1 0 0 0 OA 抵抗溶接プロセス予測モデルの最前線(<特集>溶接プロセス予測モデルの最前線)

- 著者

- ディルタイ ウーリッヒ オーセ ピーター

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.76, no.2, pp.90-94, 2007-03-05

- 被引用文献数

- 2 3

抵抗溶接プロセスにおける予測モデルの現状について,冒頭に著者の意見が述べられている. 1949年にGelmannによって始まった抵抗溶接モデリングに関する研究は, Greenwoodら多くの研究者によって,知識の洗練が成されてきた.今日では,シミュレーションソフトウェアとして,その成果を広く利用できるようになった.本レビューは,抵抗溶接モデリングの歴史と各種シミュレーションソフトウェアの特徴が紹介されており,本分野の世界的動向が一望できる内容となっている.以下は,後者の要約である.デンマーク工科大学からスピンオフしたSwantec社のソフトウェアSorpasでは,材料物性, ISO標準電極および製品形状に関するデータベースの利用により,計算結果を得る.アーヘン工科大学(ドイツ)の著者がトゥーラ大学(ロシア)と共同開発したSpotSIMでは,溶接中の材料の塑性変形および電流波形の経時変化を計算する.その結果,ナゲット形状だけでなく圧痕,溶接後のギャップおよびチリの発生を検討することが可能である.また,その計算手法について紹介されている.シュットガルト大学(ドイツ)のGreitmannらは汎用FEMソフトANSYSを利用したSpotwelderを開発した.これにより溶接部の応力分布,変形,温度分布および電流密度が可視化された.計算には,接触抵抗も考慮される.ノッティンガムトレント大学(イギリス)のAravinthanらは,汎用FEMソフトANSYS用シミュレーションツールを開発した.本ツールにより,構造計算およびナゲット成長に関する熱電気計算を行うことができる.南カリフォルニア大学(アメリカ)のKhanらは,アルミニウムを対象としたナゲット成長モデルを構築した.本モデルでは,相変態および熱伝達データベースを利用する.ベルリン工科大学(ドイツ)のDeらは,インド工科大学とアルミニウム合金に関するシミュレーションモデルを共同開発した.非線形熱依存性,融解エンタルピーおよび凝固が考慮される.大阪大学接合科学研究所(日本)のMurakawaは,スポット溶接およびシーム溶接に関するモデルを構築した.電場,熱伝導および変形を考慮した計算が特徴である.マサチューセッツ工科大学(アメリカ)のMatsuyamaは,可視化プログラムを開発した.本プログラムは通常のナゲット成長モデルに加えて,インライン制御を想定した高速計算モデルを含むため, Hybrid simulationと称される.本レビューは,著者による今後の展望によって締めくくられている.

1 0 0 0 OA 接着接合のための表面処理技術

- 著者

- 柳原 榮一

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.70, no.4, pp.409-415, 2001-06-05 (Released:2011-08-05)

- 参考文献数

- 40

- 被引用文献数

- 5

1 0 0 0 OA ろう付・はんだ付の起源と歴史(その1)

- 著者

- 雀部 謙

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.66, no.3, pp.138-141, 1997-04-05 (Released:2011-08-05)

- 参考文献数

- 3

- 著者

- 阪上 隆英

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.72, no.4, pp.251-255, 2003-06-05

- 参考文献数

- 5

1 0 0 0 OA 伊勢湾大橋と溶接橋梁の問題点

- 著者

- 菊池 洋一

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.45, no.2, pp.91-98, 1976-02-05 (Released:2011-08-05)

- 参考文献数

- 4

1 0 0 0 溶接後熱処理は何故必要か?(溶接後熱処理の実際 (1))

1 0 0 0 OA 圧力容器におけるPWHTの効果とその条件決定

- 著者

- 鈴木 宏 岡田 八郎 橋本 浩

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.61, no.6, pp.473-477, 1992-09-05 (Released:2011-08-05)

- 参考文献数

- 6

- 被引用文献数

- 2 4

1 0 0 0 溶射

- 著者

- 小暮 寛彦

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.70, no.5, 2001-07-05

1 0 0 0 OA ウォータールー大学滞在記

- 著者

- 森 裕章

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.80, no.6, pp.553-559, 2011 (Released:2013-02-21)

- 著者

- 西口 公之 松繩 朗 北田 豊文

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.39, no.1, pp.55-63, 1970-01-25

As stated in the previous paper, there found two kinds of the cathode modes, i. e. the cold and hot cathode modes, in a low pressure arc generated between the graphite electrodes. Consumption of a graphite cathode was quite different in each cathode mode. For example, a carbon vapour stream and spattering from the cathode root were ovserved in the cold cathode mode, while no vapour stream nor spattering was seen in the hot one. The consumption characteristics of a graphite cathode and the corelation to the cathode mode were investigated to clarify the cathode mechanism. Experiments were conducted on an arc with a graphite cathode and a water cooled copper anode under the condition of the current range being 10-120Amp and of the pressure 10-100 Torr of hydrogen and 10-60 Torr of helium and argon. Results obtained in this study are as follows. (1) In addition to the cold and hot cathode modes, a new mode which was termed the plasma cathode mode was distinguished in a C(-)-Cu(+) arc at low pressure, regardless of the kinds of gas. This mode which was featured by a bright sphere in front of the cathode tip (cathode plasma ball) appeared as an intermediate stage of the cold and hot cathode modes. The existence of the plasma cathode mode was clearly recognized in the consumption characteristics of a graphite cathode but hardly detected in the electric characteristics of an arc. (2) A cathode plasma ball expaoded its size with the increase of current or the reduction of pressure. In the plasma cathode mode, it was clearly separated from the arc column by a dark space. When the dark space became undetectable, the hot cathode mode emerged. (3) Under the condition of this experiment, specific consumption rate m_C/I (mg/A min) of a graphite cathode ith the cold cathode mode was as hifih as five times or compared with so the one in the hot cathode. Meanwhile, in the plasma cathode mode, m_C/I was a little higher than that in the hot one. In the cold cathode mode, more than 90% of the consumption was the sublimation of carbon at the cathode root, and the spattering loss was less than 10%. (4) In the cold cathode mode, carbon rather than the ambient gas might be preferentially ionized in the cathode fall region. (5) The transition of the cathode mode was determined by the systematic study of the consumption characteristics of a graphite cathode. In this study, three governing factors of the cathode mode (p, I & V_i), which were mentioned in the previous paper, were clearly proved.

- 著者

- 山本 利雄 島田 弥

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.39, no.11, pp.1171-1179, 1970-11-25

Various penetration shapes formed in the plates of copper, aluminum, mild steel and stainless steel by the fixed TIG arc at reduced argon pressures are discussed in relation to the electrical and thermal characteristics of the arc mentioned in the previous reports, where the arc is formed between the 2% thoriated tungsten cathode of 4mm in diameter shaped like a pencil form and a directly or indirectly water cooled anode plate under the following conditions. Gas Pressure : 18 to 760mmHg Arc Current : 250,400,450A Arc Length (Distance between Electrodes) : 4,9,15,25mm The facts elucidated are as follows (1) At reduced gas pressure, "cathode zone" (a bright spherical zone) is observed at the neighborhood of the cathode. When the cathode zone touches the anode specimen, the contact zone on the anode surface melts rapidly and a large "conduction type penetration" is formed in the specimen. Then the cathode zone is presumed to have a higher energy density compared to the arc column. (2) In the specimen of low thermal conductivity, the "peripheral type penetration" is formed due to the convectional flow in the molten pool when the energy density of the arc is considerably high. It happens sometimes that the depth of the conduction type penetration formed at small current is deeper than that of the peripheral type penetration of larger current. (3) At higher pressure the molten pool beneath the arc depresses and the "finger type penetration" is formed in this case. For directly water cooled specimen, the shape of the molten pool is conserved down to room temperature and a hollow part is often formed when the arc length is sufficiently long. At the bottom of the hollow part a solid surface is exposed and no solidified layer is observed on it. (4) The penetration in low thermal conducters such as mild steel and stainless steel varies from the "conduction type" to the "peripheral type" and further to the combined type of "peripheral type" and "finger type", with an increase in the energy density and the plasma stream at the specimen surface. For high thermal conductors like copper and aluminum, the "conduction type" is easily formed by the thermal conduction mechanism. Although the "finger type" is likely to appear when the arc energy density is considerably high, no "peripheral type" penetration is observed.

1 0 0 0 OA 赤外線サーモグラフィによる構造物の非破壊検査

- 著者

- 阪上 隆英

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.72, no.4, pp.251-255, 2003-06-05 (Released:2011-08-05)

- 参考文献数

- 5

- 被引用文献数

- 1 1

1 0 0 0 OA パイプライン「材料編」

- 著者

- 濱田 昌彦

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.80, no.2, pp.180-187, 2011 (Released:2013-02-21)

- 参考文献数

- 42

1 0 0 0 抵抗スポット溶接 電動加圧式抵抗スポット溶接ガンの適用事例

- 著者

- 瀬渡 賢

- 出版者

- JAPAN WELDING SOCIETY

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.72, no.7, pp.575-578, 2003

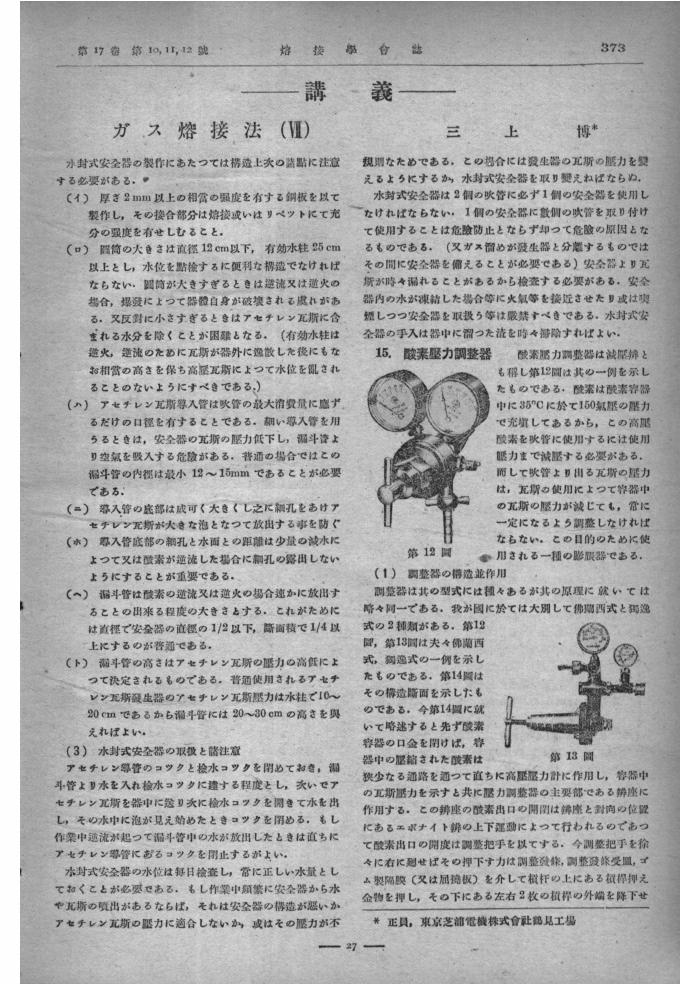

1 0 0 0 OA ガス熔接法(VII)

- 著者

- 三上 博

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.17, no.10-12, pp.373-374, 1948 (Released:2009-06-12)

1 0 0 0 OA 海洋情報都市

- 著者

- 寺井 精英

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.57, no.1, pp.8-16, 1988-01-05

- 著者

- 岡田 実 西口 公之 丸尾 大 谷 隆之

- 出版者

- 社団法人溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.36, no.1, pp.44-52, 1967-01-25

An excellent dense and oxide free coating of Ni-Cr-B-Si alloy was obtained by the shielded plasma spraying method as shown in the previous report. The present report describes certain effects of spraying conditions, such as spraying atmosphere and preheating of substrate surface, on the quality of coating. And the application of shield nozzle and its effect are also investigated in details. Usually, plasma spraying of Ni-Cr-B-Si alloy in the air makes a porous and oxide inclusive deposit, even with use of pure argon plasma jet. It may be seen that some of these defects were caused by the oxidation of droplets in spraying. Air contamination into the plasma flame up to 90% was detected in the quantitative gas analysis of plasma flame at a distance of 90mm from the torch. Spraying in argon atmosphere gave a somewhat better coated layer compared with the spraying in the air, but is far from being perfect. These results suggest that the protection of particle and substrate from oxidation is necessary but is insufficient for obtaining perfect coating. Furthermore, thermal problems in a process should be considered at the same time. As the result of atmospheric, thermal and kinetic considerations in the processes, shield spraying method has been proposed. In the shielded spraying of this alloy, the preheating of substrate has great effect on the bond between the coated layer and the substrate. For the specimen which is shield-sprayed without any preheating, a little amount of porosity was observed at the boundary. But almost perfeet metallurgical bonding is accomplished with local preheating (300℃) of substrate surface. As for the application of shield nozzle, a series of experiments were carried out to analize the effect of nozzle. Results as follows; (1) Spraying atmosphere is kept perfectly inert. (2) Shield nozzle has an effect of raising the heat transfer from the plasma flame to the particles and substrate, since the contamination of cold gas is completely shout off. (3) Application of shield nozzle makes it easy to preheat the substrate surface with a high effluent of heat flux. (4) Temperature and velocity of particle rise as a result of increase of thermal efficiency and velocity of plasma flame.

- 著者

- 岡田 実 西口 公之 丸尾 大 谷 隆之

- 出版者

- JAPAN WELDING SOCIETY

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.36, no.1, pp.44-52, 1967

An excellent dense and oxide free coating of Ni-Cr-B-Si alloy was obtained by the shielded plasma spraying method as shown in the previous report. The present report describes certain effects of spraying conditions, such as spraying atmosphere and preheating of substrate surface, on the quality of coating. And the application of shield nozzle and its effect are also investigated in details.<BR>Usually, plasma spraying of Ni-Cr-B-Si alloy in the air makes a porous and oxide inclusive deposit, even with use of pure argon plasma jet. It may be seen that some of these defects were caused by the oxidation of droplets in spraying. Air contamination into the plasma flame up to 90% was detected in the quantitative gas analysis of plasma flame at a distance of 90 mm from the torch.<BR>Spraying in argon atmosphere gave a somewhat better coated layer compared with the spraying in the air, but is far from being perfect. These results suggest that the protection of particle and substrate from oxidation is necessary but is insufficient for obtaining perfect coating. Furthermore, thermal problems in a process should be considered at the same time. As the result of atmospheric, thermal and kinetic considerations in the processes, shield spraying method has been proposed.<BR>In the shielded spraying of this alloy, the preheating of substrate has great effect on the bond between the coated layer and the substrate. For the specimen which is shield-sprayed without any preheating, a little amount of porosity was observed at the boundary. But almost perfect metallurgical bonding is accomplished with local preheating (300°C) of substrate surface.<BR>As for the application of shield nozzle, a series of experiments were carried out to analize the effect of nozzle. Results as follows;<BR>(1) Spraying atmosphere is kept perfectly inert.<BR>(2) Shield nozzle has an effect of raising the heat transfer from the plasma flame to the particles and substrate, since the contamination of cold gas is completely shout off.<BR>(3) Application of shield nozzle makes it easy to preheat the substrate surface with a high effluent of heat flux.<BR>(4) Temperature and velocity of particle rise as a result of increase of thermal efficiency and velocity of plasma flame.

1 0 0 0 OA CIキャンペーン特別座談会

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.60, no.3, pp.170-181, 1991-04-05 (Released:2011-08-05)