2 0 0 0 OA 超々ジュラルミンと零戦(1)五十嵐勇博士と超々ジュラルミンの発明

- 著者

- 吉田 英雄

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.66, no.1, pp.26-38, 2016-01-30 (Released:2021-10-15)

- 参考文献数

- 28

- 被引用文献数

- 3 2

2 0 0 0 OA くさび型工具によるアルミニウム板の切断加工における破壊様式

- 著者

- 畑中 伸夫 山口 克彦 高倉 章雄 飯塚 高志

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.52, no.3, pp.108-114, 2002 (Released:2007-03-30)

- 参考文献数

- 19

- 被引用文献数

- 5 5

Cutting of an aluminum sheet (A1100P–H12) by indentation of wedge shape punches is investigated as a process to achieve burr-free-cutting. Numerical simulations of the cutting process are done using a rigid plastic finite element code developed by the authors. The modified Cockcroft and Latham expression is used as a fracture criterion and is linked with the simulation. Stress and strain distributions at the deformation region of the sheet are calculated and compared with the fracture threshold. The effects of nose angle and radius of the wedge shape punch on the cut edge profile are discussed based on the calculated results. To confirm the results of the finite element simulations, cutting experiments are also carried out and the shape of the cut edge is observed using an optical or a scanning electron microscope. The experimental result shows that the shape of cut edge is divided into four modes depending on the wedge angle α and nose radius r of punch. When the punch of r = 0.1 mm and α = 30 degree is used a sheet is separated by cutting, while when α = 60 and 90 degree ductile fracture occurs due to the secondary tensile force induced by the wedge indentation, and when α = 120 degree brittle fracture occurs due to the excessive work hardening during compression. When the nose radius of punch is increased from 0.1 mm to 0.5 mm, the deformation of sheet material between upper and lower punches becomes compression rather than cutting. Therefore, when punches of r = 0.5 mm are used, the separated surface has a very thin flash. These experimental results can be explained well by the simulation results.

2 0 0 0 OA アルミニウム合金の応力腐食割れ

- 著者

- 村上 陽太郎

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.31, no.11, pp.748-757, 1981-11-30 (Released:2008-07-23)

- 参考文献数

- 22

- 被引用文献数

- 11 13

2 0 0 0 OA 企業の基礎研究に思う

- 著者

- 松田 祥三

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.36, no.2, pp.61-63, 1986-02-28 (Released:2008-07-23)

2 0 0 0 OA 医療分野におけるチタンの表面処理

- 著者

- 塙 隆夫

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.55, no.11, pp.553-556, 2005 (Released:2006-02-24)

- 参考文献数

- 31

- 被引用文献数

- 18 17

2 0 0 0 OA 2024C-T3, T4, 6061-T6板材の機械的性質におよぼす加熱の影響

- 著者

- 肝付 兼博

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.14, no.3, pp.143-153, 1964-05-31 (Released:2008-10-30)

- 参考文献数

- 15

- 被引用文献数

- 1 1

This report relates to the heating effect on the mechanical properties and on "retrogression" of alclad 2024-T3, T4, as well as 6061-T6 Al-alloys which are indispensable, materials for aircraft construction.Summerized results are as follows:1) Aged 2024-alclad alloy revealed clearly retrogression and temper hardening, but showed no secondary age hardening on heating.2) Degree of retrogression can not reach to the equal value of tensile strength with that of solution heat treatment, but showed less tensile strength of 3 to 4kg/mm2 of T3 and T4 condition.3) With 6061-T6 alloy, retrogression did not take place. But with heating up above to the artificial aging temperature, strength decreases with increase of heating time.

2 0 0 0 OA 今日と明日の航空機

- 著者

- 久保 富夫

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.1956, no.20, pp.118-122, 1956-08-31 (Released:2008-10-30)

2 0 0 0 OA 純アルミニウムおよびアルミニウム合金におけるスカンジウム—その挙動と添加効果

- 著者

- 藤川 辰一郎

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.49, no.3, pp.128-144, 1999 (Released:2007-03-30)

- 参考文献数

- 239

- 被引用文献数

- 22 30

2 0 0 0 OA アルミニウムと共に

- 著者

- 北川 二郎

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.35, no.3, pp.188-194, 1985-03-31 (Released:2008-07-23)

2 0 0 0 OA アルミニウムおよびアルミニウム合金の疲労

- 著者

- 布村 成具

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.28, no.11, pp.566-574, 1978-11-30 (Released:2008-07-23)

- 参考文献数

- 32

- 被引用文献数

- 1

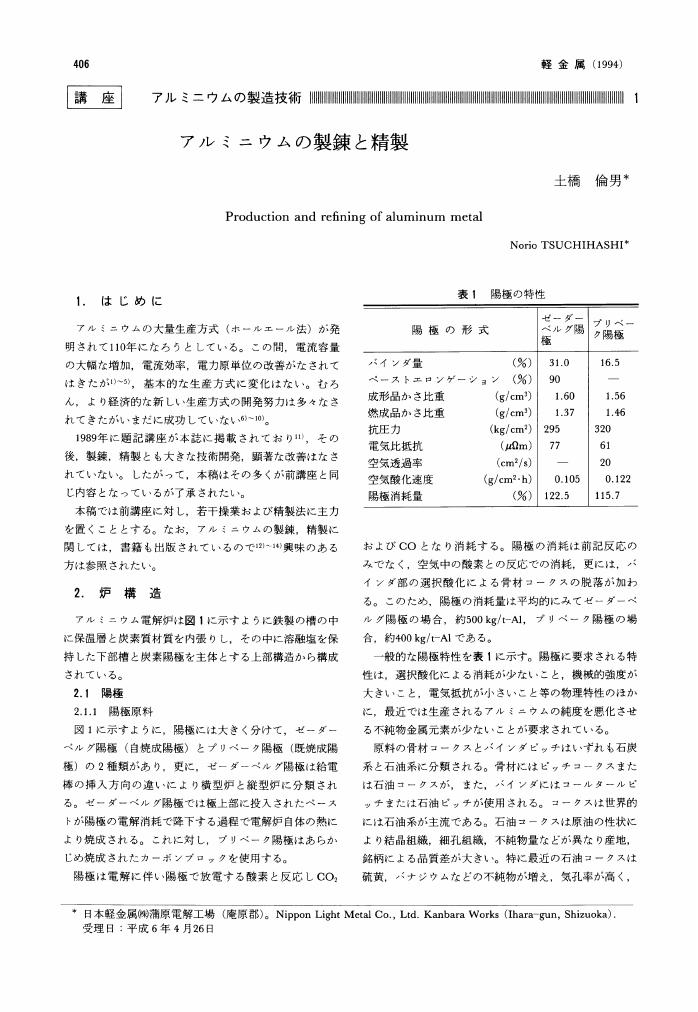

2 0 0 0 OA アルミニウムの製錬と精製

- 著者

- 土橋 倫男

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.44, no.7, pp.406-417, 1994-07-30 (Released:2008-10-30)

- 参考文献数

- 50

- 被引用文献数

- 1 1

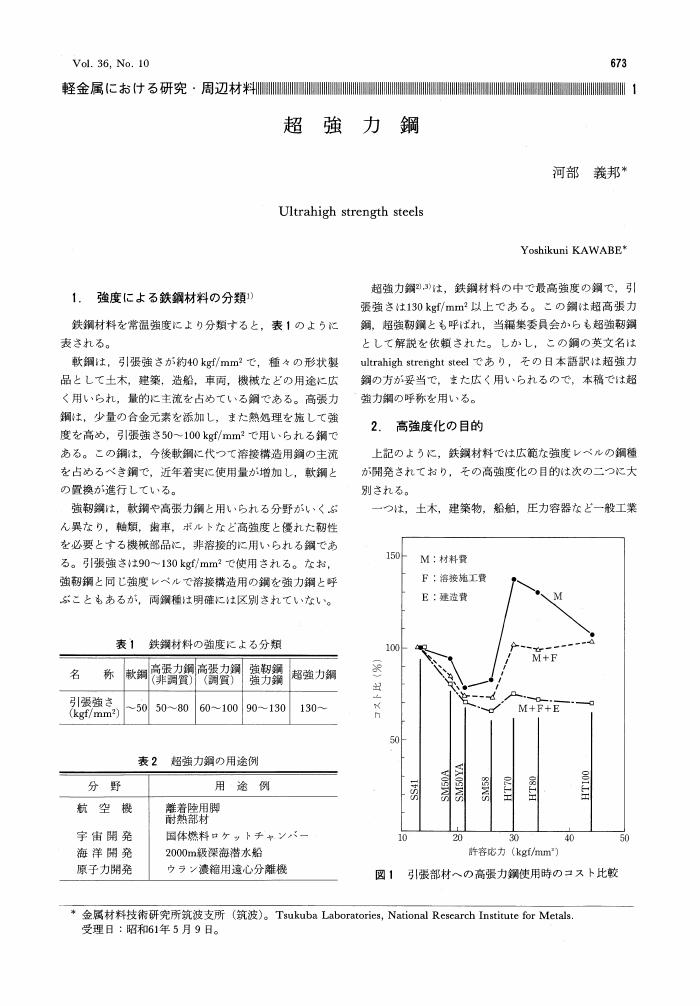

2 0 0 0 OA 超強力鋼

- 著者

- 河部 義邦

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.36, no.10, pp.673-681, 1986-10-31 (Released:2008-07-23)

- 参考文献数

- 8

2 0 0 0 OA 鉄道車両へのアルミニウム合金適用の現状と今後の展開

- 著者

- 酒井 康士

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.56, no.11, pp.584-587, 2006 (Released:2007-01-07)

- 参考文献数

- 7

- 被引用文献数

- 8 9

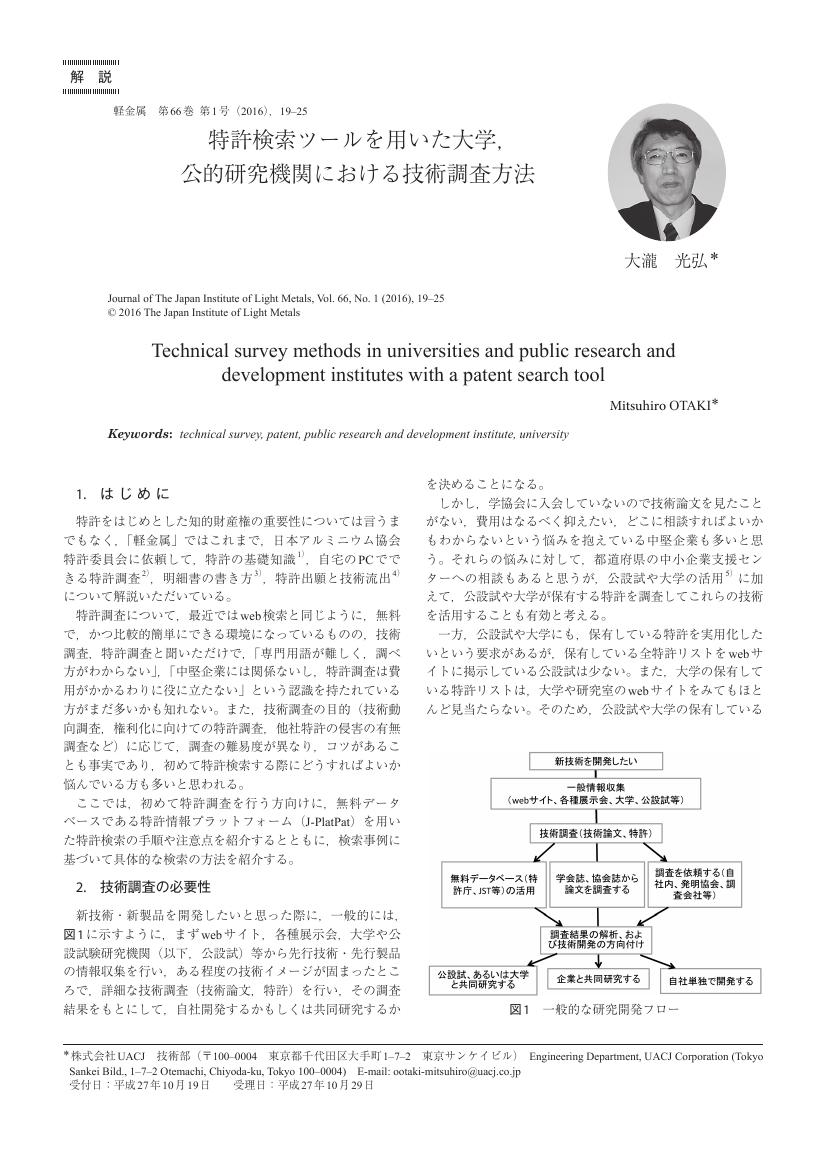

2 0 0 0 OA 特許検索ツールを用いた大学,公的研究機関における技術調査方法

- 著者

- 大瀧 光弘

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.66, no.1, pp.19-25, 2016-01-30 (Released:2016-04-30)

- 参考文献数

- 6

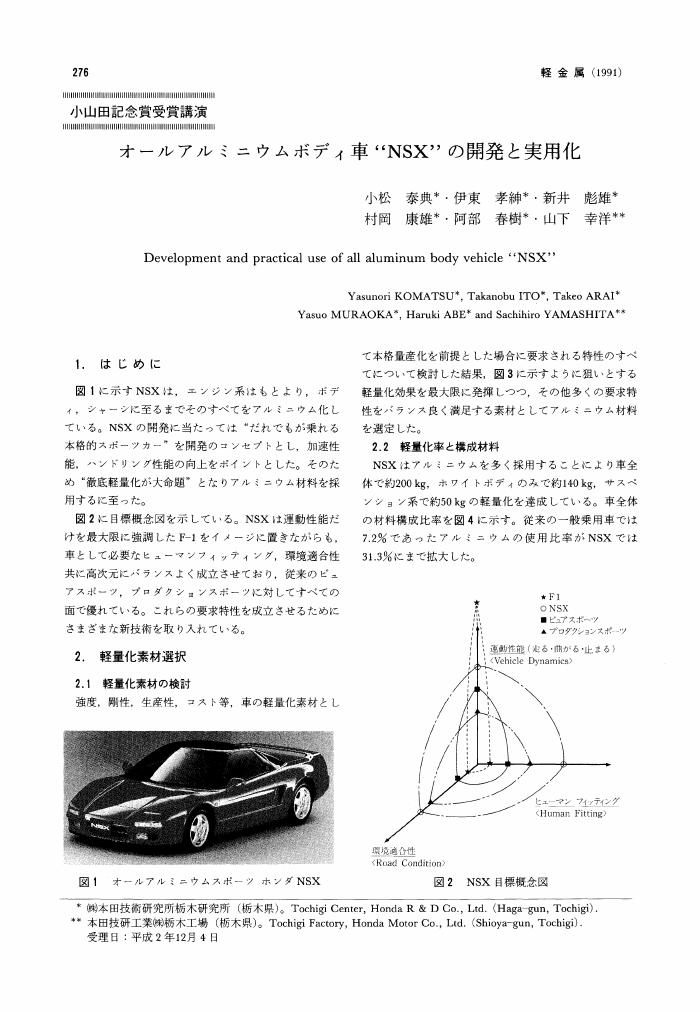

2 0 0 0 OA オールアルミニウムボディ車“NSX”の開発と実用化

2 0 0 0 OA 強冷延した(112)[111]方位のアルミニウム単結晶における再結晶集合組織

- 著者

- 上城 太一 藤原 晶彦 田中 英明 多賀谷 敦

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.41, no.3, pp.147-151, 1991-03-30 (Released:2008-10-30)

- 参考文献数

- 11

- 被引用文献数

- 5 5

Aluminum single crystals in the (112) [111] orientation were cold-rolled to 99% reduction. The main component of rolling textures changed from the initial orientation towards (4 4 11) [11 11 8] orientation above 80% rolling but it was sharp up to the maximum reduction. The weak intensity areas were observed spreading over the pole figures. The minor component which was symmetrical to the main component with respect to the transverse direction, was formed at 90% rolling and developed with increasing reduction. The deformation structure of a totated cube orientation was observed in the (100) pole figure of the crystal cold-rolled 99%. The recrystallization textures were composed of a (1 1 10) [7 3 1] orientation which was appropximately related to the cube orientation by 22° rotation around the normal direction. Any orientation change from (1 1 10) [7 3 1] to (001) [100] was not found with an increase in rolling reduction. The formation of the rotated cube texture is attributed to preferential nucleation from the deformation structure in the same orientation. The deformed matrix of S-orientation might be required for development of the cube texture of good symmetry.

2 0 0 0 OA Mg-Li-Al合金の時効硬化および機械的性質

- 著者

- 松澤 和夫 越原 俊夫 小島 陽

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.39, no.1, pp.45-51, 1989-01-30 (Released:2008-10-30)

- 参考文献数

- 6

- 被引用文献数

- 18 22

Rolling workability, age-hardening and mechanical properties of Mg-5 to 16 mass%Li-1 mass%Al alloys were studied. The limit of reduction for cold rolling of the alloys containing 16 mass%Li exceeds 99.9%. The α+β phase alloys at 8, 10 and 11 mass%Li and the β phase alloy at 16 mass%Li are age-hardenable. A remarkable decrease in elongation is encountered for the β phase alloy having the maximum hardness. Fine platelet precipitates are observed by transmission electron microscopy in the age-hardened 8 mass%Li alloy.

2 0 0 0 OA 引張試験片の寸法と形状について

- 著者

- 佐藤 四郎

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.24, no.11, pp.508-521, 1974-11-30 (Released:2008-10-30)

- 参考文献数

- 32

- 被引用文献数

- 1 2

2 0 0 0 OA アルミニウム合金の引張強さと硬さの関係

- 著者

- 佐藤 四郎 遠藤 隆

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.36, no.1, pp.29-35, 1986-01-30 (Released:2008-07-23)

- 参考文献数

- 11

- 被引用文献数

- 2 8

Tensile and Vickers and Rockwell hardness tests were carried out on a number of aluminum wrought alloys. The alloys are classified into the following three groups according as the relation between tensile strength and Vickers hardness Hv: (1) S-group; O, H112, F, T1 and T4 tempered alloys for which if Hv>45, σB=0.40Hv and if Hv<45, σB=0.35Hv, (2) H-group; work-hardened alloys for which σB=0.35Hv-3.0, and (3) T-group; heat-treated alloys except for those in S-group for which σB=0.32Hv and for 6xxx alloys σB=0.30Hv. In Rockwell hardness test, B-scale is appropriate for T-group alloys and F-scale for S- and H-group alloys. A definite chart for converting hardness to tensile strength is also shown.