81 0 0 0 OA 亜共晶Al-Si系合金におけるPと改良処理

- 著者

- 森中 真行

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.8, pp.508-516, 2013-08-25 (Released:2018-01-01)

- 参考文献数

- 65

12 0 0 0 OA 鋳鉄砲の歴史と技術問題

- 著者

- 新井 宏

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.76, no.7, pp.599-606, 2004-07-25 (Released:2015-01-10)

- 参考文献数

- 13

6 0 0 0 OA マグネシウムへのカルシウム添加による酸化被膜特性の変化と溶湯の難燃化

- 著者

- 坂本 満 秋山 茂 萩尾 剛 大城 桂作

- 出版者

- Japan Foundry Engineering Society

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.69, no.3, pp.227-233, 1997-03-25 (Released:2011-02-01)

- 参考文献数

- 10

- 被引用文献数

- 13

The oxide films formed on the molten Mg-Ca alloy were investigated by using an optical microscope, scanning electron microscope (SEM), X-ray diffraction and X-ray photoelectron spectroscopy (XPS) in order to elucidate the effect of Ca addition on the suppression of ignition and burning of the molten metal. While the pure Mg almost always ignited and burnt before melting down, the Ca addition increased the ignition temperature by about 250K, at which a very thin and uniform oxide film was formed on the molten Mg-5mass%Ca alloy, X-ray diffraction and XPS revealed that the oxide film on the Mg-5mass%Ca alloy consisted of two layers ; most upper layer of CaO and mixed layer of MgO-CaO under the CaO layer. The former was very thin and its thickness was independent of the exposure time at 973K in air, but the latter gradually grew with the exposure time. It appeared that the CaO film first formed depressed the volatilization of Mg and the permeation of oxygen gas, which made the molten alloy incombustible and manipulatable in air.

4 0 0 0 OA 幕末の鋳物の大砲 (補遺)

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.77, no.12, pp.857-862, 2005-12-25 (Released:2015-01-10)

- 参考文献数

- 27

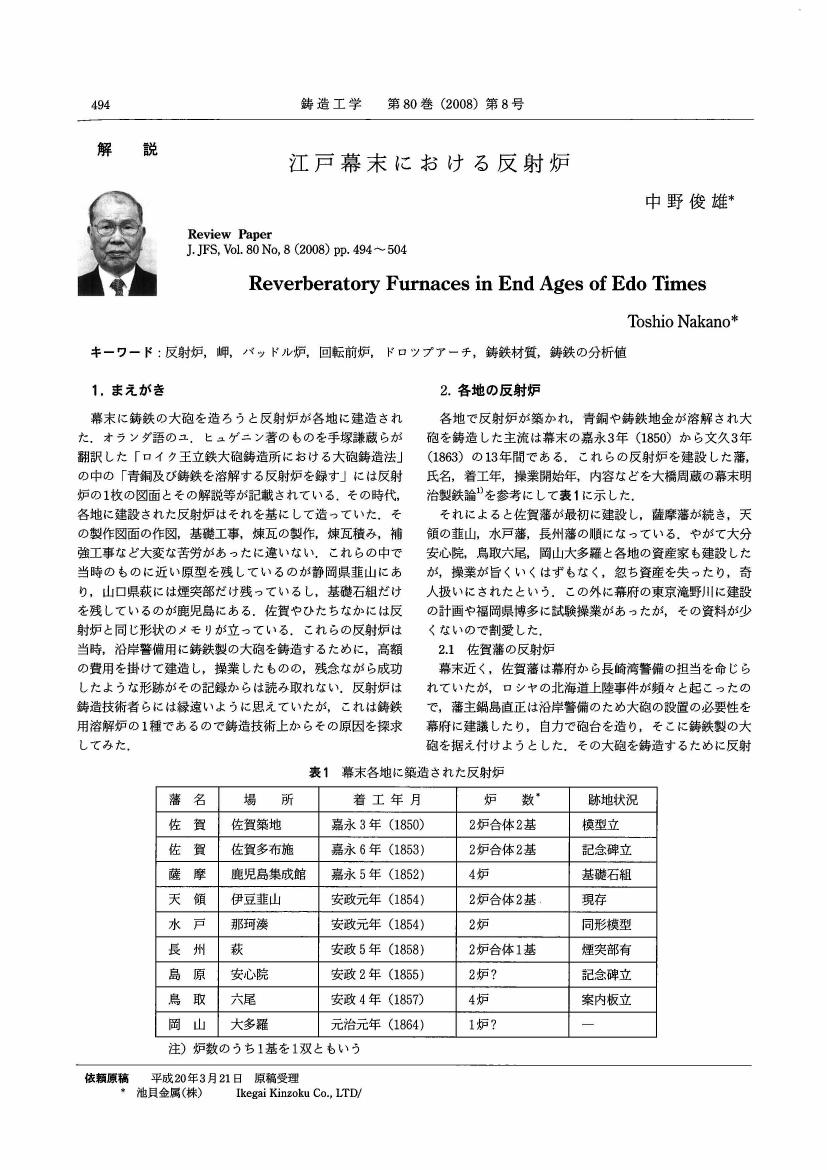

4 0 0 0 OA 江戸幕末における反射炉

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.80, no.8, pp.494-504, 2008-08-25 (Released:2015-01-13)

- 参考文献数

- 47

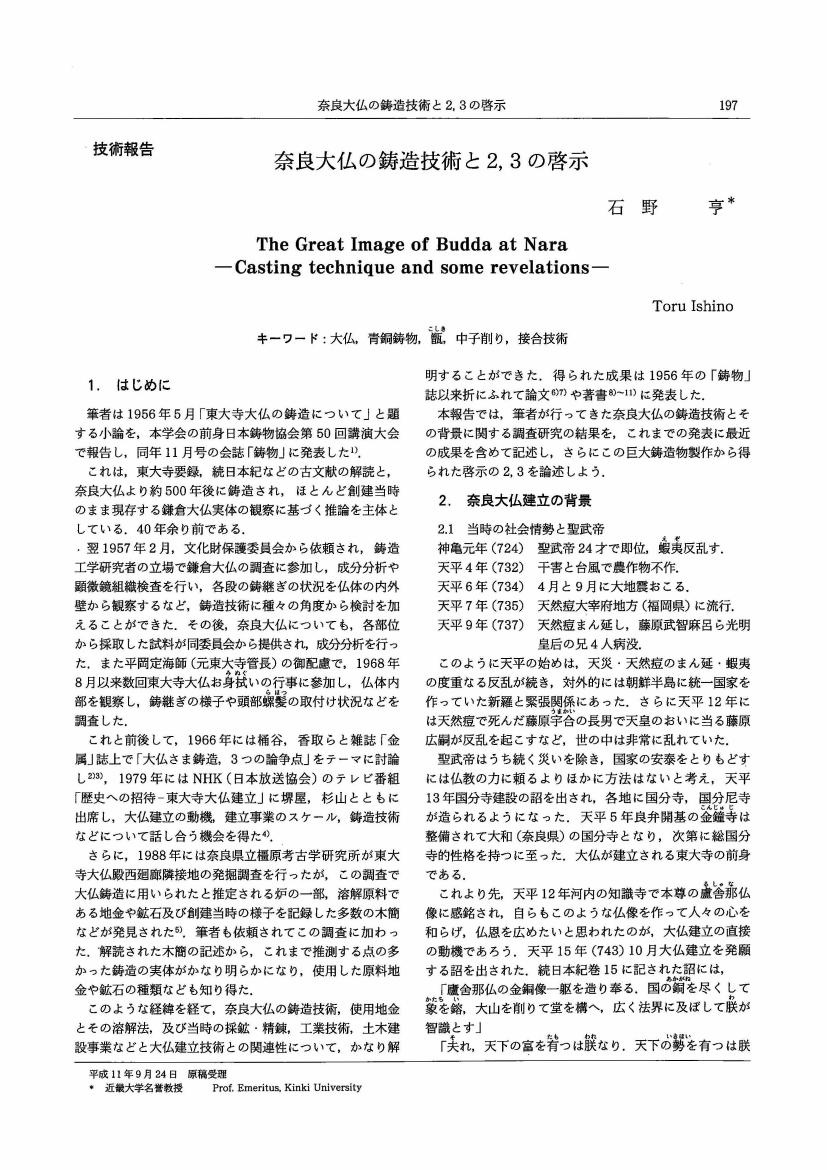

3 0 0 0 OA 奈良大仏の鋳造技術と2, 3の啓示

- 著者

- 石野 亨

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.72, no.3, pp.197-203, 2000-03-25 (Released:2014-12-18)

- 参考文献数

- 20

3 0 0 0 OA ねずみ鋳鉄の被削性に及ぼす枯らし及び応力除去焼なましの影響

- 著者

- 望月 栄治 矢島 善次郎 岸 陽一 清水 謙一 吉田 敏樹

- 出版者

- Japan Foundry Engineering Society

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.78, no.7, pp.345-350, 2006-07-25 (Released:2012-12-25)

- 参考文献数

- 9

- 被引用文献数

- 2

The machinability of gray cast iron is well-knwn to depend on its graphite morphology and matrix structure. However, machinablility occasionally changes even if graphite morphology or matrix structure has not varied. We have therefore focused attention on seasoning and stress relief annealing known to improve machinability without changing the graphite morphology or matrix structure, and carried out machining tests and a series of ultrasonic transmission speed measurements, tensile test, hardness test and structure evaluation while varying the conditions for seasoning and stress relief annealing. As a result, it was found that seasoning applied specimens subject to seasoning greatly vary in machinability despite small changes in the ultrasonic transmission speed, tensile strength, and hardness. Furthermore correlation between ultrasonic transmission speed and amount of machining tool wear was seen in some parts of the stress-relief-annealed specimens with little changes in the optical microstructure and mechanical properties.

2 0 0 0 OA 車体・シャシにおける軽金属鋳物の適用動向と今後の課題

- 著者

- 板倉 浩二

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.76, no.12, pp.957-961, 2004-12-25 (Released:2015-01-10)

- 参考文献数

- 8

- 被引用文献数

- 1

2 0 0 0 OA 鋳鉄鋳物の歴史

- 著者

- 中江 秀雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.4, pp.238-242, 2013-04-25 (Released:2018-01-01)

- 参考文献数

- 24

- 被引用文献数

- 1

2 0 0 0 OA 高りん鋳鉄の凝固組織と摩擦摩耗特性

- 著者

- 髙橋 芳朗 清水 一道 足立 真彦 大城 桂作 片岸 庄史

- 出版者

- Japan Foundry Engineering Society

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.75, no.3, pp.196-201, 2003-03-25 (Released:2011-02-01)

- 参考文献数

- 21

Solidification structures and frictional wear characteristics of high P cast iron containing 3.3 mass%C, 1.7 mass%Si, 1.4 mass%Mn, 0.3-3.0 mass%P, 0.37 mass%Cr, 0.20 mass%V were examined with an image analyzer and original braking test machine. High P cast iron consists of steadite, eutectic cementite and flaky graphite distributed in pearlitic matrix. The addition of higher levels of P increases the steadite, which raises frictional wear resistance against the wheel steel.The wear resistance effectively improved with the addition of about 0.6 mass%P. The braking ability also improved with the addition of more than 1 mass%P at the initial braking speed of above 15 m/s. The contact surface was heated above 990 K at the initial braking speed of 25 m/s and the steadite partially melted or softened, which enhanced the braking ability of cast iron.

2 0 0 0 OA 幕末川口の鋳物師と大砲

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.83, no.3, pp.161-166, 2011-03-25 (Released:2016-01-01)

- 参考文献数

- 19

2 0 0 0 OA 韮山反射炉における鋳鉄製大砲鋳造の可能性

- 著者

- 菅野 利猛

- 出版者

- Japan Foundry Engineering Society

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.78, no.1, pp.23-29, 2006-01-25 (Released:2012-12-25)

- 参考文献数

- 16

Nirayama reverberatory furnace is located at lzunokuni-city of lzu-Peninsula, Shizuoka-Prefecture. Hagi reverberatory furnace exists at Hagi-city, Yamaguchi-Prefecture, but Nirayama's one is the only one architectures that could make cast iron cannon. There are still remained some unknown matters as follows ; (1) whether cast iron was really melted or not, (2) what kind of pig-iron was used, (3) whether blowing of bellows were utilized or not, (4) what kind of fuels were used, (5) where firebricks were made, etc. On this Nirayama reverberatory furnace, the possibility of casting of cannon with iron was investigated, with melting experiment from a foundry engineering standpoint. The followings are presumed from the investigation. Firstly, at least three cannons of cast iron were manufactured. Secondly, high Silicon contained pig-iron could not be available, so casting of iron cannon was not well done. Finally, the melting time by reverberatory furnace, from preheating to pouring completion, was about eight hours and melting temperature was above 1623K.

2 0 0 0 OA 一方向凝固による発電ガスタービン用ニッケル基超合金単結晶動翼の製造

- 著者

- 吉成 明 児玉 英世 平根 輝夫

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.68, no.12, pp.1141-1147, 1996-12-25 (Released:2014-12-18)

- 参考文献数

- 22

- 被引用文献数

- 1

2 0 0 0 OA 複合化による鋳物の高機能化と自動車部品への応用

- 著者

- 梶川 義明

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.68, no.12, pp.1106-1112, 1996-12-25 (Released:2014-12-18)

- 参考文献数

- 23

- 被引用文献数

- 2

2 0 0 0 OA 中世, 近世の鋳鉄の灯ろう (その1) ―歴史, 鋳造方法, 御鋳物師と釣灯ろう

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.75, no.1, pp.52-59, 2003-01-25 (Released:2015-01-07)

- 参考文献数

- 13

2 0 0 0 OA Al-Si-Cu系合金ダイカストのさi張特性に及ぼすけい素含有量の影響

- 著者

- 岡安 光博 西 直美 金沢 憲一

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.70, no.4, pp.266-272, 1998-04-25 (Released:2011-02-01)

- 参考文献数

- 8

- 被引用文献数

- 4

Effects of silicon content are investigated on tensile properties and crack propagation behavior of Al-Si-Cu alloy die castings. The specimens are made by the low velocity shot die casting method. Silicon content of alloy is varied from 8.6 mass % to 15.4 mass %. The tensile strength and the elongation of hypo-eutectic Al-Si alloys are higher than those of hyper-eutectic Al-Si alloys. In the case of hypo-eutectic Al-Si-Cu alloys, a crack propagates through the eutectic phase in inter-dendrite region or α-Al dendrite. In the case of hyper-eutectic silicon alloy, the primary silicon acts as the origin of fracture because primary silicon crystallizes with facet planes. The crack mainly propagates through primary silicon grains or along eutectic silicon. Primary silicon particles tend to segregate in case of low velocity injection casting. This macro-segregation of primary silicon particles deteriorates the mechanical properties. Especially tensile strength decreases with increase of segregation.

1 0 0 0 OA 鋳造シミュレーションソフトTopCAST

- 著者

- 安藤 彰祐 羽座 健二

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.86, no.12, pp.946-950, 2014-12-25 (Released:2019-01-01)

- 参考文献数

- 8

- 被引用文献数

- 1

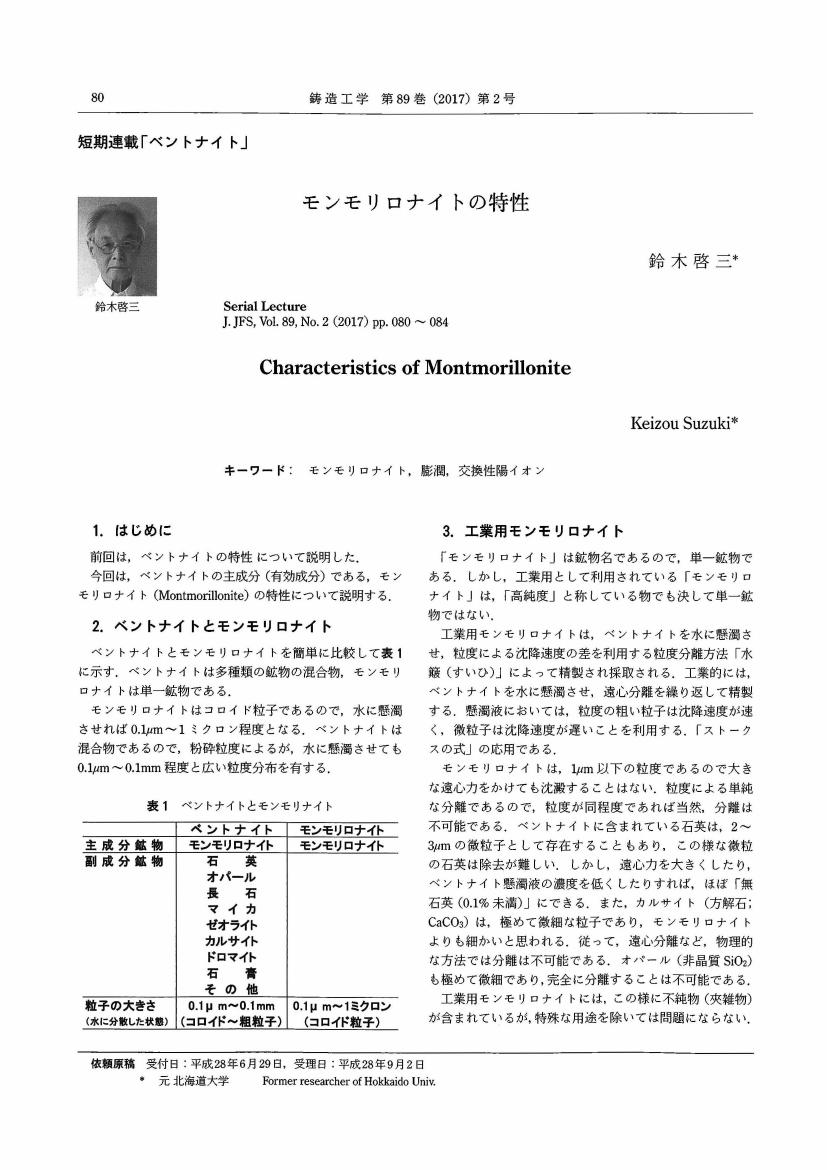

1 0 0 0 OA モンモリロナイトの特性

- 著者

- 鈴木 啓三

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.89, no.2, pp.80-84, 2017-02-25 (Released:2022-01-01)

- 参考文献数

- 9

1 0 0 0 OA 幕末の鋳物の大砲

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.72, no.2, pp.117-122, 2000-02-25 (Released:2014-12-18)

- 参考文献数

- 23

- 被引用文献数

- 2

1 0 0 0 OA NC切削加工による高速鋳型作製技術

- 著者

- 岩田 靖 岩堀 弘昭 内藤 国雄 大庫 和孝

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.75, no.12, pp.870-874, 2003-12-25 (Released:2015-01-07)

- 参考文献数

- 3

A sand block was developed for direct machining with a numerical contorol machine. The sand block has a cutting resistance of 30N which is as small as 1/300 that of steel block. Especially, sand blocks made of fine spherical particles have better dischargeability and dimensional accuracy, thus providing excellent machinability. Direct machining of a sand block reduces molding time. For example, it takes merely four hours to complete the mold for the cylinder head cover of an automobile engine.