1 0 0 0 OA 帯電現象と材料表面

- 著者

- 村田 雄司

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.56, no.8, pp.436-436, 2005 (Released:2006-03-29)

- 参考文献数

- 16

- 被引用文献数

- 2 4

1 0 0 0 OA 溶融亜鉛めっき鋼板の歴史

- 著者

- 久松 敬弘

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 金属表面技術 (ISSN:00260614)

- 巻号頁・発行日

- vol.34, no.7, pp.354-360, 1983-07-01 (Released:2009-10-30)

- 参考文献数

- 16

- 被引用文献数

- 3 3

1 0 0 0 OA 水の基礎化学

- 著者

- 片岡 洋右

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.51, no.2, pp.128-133, 2000-02-01 (Released:2009-10-30)

- 参考文献数

- 14

1 0 0 0 OA フルカラー無機ELディスプレイの現状と将来の展望

- 著者

- 伊東 純一

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.56, no.5, pp.260-260, 2005 (Released:2005-11-28)

- 参考文献数

- 19

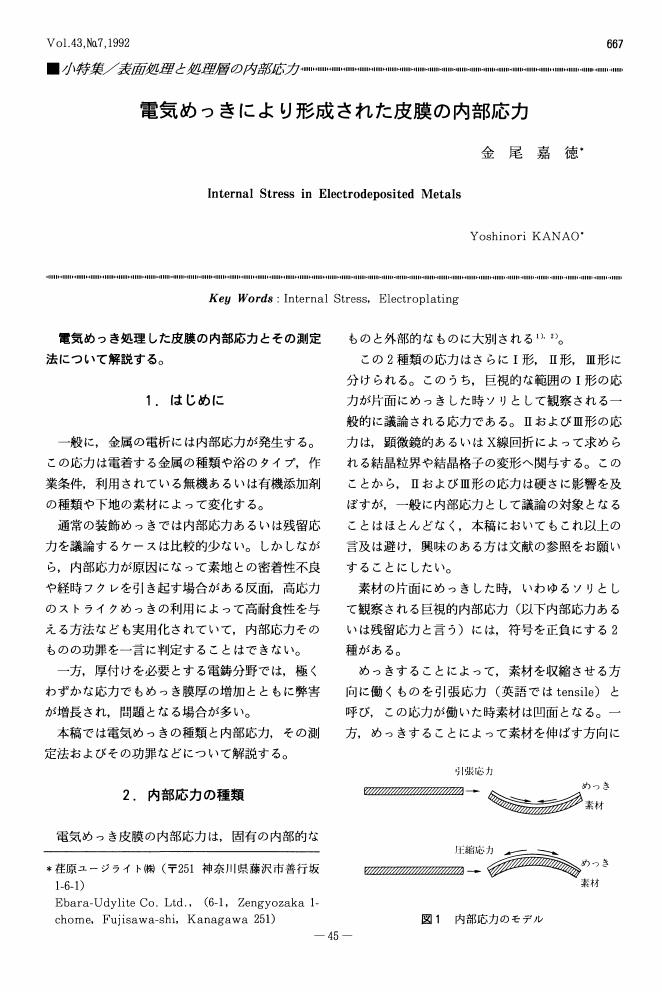

1 0 0 0 OA 電気めっきにより形成された皮膜の内部応力

- 著者

- 金尾 嘉徳

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.43, no.7, pp.667-670, 1992-07-01 (Released:2009-10-30)

- 参考文献数

- 11

- 被引用文献数

- 2

1 0 0 0 OA 燃焼炎を用いた大気中でのダイヤモンド合成とその応用

- 著者

- 広瀬 洋一 坂本 明徳 藤田 信行

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.40, no.1, pp.104-105, 1989-01-01 (Released:2009-10-30)

- 参考文献数

- 5

- 被引用文献数

- 3 1

1 0 0 0 OA スタッドピン型垂直引張試験機による密着性測定

- 著者

- 大山 健

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.58, no.5, pp.292-292, 2007 (Released:2007-11-27)

- 参考文献数

- 2

- 被引用文献数

- 2 2

1 0 0 0 OA タングステンメッキ析出機構の研究

- 著者

- 乾 忠孝

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 金属表面技術 (ISSN:00260614)

- 巻号頁・発行日

- vol.8, no.7, pp.224-228, 1957-11-30 (Released:2009-10-30)

- 参考文献数

- 1

- 被引用文献数

- 1

The mechanism of tungsten plating was investigated and the following results were obtained.1) The decomposition potential of tungsten in Na2WO4 solution is more negative than that of hydrogen, and its accurate decomposition potential could not be obtained from its current density potential curves. Of course, its decomposition potential differs according to the kind of cathodic metals.2) In the constant current density electrolysis, the cathodic potential is elevated with the progress of the electrolysis.3) In the constant potential electrolysis (e.g. 0.124V for Pt-W poles), a beautiful deposition of whitish grey metalic luster is obtained, with a little higher potential (e.g. 0.184V for Pt-W poles) a reddish brown metalic luster, and with a much higher potential black and spongy. With the lower potential, nothing is obtained but the generation of hydrogen.4) By the electron diffraction analysis, it is found that the whitish grey metalic deposition is chiefly composed of W-oxide (not WO2 or WO3) with a little metalic tungsten.5) When the Na2WO4 solution is electrolised, the tungsten becomes special cation of its oxide. When the solution is electrolysed with constant cathodic potential, the tungsten is regularly obtained as metalic deposition on the cathode. This deposition is chiefly composed of lower oxide tungsten (such as WO) containing a little tungsten. So, the resistance increases and the potential is elevated with the progress of electrolysis.As the potential is gradually elevated, the deposition grows rich in higher oxide and finally becomes to be spongy.After all, it might be concluded that, in order to obtain thick deposition from Na2WO4 solution, the amount of metallic ions in the solution is to be restricted and hydrogen ions increased, or some other reducing regents more powerful than hydrogen are to be used, or the alloy-plating is to be applyed.

1 0 0 0 OA プリント配線板技術の現状と将来

- 著者

- 中井 通 國嶋 眞文

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.45, no.7, pp.668-672, 1994-07-01 (Released:2009-10-30)

- 参考文献数

- 26

1 0 0 0 OA 鉄を電解加工した時の陽極溶解, 加工条件, 加工性について

- 著者

- 江口 晴一郎

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 金属表面技術 (ISSN:00260614)

- 巻号頁・発行日

- vol.15, no.7, pp.249-255, 1964-07-20 (Released:2009-10-30)

- 参考文献数

- 13

Many industrial merits are found in electro-chemical machining of metals as compared with other conventional methods of metal working though the accuracy of the worked piece by electro- chemical machining is not very satisfactory.The author investigated anodic dissolution, working condition, and workability of removing iron in electro-chemical machining and the following experimental results were obtained:(1) Electro-chemical machining of iron could be successfully performed when halogen compounds were used for electrolyte.(2) The accuracy of worked piece was variant depending on distance between electrodes, nature of electrolyte and chemical composition and microstructure of working material.Electro-chemical machining of irons of almost same composition in sodium chloride solution gave variable results of anodic polarization potential depending upon the microstructure of working material.When anodic polarization potential was lower, both current efficiency and penetration rate were higher and also the removing was more effective.

1 0 0 0 OA アルミニウムのアルカリ性浴陽極酸化皮膜に及ぼす電流波形および周波数の影響

- 著者

- 野口 駿雄 吉村 長蔵

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.40, no.4, pp.584-589, 1989-04-01 (Released:2009-10-30)

- 参考文献数

- 4

Specimens were electrolyzed by AC with various current waveform (sine wave, square wave and saw-tooth wave) and frequencies (10∼kHz) in NH4OH-NH4F system bath and NaOH-H2O2 system bath at a current density of 2A/dm2 for 30min, at 20°C.The use of a 10Hz square waveform resulted in a formation of a thicker film (5∼6μm) in both the NH4OH-NH4F and NaOH-H2O2 system baths. In the former case (NH4OH-NH4F system bath), film thickness decreased at frequencies above about 200Hz, reaching about 1∼2μm at frequencies above 1kHz. In the latter case (NaOH-H2O2 system bath), film thickness decreased according to increase of frequency, and it was about 0.5∼1μm in thickness at high frequency more than about 500Hz.The films anodized in the NaOH-H2O2 system bath with square current waveform was much rougher than those fromed using with sine or saw-tooth waveforms and larger pores were observed by microscope.Many large pores were observed in the coatings formed at high frequency and those formed in NaOH-H2O2 system bath had larger pores than those fromed in NH4OH-NH4F system bath.

1 0 0 0 OA 低温溶融塩・室温イオン液体を用いるAlおよびAl合金電析

- 著者

- 上田 幹人 宇井 幸一

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.60, no.8, pp.491-491, 2009-08-01 (Released:2010-03-03)

- 参考文献数

- 59

- 被引用文献数

- 6 8

1 0 0 0 OA 炎焼入レの問題点

- 著者

- 佐々木 敏美 中村 英紀

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 実務表面技術 (ISSN:03682358)

- 巻号頁・発行日

- vol.19, no.2, pp.70-76, 1972-02-01 (Released:2009-10-30)

1 0 0 0 OA 炎焼入レについて

- 著者

- 竹内 栄一

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 金属表面技術 (ISSN:00260614)

- 巻号頁・発行日

- vol.21, no.8, pp.443-449, 1970-08-01 (Released:2009-10-30)

1 0 0 0 OA 裁判所から見た発明と特許権の及ぶ範囲

- 著者

- 富岡 英次

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.57, no.5, pp.337-337, 2006 (Released:2006-11-21)

- 参考文献数

- 5

1 0 0 0 OA 液体バフ研摩剤 固体研摩剤の領域に食い込むか?

- 著者

- 小林 日出男

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 金属表面技術 現場パンフレット (ISSN:03685527)

- 巻号頁・発行日

- vol.8, no.12, pp.22-24, 1961-12-15 (Released:2009-10-07)

1 0 0 0 OA 浅草寺 五重塔のアルミ合金瓦について

- 著者

- 原 正育

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 実務表面技術 (ISSN:03682358)

- 巻号頁・発行日

- vol.21, no.10, pp.478-481, 1974-10-01 (Released:2009-10-30)

1 0 0 0 OA 水和酸化クロム皮膜の検討

- 著者

- 井川 進

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 金属表面技術 (ISSN:00260614)

- 巻号頁・発行日

- vol.22, no.3, pp.117-121, 1971-03-01 (Released:2009-10-30)

- 参考文献数

- 5

The following experimental results were obtained by chemical analysis, DTA, TGA, X-ray diffractiometry, using infrared spectrometer, etc.(1) The hydrated chromium oxide film electrolytically formed on cathode from aqueous solution of single chromic acid was composed of chromium hydroxide with chromic anhydride adsorbed thereon.(2) The water content on chromium hydroxide in hydrated chromium oxide film was 33.5% and content of chromium anhydride adsorbed on the film was 16.5%(3) The approximate structural formula of the hydrated chromium oxide film was as follows:(CrO3)(Cr2O3)2⋅10H2O

1 0 0 0 OA 過酸化水素系の化学研磨の原理と応用

- 著者

- 川村 利光

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.57, no.11, pp.768-768, 2006 (Released:2007-06-05)

- 参考文献数

- 3

- 被引用文献数

- 1 2

1 0 0 0 OA TiO2粉末光触媒を用いる有機態窒素化合物の分解処理

- 著者

- 久米 道之 小野 さとみ 大澤 松夫

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.42, no.8, pp.854-855, 1991-08-01 (Released:2009-10-30)

- 参考文献数

- 2

- 被引用文献数

- 1