1 0 0 0 OA アルミニウムの水蒸気による腐蝕試驗

- 著者

- 松田 正美

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.1952, no.5, pp.109-112,108, 1952-11-30 (Released:2008-10-30)

- 参考文献数

- 3

For aluminum and its alloys are cmployed for constructional materials contact with steam, they must have superior corrosion resistance in it, but the investigations on the action of steam vapor on aluminum and its alloys almost have not been canied out in the past. This corrosion test were made on usual trade aluminum alloys to determine the resistance to corrosion in steam atmosphere by measuring the weight loss, and the decreasing of tensile strength and elongation during test.(1) As compared with Fe, aluminum and its alloys has become established high resistance to corrosion in steam.(2) High-purity aluminum, under steaming stmosphere, surpasses the other aluminum and its alloys in resistance to corrosion. This resistance increases with increase in purity. However, the effects of a few impurity, Fe and Cu, to the resistance to corrosion are to be considered.(3) It is unexpected that the resistance of 52S is following to high-purity aluminum.

1 0 0 0 OA アパタイト被覆二酸化チタン光触媒の応用

- 著者

- 岩田 匡平

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.55, no.12, pp.624-628, 2005 (Released:2006-02-24)

- 被引用文献数

- 1

1 0 0 0 銅精鉱輸送用アルミニウム合金製パレットの開発

- 著者

- 竹内 勝治 中安 静雄 中村 授

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.18, no.11, pp.586-592, 1968

Copper concentrate-ores were generally filled in jute bags for transportation by ships and trains from Peko Mines Co., Australia to Sumitomo Metal Mining Co., Japan. The rationalization of shipping works for the ores was required, because there were dangers of ignition of accumulated bags due to heat generation of the filling ores when they were moistened and exposed to high atmospheric temperature.In February 1967, the "Spensa-maru" which had been built for exclusive transportation of copper, zinc, and lead ores, was put in commission. The ship solved the above problems by the application of palletization for avoiding the heat generation and ignition and also getting rationalization of shipping work.In designing the pallets, there were no other proper means than assuming uniform distribution of the load on the pallets. However, the practical distribution of the load was not always uniform. Sometimes, the stresses in frames are higher than those of calculated values; or deformation of lower deck-board of second floor pallet is caused by concentrated load due to rugged arrangement of jute bags. However, these stresses or deformation shall be neglected in the practical work, if they are small.As being understood from the above facts, the loading test must be conducted with the practical loads.Of course, special care shall be taken in the operation of fork-lift trucks, and the pallets must be equipped with replaceable parts against damages by accidents.

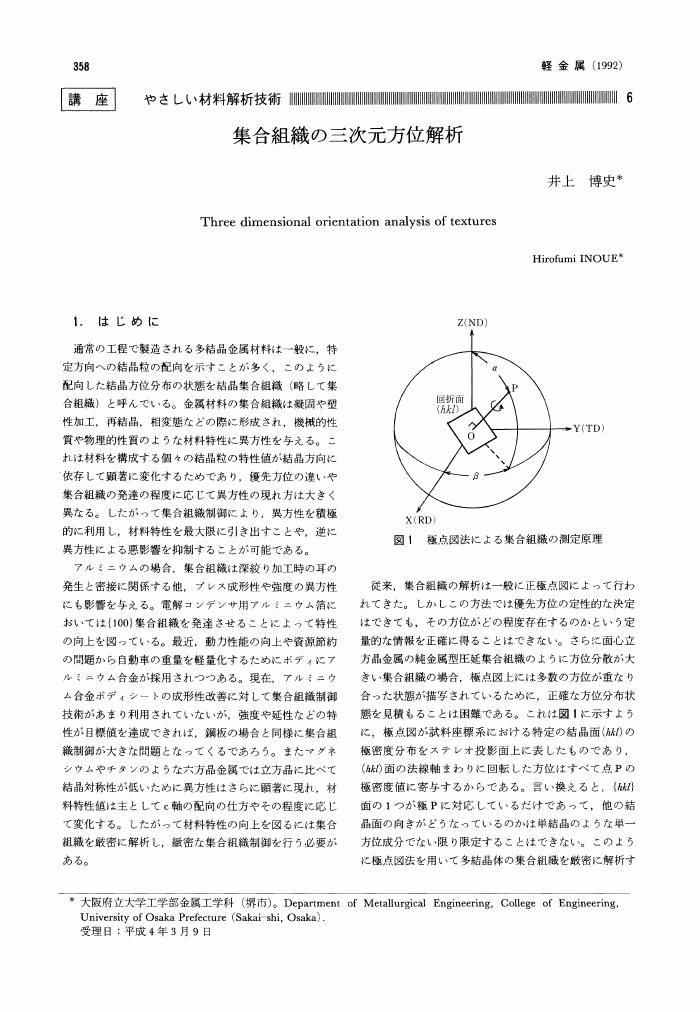

1 0 0 0 OA 集合組織の三次元方位解析

- 著者

- 井上 博史

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.42, no.6, pp.358-367, 1992-06-30 (Released:2008-10-30)

- 参考文献数

- 50

- 被引用文献数

- 8 7

1 0 0 0 OA 新しい領域での微生物の研究

- 著者

- 井上 真由美

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.35, no.6, pp.319-320, 1985-06-30 (Released:2008-07-23)

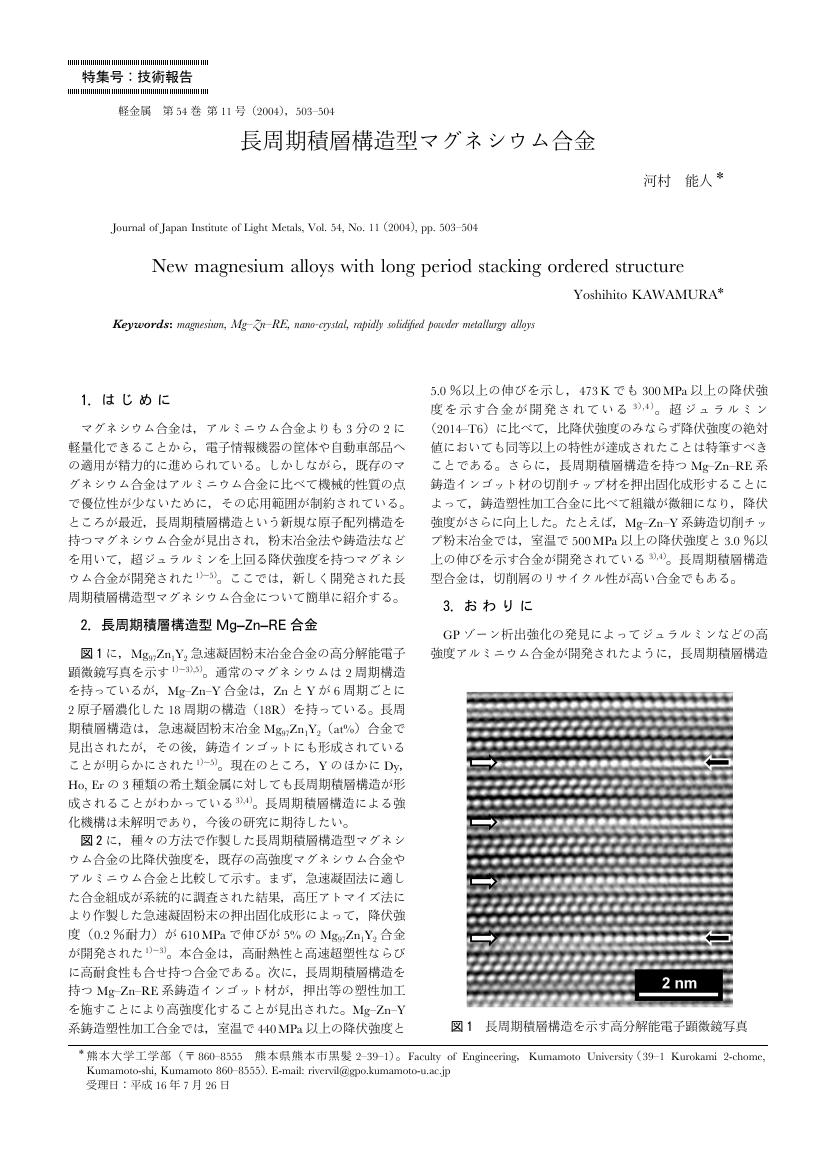

1 0 0 0 OA 長周期積層構造型マグネシウム合金

- 著者

- 河村 能人

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.54, no.11, pp.503-504, 2004 (Released:2007-02-20)

- 参考文献数

- 5

- 被引用文献数

- 2 5

1 0 0 0 OA Al-Zn合金のスピノーダル温度の上下におけるG.P.ゾーンの形成, 成長について

- 著者

- 太田 陸奥雄 金谷 輝人 山田 益男 榊原 精

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.29, no.8, pp.315-321, 1979-08-30 (Released:2008-10-30)

- 参考文献数

- 27

- 被引用文献数

- 3 3

Measurements of electrical resistivity and intensity of small-angle X-ray scattering and transmission electron microscopy were made on several compositions of Al-Zn alloys. G. P. zones are formed above the spinodal temperature in the nucleation-and-growth mechanism. The nucleus has a critical size for growth. This size becomes larger when aged at higher temperatures. The G. P. zones formed in this mechanism distribute broadly, but those formed by the spinodal decomposition do closely. The number of G. P. zones is much larger in the latter case (127°C) than that in the former (132°C). The spinodal temperatures estimated for Al-10.0, 12.5, 15.0 and 20.0wt% Zn alloys are 90-95°, 105-110°, 125-130° and 170-180°C respectively. The critical temperatures below which G. P. zones are observed in these alloys are 105-115°, 125-135°, 150-160° and 200-210°C respectively.

- 著者

- 松石 藤夫

- 出版者

- 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.19, no.7, pp.287-298, 1969-07

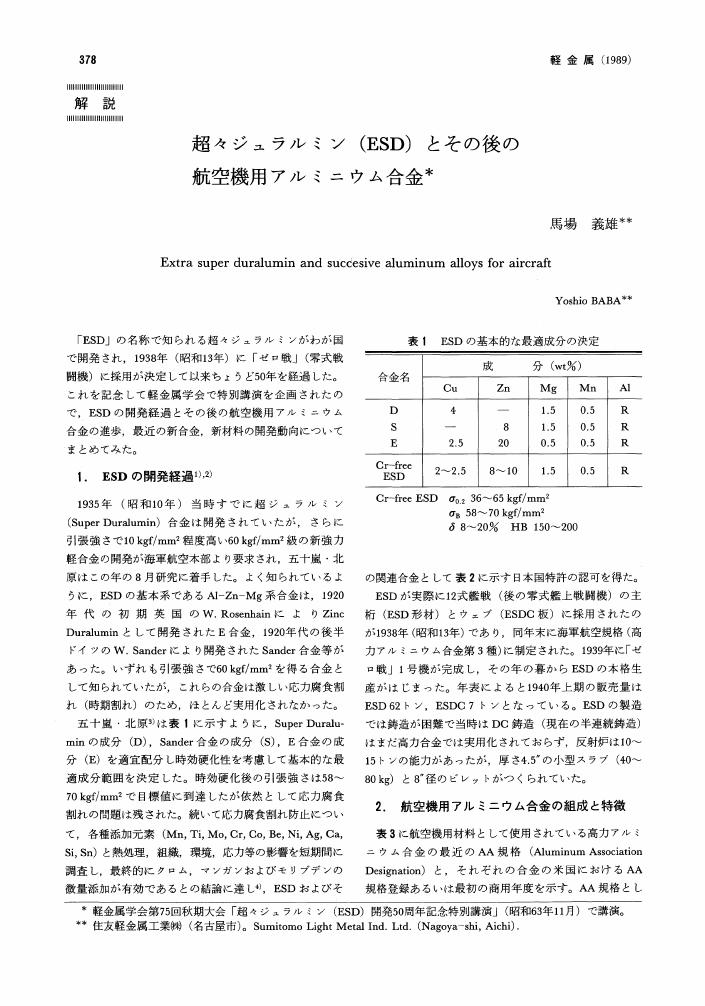

1 0 0 0 OA 超々ジュラルミン (ESD) とその後の航空機用アルミニウム合金

- 著者

- 馬場 義雄

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.39, no.5, pp.378-395, 1989-05-30 (Released:2008-10-30)

- 参考文献数

- 61

- 被引用文献数

- 1 5

1 0 0 0 OA アルミニウム合金の孔食の発生と成長

- 著者

- 当摩 建 竹内 庸

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.31, no.6, pp.422-430, 1981-06-30 (Released:2008-07-23)

- 参考文献数

- 54

- 被引用文献数

- 3 3

1 0 0 0 OA 溶融アルミニウムに対する炭素の溶解度

- 著者

- 大日方 一司 小松 登

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.14, no.4, pp.226-230, 1964-07-31 (Released:2008-10-30)

- 参考文献数

- 8

- 被引用文献数

- 2 7 3

Molten aluminium is equilibrated with pure carbon over a temperature range of 800° to 1400°C under the pressure of 4×10-5mm Hg, and atmosphere. of argon Solubility of carbon in liquid aluminium under pres sure of 4×10-5mmHg is 0.10, 0.14, 0.16, and 0.32wt% at 800°, 1000°, 1100°, and 1200° respectively, and is high compared with the value obtained in the atmosphere of argon. The difference of solubility data was discussed as based on the existence of small amount of oxygen in the system. Solibility of carbon in solid aluminium is estimated to be 0.015wt% from the analytical data of graphite carbon.

1 0 0 0 OA Mg3Cd合金単結晶における底面すべり

- 著者

- 吉岡 正三 中山 豊 伊藤 太一郎 高田 勝典

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.24, no.7, pp.265-269, 1974-07-30 (Released:2008-10-30)

- 参考文献数

- 16

The basal slip of Mg3Cd single crystals was studied in the disordered and the ordered states. Results obtained are as follows:(1) The ordered specimens were very brittle and showed pronounced serrated flow.(2) In the disordered state CRSS depended on temperature below -78°C, while in the ordered state it scarcely depended on temperature.(3) CRSS at 20°C increased from-1.3kg/mm2 in the disordered state to-5.0kg/mm2 in the ordered state.(4) Slip lines in the disordered state were straight, coarse and distributed rather uniformly, while in the ordered state they diffused and localized.(5) In the disordered specimens dislocations arranged as pile-up arrays on the basal plane, and few dislocations on the nonbasal planes were observed. While, in the ordered specimens superlattice dislocations were observed on the basal plane where the dislocation density was low, however dislocation tangles consisting of unit dislocations on the basal and nonbasal planes were observed where the dislocation density was relatively high.

1 0 0 0 OA 情報統計力学に基づいた高次元データ駆動型特性予測

- 著者

- 足立 吉隆 定松 直 増田 雄太 吉田 拓真 松下 康弘

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.64, no.11, pp.533-541, 2014-11-30 (Released:2015-02-28)

- 参考文献数

- 10

- 被引用文献数

- 1

1 0 0 0 OA 常温付近でのアルミニウム電析技術

- 著者

- 塩見 卓 三宅 正男 平藤 哲司

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.63, no.6, pp.234-242, 2013-06-30 (Released:2013-09-30)

- 参考文献数

- 61

- 被引用文献数

- 3

1 0 0 0 OA シルミンに及ぼす20種の添加元素の影響に就いて

- 著者

- 津村 善重

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.1955, no.17, pp.51-70, 1955-11-10 (Released:2008-10-30)

- 参考文献数

- 11

- 被引用文献数

- 1

Effect of Ca, Ti, P, S and C, which will possiblly be alloyed in Silumin from the raw material; Silicon, on Silumin has already been reported. In this report effects of other 20 adding elements (Ag, B, Ba, Be, Bi, Cd, Co, Cr, Cu, Fe, Mg, Mn, Mo, Ni, Pb, Sb, Sn, V, W and Zn) on the hardness, microstructure and casting surface of Silumin has been studied. Relations between the content of additional elements and the Rockwell hardness (B scale) of Silumin are shown in Table 2 and Fig. 1a-d. Microstructures of slowly cooled or chillcast specimens are shown in Photo. 1-92, and the casting surfaces are also shown in Photo. 96-115. The results of observations may be summarized as follows;(1) The most effective element to increare the hardness of Silumin is found to be Mg followed by Cu, although the addition of Co, Cr, Ni and Mn are found also to be very effective, and the effect of Ba, Bi, Ag, Fe and Mo is not so conspicuous. Zn, Cd and Pb have little or no effect.(2) Ba, Sb, Bi and Mg modify the structure of Silumin especially as chilled but their modifying power is not so strong as Na. The microstrcture of Silumin modified by these elements are not so fine as modified by Na especially as slow cooled.(3) Ba, Sb, Bi and Mg make the casting surface of Silumin like toad's skin which is disliked by founder. This phenomenon is a result of feeble modification in which Al dendrites grow rectangular to the casting surface.

1 0 0 0 OA 6061アルミニウム合金の湿潤空気中における疲労き裂進展特性

- 著者

- 大﨑 修平 原野 徹 薮田 均

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.58, no.9, pp.456-461, 2008-09-30 (Released:2008-10-31)

- 参考文献数

- 20

- 被引用文献数

- 2 4

Fatigue crack growth (FCG) properties were determined for aluminum alloy 6061-T6 and 7075-T6 plates exposed to a humid (relative humidity RH=90%) air or dry nitrogen gas, and the effect of hydrogen on the FCG process was discussed together with a fractographic study of fracture surfaces. The 6061-T6 shows a superior FCG resistance to the 7075-T6, resulting in no increase in FCG rate with a reduction of frequency from 10 Hz to 0.1 Hz and also with a change of cyclic loading wave from sine to trapezoid. This response is attributed to the effect of hydrogen to assist localized slip deformation, leading to a crack-tip bunting. According to applying the present FCG data to design a high-pressure container liner for automobile on a basis of the engineering standard JARI S001, it is found that the 6061-T6 can possess a higher allowable stress than the 7075-T6.

1 0 0 0 Al-Mg-Si系合金の用途と製造技術-押出材

- 著者

- 松田 眞一 吉田 英雄

- 出版者

- The Japan Institute of Light Metals

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.53, no.11, pp.483-489, 2003-11-30

- 被引用文献数

- 2 3

- 著者

- 池野 進 片山 暢 松田 健二 蓮覚寺 聖一 品川 不二雄 上谷 保裕

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.48, no.4, pp.179-184, 1998 (Released:2007-03-30)

- 参考文献数

- 9

- 被引用文献数

- 1 1 1

Al–1.0 mass%Mg2Si–0.34 mass%Si alloy specimens which had been aged at 423 K for various times were tensile tested at room temperature. Changes in local deformation near grain boundaries with aging time were investigated by scanning tunneling microscopy. When a little loss in elongation occurred at early stage of aging, the folds generated at the grain triple junction. But they were very ambiguous and did not develop with increasing amount of deformation. The fold formations were difficult to be explained by the maximum resolved shear stress on a grain boundary plane (Fmax). If the elongation appreciably decreased and intergranular fracture began to occur with the progress of aging, the folds developed and became more clear. The fold formations at this stage could be explained by the Fmax in many cases. Frequencies of fold formations increased with the aging time over a range of under-aged to peak-aged condition, and this correlated approximately to the decrease in elongation. Even if the elongation considerably recovered in the specimen which had been aged at 473 K up to over-aged condition, the frequency of fold formation was similar to that of the peak-aged condition. In this case, however, two types of folds which had developed largely or had developed scarcely with the progress of deformation were observed and the frequency of the former ones decreased to about a half of the all folds.

1 0 0 0 OA フェーズフィールド法によるAl-Zn二元合金のデンドライト成長シミュレーション

- 著者

- 篠嶋 妥 市村 稔

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.55, no.1, pp.2-8, 2005 (Released:2006-02-24)

- 参考文献数

- 29

- 被引用文献数

- 2 2

Dendrite growth of Al-Zn binary alloy in one directional solidification process was simulated using the phase field method. The development of Zn composition profile and phase field were calculated and the effects of temperature gradient G and growth velocity V on the morphology of crystal growth were investigated. The obtained results dynamically showed that the curvature radius of the tip of the primary dendrite arm, R, became small and the number of the arms per unit length increased (i.e. the spacing between the primary dendrite arms, λ1, decreased) with increasing growth velocity V. The quantitative relationship between λ1 and V and that between the spacing of the secondary dendrite arm λ2 and the solidification time t were determined as λ1 α V-0.5 and λ23 α t, respectively. It was found that the values of R and the exponent of V for R agree well with the dendrite growth theory.

1 0 0 0 OA ECAE法により作製した5056アルミニウム合金の高サイクル疲労特性

- 著者

- 出村 良広 北川 和夫 川添 正孝

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.51, no.6, pp.324-328, 2001 (Released:2007-03-30)

- 参考文献数

- 11

The fatigue behavior of the fine-grained 5056 aluminum alloy produced by equal-channel angular extrusion (ECAE) is explored. This material exhibits a slightly enhanced fatigue life at high stress amplitude. However, no improvement in the fatigue limit is observed. Fatigue performance is discussed in terms of fatigue life, crack nucleation and propagation. Structural change during fatigue test is investigated by transmission electron microscopy and DSC. It is shown that the fine structure achieved during processing is unstable and tends to relax with cycling, resulting in local recovery of the pre-deformed material. Structure relaxation during fatigue test is supposed to provoke notable cyclic softening that is particularly pronounced at higher applied stress. It is found that the crack growth rate is greater in the fine grain ECAE material than in the coarse grain counterpart. The improvement of fatigue properties at low-cycle regime is believed to be due to higher resistance to crack nucleation in the fine-grained material having a larger proof stress value.