1 0 0 0 水着の変遷と未来

- 著者

- 永島 和祥

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.62, no.1, pp.P.25-P.28, 2006

1 0 0 0 生物紡糸:低エネルギー・スーパー紡糸(クモ)

1 0 0 0 繊維製品事故例, 品質相談室に寄せられたお客様情報

- 著者

- 小松 透

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.53, no.8, pp.265-269, 1997-08-10

1 0 0 0 OA 繊維の表面と集合体の性質

- 著者

- 西海 四郎

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.31, no.3, pp.P63-P67, 1975-03-10 (Released:2008-11-28)

- 参考文献数

- 22

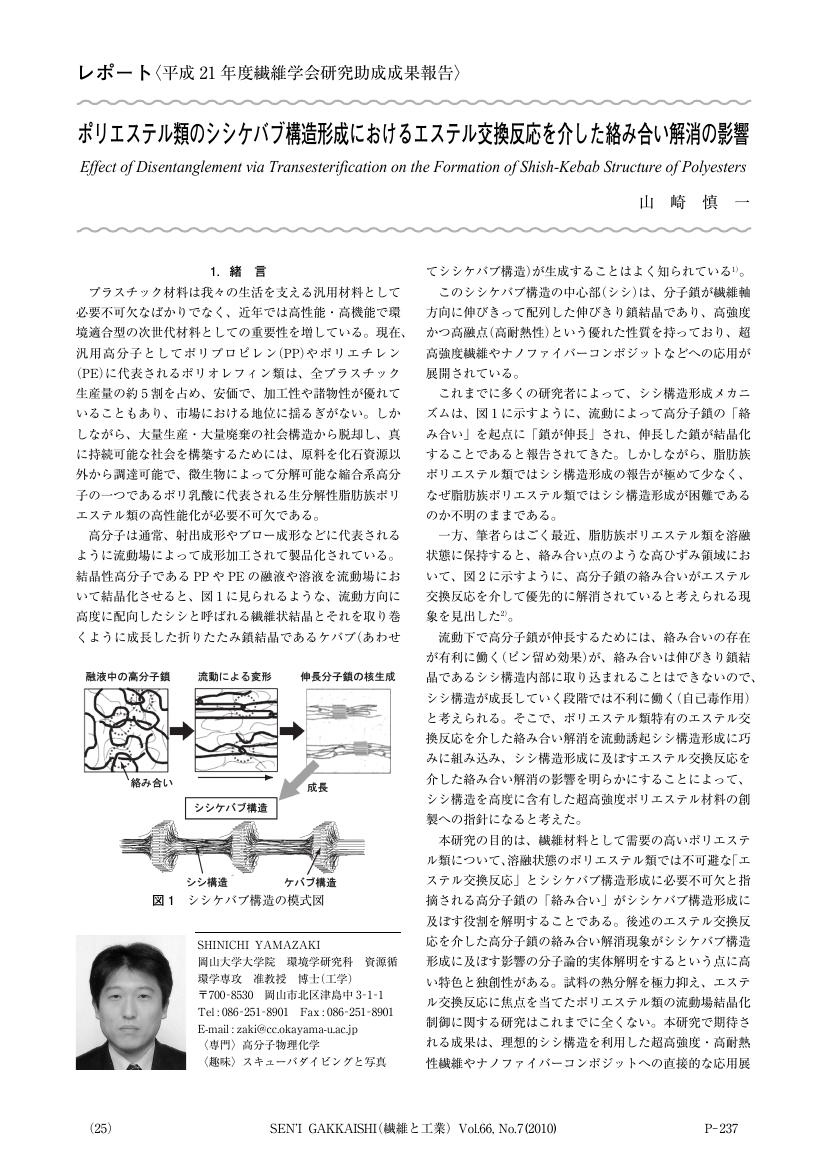

1 0 0 0 OA ポリエステル類のシシケバブ構造形成におけるエステル交換反応を介した絡み合い解消の影響

- 著者

- 山崎 慎一

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.66, no.7, pp.P_237-P_239, 2010-07-10 (Released:2010-08-17)

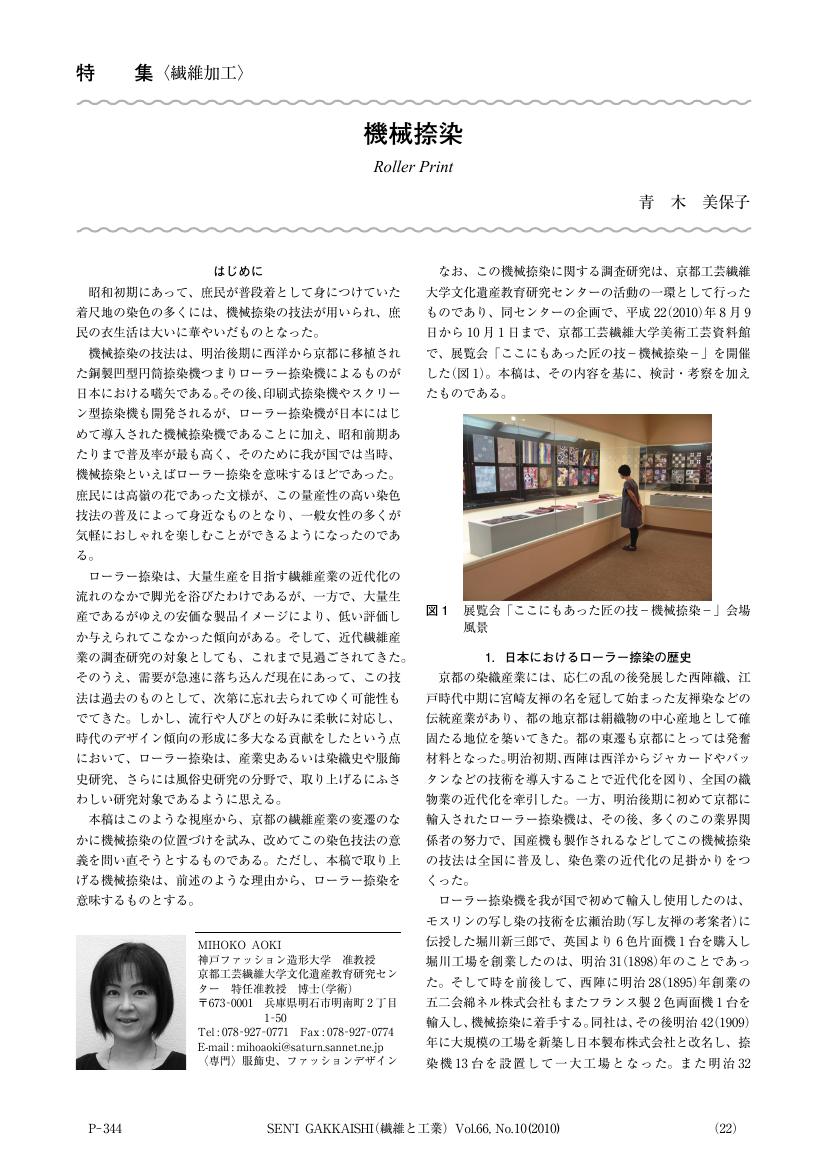

1 0 0 0 OA 機械捺染

- 著者

- 青木 美保子

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.66, no.10, pp.P_344-P_349, 2010 (Released:2010-11-19)

1 0 0 0 OA 超高速回転における軸受の諸問題

- 著者

- 矢部 寛

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.38, no.9, pp.P442-P447, 1982-09-10 (Released:2008-11-28)

- 参考文献数

- 26

1 0 0 0 コラーゲンを用いたメカノケミカル・タービンの特性

- 著者

- 中島 勝 熨斗 秀夫 今仲 明夫 山崎 隆 矢田 尚登

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.38, no.3, pp.T109-T115, 1982

The apparatus of mechanochemical turbine in the mechanical shape and materials similar to those designed by A. Katchalsky was constructed. The experiment on the driving of mechanochemical turbine was performed to make clear some obscure points in Katchalsky's paper such as proper condition of crosslinking treatment of collagen film, theoretically induced revolution number and situation of turning.<br>The following results were obtained; 1) crosslinking of collagen film with 2% formaldehyde aqueous solution and 10M LiBr aqueous solution as a contracting liquid were found to be suitable, 2) the equation of the calculated revolution number using the mechanochemical diagram was induced, 3) this turbine could not be turned continuously for a long period of time, but continuous several turnings were gained temporarily, and it was found that the observed revolution number was 2.5 sec<sup>-1</sup> and the power was 26.5mW closed to the figure of 30mW obtained by Katchalsky. The results indicate that the induced equation of revolution number is valid and the power of 26.5mW would be acceptable.

1 0 0 0 OA わが国における洗毛の現状

- 著者

- 佐貫 治夫

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.35, no.9, pp.P258-P265, 1979-09-10 (Released:2008-11-28)

- 参考文献数

- 9

1 0 0 0 繊維産地の盛衰3

- 著者

- 松下 義弘

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.77, no.9, pp.P-496-P-507, 2021-09-15 (Released:2021-10-01)

1 0 0 0 ポリエステル長繊維生産設備の変遷(その2)

- 著者

- 中田 賢一

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.73, no.12, pp.P-516-P-521, 2017

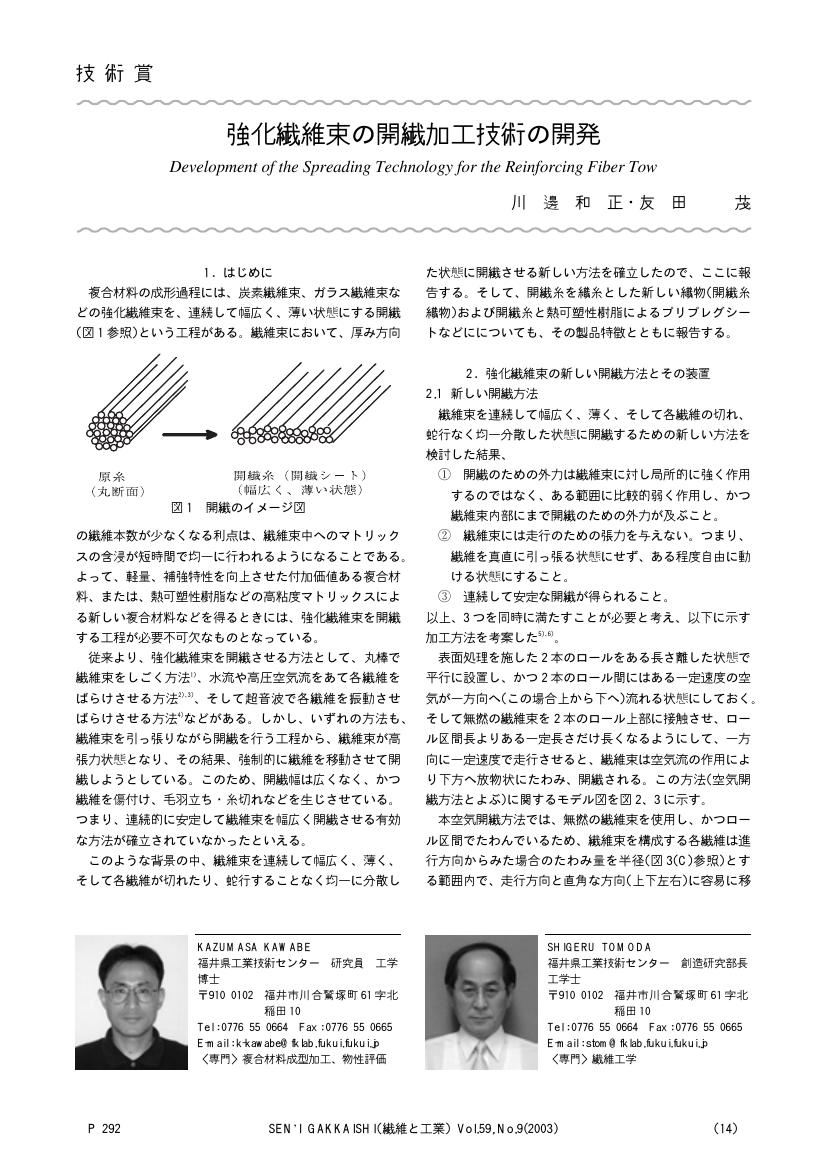

1 0 0 0 OA 強化繊維束の開繊加工技術の開発

1 0 0 0 ポリエステル長繊維生産設備の変遷(その3)

- 著者

- 中田 賢一

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.74, no.3, pp.P-110-P-114, 2018

1 0 0 0 ポリエステル長繊維生産設備の変遷(その1)

- 著者

- 中田 賢一

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.73, no.10, pp.P-392-P-396, 2017

1 0 0 0 OA 布の動的変形予測における風の影響

- 著者

- 山崎 華恵 今岡 春樹

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.52, no.6, pp.284-292, 1996-06-10 (Released:2008-06-30)

- 参考文献数

- 9

- 被引用文献数

- 2 1

The influence of wind blowing was investigated as an essential factor that should be taken into account when the motion and deformation of textile fabrics in the air are predicted by numerical simulation. A few alternative analytical models to express how the resistance of the air exerted on rectangular strips of cloth depends on the relative velocity of fluid were examined and compared with experimental observations. The obtained results suggested that the second order model, in which the air resistance depends on a linear combination of the. velocity and the square of it, gave a better approximation than the conventional model only with the first order term.

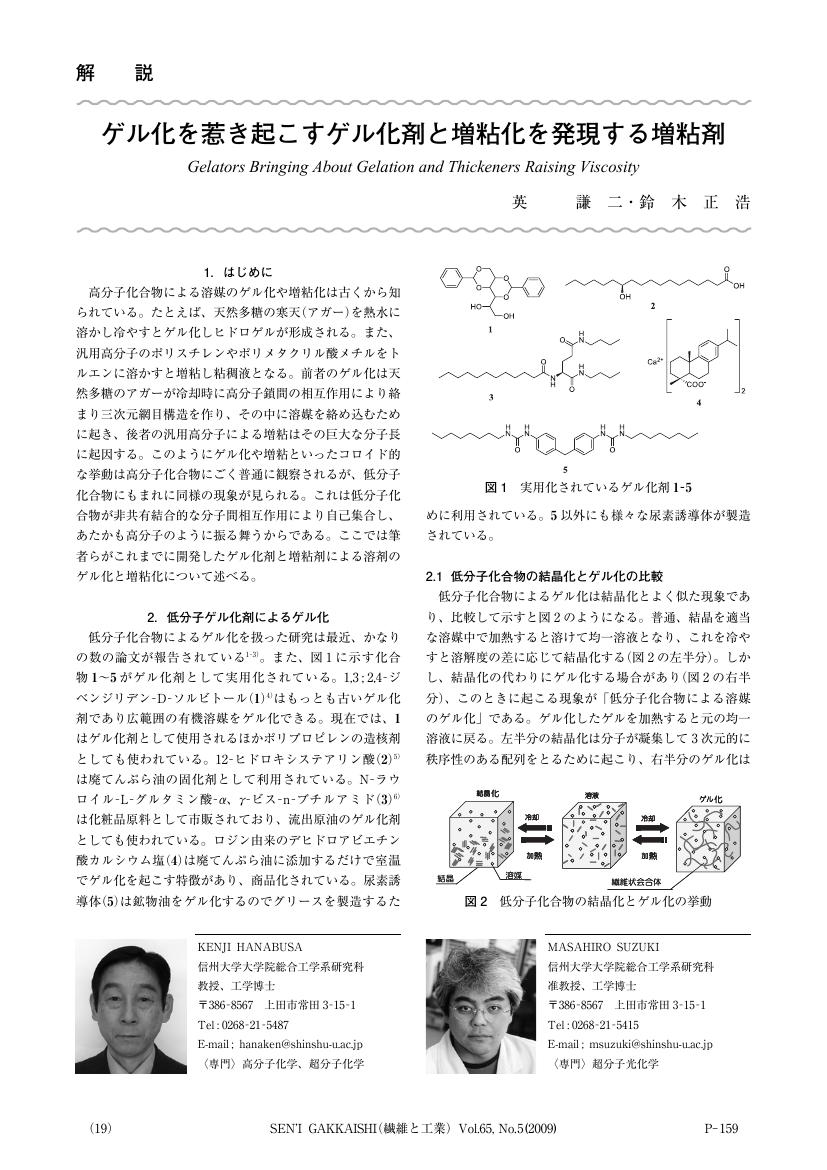

1 0 0 0 OA ゲル化を惹き起こすゲル化剤と増粘化を発現する増粘剤

Amilan (Nylon 6, Toyo Rayon Co.) was dyed by the so-called changing dyebath method which is a variation of the infinite dyebath method, adjusting the pH in the dyebath with such a concentration of phosphate buffer solution that the salt anion did not affect the dye uptake on the fibre. In this method the dyebath was changed frequently with fresh dye liquor having the same composition as the initial one as the dyeing proceeds, repeating this process until the equilibrium was attained. By the above method we are to obtain the dyeings which are in equilibrium with any arbitrary concentration of the dyebath. In the present experiment, however, the dyebath concentration was kept in the pH range 2-8. We have calculated the affinity of dye acid by the application of Gilbert-Rideal equation to our results.<br>The affinities of 14 acid azodyes, which were determined by this method at 59°C, were compared with those measured by usual dye acid adsorption method. This new method was found to be useful for the determination of affinity, since it shortenes the time of attaining to the dyeing equilibrium to 1/5_??_1/3 times of that required in the case of dye acid adsorption method, besides the experiment could be more easily performed.<br>From the fact that for 10 out of 14 dyes the saturation values agrees with each other, being 4.71×10<sup>-2</sup> eq./kg., ± 2%, it is deduced that the sites (terminal amino groups in Amilan) would be stoichiometrically occupied not only by monobasic dyes, but also by polybasic dyes. Moreover, it was observed that the affinity increases with the molecular weight of dyes; i.e., when a benzene ring is substituted with a naphthalene ring, it increases by 2.1 Kcal. and 1.7 Kcal. for monobasic and dibasic dyes respectively. Also if an additional benzene-azo group is introduced into the molecules, the increment of affnities becomes 3.5 Kcal. and 3.0 Kcal. for respective cases.

1 0 0 0 OA ナノファイバーテクノロジー

1 0 0 0 摩擦堅牢度に及ぼす添付白布の摩擦係数の影響

- 著者

- 菅沼 恵子

- 出版者

- The Society of Fiber Science and Technology, Japan

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.66, no.8, pp.194-198, 2010-08-10

- 参考文献数

- 9

- 被引用文献数

- 2

Rub-fastness of dyed fabrics is a matter of importance for practical use. Generally speaking, vat and naphthol dyes tend to suffer from poor rub fastness. However poor it is, it depends on the friction coefficient between dyed fabric and rubbed cloth. That is, smooth one should have good rub-fastness. In this paper rubbing-off behavior of denims using various white cloths is investigated from the kinetic viewpoint so that the interesting results are obtained. That is, the values of the rate constant k<sub>1</sub> of transfer of dye from dyed fabric to white cloth and the equilibrium constant K (k<sub>1</sub>/k<sub>-1</sub>) are ranged about ten times by various white cloths. These values depend on friction coefficient of white cloth, with having nothing to do with variety of fibers, fabrics and so on. Natural logarithm of each constant is linearly related to the reciprocal of friction coefficient. It suggests that the measurement of friction coefficient should be effective for standard of rub-test in addition to a designation of cloth or adjustment of moisture regain.

1 0 0 0 均一過ヨウ素酸酸化によって得られたジアルコールセルロースの粘弾性

- 著者

- 師岡 淳郎 則元 京

- 出版者

- 社団法人 繊維学会

- 雑誌

- 繊維学会誌 (ISSN:00379875)

- 巻号頁・発行日

- vol.47, no.7, pp.328-333, 1991

- 被引用文献数

- 4

In accordance with the newly developed homogeneous periodate oxidation procedure, we prepared high cleavage level 2, 3-dialcohol cellulose (DAC) which gives off a clear and transparent film. Viscoelastic properties of DAC were investigated in relation to those of cellulose. Dynamic mechanical measurements for DAC at 110Hz over the temperature range from -150°C to 150°C revealed two kinds of relaxation processes, which were respectively centered around -70°C and 112°C. The first process at -70°C was related to dielectric relaxion, and was regarded to be, similar to the process in cellulose, due to the motion of methylol groups. On the other hand, the cleavage of C<sub>2</sub>-C<sub>3</sub> bonds of the glucopyranose ring resulted in the process at around 112°C, while no comparable process has been reported for cellulose in the similar region. This process was ascribed to the micro- Brownian motion along the main chain. From the temperature variation of the stress-elongation diagrams, the glass transition temperature Tg for DAC was estimated to be about 80°C. The DAC film above Tg showed a marked elongation reaching 200% at 112°C.