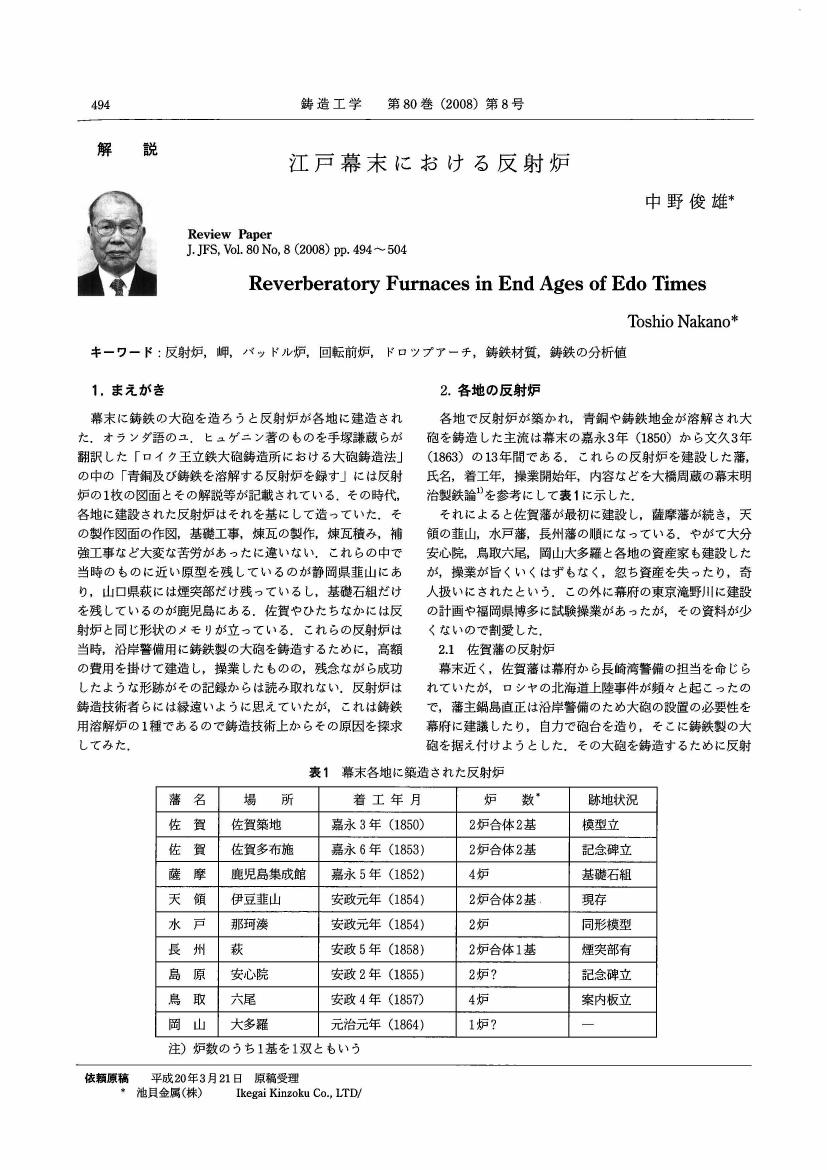

4 0 0 0 OA 江戸幕末における反射炉

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.80, no.8, pp.494-504, 2008-08-25 (Released:2015-01-13)

- 参考文献数

- 47

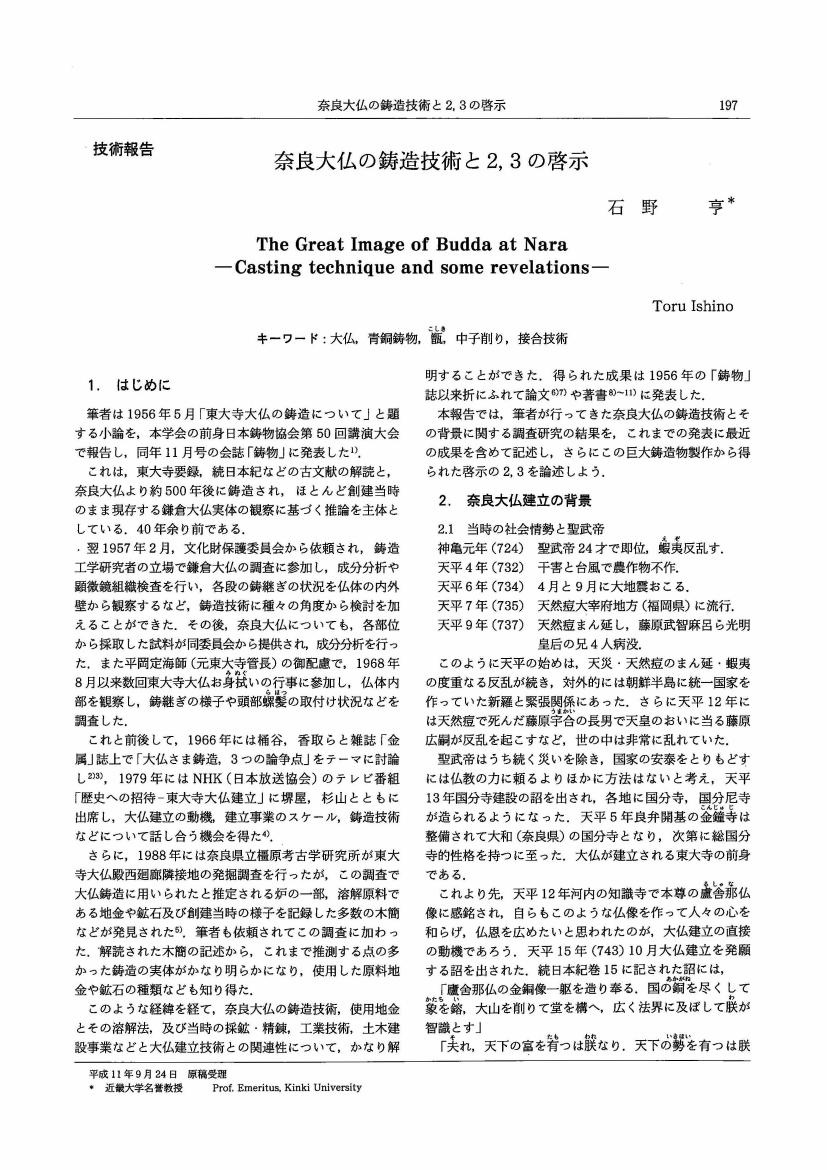

3 0 0 0 OA 奈良大仏の鋳造技術と2, 3の啓示

- 著者

- 石野 亨

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.72, no.3, pp.197-203, 2000-03-25 (Released:2014-12-18)

- 参考文献数

- 20

3 0 0 0 OA アルミニウム鋳物適用による自動車部品の軽量化とその課題

- 著者

- 神戸 洋史 東畑 透

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳物 (ISSN:00214396)

- 巻号頁・発行日

- vol.64, no.12, pp.870-874, 1992-12-25 (Released:2015-01-22)

- 参考文献数

- 7

- 被引用文献数

- 6

2 0 0 0 OA 車体・シャシにおける軽金属鋳物の適用動向と今後の課題

- 著者

- 板倉 浩二

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.76, no.12, pp.957-961, 2004-12-25 (Released:2015-01-10)

- 参考文献数

- 8

- 被引用文献数

- 1

2 0 0 0 OA 鋳鉄鋳物の歴史

- 著者

- 中江 秀雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.4, pp.238-242, 2013-04-25 (Released:2018-01-01)

- 参考文献数

- 24

- 被引用文献数

- 1

2 0 0 0 OA 梵鐘の音色と鋳物つくり

- 著者

- 堀江 孝男

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 全国講演大会講演概要集 第160回全国講演大会講演概要集 (ISSN:18805388)

- 巻号頁・発行日

- pp.147, 2012 (Released:2017-03-01)

2 0 0 0 OA 幕末川口の鋳物師と大砲

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.83, no.3, pp.161-166, 2011-03-25 (Released:2016-01-01)

- 参考文献数

- 19

2 0 0 0 -幻の世界最大鐘-四天王寺頌徳鐘の悲劇の生涯

- 著者

- 市村 元

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 = Journal of Japan Foundry Engineering Society (ISSN:13420429)

- 巻号頁・発行日

- vol.70, no.1, pp.57-62, 1998-01

2 0 0 0 OA 一方向凝固による発電ガスタービン用ニッケル基超合金単結晶動翼の製造

- 著者

- 吉成 明 児玉 英世 平根 輝夫

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.68, no.12, pp.1141-1147, 1996-12-25 (Released:2014-12-18)

- 参考文献数

- 22

- 被引用文献数

- 1

2 0 0 0 OA 複合化による鋳物の高機能化と自動車部品への応用

- 著者

- 梶川 義明

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.68, no.12, pp.1106-1112, 1996-12-25 (Released:2014-12-18)

- 参考文献数

- 23

- 被引用文献数

- 2

2 0 0 0 OA 中世, 近世の鋳鉄の灯ろう (その1) ―歴史, 鋳造方法, 御鋳物師と釣灯ろう

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.75, no.1, pp.52-59, 2003-01-25 (Released:2015-01-07)

- 参考文献数

- 13

2 0 0 0 OA Al-Si-Cu系合金ダイカストのさi張特性に及ぼすけい素含有量の影響

- 著者

- 岡安 光博 西 直美 金沢 憲一

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.70, no.4, pp.266-272, 1998-04-25 (Released:2011-02-01)

- 参考文献数

- 8

- 被引用文献数

- 4

Effects of silicon content are investigated on tensile properties and crack propagation behavior of Al-Si-Cu alloy die castings. The specimens are made by the low velocity shot die casting method. Silicon content of alloy is varied from 8.6 mass % to 15.4 mass %. The tensile strength and the elongation of hypo-eutectic Al-Si alloys are higher than those of hyper-eutectic Al-Si alloys. In the case of hypo-eutectic Al-Si-Cu alloys, a crack propagates through the eutectic phase in inter-dendrite region or α-Al dendrite. In the case of hyper-eutectic silicon alloy, the primary silicon acts as the origin of fracture because primary silicon crystallizes with facet planes. The crack mainly propagates through primary silicon grains or along eutectic silicon. Primary silicon particles tend to segregate in case of low velocity injection casting. This macro-segregation of primary silicon particles deteriorates the mechanical properties. Especially tensile strength decreases with increase of segregation.

2 0 0 0 OA ピアノフレーム用ねずみ鋳鉄の音響特性に及ぼす基地組織の影響

- 著者

- 堤 信久 橋本 長人

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳物 (ISSN:00214396)

- 巻号頁・発行日

- vol.63, no.11, pp.877-882, 1991-11-25 (Released:2011-07-08)

- 参考文献数

- 10

- 被引用文献数

- 1

Two antagonistic properties i. e., higher modulus of elasticity and higher damping capacity are required simultaneously to piano frame with gray iron castings. With a view of improving the quality of present frame, damping capacity, natural frequency and power spectrum of gray cast iron specimen were analyzed by measuring the sound emission when the center of the specimen held at two fixed positions by tungsten wires was hammered on specially designed experimental apparatus. From results obtained, it has been clarified that the changing of matrix to ferritic from pearlitic raises damping capacity, but decreases power spectrum. The changing of matrix to pearlitic or martensitic from ferritic, however, lowers natural frequency which has been thought as the parameter of modulus of elasticity of cast iron.