- 著者

- Hiroyuki Uchima Masayoshi Kumagai Junzo Shimbe Akihiro Tanabe Yuta Mizuno Yusuke Onuki

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.62, no.5, pp.998-1003, 2022-05-15 (Released:2022-05-24)

- 参考文献数

- 38

- 被引用文献数

- 9

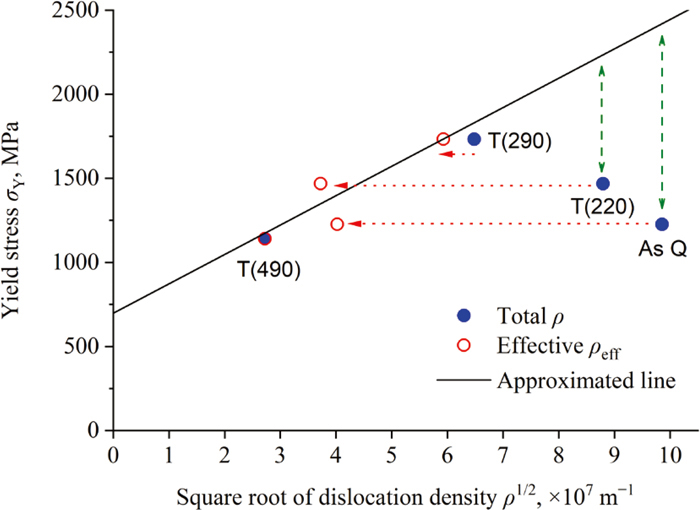

Middle-carbon martensite steels are vital materials for mechanical components and their mechanical properties have attracted significant interest. However, the decrease in the elastic limit of the as-quenched materials is one of the remaining puzzles. Herein, we quantitatively characterized the dislocation density and its structure in the as-quenched and tempered martensite steel by neutron diffraction line profile analysis and discussed their impact on the yield stress. The dislocation density in the as-quenched specimen was the highest at 9.7 × 1015 m−2, while it decreased with an increase in the tempering temperature. In addition, the component ratios of edge and screw dislocations decreased and increased, respectively, depending on the increase in the tempering temperature. The dislocation arrangement parameter (M) varied between the tempering temperatures of 220 and 290°C. Although there was a large difference between the yield stress obtained from the tensile test and that estimated from the dislocation density, the experimental results could be explained by correcting them with the inverse of M value as an index showing the effective dislocation density ratio.

- 著者

- Hiroyuki Uchima Masayoshi Kumagai Junzo Shimbe Akihiro Tanabe Yuta Mizuno Yusuke Onuki

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- pp.ISIJINT-2021-443, (Released:2022-01-07)

- 参考文献数

- 38

- 被引用文献数

- 9

Middle-carbon martensite steels are vital materials for mechanical components and their mechanical properties have attracted significant interest. However, the decrease in the elastic limit of the as-quenched materials is one of the remaining puzzles. Herein, we quantitatively characterized the dislocation density and its structure in the as-quenched and tempered martensite steel by neutron diffraction line profile analysis and discussed their impact on the yield stress. The dislocation density in the as-quenched specimen was the highest at 9.7 × 1015 m-2, while it decreased with an increase in the tempering temperature. In addition, the component ratios of edge and screw dislocations decreased and increased, respectively, depending on the increase in the tempering temperature. The dislocation arrangement parameter (M) varied between the tempering temperatures of 220 and 290°C. Although there was a large difference between the yield stress obtained from the tensile test and that estimated from the dislocation density, the experimental results could be explained by correcting them with the inverse of M value as an index showing the effective dislocation density ratio.

- 著者

- Kodai Murasawa Masato Takamura Masayoshi Kumagai Yoshimasa Ikeda Hiroshi Suzuki Yoshie Otake Takayuki Hama Shinsuke Suzuki

- 出版者

- The Japan Institute of Metals and Materials

- 雑誌

- MATERIALS TRANSACTIONS (ISSN:13459678)

- 巻号頁・発行日

- pp.M2017380, (Released:2018-06-01)

- 参考文献数

- 22

- 被引用文献数

- 6

Neutron diffraction profile analysis using the whole profile fitting method is useful for obtaining microscopic information on metallic materials. To determine an appropriate fitting approach for obtaining reasonable and non-arbitrary results, we applied diffraction line profile analyses using the Convolutional Multiple Whole Profile (CMWP) method to diffraction patterns obtained using the Engineering Materials Diffractometer (TAKUMI, BL19) at the Materials and Life Science Facility (MLF) of the Japan Proton Accelerator Research Complex (J-PARC). The tensile specimens of 780 MPa grade bainitic steel were uniaxially stretched until the plastic strain reached a value of 0.05. We performed CMWP analyses on the obtained diffraction patterns during tensile test with various initial parameters of dislocation density and crystallite size. These parameters were optimized in the fitting procedures to minimize the weighted sums of squared residuals (WSSRs). Following this approach, we found that unsuitable initial parameter values resulted in unreasonable convergence. Therefore, initial fitting parameters should be chosen to ensure that the initial profiles are as broad as possible. Reasonable results were obtained following this suggestive approach even when the strain anisotropy parameter is set to arbitrary values.

- 著者

- Shigeru Suzuki Koji Hotta Eui Pyo Kwon Shun Fujieda Kozo Shinoda Masayoshi Kumagai Kentaro Kajiwara Masugu Sato Shigeo Sato

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.55, no.10, pp.2158-2165, 2015-10-15 (Released:2015-10-28)

- 参考文献数

- 48

- 被引用文献数

- 7

Electron backscatter diffraction was used to observe the microstructure of an austenitic high-manganese twinning-induced plasticity steel and investigate the crystal orientation of grains in this steel. The results showed that mechanical twins are formed in a grain with a high Schmid factor during the tensile test. The orientation data obtained were used to estimate the anisotropic elasticity of the grains in the steel. The microscopic stress and strain evolved in the microstructure of the steel unloaded after plastic deformation were estimated using finite element method simulation in which the elastic anisotropy of the steel was taken into account. The simulation indicated that the evolution of microscopic stress and strain in the microstructure is considerably influenced by the crystal orientation of the grains. Furthermore, white X-ray diffraction with microbeam synchrotron radiation was used to characterize the evolution of microscopic stress and strain in the grains of the steel. The stress analysis during white X-ray diffraction indicated the formation of residual microscopic stress after tensile deformation, which was found to be distributed heterogeneously in the steel. It was also shown that the direction of the maximum principal stresses at different points in the microstructure under loading were mostly oriented along the tensile direction. These results are fairly consistent with the results obtained by the simulation, although absolute values of the real principal stresses may be influenced by the heterogeneously evolved strain and the several assumptions used in the simulation.

1 0 0 0 OA Residual Stress Analysis of Cold-drawn Pearlite Steel Wire Using White Synchrotron Radiation

- 著者

- Masayoshi Kumagai Shigeo Sato Shigeru Suzuki Muneyuki Imafuku Hitoshi Tashiro Shin-ichi Ohya

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.55, no.7, pp.1489-1495, 2015-07-15 (Released:2015-07-30)

- 参考文献数

- 19

- 被引用文献数

- 1 3

Measurement of the residual stresses in cold-drawn pearlitic steel wire was conducted using an energy dispersive X-ray diffraction technique. The residual stresses of the ferrite and cementite phases were determined for different crystal orientations and large residual stresses were found to exist in the cold-drawn pearlitic steel wire. The residual stresses in the ferrite phase were compressive in the axial direction but nearly zero in the hoop and radial directions. In addition, the residual stresses of the reflection indices for the ferrite phase were similar to one another. For the cementite phase, while tensile residual stress existed in the axial direction, compressive residual stress existed in the hoop and radial directions. These stresses in the ferrite phase in the axial direction and cementite phase in all directions decreased along the radial positions. A residual stress state model was proposed on the basis of the aligned lamellar structure along the drawing direction; the model explains the effect of the lamellar direction on residual stress. Reanalysis of the wire sample using the proposed model provided residual strains and stresses in the lamellar direction that were different from the average values estimated using the simple stress analysis method.