1 0 0 0 OA レーザーによるカラー発色加工

- 著者

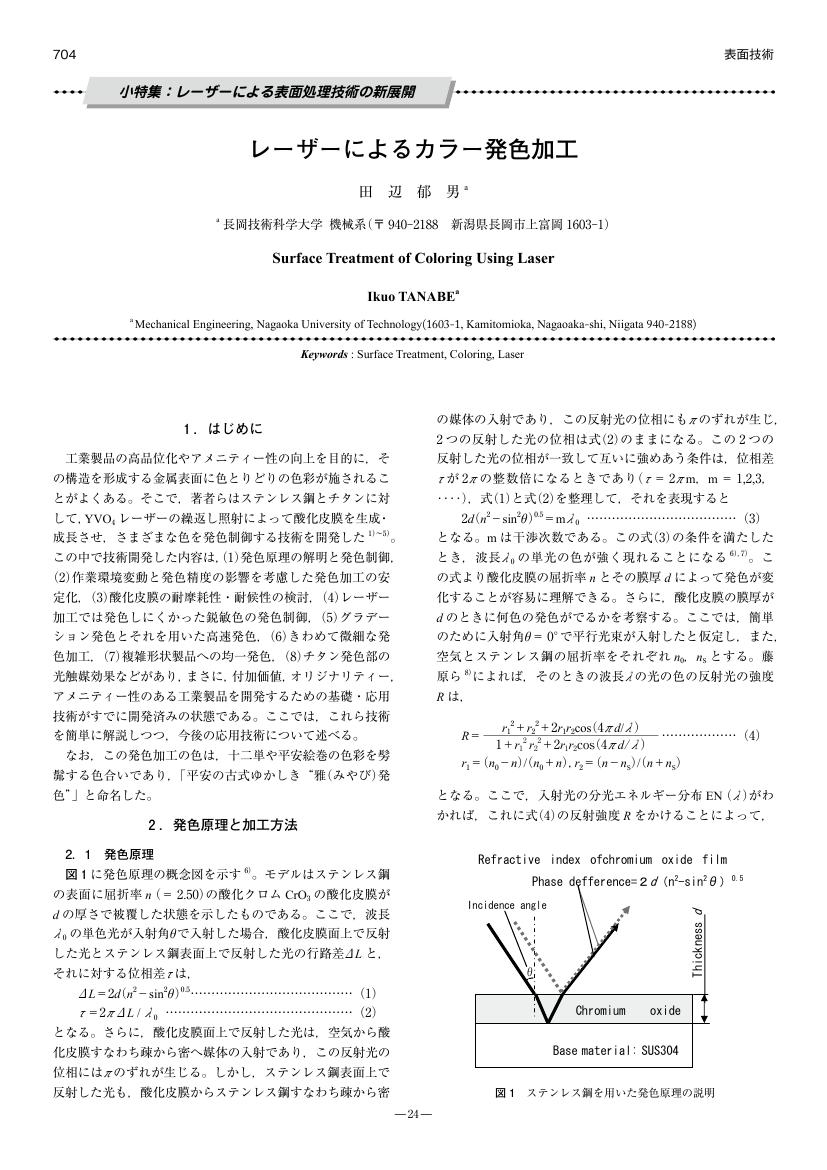

- 田辺 郁男

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.60, no.11, pp.704, 2009-11-01 (Released:2010-05-28)

- 参考文献数

- 9

- 被引用文献数

- 1 1

1 0 0 0 OA マイクロバブルを混入した強アルカリ水を用いたドリル加工技術

- 著者

- 田辺 郁男 ジュニオール ライムンド ダ クルス イエー トット ソー 富岡 恭平 高橋 智

- 出版者

- 一般社団法人 日本機械学会

- 雑誌

- 日本機械学会論文集C編 (ISSN:18848354)

- 巻号頁・発行日

- vol.79, no.799, pp.748-758, 2013 (Released:2013-03-25)

- 参考文献数

- 16

- 被引用文献数

- 2 2

In the 21st century, as it is important to produce products with care for protecting the earth, a producer must be careful to conserve energy, save resources and reduce waste which pollutes environment. On the other hand, in case of a drilling, much cutting oil was also used for lubrication and cooling. This is large problem for protecting the earth. Therefore drilling technology using strong alkali water with micro-bubble was developed. A drill with through hole was used for this technology. Cooling effect of strong alkali water with micro-bubble was firstly investigated on the experiment. Then heat transfer coefficient of the drill with through hole was evaluted for cooling capacity. Tool life of the drill using strong alkali water with micro-bubble was also evaluated in the experiment of drilling using Ti6Al4V which has small thermal conductivity and is a material with difficult machining. It is concluded from the results that; (1) Cooling of strong alkali water with micro-bubble was very effectuive, (2) Heat transfer coefficient of the drill using strong alkali water with micro-bubble was 3.5 times of that of dry drilling, (3) Tool life of the drill using strong alkali water with micro-bubble was 6.5 times of that of dry drilling and 2 times of that of ordinary wet drilling respectively, (4) The drilling using strong alkali water with micro-bubble was economical and eco-friendly.

1 0 0 0 OA 実験計画法における制御因子間の相乗効果を探索するプログラムの開発

- 著者

- 田辺 郁男 水谷 淳之介 高橋 智 熊井 達也

- 出版者

- 一般社団法人 日本機械学会

- 雑誌

- 日本機械学会論文集 (ISSN:21879761)

- 巻号頁・発行日

- vol.84, no.863, pp.17-00516, 2018 (Released:2018-07-25)

- 参考文献数

- 12

- 被引用文献数

- 1

Recently the design of experiments is used to decide optimum processing conditions. However when the control factor interaction between the several control factors becomes large, the calculated accuracy using the design of experiments becomes very bad. Then everybody should check the results regarding the best and the worst conditions in the experiments. If differences between the calculated vale and the experimental value for the best and the worst conditions become large, the results using the design of experiments are never used. Therefore, in the previous research, we have developed the tool for easily finding the control factor interaction in the design of experiments. This control factor interaction between the several control factors action is large fault, an obstacle for innovation and disliked by everybody. However when the reaction between the several control factors becomes large effect which is surpassed the estimate, the control factor interaction becomes the synergistic effect which is liked by everybody, the synergistic effect finally brings large profit, excellent license and innovation. Therefore in this research, the tool for easily finding the synergistic effects between the control factors was developed and evaluated using the program in the previous research. The program was the tool for finding the control factor interaction in the design of experiments, it was improved for the easily finding the synergistic effects by using the new algorithm, and was evaluated by the several mathematical models and the experiment. It is concluded from the result that (1) the new program can clear the synergistic effects between the control factors, (2) the program also can clear the complex multiplier effects and (3) the program can clear the synergistic effects with innovative profit in the actual example.

1 0 0 0 OA 実験計画法を用いた最適条件探索プログラムの開発

- 著者

- 田辺 郁男 高橋 宗一郎 高橋 智

- 出版者

- 一般社団法人 日本機械学会

- 雑誌

- 日本機械学会論文集 (ISSN:21879761)

- 巻号頁・発行日

- vol.84, no.862, pp.18-00171, 2018 (Released:2018-06-25)

- 参考文献数

- 16

- 被引用文献数

- 1

The Design of Experiments (DOE) is a method that is widely used due to its effectiveness to select optimum conditions in the design stage of product development. On the other hand, a fast, low cost, labor saving and energy-saving innovative development is also required in industry. In this research, a program for quickly searching the optimum condition using design of experiments is developed and evaluated. Relationships between each parameter and the final property are firstly cleared for each formula by using the design of experiments. Then the optimum conditions for each parameter were decided by using these formulas in a program. The optimum final property with each optimum level value were calculated. In addition, the optimum condition for cooling system using alkaline water mist was investigated for evaluating this program in an experiment. It is concluded from the result that (1) the program using the design of experiments was useful for fast development process, (2) this program could quickly and accurately decide the optimum cooling condition for cooling system using alkaline water mist.

- 著者

- 田辺 郁男 西山 晃 五宝 純一 高橋 智

- 出版者

- 一般社団法人 日本機械学会

- 雑誌

- 日本機械学会論文集 (ISSN:21879761)

- 巻号頁・発行日

- vol.83, no.851, pp.16-00449-16-00449, 2017 (Released:2017-07-25)

- 参考文献数

- 15

As accuracy of industrial product was reduced by thermal deformation of a machine tool, a tool and a workpiece during cutting, there are several countermeasures for machining field. In the old days, we had developed and evaluated for a lathe with insensibility function for thermal and temperature change. The lathe has the structure of zero-center on three directions, the structure of self-compulsory cooling and the structure of thermal synchronism. Particularly the structure of thermal synchronism was developed for wet cutting. However the control method for the structure of thermal synchronism was yet to establish. Therefore the control using thermal synchronism at wet cutting in machine tool was developed and evaluated. The control system of fluid quantity on the structure of thermal synchronism using inverse analysis of neural network was developed for insensibility function of thermal and temperature change. Then thermal deformations of the developed lathe were measured and evaluated in the several experiments. It is concluded from the results that; (1) Thermal deformation of the bench lathe was very small in spite of no-forced cooling, (2) The control system of fluid quantity on the thermal synchronism using inverse analysis of neural network was effective for its working stability during wet cutting.