- 著者

- 鈴木 敏夫 Suzuki Toshio

- 出版者

- 法政大学大原社会問題研究所

- 雑誌

- 大原社会問題研究所雑誌 (ISSN:09129421)

- 巻号頁・発行日

- no.668, pp.24-37, 2014-06

6 0 0 0 IR 江戸時代における養生書の研究--身体運動の養生的価値をめぐって

- 著者

- 鈴木 敏夫

- 出版者

- 北海道大學教育學部

- 雑誌

- 北海道大学教育学部紀要 (ISSN:04410637)

- 巻号頁・発行日

- no.22, pp.411-424, 1973-11

- 被引用文献数

- 1

3 0 0 0 OA 関東大震災をめぐる教育現場の歴史修正主義

- 著者

- 鈴木敏夫

- 出版者

- 法政大学大原社会問題研究所

- 雑誌

- 大原社会問題研究所雑誌

- 巻号頁・発行日

- vol.2014年(6月), no.668, 2014-06-25

- 著者

- 加賀 秀雄 鈴木 敏夫

- 出版者

- 一般社団法人 日本体育学会

- 雑誌

- 日本体育学会大会号

- 巻号頁・発行日

- vol.37, 1986

3 0 0 0 OA 北海道における小学校運動会の起源

- 著者

- 鈴木 敏夫

- 出版者

- 北海道大学大学院

- 雑誌

- 北海道大学大学院教育学研究科紀要 (ISSN:13457543)

- 巻号頁・発行日

- vol.89, pp.31-52, 2003-03

2 0 0 0 グスタフ・フライタ-クの<借り方と貸し方>(試訳)

- 著者

- Fontanes Theodor 鈴木 敏夫

- 出版者

- 城西大学

- 雑誌

- 城西人文研究 (ISSN:02872064)

- 巻号頁・発行日

- vol.15, no.2, pp.p73-100, 1987-12

1 0 0 0 OA 札幌農学校のミリタリー・ドリル 担当教員の推移を中心として

- 著者

- 鈴木 敏夫

- 出版者

- 体育史学会

- 雑誌

- 体育史研究 (ISSN:09144730)

- 巻号頁・発行日

- vol.17, pp.33-44, 2000 (Released:2022-10-12)

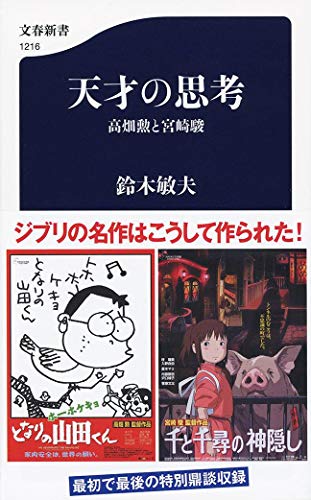

1 0 0 0 天才の思考 : 高畑勲と宮崎駿

1 0 0 0 IR 教育家と衛生家との衝突--「学校衛生顧問会」と武術の学校正科編入問題

- 著者

- 鈴木 敏夫

- 出版者

- 北海道大學教育學部

- 雑誌

- 北海道大学教育学部紀要 (ISSN:04410637)

- 巻号頁・発行日

- no.54, pp.p1-12, 1990-02

1 0 0 0 OA 教育家と衛生家との衝突「学校衛生顧問会」と武術の学校正科編入問題

- 著者

- 鈴木 敏夫

- 出版者

- 北海道大學教育學部

- 雑誌

- 北海道大學教育學部紀要 (ISSN:04410637)

- 巻号頁・発行日

- vol.54, pp.1-12, 1990-02

1 0 0 0 キトサンを用いた船底塗料の摩擦抵抗特性

- 著者

- 田中 寿夫 下山 敬次 戸田 保幸 山盛 直樹 肥後 清彰 鈴木 敏夫

- 出版者

- 公益社団法人日本船舶海洋工学会

- 雑誌

- 関西造船協会講演概要集 = Proceedings of the Kansai Society of Naval Architects (ISSN:13465791)

- 巻号頁・発行日

- no.20, pp.39-40, 2003-05-22

- 参考文献数

- 4

1 0 0 0 OA 徳川幕府法令における遊戯統制

- 著者

- 鈴木 敏夫

- 出版者

- 北海道大學教育學部

- 雑誌

- 北海道大學教育學部紀要 (ISSN:04410637)

- 巻号頁・発行日

- vol.35, pp.77-89, 1980-03

1 0 0 0 OA 102 徳川幕府諸法令に見られる庶民の遊戯統制について

- 著者

- 鈴木 敏夫

- 出版者

- 一般社団法人 日本体育学会

- 雑誌

- 日本体育学会大会号 第30回(1979) (ISSN:24330183)

- 巻号頁・発行日

- pp.86, 1979 (Released:2017-08-25)

1 0 0 0 OA 札幌農学校遊戯会の成立過程

- 著者

- 鈴木 敏夫

- 出版者

- 北海道大學教育學部

- 雑誌

- 北海道大學教育學部紀要 (ISSN:04410637)

- 巻号頁・発行日

- vol.75, 1998-03

1 0 0 0 OA マグネシウム鍛造材ZK60A合金の機械的性質•疲れ強さに及ぼすメタル•フローの影響

- 著者

- 原田 雅行 鈴木 敏夫 福井 泉

- 出版者

- 一般社団法人 軽金属学会

- 雑誌

- 軽金属 (ISSN:04515994)

- 巻号頁・発行日

- vol.34, no.5, pp.265-272, 1984-05-31 (Released:2008-07-23)

- 参考文献数

- 11

- 被引用文献数

- 1 1

Effects of metal flow on mechanical properties particularly on fatigue strength of ZK60A forgings were studied. The forgings are the most strong in yield, tensile and fatigue strength in the longitudinal direction and weaken as the loading direction turns to the transverse direction. They have particularly the yield strength so weak as 13 to 15 kgf/mm2 that corresponds to only a half of the strength in the longitudinal direction. The maximum elongation is achieved at angles 45° to 60° to the metal flow direction. The fatigue strength σW is expressed as a function of tensile strength σB, σW/σB 0.87-0.07 logN. where N is cycles: ZK60A magnesium forgings have a greater effect of metal flow on strength than aluminum alloy and AZ80A magnesium alloy forgings.

1 0 0 0 OA 当院における注射オーダーシステムの構築とその評価

- 著者

- 寒河江 喜紀 福井 了三 吉岡 克己 近藤 克幸 松本 喜良 鈴木 敏夫

- 出版者

- 一般社団法人日本医療薬学会

- 雑誌

- 医療薬学 (ISSN:1346342X)

- 巻号頁・発行日

- vol.27, no.2, pp.159-166, 2001-04-10 (Released:2011-03-04)

- 参考文献数

- 5

The ordering system for injections in the total medical informational system in the Akita University Hospital was established after modifying the old system in 1999. The Auto Ample dispense (AAD) system was combined with this ordering system by TCP/IP protocol and was also introduced in our department. The stable use of this total system has been underway for the dispensation of injections since November 1999. The usefulness and efficacy of this system was evaluated in our department based on the findings of working charts, time courses, and appropriate prescriptions of the injections.The smooth and stable dispensation of all injections using this AAD system was carried out not only for regular orders, but also for temporary orders. All nurses gave this system a favorable evaluation. The statistical data indicated that more prescription sheets were issued with this system than with the previous system, and it required much time for the packaging of injections in this system compared with the manual way. However, the efficient transport of the drugs was maintained in all wards using this system. A minor revision in this system was introduced in order to promote the appropriate dosage for every injection. The incidence of injection mistakes was thus reduced to less than 10 per month.

1 0 0 0 OA 江戸時代における養生書の研究:身体運動の養生的価値をめぐって

- 著者

- 鈴木 敏夫

- 出版者

- 北海道大學教育學部 = THE FACULTY OF EDUCATION HOKKAIDO UNIVERSITY

- 雑誌

- 北海道大學教育學部紀要 (ISSN:04410637)

- 巻号頁・発行日

- vol.22, pp.411-424, 1973-11

- 著者

- 永松 哲郎 児玉 良明 角川 明 高井 通雄 村上 恭二 石川 暁 上入佐 光 荻原 誠功 吉田 有希 鈴木 敏夫 戸田 保幸 加藤 洋治 池本 晶彦 山谷 周二 芋生 秀作 山下 和春

- 出版者

- 公益社団法人日本船舶海洋工学会

- 雑誌

- 日本造船学会論文集 (ISSN:05148499)

- 巻号頁・発行日

- no.192, pp.15-28, 2002-12

- 参考文献数

- 11

- 被引用文献数

- 7 12

This paper is the second half of the report on the study on microbubbles carried out by the SR239 project of the Shipbuilding Research Association of Japan, and describes the full-scale experiment using "SEIUN MARU", a 116m-long training ship that belongs to the Institute for Sea Training. Using numerical analysis and the experimental data obtained in the preparatory study described in the first half of the report, the net energy saving of SEIUN MARU by microbubbles at 14kts was estimated to be 2%. In the full-scale experiment, the trajectory of the generated bubbles was observed using underwater TV cameras and was found to shift more upward than predicted. The local skin friction was measured at several locations on the hull surface, and the skin friction increase as well as decrease by the bubbles was measured. The local void ratio was measured at one point on the hull surface, and the bubbles were found to travel slightly away from the hull surface. The change of the ship speed and shaft horsepower by microbubbles was measured, and the decrease or increase of engine power at constant ship speed was analyzed. In the most cases of the experiment the ship speed decreased by the bubble injection, mainly due to the increase of ship resistance and the decrease of propeller efficiency caused by the bubbles going into the working propeller. But, by carefully choosing the bubble injection location and thus avoiding the bubble entrainment into the propeller, the 3% power saving at a constant speed of 14kts was obtained. By taking into account the power needed to inject bubbles against hydrostatic pressure due to water depth at the injection point, this corresponds to the net power saving of 2%. Thus the net power saving by microbubbles was measured on a full-scale ship for the first time in the world.

- 著者

- 斎藤 環 川上 量生 鈴木 敏夫

- 出版者

- スタジオジブリ

- 雑誌

- 熱風 : スタジオジブリの好奇心

- 巻号頁・発行日

- vol.10, no.11, pp.31-47, 2012-11