2193 0 0 0 OA 缶詰の内面腐食

- 著者

- 宮崎 俊三

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.73, no.3, pp.427-436, 1987-03-01 (Released:2010-01-18)

- 参考文献数

- 87

- 被引用文献数

- 2 1

229 0 0 0 OA 日本刀刃先部の強度と破壊抵抗に及ぼす不均一組織の影響

- 著者

- 郭 光植 山室 賢輝 峯 洋二 森戸 茂一 高島 和希

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- pp.TETSU-2023-076, (Released:2023-11-25)

- 参考文献数

- 24

Microtensile and microfracture tests were performed on the sharp-edge regions of Japanese swords fabricated in the Muromachi and Showa periods, which are called old sword (OS) and modern sword (MS), respectively, to correlate the mechanical properties with the inhomogeneous microstructures. The hardness of the sharp-edge regions was characterised by the distribution of fine pearlite mixed in martensite microstructures. The OS containing a large fraction of fine pearlite exhibited a low hardness compared to the MS. Microtensile tests using sharp-edge specimens revealed a positive correlation between their tensile strength and strain-to-failure, as opposed to the common tendency in conventional carbon steels made by modern iron-making technology. The fracture surfaces of the sharp-edge specimens were composed of intergranular and dimple fracture features. The tensile strength and dimple fracture area fraction were higher in the OS than in the MS. These findings suggest that the fine pearlite microstructure contributes to increased strength in the sharp-edge region through inhibiting the linkage of intergranular cracking owing to local plastic deformation. Microfracture tests using the sharp-edge specimens revealed that the intrinsic fracture resistance of both OS and MS was determined by the intergranular fracture, whereas the fine pearlite microstructure increased the resistance to crack propagation. The micromechanical testing study indicates that in the sharp-edge regions, their strength and fracture toughness are simultaneously enhanced by the presence of fine pearlite although depending on its distribution.

21 0 0 0 OA 製銑技術の100年 −技術導入から先進技術への展開,そして次世代技術へ−

- 著者

- 内藤 誠章 武田 幹治 松井 良行

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.1, pp.2-30, 2014 (Released:2013-12-31)

- 参考文献数

- 218

- 被引用文献数

- 9 14

The modern blast furnace operation at integrated steel works in Japan has started in 1901 by the first blown-in of Higashida No. 1 blast furnace in Yawata Works, while a 150 years history of Japanese steel industry has dated back to the first western blast furnace built by T. Ohashi in 1857. The steel industry has been supporting the Japanese economy as a key industry which supplies base materials for social infrastructure and developments throughout the pre and post war periods.After the recovery period from the war destruction, Chiba Works of Kawasaki Steel Corp., were built and started its operation in 1953 as the first integrated steel works in Keiyo Industrial Region after the war. During the rapid growth period, many coastal steel works equipped with a large blast furnace more than 3000m3 and some of 5000m3 were built for the efficient marine transportation of raw materials and steel products. Most advanced technologies, high pressure equipment, stave cooler system and bell-less charging system etc., were introduced, improved and has risen to the top level in the world with low reducing agent ratio (RAR), energy saving and long service life of a blast furnace and coke ovens.Energy shift from oil to coal by the oil crisis, cost oriented operation design and technology were tackled and the hot metal of about 80 million tons is manufactured with 27 blast furnaces including over 5000m3 large scale blast furnaces in 2012. During this period, our industry has faced many economical and social pressures of high exchange rate of yen, oligopoly of mining market, global warming problem, and surge of iron ore and coal prices by the rapid growth of the BRICs. We have kept our competitive positions by developing advanced technologies on pulverized coal injection, extended use of low cost iron resources, recycling for environment and CO2 mitigation technologies.Prospects of ironmaking technologies for other decades are discussed by reviewing various papers published and looking back the history of ironmaking developments during the last 100 years.

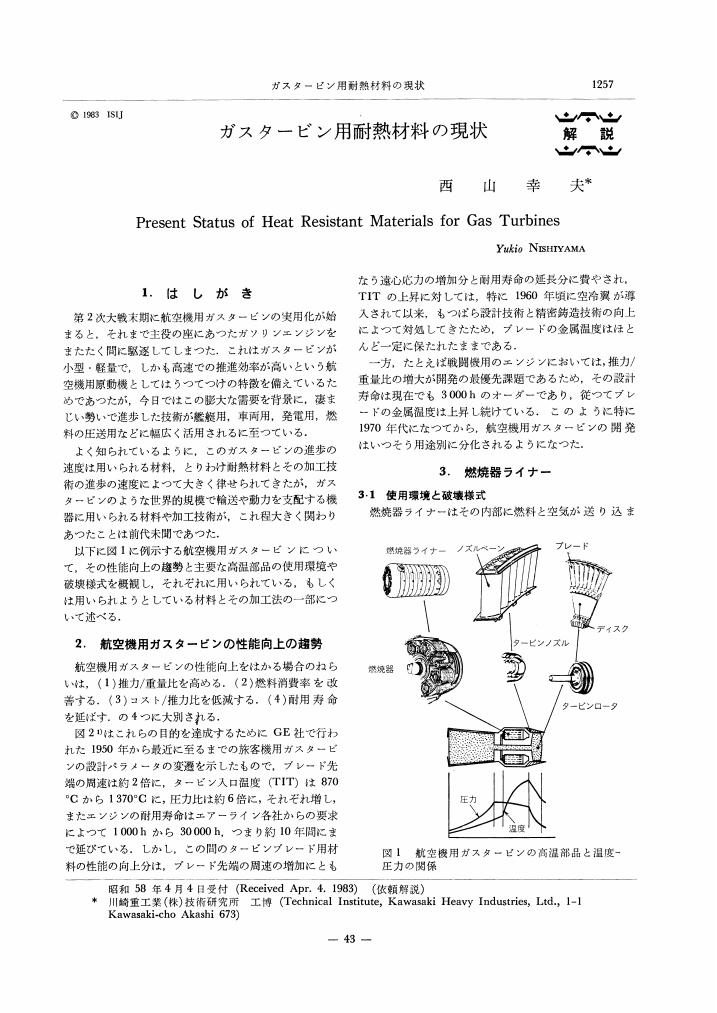

11 0 0 0 OA ガスタービン用耐熱材料の現状

- 著者

- 西山 幸夫

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.69, no.10, pp.1257-1265, 1983-08-01 (Released:2009-06-30)

- 参考文献数

- 27

- 被引用文献数

- 1

10 0 0 0 OA 日本における構造用高張力鋼の発達と溶接上の問題点

- 著者

- 木原 博

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.58, no.13, pp.1903-1912, 1972-11-01 (Released:2010-10-12)

- 参考文献数

- 26

10 0 0 0 OA 日本刀の強度-靭性バランスと刃金用玉鋼の折返し鍛錬による炭素量,焼入れ硬さの変化

- 著者

- 佐々木 直彦 堀井 胤匡 藤原 幹男 斎藤 英之 三澤 俊平

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.86, no.1, pp.45-50, 2000-01-01 (Released:2009-06-19)

- 参考文献数

- 13

- 被引用文献数

- 7

Micro-strucure, micro-hardness and micro-absorbed impact energy in the Japanese sword have been investigated to clarify excellent mechanical properties of the Japanese sword. The Japanese sword specimen used in the present research has been made by using TSUKURIKOMI process which combines four kinds of steels; HAGANE (edge), SHINGANE (core), MUNEGANE (back) and KAWAGANE (side) steels, with different carbon contents. By this process, HASAKI (edge) side becomes high carbon steel and MUNE (back) side possesses low carbon steel. The cooling velocity in quenching of the Japanese sword is controlled by TSUCHIOKI treatment which coats the clay thinner in the HASAKI side and thicker in the MUNE side. The HASAKI side is quickly cooled and the MUNE side is slowly cooled. The micro-structure in the HASAKI side shows martensite while the MUNE side shows the coexist structure of ferrite and pearlite. The HASAKI side has a lower value while the MUNE side shows a higher value in the micro absorbed impact energies obtained with the 1.0 and 0.7 mm square miniaturized specimens. It has been shown clearly that the TSUKURIKOMI and the TSUCHIOKI processes give the excellent gradated balance of strength-toughness to the Japanese sword.The ORIKAESHI (folding) forging has an effect both on the carbon content and as quenched hardness in HAGANE steel. The most suitable times of ORIKAESHI cycles which adjust to the carbon content of 0.55-0.60 mass% and hardness of 800HV1 have been determined to be thirteen times. These times of ORIKAESHI cycles correspond to the optimum traditional cycles lying between twelve and fifteen times. The present research from the viewpoint of the metallurgy sheds light on the empirical rule in the traditional Japanese sword processing.

9 0 0 0 OA ラジオアイソトープによる高炉炉壁の侵蝕調査(I)

- 著者

- 富永 在寛 八塚 健夫 庄野 四朗

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.46, no.1, pp.7-11, 1960 (Released:2012-07-12)

- 参考文献数

- 5

To measure the wearing state of a blast-furnace brick-work during its operation, a test method using a radioactive isotope (Co60) was investigated. In this report, some basic investigations which include the measurement of absorption coefficients of the blast furnace construction materials, determination of the burying amounts of Co60, and experiments with a brick-work model are described.

9 0 0 0 OA 鉄鋼生産技術の展望

- 著者

- 山岡 武

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.53, no.1, pp.3-10, 1967-01-01 (Released:2010-10-12)

7 0 0 0 OA 加速器質量分析による日本刀の14C年代と暦年代

- 著者

- 永田 和宏 松原 章浩 國分(齋藤) 陽子 中村 俊夫

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.102, no.12, pp.736-741, 2016 (Released:2016-11-30)

- 参考文献数

- 15

- 被引用文献数

- 2 2

Steel of Japanese swords has been produced with Tatara process from iron sand and charcoal. Carbon dissolved in steel was absorbed from wooden charcoal fuel during the production of the steel. From the decay of 14C activity in the steel, the 14C age of Japanese sword can be determined. The 14C ages of 4 Japanese swords were measured with accelerator mass spectrometry and calibrated to calendar years. Each 14C age provided plural calendar year periods with definite probabilities, and one of the periods agreed with the production year of each sword that was determined from the sword master’s name cut in the grip of his sword after taking the age range of charcoal used for steel production and usage for several generations of the same names of sword masters into account.

7 0 0 0 OA 臨界粒界せん断応力に基づいた多結晶フェライト鋼における上降伏点の解釈

- 著者

- 土山 聡宏 荒木 理 高木 節雄

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.106, no.6, pp.382-390, 2020 (Released:2020-05-31)

- 参考文献数

- 22

- 被引用文献数

- 1 4

The upper and lower yield points of ferritic steel containing a small amount of carbon were discussed in terms of the critical stress for dislocation emission from a grain boundary, namely, “critical grain boundary shear stress”, on the assumption of the pile-up model. Considering some experimental results such as tensile testing, relaxation testing and nanoindentation testing on grain boundaries, we concluded that both upper and lower yield points could be similarly understood as a phenomenon of dislocation emission from dislocation sources existing at grain boundaries. The difference in stress between upper and lower yield points was explained in terms of the density of mobile dislocations, which determines the extent of stress concentration at grain boundary caused by pile-up of the dislocations. Slow cooling after annealing or aging at low temperature, by which Cottrell atmosphere is formed, leads to a significant decrement of the mobile dislocation density, and this results in an occurrence of the sharp upper yield point because of a reduced number of piled-up dislocations and insufficient stress concentration at grain boundaries.

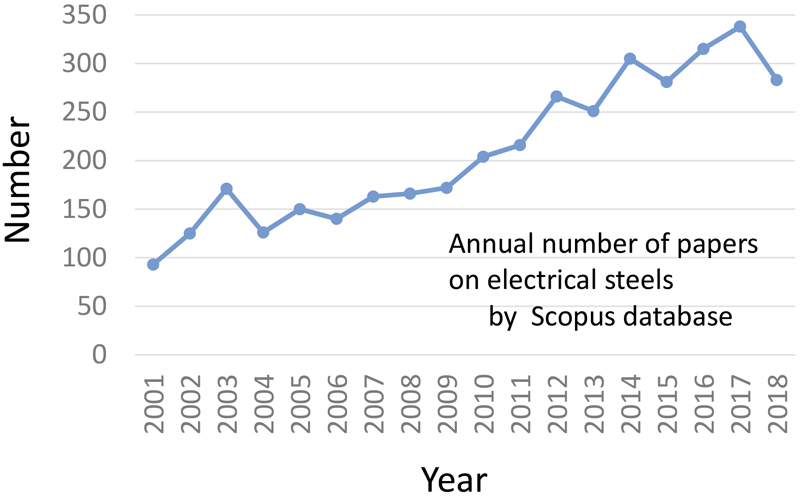

6 0 0 0 OA 無方向性電磁鋼板の最近の開発動向

- 著者

- 早川 康之

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.106, no.10, pp.683-696, 2020 (Released:2020-09-30)

- 参考文献数

- 76

- 被引用文献数

- 1 5

This paper gives an overview of developments in the field of non-oriented electrical steels that are widely used in motor cores in recent years, focusing mainly on texture control. ND//<100> texture is recognized as the ideal texture for application to motor cores. To obtain a suitable texture, precise control is required during each manufacturing process. This involves adjusting the chemical components during the steel making, fine temperature and reduction control during hot rolling, temperature control during hot-band annealing, temperature and reduction control during cold rolling and heating rate and temperature control during final annealing. High silicon Fe-Si alloy containing 6.5 mass% Si has been recognized as a promising core material for high frequency applications. When producing high silicon steel by the continuous chemical vapor deposition (CVD) siliconizing process, materials with a gradient Si concentration in the sheet thickness direction have been found to display superior high-frequency iron loss.

5 0 0 0 OA 高炉耐火物とその診断技術の進歩

- 著者

- 田村 節夫

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.68, no.15, pp.2108-2115, 1982-11-01 (Released:2010-01-19)

- 参考文献数

- 53

高炉耐火物の損傷機構と対策,および耐火物侵食診断技術の現状について概説した.耐火物は種々の原因によつて損傷されるが,いずれにおいても,何らかの形で炉内温度変動が関与しており,損傷の直接原囚として,遠因として,あるいは加速要因として作用する.従つて,炉況の安定が耐火物損傷防止の基本であり,また逆に損傷防止が炉況の安定につながることから,耐火物の寿命延長と安定操業は不可分の関係にある.また損傷機構の解明は,耐火物の材質・構造選定の上からも重要であり,このため損傷過程にある耐火物サンプルの解析あるいは試験室的な損傷状況の再現試験が有力な手段となろう.診断技術については,単に侵食量の推定だけでなく,れんが内で生じる現象,たとえば,き裂の発生,れんがの変質,溶銑の侵入,付着物の形成などの検出,推定まで含めた診断技術の開発が必要である.

5 0 0 0 OA 参考文献

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.51, no.7, pp.1331-1333, 1965-06-01 (Released:2010-12-22)

5 0 0 0 OA 金属間化合物により粒界被覆した多結晶Ni基耐熱合金の微細組織とクリープ特性

- 著者

- 伊藤 孝矩 山﨑 重人 光原 昌寿 中島 英治 西田 稔 米村 光治

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- pp.TETSU-2016-107, (Released:2017-03-06)

- 参考文献数

- 37

- 被引用文献数

- 4

Creep properties and microstructures for a polycrystalline Ni-based heat-resistant alloy whose grain boundaries were covered by dense intergranular intermetallics were investigated. Creep tests were carries out at 850°C and 80-130 MPa. The creep strength of this alloy was higher than the Alloy617 and HR6W, and equal to the Alloy740, which are pre-existing candidate materials for steam pipes of A-USC power plant. The retardation of acceleration of creep rate was observed characteristically in the creep curves. This retardation behavior was deeply related to the superior creep strength of this alloy. The spherical Ni3Al (γ’) particles were distributed uniformly in the grain interior, whose coarsening behavior was monotonically dependent on the creep time. The intermetallics of Laves phase and σ pahse were formed densely at grain boundary. High coverage ratio of the intergranular intermetallics was maintained until the later stage of acceleration creep region. Therefore, it suggested that the retardation of creep acceleration was not caused by the precipitates behavior of intragranular γ’ particles and intergranular intermetallics, though both the precipitates were understandably effective against the creep strengthening. The plate-like Laves phase was formed in the grain interior during creep. The evolution of volume fraction of intragranular Laves phase depended on not creep time but creep strain. From the results of SEM/EBSD analyses and TEM observations, it revealed that the intragranular Laves phase enhanced the work-hardenability due to the constraint on plasticity and originated the retardation of creep acceleration.

5 0 0 0 OA 鉄鋼に関する50年の推移

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.51, no.8, pp.1347-1382, 1965-07-01 (Released:2010-10-12)

- 被引用文献数

- 1

4 0 0 0 OA 人の意思決定が埋め込まれた生産システムのモデル化と分析

- 著者

- 水山 元

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.109, no.6, pp.501-512, 2023-06-01 (Released:2023-05-31)

- 参考文献数

- 58

- 被引用文献数

- 1

Most production systems are operated in a human-in-the-loop fashion, and it is sometimes argued that the human decisions involved make it possible, or at least easier, for the systems to cope with various stationary and nonstationary variations. However, it has not been well-studied and understood how this positive contribution of human decisions work, what factors determine its effect, how the function should be supported or fostered, etc. This paper first briefly reviews conventional production systems simulation techniques and discusses why it is difficult for them alone to address aforementioned questions. This next points to some recent attempts, in production systems engineering and related areas, to study human decisions and their effects by complementally using gaming simulation and agent-based simulation and highlights the potential of combining such behavioral and computational scientific approaches. Then, the paper introduces a cognitive framework model composed of interface, interaction, and incentive dimensions. It can be used for formally characterizing the decisions made by an individual facing a problem situation in operating a production system, and functions as a bond connecting behavioral and computational analyses of the decision maker. The paper further presents some example ongoing research projects worked on by the author’s team in this direction and discusses some future perspective.

4 0 0 0 OA 水素還元によって得られた純鉄中の不純物の熱力学

- 著者

- 柏谷 悦章 長谷川 将克

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.2, pp.302-311, 2014 (Released:2014-01-31)

- 参考文献数

- 16

- 被引用文献数

- 4 2

Hydrogen itself is not a primary energy and needs an energy for its production, which means that CO2 will be exhausted during the production process, more or less. However, when a Green Hydrogen can be produced, it is a best way to use the hydrogen instead of carbon.In this study, two kinds of iron ore were reduced and melted both under hydrogen and carbon atmosphere. The obtained iron metal under hydrogen atmosphere was quite pure one. The impurities in the metal were chemically and thermodynamically analyzed. The characteristics and benefits of hydrogen reduction were discussed in comparison with the carbon reduction.The content of silicon in the metal under hydrogen atmosphere was one tenth to the iron obtained by carbon reduction. Manganese was about one third to one tenth against the carbon reduction. However, phosphorus in the hydrogen reduction was almost the same level to the carbon reduction. Sulfur content became half in the hydrogen reduction. Moreover, the content of hydrogen in the metal was the same level between the hydrogen reduction and the carbon reduction. It was found that the rate of hydrogen evolution from a molten metal during solidification was fast significantly. The activities of elements in the metal were calculated through the thermochemical data, and the relationships among those elements were elucidated.From the thermodynamic analysis, a high oxygen activity in the metal obtained under hydrogen atmosphere caused to a low content of impurities and high activity of oxides related.

4 0 0 0 OA 転位論・強化機構論 −その歴史の概略と現状の問題点−

- 著者

- 丸川 健三郎 大村 孝仁

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.9, pp.1076-1088, 2014 (Released:2014-08-31)

- 参考文献数

- 98

- 被引用文献数

- 6 4

A short historical review is given for the dislocation theory in the special reference to the mechanism of metal strengthening. Until the mid of 1950’s, the basic formalism of the dislocation theory has been completed. However, the further development has been confronted by various difficulties in the application of the theory to elucidate the strengthening mechanism, although some progress in problems, such as the visualization of individual dislocations and the measurement of the dislocation velocity, has been made. The present status of this research field, inclusive of recent developments, is described. The solution hardening, the work hardening, the low temperature strength and others are discussed in some details. Recent experimental treatises to examine the strengthening mechanisms are also overviewed.

4 0 0 0 OA 雑録

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.27, no.8, pp.620-636, 1941-08-25 (Released:2009-07-09)

4 0 0 0 OA 伝統的鍛錬工程における日本刀材料の炭素量変化

- 著者

- 佐々木 直彦 桃野 正

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.93, no.12, pp.792-798, 2007-12-01 (Released:2009-02-13)

- 参考文献数

- 6

- 被引用文献数

- 3 3

The Japanese sword has excellent strength-toughness balance given by two traditional processes. One process is compounding of inner tough iron and outer strong steel. And the other process is cooling-rate control quenching by using thickness of clay-coating before quenching. However, it is a precondition for acquiring high strength-toughness that carbon content of sword parts are regulated in proper quantities. Carbon content of sword parts is very important and controlled under forging process which contains TSUMI-WAKASHI (forge-welding piled steel chips) work and fold-forging.Therefore, changes in carbon content of TAMA-HAGANE steels and carbon steels under traditional forging process were investigated in this study. Changes in carbon content depended on enclosing decarburized or carburized surface in steel as forge-weld interface. Total changes in carbon content were proportional to total layers of included surface in steel. Changes in carbon content per one forge-welded layer. “d (mass%/layer)” was ruled by carbon content of raw materials “C0 (mass%)”. When C0 is over 0.2 mass%, carbon content of forged steel is decreasing and the more C0, the more |d |. C0 is under 0.2 mass%, carbon content is increasing. The mass of forged steels is 4% increasing per one fold-forging cycle, but d is not affected by changes in mass of them.