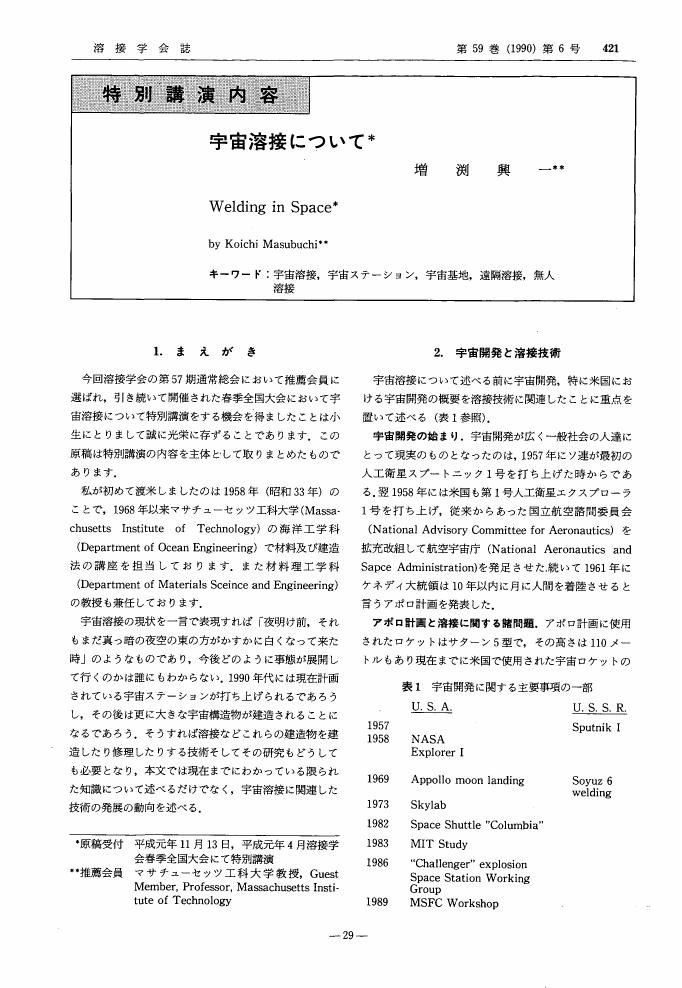

1 0 0 0 OA 宇宙溶接について

- 著者

- 増渕 興一

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.59, no.6, pp.421-427, 1990-09-05 (Released:2011-08-05)

- 参考文献数

- 16

- 被引用文献数

- 3 3

1 0 0 0 OA 加圧はんだ付の接合機構

- 著者

- 服巻 孝 中村 満夫

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.10, no.3, pp.337-342, 1992-08-05 (Released:2009-06-12)

- 参考文献数

- 8

- 被引用文献数

- 1 1

Copper to copper lap joint was made by the resistance heating, applying pressure simultaneously. The copper plate was pre-soldered and the alloyed layer was pre-formed by using Pb-50Sn solder and then joint mechanism of press-soldered joints was analyzed.The reason of enhancing strength and heat resistance heated by applying voltage in press-soldered joints is summarized as follows.(1) Solder composition turns to Cu-Sn alloy composition.(2) Joint layer with higher melting point was formed in which Cu increases and Sn decreases.(3) In terms of the crystal structure, Cu3Sn, Cu6Sn5 and Cu(α) phases turns to Cu41Tn11 and Cu(α) phases which have high heat resistance.

1 0 0 0 OA 超小型試験片による局所材料強度特性評価 ―スポット溶接継手の強度予測への応用―

- 著者

- 中山 英介

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.75, no.6, pp.461-465, 2006 (Released:2011-08-01)

- 参考文献数

- 4

- 被引用文献数

- 3 3

1 0 0 0 OA 2-2 合金と平衡状態図

- 著者

- 田中 敏宏

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.77, no.6, pp.576-581, 2008 (Released:2012-10-05)

- 参考文献数

- 8

1 0 0 0 OA 3-2 材料の機械的特性試験

- 著者

- 田川 哲哉

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.77, no.4, pp.304-311, 2008 (Released:2012-10-05)

- 参考文献数

- 19

- 被引用文献数

- 2

1 0 0 0 OA ろう付技術の現状と課題

- 著者

- 竹本 正

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.61, no.4, pp.305-312, 1992-06-05 (Released:2011-08-05)

- 参考文献数

- 41

- 被引用文献数

- 1 1

1 0 0 0 OA 銅一異種材加圧はんだ付継手の特性

- 著者

- 服巻 孝 中村 満夫

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.10, no.2, pp.228-233, 1992-05-05 (Released:2009-06-12)

- 参考文献数

- 7

Copper and some other materials were joined using the resistance heating apparatus by which heating and pressure could be applied simultaneously. The materials used were presoldered and the alloyed layer was formed on each of them by using Pb-Sn solder.Tensile test at the room temperature revealed that fracture of all specimens originated in copper material.The layers consisted mainly of Cu-Sn, Cu-Zn-Sn, Cu-Ni-Sn, Cu-Fe-Ni-Sn when copper, brass, nickel, and Fe-42Ni alloys were jointed with copper respectively.

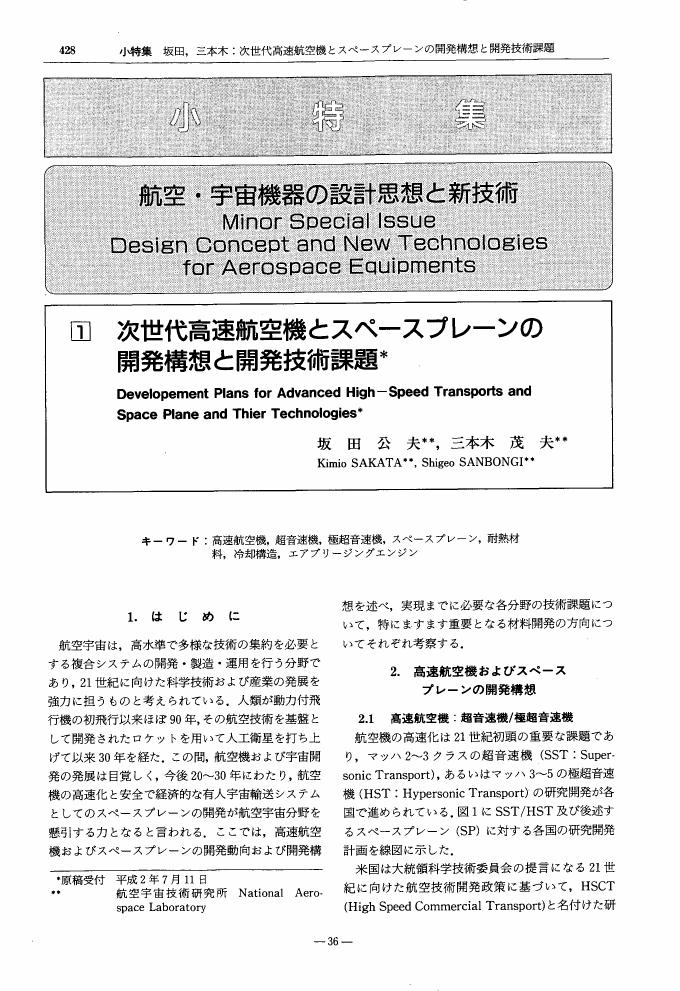

1 0 0 0 OA 1 次世代高速航空機とスペースプレーンの開発構想と開発技術課題

- 著者

- 坂田 公夫 三本木 茂夫

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.59, no.6, pp.428-437, 1990-09-05 (Released:2011-08-05)

- 参考文献数

- 12

1 0 0 0 OA はんだ付技術の要点

- 著者

- 竹本 正

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.60, no.4, pp.291-295, 1991-06-05 (Released:2011-08-05)

- 参考文献数

- 22

- 著者

- 才田 一幸 藤本 哲哉 西本 和俊

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会論文集 (ISSN:02884771)

- 巻号頁・発行日

- vol.28, no.2, pp.216-221, 2010 (Released:2010-07-21)

- 参考文献数

- 19

- 被引用文献数

- 5 5

In order to clarify the behaviour and mechanism of the hydrogen embrittlement in SUS304ULC/Ta/Zr explosive bonded joint, the hydrogen embrittlement cracking at Ta/Zr bond interface was characterised. Cracks occurred in the Zr substrate along the wavy interface of the hydrogen-charged Ta/Zr joint. The cracking susceptibility increased drastically when the potential of specimen during hydrogen-charging was reduced below the redox potential of hydrogen. γ-ZrH and δ-ZrH were precipitated in the hydrogen-charged Zr and the precipitated γ-ZrH possessed a (0002)α-Zr//(11-1)γ-ZrH, [21-1-0]α-Zr//[110]γ-ZrH crystallographic relationship. An in-situ observation of the hydrogen embrittlement cracking with SEM and TEM revealed that cracks were initiated in zirconium hydrides and propagated preferentially along zirconium hydrides. These results suggested that the hydrogen embrittlement mechanism of the Zr base metal was caused by the precipitation of zirconium hydrides and the brittle fracture of them.

- 著者

- 菊池 正夫

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.72, no.7, pp.552-556, 2003

- 被引用文献数

- 5

1 0 0 0 OA 溶接部の腐食(II) 炭素鋼の溶接部の腐食と対策

- 著者

- 松島 巖

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.61, no.2, pp.76-81, 1992-03-05 (Released:2011-08-05)

- 参考文献数

- 20

- 被引用文献数

- 5 6

1 0 0 0 安全衛生関連-溶接作業の安全衛生に関する最近の動向

- 著者

- 神山 宣彦

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 = Journal of the Japan Welding Society (ISSN:00214787)

- 巻号頁・発行日

- vol.81, no.5, pp.446-447, 2012-07-05

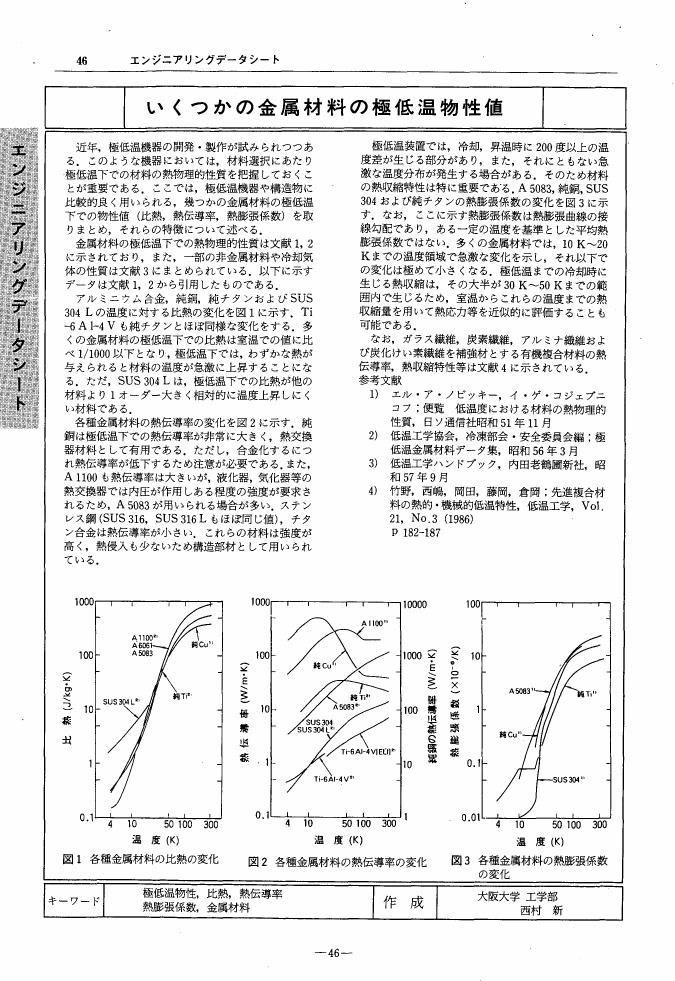

1 0 0 0 OA エンジニアリングデータシート

- 著者

- 西村 新

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.58, no.1, pp.46, 1989-01-05 (Released:2011-08-05)

- 参考文献数

- 4

- 著者

- 松田 昇一 棚原 靖 田中 学

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会全国大会講演概要

- 巻号頁・発行日

- vol.2021, pp.8-9, 2021

ガスメタルアーク(GMA)溶接は,一般に溶着速度が速く,溶込みが深い高能率な溶接法である.しかしながら電極が溶融することから,熱源が時間的・空間的に変動し,アークが不安定になる.そのためスパッタが発生しやすくなり,溶接欠陥が生じやすい.本研究の目的は,交流磁場を用いた新しい高品質・高効率なGMA溶接法の開発である.本報では交流磁場がアークおよびビード形状に与える影響を報告する.

1 0 0 0 OA 高マンガン鋼と高炭素鋼との溶接(第2報) ガスシールドアーク溶接の場合

- 著者

- 木俣 登 安藤 精一

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.40, no.9, pp.917-928, 1971-09-25 (Released:2011-08-05)

- 参考文献数

- 8

In report 1, the manual arc welding of austenitic manganese steel to high carbon steel was studied, the main characteristic of which was to butter, before joining, the groove face of high carbon steel with austenitic covered electrode.This paper describes the results of some experiments on welding of the above two dissimilar metals by gas shielded arc welding process.To select appropriate welding wire and welding conditions for buttering, single bead weld test and FISCO cracking test were made using high carbon steel as base metal, five austenitic welding wire as electrode, and CO2, CO2-A, A or N2 as shielding gas.16 Mn-16 Cr and 25 Cr-20 Ni welding wire are available for buttering electrode and CO2-A for shielding gas from the viewpoints of weld metal hardness, microstructure, weld defects and crack susceptibility of weld metal.Carbon steel rail and austenitic manganese steel rail (50 PS type) were then welded together automatically by gas shielded arc welding process: The groove face of the former was buttered vertically with above-mentioned wires and shielding gas and rail welding apparatus, which could be used not only for rail joining by welding but also for buttering with some modifications. An austenitic manganese steel rail was welded to the buttered carbon steel rail with I-groove and almost the same welding conditions as in the case of gas shielded arc welding of austenitic manganese steel rails investigated previously by the authors. The values of maximum load and deflection in bending tests of welded rails were 75-85 t and 56-84 mm with head-up (span 1 m, load applied at mid span) and they are almost equal to the welds by manual arc welding with V-or I-groove joint.Welding takes about 11 minutes for buttering and 7.5 minutes for joining.

1 0 0 0 溶接構造物の非破壊試験技術

- 著者

- 横野 泰和

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.79, no.8, pp.717-732, 2010

- 被引用文献数

- 2

1 0 0 0 非破壊検査による表面欠陥の検出と評価

- 著者

- 横野 泰和

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.66, no.2, pp.86-89, 1997

1 0 0 0 溶接部の浸透探傷試験方法

- 著者

- 津村 俊二 谷 峰

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.80, no.8, pp.709-712, 2011

- 被引用文献数

- 1

1 0 0 0 実用講座 非破壊検査の種類と特徴

- 著者

- 横野 泰和

- 出版者

- 一般社団法人 溶接学会

- 雑誌

- 溶接学会誌 (ISSN:00214787)

- 巻号頁・発行日

- vol.59, no.6, pp.410-413, 1990

- 被引用文献数

- 2