15 0 0 0 OA 1.軸系電位と防食にかかわる概説

- 著者

- 太田 元久 畑井 洋一郎

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.18, no.2, pp.74-82, 1983-02-01 (Released:2010-05-31)

- 参考文献数

- 5

15 0 0 0 OA ジェットフォイルとウォータージェットポンプ

- 著者

- 中村 荘六 鍋潟 鋭而

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.29, no.11, pp.810-822, 1994-11-01 (Released:2010-05-31)

13 0 0 0 OA 渋谷文庫にみる軸系技術の変遷*

- 著者

- 福留 理夫

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.34, no.1, pp.6-14, 1999-01-01 (Released:2010-05-31)

- 参考文献数

- 5

12 0 0 0 OA 舶用ガスタービンMFT8

- 著者

- 上松 一雄 森 秀隆 間瀬 正隆

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.31, no.11, pp.808-816, 1996-11-01 (Released:2010-12-08)

- 参考文献数

- 7

Mitsubishi Heavy Industies, Ltd. developed high-efficient, high-reliable and compact, ‘Marine Gas Turbine MFT 8’ for Goverment sponsored project ‘Techno Super Liner’ which is getting much attention as Marine Super Express. As a result we succeeded Sea Trial in '94 and real transportation test including night operation in '95 by using a experimental ship ‘TSL-A70’ which were developed by Mitsubishi and Mitsui. This paper reports these results and the future of Marine Gas Turbine.

12 0 0 0 OA 1994年における舶用機関技術の進歩

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.30, no.7, pp.489-527, 1995-07-01 (Released:2010-05-31)

10 0 0 0 OA 日本の舶用蒸気タービン発達史 (1945年まで)

- 著者

- 日本舶用機関史編集委員会

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.28, no.1, pp.4-18, 1993-01-01 (Released:2011-01-31)

- 参考文献数

- 27

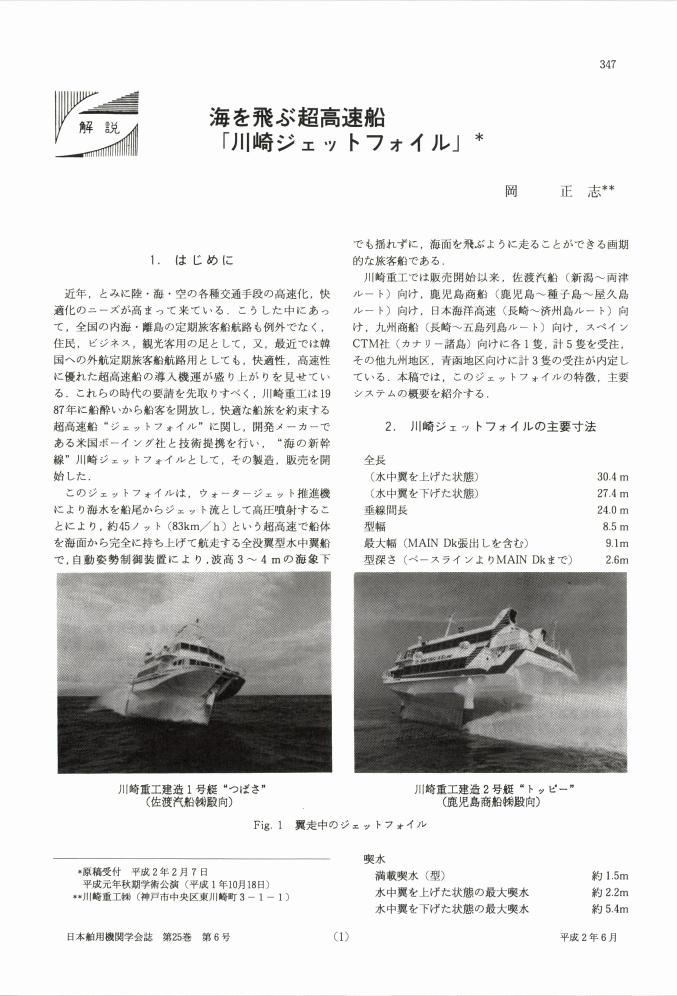

9 0 0 0 OA 海を飛ぶ超高速船「川崎ジェットフォイル」

- 著者

- 岡 正志

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.25, no.6, pp.347-352, 1990-06-01 (Released:2010-05-31)

9 0 0 0 OA 日本の艦艇・商船の内燃機関技術史 (第2次世界大戦終結まで)

- 著者

- 藤田 秀雄 村田 正之 大原 信義 片岡 敏道

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.30, no.7, pp.475-488, 1995-07-01 (Released:2010-05-31)

8 0 0 0 1994年における舶用機関技術の進歩

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.30, no.7, pp.489-527, 1995

6 0 0 0 OA 舶用造水装置

- 著者

- 高見 朝成

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.8, no.10, pp.736-744, 1973 (Released:2010-05-31)

- 参考文献数

- 3

6 0 0 0 OA アクティブ排気消音システムの研究開発 (その1)

- 著者

- 米澤 徹 大久保 稔 石田 慎一郎 苅田 広

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.35, no.5, pp.309-317, 2000-05-01 (Released:2010-05-31)

- 参考文献数

- 7

In recent years, the demand for reduction of noise emitted into the environment has strongly increased for preventing noise pollution. For example, the ships, which have high noise levels, are refused entry to ports at night. As the major contributor of emitted noise to the environment is exhaust noise, it is necessary to reduce the exhaust noise as much as possible.Conventionally, such as passive silencer technique, a larger silencer is needed in order to achieve larger noise reduction. Therefore, because of the limitation of space, it was actually difficult to reduce the exhaust noise of the ship.For reducing the exhaust noise as well as minimizing the occupied space, the active noise cancellation technique was applied to the exhaust noise silencer for a diesel engine. In order to reduce the exhaust noise efficiently, at first, the acoustic behavior in an exhaust pipe was calculated by the boundary element method. At first, for optimizing the length of pipes and the positions of microphones and speakers, the active exhaust noise cancellation system (AENC) could be applied to the main engine for marine use. Also, by applying acoustic resonance aggressively, the AENC with only one speaker system could be developed for auxiliary engine.The Filtered-X LMS algorithm with a signal filter was used for adaptive control. Finally, by assembling a passive silencer for high frequency noise, the active exhaust noise silencer was developed. Then the exhaust noise was drastically reduced to less than 65dB (A) at lm from the outlet.

6 0 0 0 巡航タービンによるVLCCの減速運航について

- 著者

- 桑田 宏策 上中 昂和

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.14, no.6, pp.465-467, 1979

5 0 0 0 OA 深海潜水船の最新技術

- 著者

- 清水 徹

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.21, no.2, pp.105-111, 1986 (Released:2010-05-31)

- 参考文献数

- 26

5 0 0 0 OA 4.「ジェットフォイル」の自動姿勢制御システム

- 著者

- 今村 博

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.27, no.2, pp.169-175, 1992-02-01 (Released:2010-05-31)

5 0 0 0 OA 海上保安庁所属船艇の信頼性維持体制

- 著者

- 力安 貞直 島田 伸和

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.28, no.2, pp.60-63, 1993-02-01 (Released:2010-05-31)

- 参考文献数

- 5

5 0 0 0 OA 海水管系の犠牲管の装備基準

- 著者

- 機関研究委員会機関第三研究部会

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.19, no.5, pp.421-424, 1984-05-01 (Released:2010-05-31)

- 参考文献数

- 5

Recently, anti-corrosive pipe lined with rubber or polyethylene is used for sea water system, especially sea water cooling system in many vessels.In such system using lining pipe, pipes without lining are very often installed near pumps and heat exchangers in order to protect them. They are called sacrificial pipe.This paper shows the effect of the sacrificial pipe and gives the instruction for its installation. The instruction is based on two activities of the sacrificial pipe, one of which is sacrificial anode and the other is supplier of ferrous ion.

5 0 0 0 OA ボイラ特集号 随想

- 著者

- 石谷 清幹 武田 康生 久保田 芳雄 幸田 功 吉見 豊 石川 哲司

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.10, no.1, pp.1-11, 1975-01-01 (Released:2010-05-31)

- 被引用文献数

- 2

5 0 0 0 OA 船舶の省エネ付加物とその動向

- 著者

- 佐々木 紀幸

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.33, no.9, pp.623-633, 1998-09-01 (Released:2010-05-31)

- 参考文献数

- 43

5 0 0 0 OA 1988年における舶用機関技術の進歩

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.24, no.7, pp.187-224, 1989-07-01 (Released:2010-05-31)

5 0 0 0 OA 渋谷隆太郎氏を囲んで

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.8, no.7, pp.405-412, 1973 (Released:2010-05-31)