1 0 0 0 OA 奈良時代における絹生産の動向

- 著者

- 三木 六男

- 出版者

- 日本シルク学会

- 雑誌

- 日本シルク学会誌 (ISSN:18808204)

- 巻号頁・発行日

- vol.18, pp.83-90, 2010 (Released:2011-03-18)

- 参考文献数

- 33

The results of this study were obtained from an investigation of the archives of silk production in relation to the tax on silk during the Nara period in the 8th century. The silk producing districts ranged from the Kanto region to Shikoku and Kyushu, and there were over 40 silk producing districts in the middle of the 8th century. Three main kinds of silk were produced, namely Ashiginu fabrics, silk fiber and floss silk, and there were 15 districts producing Ashiginu fabrics (42%). The districts producing the largest amount of silk annually were Echu (floss silk), Inaba (Ashiginu fabrics, silk fiber and floss silk) and Iwami (floss silk). The districts that were the largest annual producers of the three different types of silk were Mikawa (Ashiginu fabrics), Inaba (silk fiber) and Echu (floss silk). Mulberries were cultivated in Echu district in 759 A.D. and this was the only example of mulberry field cultivation in the Nara period. Two hamlets in the Echizen district in 740 A.D. were the only locations where sericulture was practiced in the Nara period. These were produced against the tax of silk by Ashiginu fabrics and floss silk. And the weights of these products were 2.4 and 1.8kg, respectively, and the used cocoon weights were 40 and 30 kg, respectively, from a trial calculation for harvesting cocoons. Moreover, the total harvesting cocoon were about 80 and 90 kg by addition to Ashiginu fabrics. (E mail: mutsuo_miki@yahoo.co.jp)

1 0 0 0 OA 絹鳴りからみた絹の音響特性

- 著者

- 諸岡 英雄

- 出版者

- 日本シルク学会

- 雑誌

- 日本シルク学会誌 (ISSN:18808204)

- 巻号頁・発行日

- vol.17, pp.68-69, 2008 (Released:2009-03-05)

- 参考文献数

- 5

1 0 0 0 OA 南インドの繭市場を訪ねる~活発な繭取り引きの現場を見たい~

- 著者

- 上岡 和江

- 出版者

- 日本シルク学会

- 雑誌

- 日本シルク学会誌 (ISSN:18808204)

- 巻号頁・発行日

- vol.25, pp.101-108, 2017 (Released:2017-03-17)

1 0 0 0 明治・大正時代の日本の養蚕・蚕糸業と「養蚕唱歌」

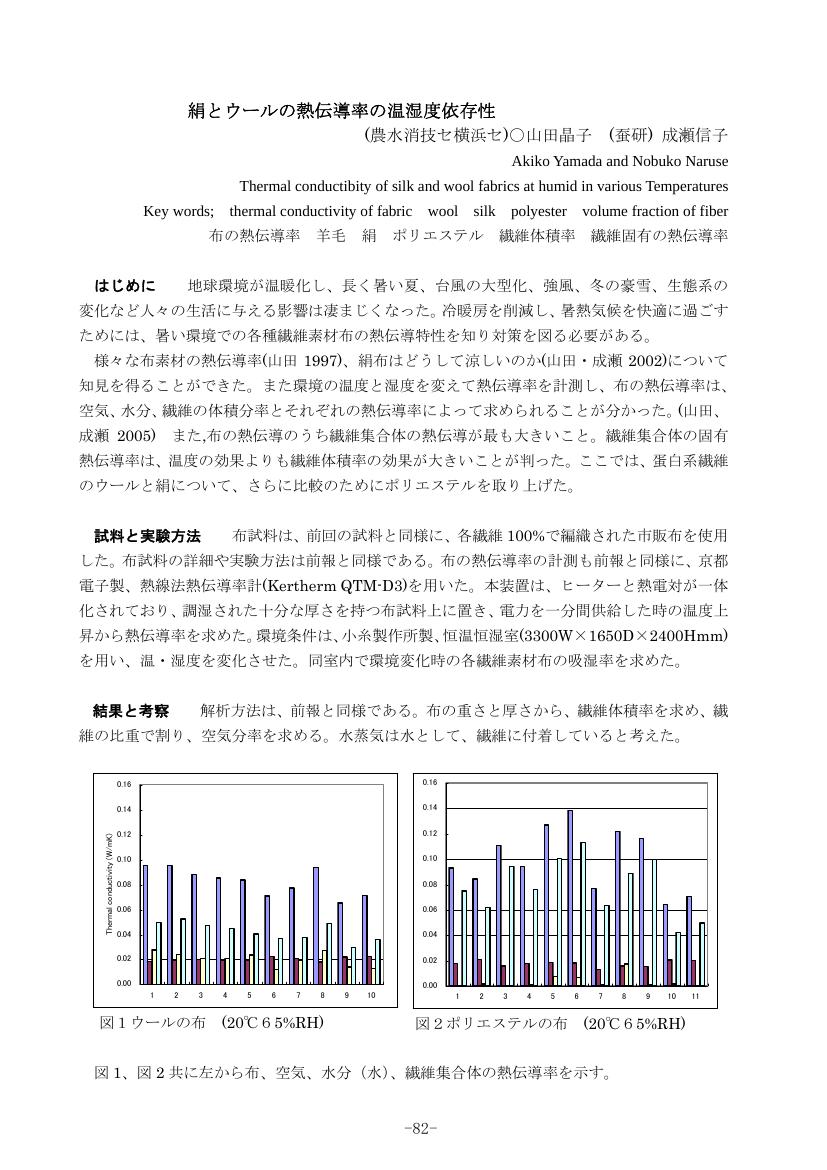

1 0 0 0 OA 絹とウールの熱伝導率の温湿度依存性

1 0 0 0 五泉織物産地における戦後の展開過程と生産構造の特徴

- 著者

- 張 娟 横山 岳 数納 朗 范 作冰 小野 直達

- 出版者

- The Japanese Society of Silk Science and Technology

- 雑誌

- 日本シルク学会誌 (ISSN:18808204)

- 巻号頁・発行日

- vol.19, pp.3-8, 2011

The purpose of this study was to understand how resources in the Gosen textile production area were deployed in the postwar period and the area's production structure, so as to support the continued survival of local small and medium-size textile producers. We interviewed members of Gosen weaving cooperatives and a representative weaving company. The scale of production in the Gosen area has reduced gradually since 1975, as shown in the number of weaving companies, production quantity, and shipments: that is, the production base has been weakening. Both high-ranking and low-ranking companies have coexisted in the area. Respondents emphasized that Gosen weaving companies have maintained a traditional technique, called <i>Nureyoko</i>. These findings highlight two factors necessary for the continued survival of weaving in Gosen: it is necessary to build a new production system as soon as possible, and to maintain traditional techniques and high-quality <i>Sirokiji</i>, while at the same time developing new weaving goods which consumers want. ( E-mail: zhangjuanrq@hotmail.co.jp)

1 0 0 0 西陣織物産地における金襴部門の地位と産業構造の特徴

- 著者

- 張 娟 范 作冰 横山 岳 数納 朗 小野 直達

- 出版者

- The Japanese Society of Silk Science and Technology

- 雑誌

- 日本シルク学会誌 (ISSN:18808204)

- 巻号頁・発行日

- vol.19, pp.9-14, 2011

The purpose of this study was to clarify the position of the <i>kinran</i> sector and its production and marketing structures in the Nishijin textile production area in order to revitalize the <i>kinran</i> sector. We interviewed members of Nishijin weaving cooperatives and a representative <i>kinran</i> weaving company. The position of the <i>kinran</i> sector has been rising, but shipments have decreased since 1975. Labor has become better organized in both <i>kinran</i> weaving companies and related companies, but <i>kinran</i> companies remain small-scale family businesses. The market is predominantly temples, so demand is small. Three factors could revitalize the <i>kinran</i> sector: to catch demand from temples as soon as possible, to cooperate with all temples in both production and marketing, and to assist sales promotion with Nishijin weaving cooperatives. (Juan Zhang, Email:zhangjuanrq@hotmail.co.jp)

1 0 0 0 OA 和楽器弦ができるまで

- 著者

- 金子 敦子

- 出版者

- 日本シルク学会

- 雑誌

- 日本シルク学会誌 (ISSN:18808204)

- 巻号頁・発行日

- vol.17, pp.70-71, 2008 (Released:2009-03-05)

1 0 0 0 OA 植物染料の抗菌性について (2)

- 著者

- 三村 温子 中島 健一

- 出版者

- 日本シルク学会

- 雑誌

- 日本シルク学会誌 (ISSN:18808204)

- 巻号頁・発行日

- vol.11, pp.186-187, 2002-12-02 (Released:2013-02-16)