1 0 0 0 OA ダイエットはサイエンス

- 著者

- 西 直美

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.86, no.3, pp.266-267, 2014-03-25 (Released:2019-01-01)

1 0 0 0 OA バイオコークスを用いた鋳造におけるバイオマス材質の影響

- 著者

- 冨田 義弘 中村 幸吉

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 全国講演大会講演概要集 第161回全国講演大会講演概要集 (ISSN:18805388)

- 巻号頁・発行日

- pp.49, 2012 (Released:2017-03-01)

1 0 0 0 OA ―幻の世界最大鐘― 四天王寺頌徳鐘の悲劇の生涯

- 著者

- 市村 元

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.70, no.1, pp.57-62, 1998-01-25 (Released:2014-12-18)

1 0 0 0 OA IX. 我が国の工業用精密鋳造の初期から現在までのいくつかの話題

- 著者

- 錦織 徳郎

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.72, no.12, pp.835-839, 2000-12-25 (Released:2014-12-18)

1 0 0 0 OA 銅合金鋳物の歴史

- 著者

- 岡根 利光

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.6, pp.381-385, 2013-06-25 (Released:2018-01-01)

- 参考文献数

- 14

1 0 0 0 鋳物砂の粒子径画像解析法による粒度測定

- 著者

- 宗形 江里子 成瀬 康子 鈴木 亜美 中澤 裕香 鈴木 みどり 高木 良輔

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 全国講演大会講演概要集 (ISSN:18805388)

- 巻号頁・発行日

- vol.173, pp.54, 2019

1 0 0 0 新パッチング材の試作と実用試験

- 著者

- 太田 太郎 西川 幸男

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳物 (ISSN:00214396)

- 巻号頁・発行日

- vol.32, no.5, pp.340-345, 1960

There have been ardent requirements for reducing troubles of bricklaying and repairing of cupola linings. New type of patching material was made of coarse Quarzite grain and fine Pyrophyllite grain. Reduction of <sup>1</sup>⁄<sub>3</sub> of labour and time and good results were obtained by practical use. Specimens of used patching material were tested by microscope, Spectral analysis and X-ray diffraction patterns.

1 0 0 0 溶融堆積法を用いて作製した中実構造材の形状制御条件

- 著者

- 安達 慎一郎 森本 貴幸 大石 郁 水本 将之 香川 明男

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 全国講演大会講演概要集 (ISSN:18805388)

- 巻号頁・発行日

- vol.143, pp.143, 2003

1 0 0 0 溶融堆積法により作製した角筒積層材の形状制御

- 著者

- 大石 郁 森本 貴幸 水本 将之 香川 明男

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.76, no.7, pp.582-587, 2004

Al-4 mass%Cu alloy was melted in a quartz tube with a small nozzle at the bottom. By pressing the melt surface with argon gas pressure of 0.12 to 0.13 MPa, the alloy melt flowed out through the nozzle onto the copper substrate and was rapidly solidified. A rectangular tube specimen was formed by moving the sub. strate in the X-Y horizontal directions and downwards simultaneously. <br> With increasing the moving speed of the substrate, the thickness of one layer deposited reduced and the spacing between eutectics in the interdendritic regions increased, while the width of the castings remained almost constant. With increasing the number of layers, the cooling rate was decreased, and the weldability between the layers improved. Under optimum conditions, a coexisting solid-liquid region was formed between the layers, resulting in smooth side surface of the castings due to the surface tension of the liquid phase in the region.

1 0 0 0 溶融堆積法により作製した異材2重管の界面溶着条件

- 著者

- 森本 貴幸 安達 慎一郎 大石 郁 水本 将之 香川 明男

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 全国講演大会講演概要集 (ISSN:18805388)

- 巻号頁・発行日

- vol.143, pp.142, 2003

1 0 0 0 OA 日本の鉄仏の成立とその鋳造方法

- 著者

- 中野 俊雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.69, no.9, pp.767-774, 1997-09-25 (Released:2014-12-18)

- 参考文献数

- 19

- 被引用文献数

- 4

1 0 0 0 OA 高真空ダイカスト法による自動車車体用大型薄肉高延性部品の開発

- 著者

- 浅井 宏一 大杉 泰夫 八下田 健次

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.82, no.12, pp.819-826, 2010-12-25 (Released:2015-04-21)

- 参考文献数

- 3

1 0 0 0 OA 鉄鋳物の歴史 (3)

- 著者

- 中江 秀雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.7, pp.452-462, 2013-07-25 (Released:2018-01-01)

- 参考文献数

- 40

1 0 0 0 Sn浴法によるADI 製造時のSn付着防止

- 著者

- 勝負澤 善行 茨島 明 高川 貫仁 佐藤 孝一 ロメロ セサル コルデロ イサク

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 全国講演大会講演概要集 (ISSN:18805388)

- 巻号頁・発行日

- vol.137, pp.72, 2000

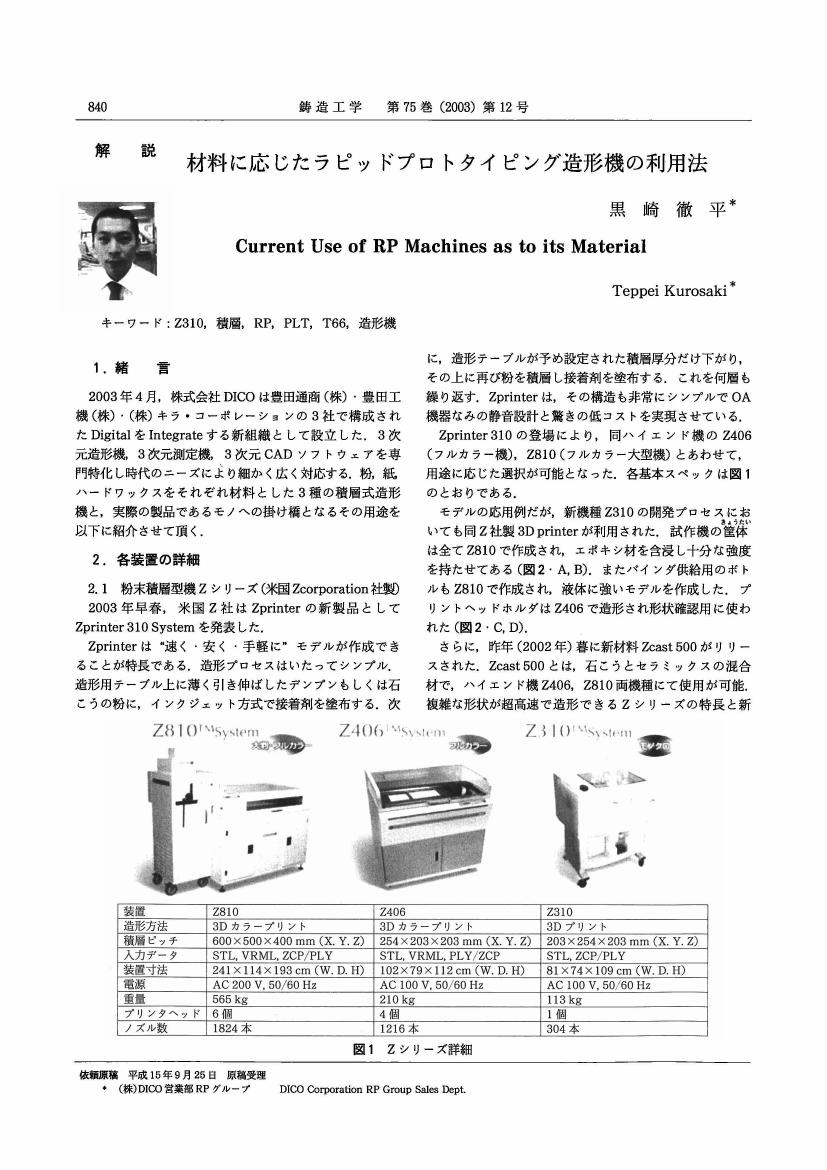

1 0 0 0 OA 材料に応じたラピッドプロトタイピング造形機の利用法

- 著者

- 黒崎 徹平

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.75, no.12, pp.840-845, 2003-12-25 (Released:2015-01-07)

- 被引用文献数

- 1

1 0 0 0 OA システム制御理論の最近の動向と展望

- 著者

- 寺嶋 一彦

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.72, no.1, pp.47-56, 2000-01-25 (Released:2014-12-18)

- 参考文献数

- 31

- 被引用文献数

- 3

1 0 0 0 OA アルミニウム青銅鋳物の標準性質と実体強さ

- 著者

- 粟田 昌良 岩野 伸也 谷沢 治勇 吉田 章吾 山県 欽弥

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳物 (ISSN:00214396)

- 巻号頁・発行日

- vol.32, no.12, pp.948-957, 1960-12-25 (Released:2012-10-30)

The mechanical properties of the specified tensile test bars and of the stepped and L-secctioned castings in aluminum bronzes (JIS. AlBC 1, 2 and 3) were determined. Preferable gating systems to produce the stepped and L-sectioned castings without defects were examined with radiographic technique. The castings made under those of careful conditions have a little scatter of the mechanical properties interioly and have a slight fall in the properties even in the heavy section.

1 0 0 0 韮山反射炉における鋳鉄製大砲鋳造の可能性

- 著者

- 菅野 利猛

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 = Journal of Japan Foundry Engineering Society (ISSN:13420429)

- 巻号頁・発行日

- vol.78, no.1, pp.23-29, 2006-01-25

- 参考文献数

- 16

Nirayama reverberatory furnace is located at lzunokuni-city of lzu-Peninsula, Shizuoka-Prefecture. Hagi reverberatory furnace exists at Hagi-city, Yamaguchi-Prefecture, but Nirayama's one is the only one architectures that could make cast iron cannon. There are still remained some unknown matters as follows ; (1) whether cast iron was really melted or not, (2) what kind of pig-iron was used, (3) whether blowing of bellows were utilized or not, (4) what kind of fuels were used, (5) where firebricks were made, etc. On this Nirayama reverberatory furnace, the possibility of casting of cannon with iron was investigated, with melting experiment from a foundry engineering standpoint. <br> The followings are presumed from the investigation. Firstly, at least three cannons of cast iron were manufactured. Secondly, high Silicon contained pig-iron could not be available, so casting of iron cannon was not well done. Finally, the melting time by reverberatory furnace, from preheating to pouring completion, was about eight hours and melting temperature was above 1623K.

1 0 0 0 OA 凝固制御用セラミック中子について

- 著者

- 加藤 清隆 野崎 佳彦

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳物 (ISSN:00214396)

- 巻号頁・発行日

- vol.62, no.9, pp.726-731, 1990-09-25 (Released:2011-07-27)

- 参考文献数

- 9

The basic research of ceramic core was carried out on the core which could be used solidification controled castings of Ni-base superalloy such as single crystal casting. Fused silica was selected as a main material of core because of high leachability to aqueous alkaki solution, and the test piece of core was producted by press molding process. When the burning temperature is 1300∼1320°C, this ceramic core shows very low thermal expansion ratio (0.1%) and the highest deflective strength at room temperature (about 20°C : 400 kgf/cm2). With the addition of 10∼20wt% cristobalite to fused silica, it restrains softening of the core at high temperature and shrinkage of the core after reburning. Furthermore the influence of the grain size change of fused silica on the properties of the core was also investigated.

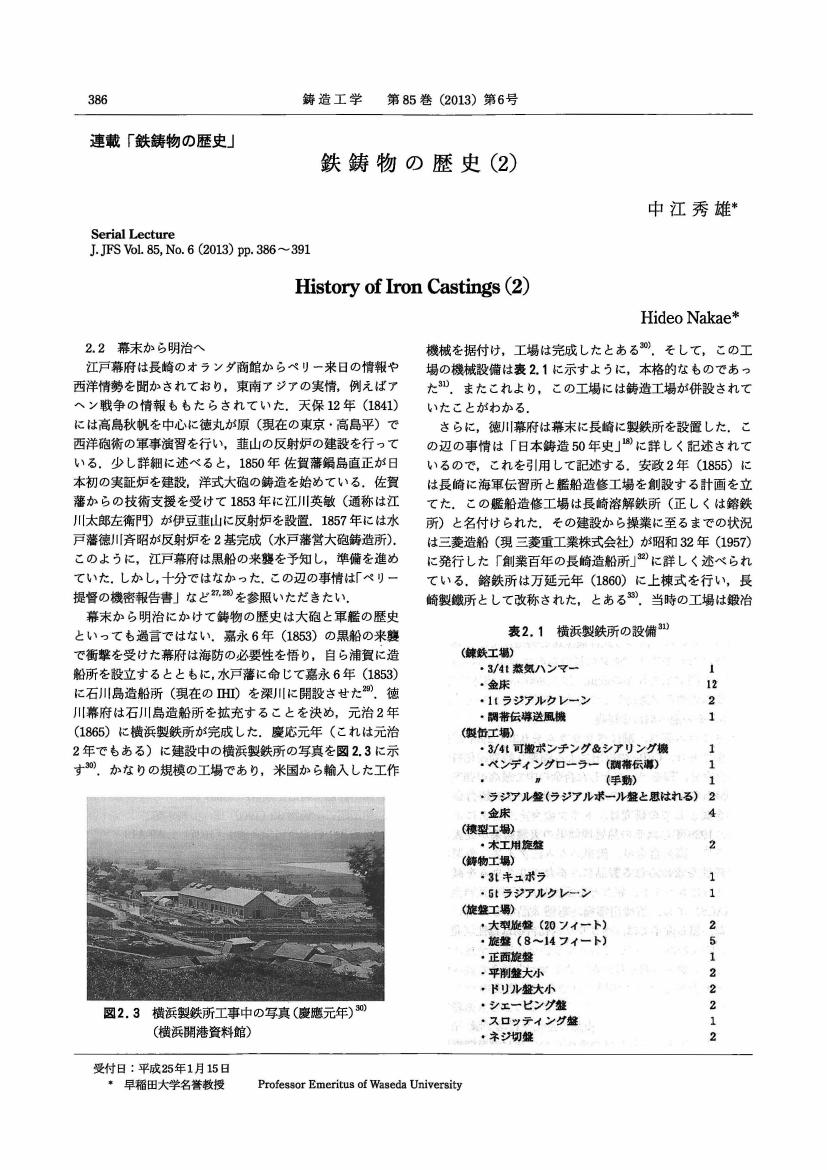

1 0 0 0 OA 鉄鋳物の歴史 (2)

- 著者

- 中江 秀雄

- 出版者

- 公益社団法人 日本鋳造工学会

- 雑誌

- 鋳造工学 (ISSN:13420429)

- 巻号頁・発行日

- vol.85, no.6, pp.386-391, 2013-06-25 (Released:2018-01-01)

- 参考文献数

- 22