2 0 0 0 OA 温度・拘束圧・持続載荷期間に依存する堆積岩不連続面の変形・透水特性

- 著者

- 木下 尚樹 安原 英明

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.133, no.3, pp.53-57, 2017-03-01 (Released:2017-03-31)

- 参考文献数

- 16

It is of significant importance to safely isolate the radioactive wastes from the human environments. Entombment of the wastes in deep subsurface may be a plausible solution on this issue, and will be adopted in the countries where the nuclear power plants are in operation. Before burying them in the targeted rocks, the longterm evolution of the mechanical and the hydraulic properties of the targeted rocks should be predicted with a certain precision. To this end, in this study we examined the change of the apparent secant elastic modulus and the permeability of a single fracture in the Berea sandstone and the Horonobe mudstone samples under the relatively high temperature and confining pressure conditions. The apparent secant elastic modulus of the mudstone increased with the increase of the holding time and specifically, the values at 90 ºC were greater than those at 25 ºC, while that of the sandstone little increased with time. In contrast, the permeability of both the mudstone and sandstone samples monotonically decreased with time, and the rates of the permeability reduction were close among all the samples. The increase of the elastic modulus and the decrease of the permeability may be attributed to the chemomechanical processes such as pressure solution and the mechanisms explaining the changes should be clarified. Although the mechanisms are still ambiguous, the increase of the elastic modulus and the permeability reduction with time may improve the integrity of the targeted rocks.

2 0 0 0 OA 動的シミュレーションによる 高エネルギー吸収型落石防護網の性能評価

- 著者

- 木下 尚樹 安原 英明 矢田部 龍一 加賀山 肇

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.133, no.3, pp.45-52, 2017-03-01 (Released:2017-03-31)

- 参考文献数

- 17

- 被引用文献数

- 1

Rockfall is an important geo-hazard of mountainous area in Japan and has gained greater attention and recognition due primarily to the severe accidents and mortalities happening in roadways and railways. Rock fall countermeasures are classified into preventive works and protectors. In rock protectors that have high rigidity, there are rock protecting fence, rock protecting wall and rock shed, etc. On the other hand, there is a pocket type rock net which excels in the application condition of the topography and absorbs energy by deforming itself. The standard absorbable energy of the pocket type rock net is 100 kJ. Then, the rock net is designed so that the absorbed energy exceeds the falling rock energy. However, in recently, many types of rock net such as high energy type and long span type have been developed, and there are cases where conventional design methods cannot be applied. In this study, the performance of a long span pocket type rock net was evaluated by dynamic analysis. Firstly, the physical properties of the rock net members were identified by comparing the results of the real scale field experiments with the dynamic analyses. Then, the relationships between the displacement of the net and the net width, the maximum tensional force of a horizontal rope and the rope position, etc. were evaluated by the dynamic analyses. Typically, these evaluations by conventional design methods are laborious and are carried out using the results of real scale field experiments. However, the current study revealed that the predictions by the dynamic, numerical analyses showed the validity of the performance evaluation by this means.

2 0 0 0 OA 墨洋丸沈没の原因に就て

- 著者

- 氷上 克之

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.58, no.687, pp.458-459, 1942-07-22 (Released:2011-07-13)

墨洋丸沈没後直ちに北米合衆國の保險業者は各荷主に對して保險金を仕拂ひたる處なれども、一方當保險業者は引續き日本郵船會社を相手取り北米合衆國の法廷に損害賠償の訴訟を提出せり。即ち自然發火の危險性ある銅精鑛と共に棉花其の他の貨物を積載し、銅精鑛の自然發熟の爲本船を沈没に至らしめ、從つて他の貨物をも損失せしめたるは、船會社其の責を負ふべきなりとの理由に基くものなり。其の要求する賠償金額は邦貨にして約110萬圓にして、國家非常の時に際し外貨にてかゝる多額の金を仕拂ふことは實に大なる損失なるを深く憂ひ、郵船本社の外、關係者に於て有利に導かんと苦心努力したれども、當初に於ては殆ど勝算なく深く焦慮したる處なり。然るに時偶々、筆者等の銅精鑛の發熱性及び其の防止法の研究もやうやく進捗したるを以て、其の研究報告と本文に示す墨洋丸沈没原因に關する考察を、參考として、北米合衆國法廷に提出したる處、状態は急に我に有利に好轉し、遂に多額の外貨の流失なく、無事決着を見たるは誠に欣快の至りなり。即ち本文に示す如く、墨洋丸乗組員の當時取りたる應急處置(漲水)は麻袋等の有機物が燻り居たるを消火せんとして行ひたるものにて保險法規上何等の手落なく、然るに結果より見てそれが適當ならざりしに依り沈没にまで至りたるものにて、全く從來銅精鑛の發熟に對する研究もなく、其の知識も不明なりしに基因するものにて、其の責任を會社が負ふべき要なきを強調せしものなり。此處に當時の報文を其儘示し、參考に供さんとす。

2 0 0 0 OA 大江山製造所のフェロニッケル製錬と副産物の製造 (日本冶金工業 (株))

- 著者

- 内山 恭輔 松田 健男 松森 豊己

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 資源と素材 (ISSN:09161740)

- 巻号頁・発行日

- vol.109, no.12, pp.1082-1086, 1993-12-25 (Released:2011-01-27)

- 被引用文献数

- 2 3

The Oheyama plant of Nippon Yakin Kogyo Co., Ltd. was built here at Miyazu city in 1942, for treatment of low grade nickel oxide are (0.4-0.7% Ni) from nearby Oheyama mine by Krupp-Renn process. but at the end of war in 1945, the nickel smelting operation was stopped.In 1950, the Kawasaki plant of Nippon Yakin Kogyo Co., Ltd. succeeded in producing stainless steel for the first time in Japan by oxygen top blowing in an arc-furnace, paving the way to mass production of stainless steel. This achievement quickly increased the demand for nickel, an important raw material of stainless steel, making the Oheyama plant resume its operation in 1952 by switching to higher grade nickel oxide ores imported from New Caledonia. Thus Nippon Yakin Kogyo Co., Ltd. established a vertically-integrated production process from Ni smelting to finished stainless steel products for the first time in Japan.Since then the process of the Oheyama plant has been greatly modified and developed to establish “Nippon Yakin Oheyama Process”, the only method in the world that uses a rotary kiln for smelting nickel oxide ores.The nickel ores are first ground by both dry and wet methods and blended well with anthracite and limestone, to be formed into briquets. They are first dried and preheated efficiently in a grate directly connected with a rotary kiln and then charged into the kiln, where all the metallurgical reactions such as dehydration, reduction, slag-formation and refining by excess air near discharge end, occur to form ferro-nickel nodules (0.3-20mm).The Oheyama Process is considered a very useful method to obtain nickel material for stainless steel production, because its low energy cost as well as individuality of its product, easy to handle and almost free of impurities, help significantly reduce the cost of stainless steel production.The Oheyama plant is now producing 1, 150t of Ni as ferro-nickel a month, and besides, 35, 000t of byproduct, “NAS Sand” a month from slag, which is mainly used as public works materials such as asphalt aggregate, concrete aggregate and so on.Situated near Amano-hashidate, one of Japan's Three Famous Views, the Oheyama plant pays full attention to protecting the surrounding environment and to existing in harmony with nature.

2 0 0 0 OA 摘録

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.80, no.919, pp.1176-1188, 1964-12-25 (Released:2011-07-13)

2 0 0 0 OA 卸向厚層用ダブルレンジングドラムカッタについて

- 著者

- 沢田 仁 佐藤 祐治

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.95, no.1099, pp.611-615, 1979-09-25 (Released:2011-07-13)

2 0 0 0 OA 太平洋炭鉱における通気改善計画について

- 著者

- 伊藤 和之

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.100, no.1159, pp.708-711, 1984-09-25 (Released:2011-07-13)

2 0 0 0 OA 非常制動時の立坑巻索の振動実測とその理論的解析

- 著者

- 会田 俊夫 石橋 重遠 佐進 進

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.78, no.887, pp.377-384, 1962-05-25 (Released:2011-07-13)

- 参考文献数

- 2

In this paper we have studied the characteristics of the vibration of winding ropes in vertical shafts when the drums are braked in an emergency, measuring the vibration and analying the measured results by the theoretical methods published in our former paper.Some results we have obtained through our researches are as follows;1) The maximum vibration of a winding rope in a vertical shaft when the drum is braked in an emergency can safely be estimated to be 1.3 times as large as the maximum acceleration of the winding drum.2) The shock absorber is hardly effective for reducing the vibration of a winding rope in an emergency braking.3) We find that the length of a winding rope has nothing to do with its vibration in a shaft.

2 0 0 0 OA 炭鉱の立坑ライニングの応力の測定

- 著者

- 平松 良雄 岡 行俊

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.76, no.866, pp.543-548, 1960-08-25 (Released:2011-07-13)

- 参考文献数

- 5

For the purpose of contributing to the design of shaft linings, especially of coal mines, the authors have attempted to measure the stress in the shaft linings in several coal mines in Japan with the photoelastic apparatus contrived by them.The results show that the lining in a solid ground is generally subjected to but a low stress, but sometimes to a stress about 30kg/cm2, that in a crushed ground the lining is subjected to a medium or high stress fluctuating, and that in a loose ground there appears such an earth pressure acting on the outer surface of the lining that may be estimated by the formula of the soil pressure.

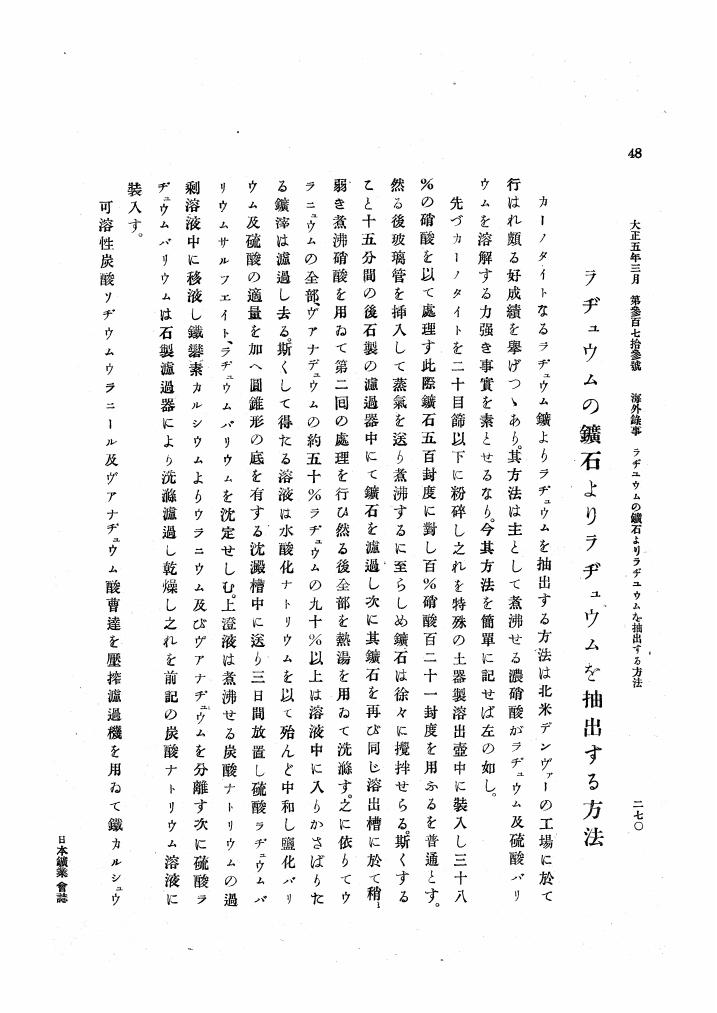

2 0 0 0 OA ラヂュウムの鑛石よりラヂュウムを抽出する方法

- 著者

- T、K

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.32, no.373, pp.270-272, 1916-03-22 (Released:2011-07-13)

2 0 0 0 OA 赤平炭鉱酸素マスク導入の経緯

- 著者

- 大和 昇

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 資源と素材 (ISSN:09161740)

- 巻号頁・発行日

- vol.109, no.9, pp.684-687, 1993-09-25 (Released:2011-01-27)

2 0 0 0 OA 緊急脱出用酸素マスク (PEBA PE-3M) の概要

- 著者

- 山本 雅則

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1136, pp.997-999, 1982-10-25 (Released:2011-07-13)

- 被引用文献数

- 2

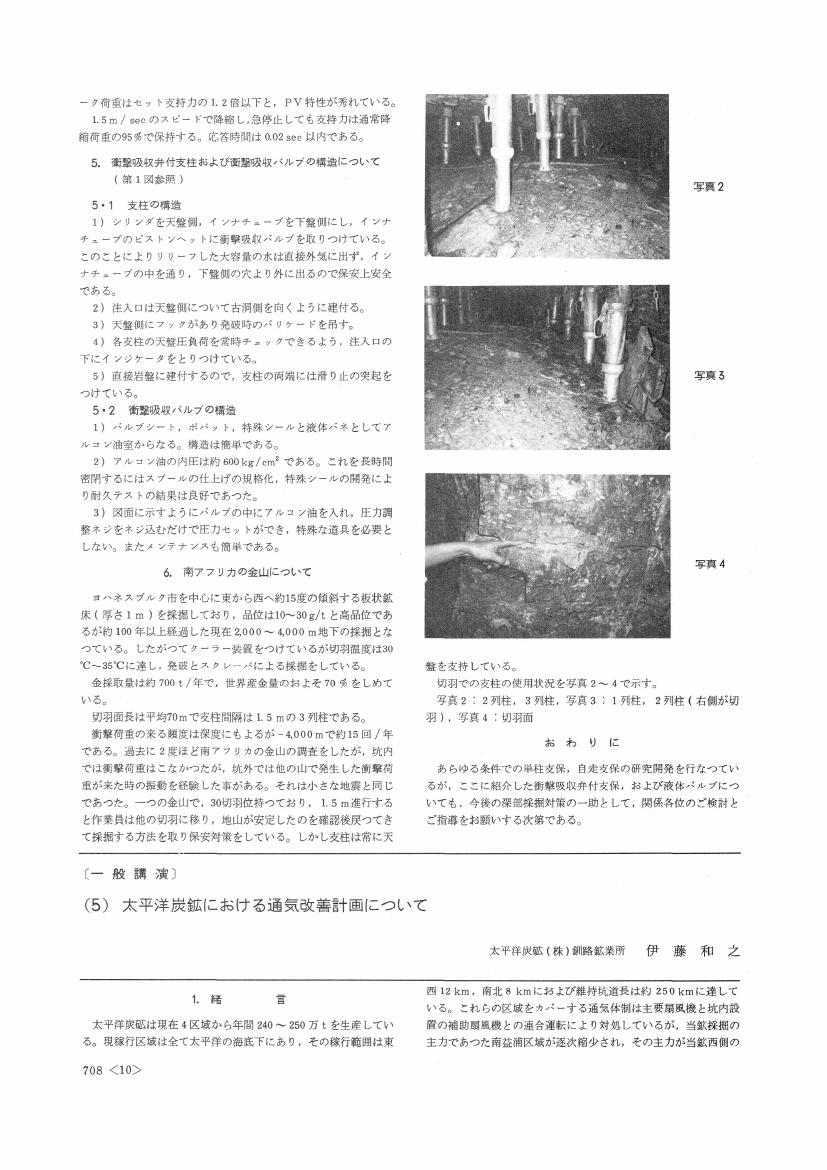

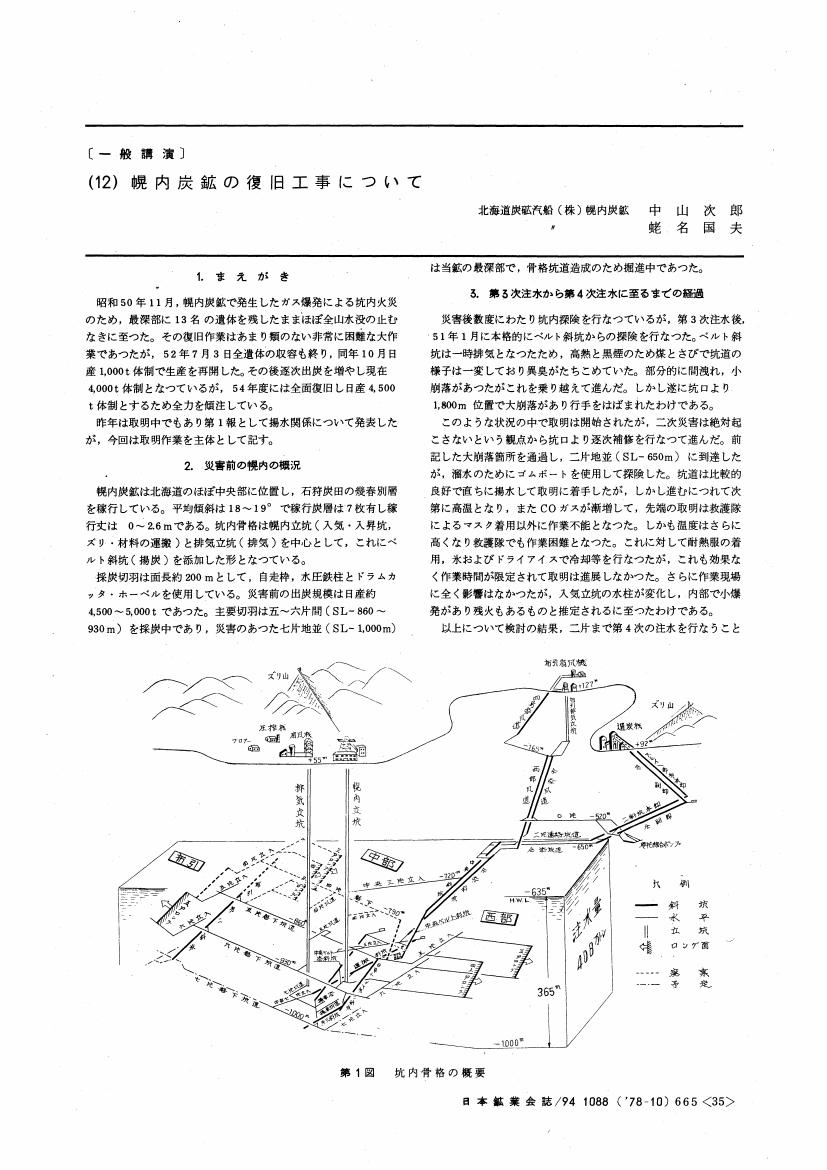

2 0 0 0 OA 幌内炭鉱の復旧工事について

- 著者

- 中山 次郎 蛯名 国夫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1088, pp.665-668, 1978-10-25 (Released:2011-07-13)

2 0 0 0 OA 太平洋選炭工場の現状について

- 著者

- 遠藤 一

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 資源と素材 (ISSN:09161740)

- 巻号頁・発行日

- vol.106, no.11, pp.698-700, 1990-10-25 (Released:2011-01-27)

- 参考文献数

- 3

2 0 0 0 OA 省力化選炭に向けた予選工程の改善

- 著者

- 鈴木 勝彦

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 資源と素材 (ISSN:09161740)

- 巻号頁・発行日

- vol.113, no.10, pp.764-767, 1997-10-25 (Released:2011-01-27)

2 0 0 0 OA 三菱美唄炭鉱におけるストコ及びカーゴット採炭について

- 著者

- 矢野 隆二

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.68, no.770, pp.347-352, 1952-08-25 (Released:2011-07-13)

“Stoco” and “Cargot” are the same principle as “Cardox”. In the Bibai Coal Mine “Stoco” was tested for the first time July 1949 and “Cargot” August 1950. In these tests, we found many imperfect points, and then we have made the effects to improve these points. Now, these tools are used practically in this Coal Mine.This report contains the progress improving the mechanism of these tools and results of the coal getting by these tools.

2 0 0 0 OA 三井松島リソーシス(株)における海外炭鉱技術者の研修

- 著者

- 熊川 幸平

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 資源と素材 (ISSN:09161740)

- 巻号頁・発行日

- vol.122, no.10_11, pp.537-541, 2006-11-25 (Released:2009-09-18)

The Nagasaki Coal Mine Technology Training Center was established following the closure of Matsushima Coal Mine Co. Ltd. in November 2001. A part of mining concession area formerly owned by Matsushima Coal Mine was then purchased to be used as training facilities. The training program is focused on transfer of coal mine technology, and conducted by NEDO (New Energy and Industrial Technology Development Organization). The objectives of the training program is to promote the transfer of technology on underground coal mining to engineers from coal producing countries such as China, Indonesia, and Vietnam. For these countries, the technology will serve as valuable tool to face changes that will likely occur in near future. These changes include a shift in mining method from open cut to underground mining, or deterioration in mining conditions as mining locations become deeper and deeper. Through the technological cooperation and transfer of Japan's coal mining technology, efforts were made to achieve the stable coal supply-demand in Asian region and stable supply of foreign coal to Japan.

2 0 0 0 OA 分岐管式給炭装置を用いた石炭の水力輸送に関する研究

- 著者

- 渡辺 慶輝

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.82, no.936, pp.333-341, 1966-04-25 (Released:2011-07-13)

- 参考文献数

- 19

The results of fundamental experiments revealed that the coal filled in a pipe was moved by low water pressure, and it flowed in a pipeline with little delay when velocity of stream exceeded 3.5m/s. According to these results a multi-pipe type coal feeder was invented. It consists of several parallel long lock chambers which are branched from a delivery pipe of a high pressure pump. And they have approximately the same diameter of the conveying pipe. One of these is fed coal and water mixture by means of a low pressure sand pump. After this, the mixture is pushed into the conveying pipe by the high pressure water. This process is repeated one after another, and coal is transported continuously.The auther produced a hand-operated model of this coal feeder for laboratory tests, then made its valves act automatically. The practical tests of this feeder was carried out at Yoshima colliery. 20.000t of coal was transported by 7 in. pipeline with it. The test results revealed that it had the transporting capacity of 100t/h, registering the volume concentration 20% Now the test is continued on commercial basis at Sunagawa colliery. The transportation height is 490m and the length of pipeline 2, 046m. There automatic control of concentration of coal in the pipeline is attemped to economize the transportation cost.

2 0 0 0 OA (株) 日向製錬所におけるフェロニッケル製錬

- 著者

- 小野 章

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 資源と素材 (ISSN:09161740)

- 巻号頁・発行日

- vol.109, no.12, pp.1077-1081, 1993-12-25 (Released:2011-01-27)

- 被引用文献数

- 1

Hyuga Smelting Co., Ltd. established by Sumitomo Metal Mining Co., Ltd. started production of ferronickel by Sintering-Electric Furnace Process in September; 1956, which is now owned by Sumitomo Metal Mining Co., Ltd.(60%), Nippon Steel Corporation (25%) and Mitsui & Co., Ltd.(15%).In accordance with the rapid increase of the market demands, the company made a steady growth, expanding the production capacity from 30 to 200 tons of nickel per month. Because the further expansion required greater productivity and broader acres, the new plant was built at present site in the coastal industrial quarter adopting Rotary Kiln-Electric Furnace Process in 1968.Since the improvement of the process, the development of new products and the energy curtailment of the whole plant have been achieved, Hyuga Smelter has become one of the most advanced coastal ferro-nickel smelters, boasting of most modern facilities and incompetitive technical knowledge.Production capacity is 1, 500 tons of nickel per month.

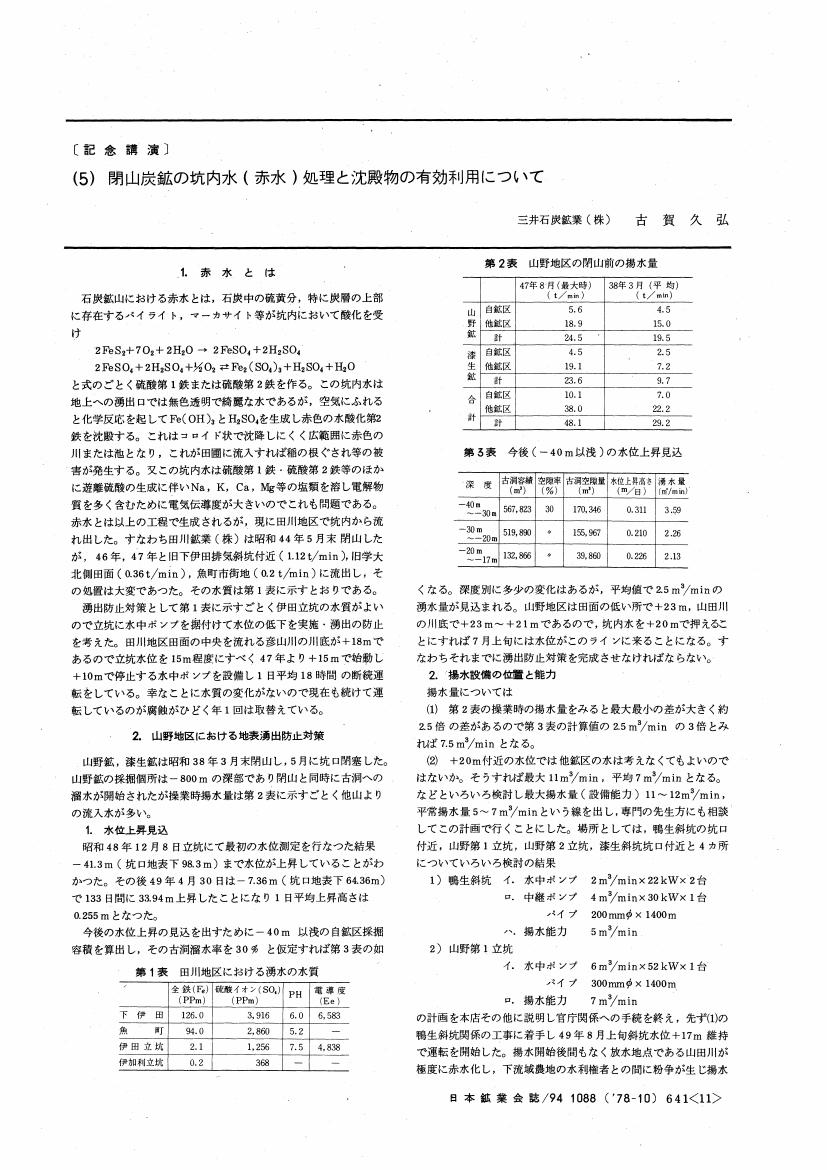

2 0 0 0 OA 閉山炭鉱の坑内水 (赤水) 処理と沈殿物の有効利用について

- 著者

- 古賀 久弘

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.94, no.1088, pp.641-645, 1978-10-25 (Released:2011-07-13)