1 0 0 0 樺太に於ける三井鑛山株式會社經營の炭礦現況

- 著者

- 守田 良太耶

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.52, no.615, pp.450-455, 1936

1 0 0 0 OA 地球環境工学特集「二酸化炭素地中貯留に関わる最新の研究動向」発刊によせて

- 著者

- 中尾 信典

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.138, no.1, pp.10-11, 2022-01-31 (Released:2022-01-28)

1 0 0 0 OA 北海道に於ける砂金及砂白金に就て

- 著者

- 松本 彬

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.44, no.521, pp.737-745, 1928-09-22 (Released:2011-07-13)

- 被引用文献数

- 1

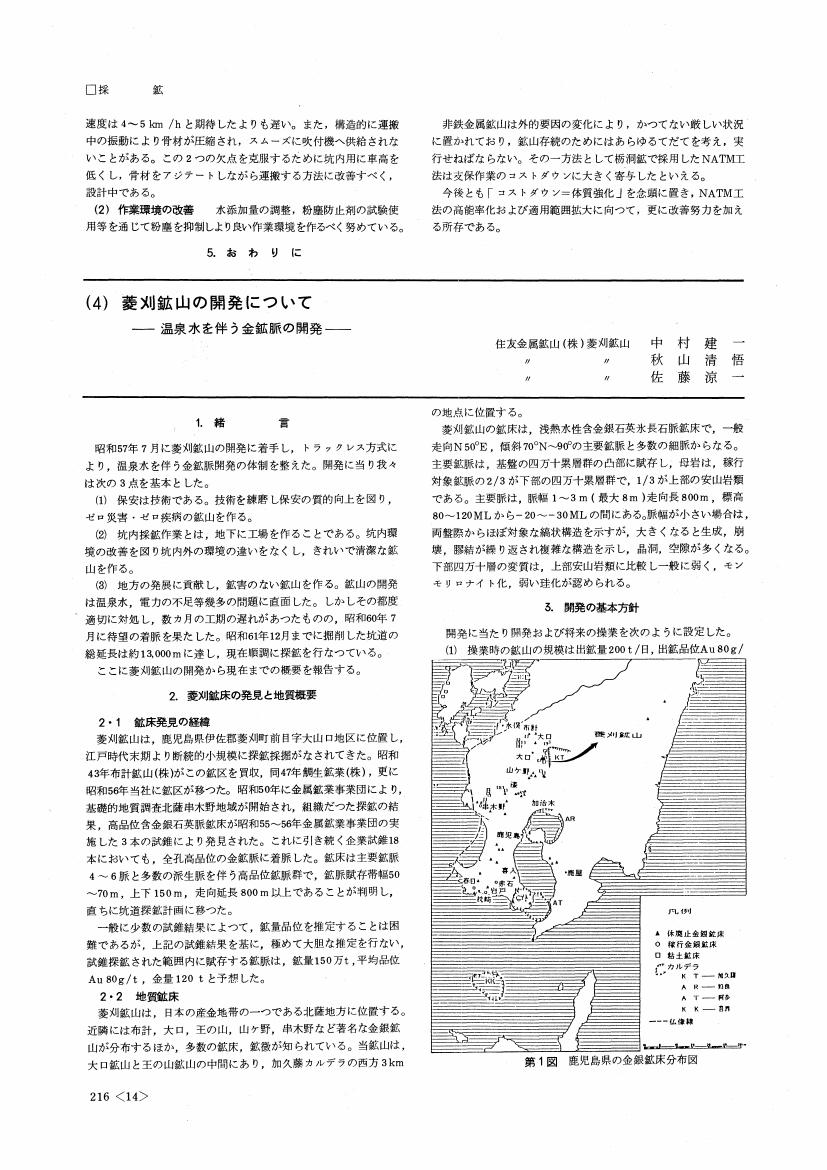

1 0 0 0 OA 菱刈鉱山の開発について 温泉水を伴う金鉱脈の開発

- 著者

- 中村 建一 秋山 清悟 佐藤 涼一

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.103, no.1190, pp.216-222, 1987-04-25 (Released:2011-07-13)

1 0 0 0 OA 鉛直立坑閉塞可視化モデルを用いた鉱石閉塞現象可視化と閉塞条件の評価

- 著者

- 佐藤 晃 森 拓実 中里 計麻

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.138, no.1, pp.1-9, 2022-01-31 (Released:2022-01-18)

- 参考文献数

- 16

Limestone is one of the most important mineral resources, and it is only one mineral that can be fully supplied by domestic producers. Generally, a certain amount of ores is stored in the ore passes temporally after blasting excavation, and extraction is carried out from the bottom of the ore pass. However, the hang-up phenomena in the ore passes sometimes occurred and some cases are recently reported. Once the hang-up phenomena in the ore passes occur, it will cause serious problems. In this study, ore flow experiments in the vertical ore passes were conducted using ore pass models which was composed of transparent acrylic tubes, and the conditions of hang-ups were discussed. Since the ore passes were assembled with transparent tubes, it was also possible to observe the hang-up phenomenon directly. To discuss the effect of cross-sectional shapes of ore passes, two kinds of ore-passes, that is, circular and square shapes of cross-sections, are prepared. Using various sizes of ores, the relation between ore size and cross-sectional area was also discussed. It was found that the hang-up phenomenon almost did not occur when the ratio of ore pass size to the mean grain size of ores exceeds the value of 5. It was also found that the circular-shaped ore passes were a little preferable to avoid ore pass hang-ups compared with the square ore pass. The same procedure was applied to the mixed ores which two types of ores with different mean diameters are mixed. In this case, also, the results were almost the same as the results obtained by single-size ores. 3D-DEM analysis was also conducted, and the validity of the experiments was discussed.

1 0 0 0 加圧浮選法による微細な重晶石-石英および方解石-石英の分離

- 著者

- 吉川 逸治 松岡 功 下飯坂 潤三

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.102, no.1179, pp.295-300, 1986

Applicability of dissolved air flotation (pressure type flotation) for separating ultrafine particles has been investigated using barite-quartz and calcite-quartz mixtures as samples.<BR>In pressure type flotation of barite-quartz mixture, good separation is obtained by the addition of smaller amount of sodium oleate as a collector than in dispersed air flotation (Denver type flotation). On the other hand, in pressure type flotation of calcite-quartz mixture, it is difficult to make calcite selectively float from quartz by adding sodium oleate. This may be explained by the reason that heterocoagulation of calcite and quartz particles can not be prevented under a comparatively static condition in pressure type flotation. However, the separation of calcite from quartz by pressure type flotation is possible when selective flocculation of calcite is achieved by using a polymeric flocculant (Separan AP30) with a dispersant such as sodium hexametaphosphate. The separation of barite-quartz and calcite-quartz mixtures by pressure type flotation is accomplished only at low pulp density below 2 to 3%.

1 0 0 0 加圧浮選法による微細な赤鉄鉱とデイッカイトの分離

- 著者

- 吉川 逸治 松岡 功 下飯坂 潤三

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.102, no.1180, pp.369-373, 1986

The flotation separation of hematite and dickite finer than 2μm has been investigated by using a pressure type and a Denver type flotators.Flotation tests were carried out by activating dickite with calcium chloride, followed by adding sodium oleate as a collector.<BR>In both pressure type and Denver type flotation, the separation of dickite from hematite was not achieved, because the addition of calcium chloride increased the floatability of hematite as well as dickite.However, in the case of the pressure type flotation, dickite could be selectively floated from hematite by adding Proper amounts of Separan AP30 (an anionicpolymeric flocculabt) and sodium oleate in the presence of asmall amount of calcium chloride at pH 8 to11. 5.The selective flotation of dickite from hematite by the pressure type flotation may be explained by the following reasons: the preferential adsorption of calcium species on dickite occurs due to its cation exchangeability in the presence of a small amount of calcium chloride at moderately alkaline pH and then hydrophobic flocs of dickite is formed as the result of the increased adsorption of Separan AP30 and oleate ion on the calcium activated dickite surface.The best separation result was obtained at low pulp density of about 1%.

- 著者

- 李 成五 呉 鍾基 申 芳燮

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 資源と素材 : 資源・素材学会誌 : journal of the Mining and Materials Processing Institute of Japan (ISSN:09161740)

- 巻号頁・発行日

- vol.115, no.11, pp.815-819, 1999-11-25

- 参考文献数

- 17

- 被引用文献数

- 1 5

鉄酸化物の溶解は,金属表面の洗浄および産業鉱物から鉄分の除去などにおいて非常に重要な湿式製錬工程である。本研究ではしゅう酸を使用して各々の初期pH,反応温度,濃度の変化によって天然の鉄鉱石であるヘマタイト(赤鉄鉱)の溶解度を調査した。酸化鉄の溶解は反応温度25~60℃においてゆっきり進行したが,90℃以上では溶解度が急激に増加した。また0.048~0.476mol/lではしゅう酸濃度の増加によって溶解度が増加した。さらにpHの変化においても,pH1.5~2.5の増加により,溶解度は急激に増加したが、pH2.5以上では溶解度が鈍化するという現象を示した。以上の方法によって鉄酸化物であるiron rust(Fe<sub>x</sub>O<sub>y</sub>・xH<sub>2</sub>O)に存在するgoethite(針鉄鉱α-FeOOH)とlepidocrocite(リン鉄鉱γ-FeOOH)と水酸化鉄(Fe(OH)<sub>3</sub>)がヘマタイトより早く溶解するという特性を示した。

1 0 0 0 OA タンクモデルおよび重回帰分析に基づく酸性坑廃水水質予測モデル

- 著者

- 淵田 茂司 門倉 正和 所 千晴

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.137, no.12, pp.116-122, 2021-12-25 (Released:2021-12-25)

- 参考文献数

- 15

- 被引用文献数

- 2

Acid mine drainage (AMD) generation is a serious problem from the environmental and economic perspectives, because it contains a large amount of heavy metals and because there are high costs associated with maintaining the facilities, purchasing neutralizing agents, and disposing sludges; which are required for the treatment process. In this study, changes in AMD quantity and quality for the next decades were predicted by a three series tank model in three stages, by combining the first order kinetic calculation of sulfide minerals' dissolution for two metal mines (X and Y) in Japan. Results from the AMD quality model represented the decrease of heavy metal concentrations below the effluent standard values in 30–140 years, by considering dilution and/or additional dissolution by heavy rain and snow melting, although these predicted values diverged by our previous model. However, the low correlation coefficient values (0.23–0.63) observed between the measured values of heavy metal concentration and the values calculated by our new model, mean that other chemical reactions, such as sulfate and/or carbonate mineral dissolution could greatly affect the AMD quality. In fact, there was no correlation between the metal potential calculated by our model and the real distribution of sulfide minerals at X mine. Our results therefore indicate that specific geochemical reaction and geological information should be included in the AMD quality prediction model, to estimate more accurately the fluctuation of each heavy metal concentration during different seasons.

- 著者

- 葛巻 星 西岡 宣泰 藤代 史 武部 博倫

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.137, no.11, pp.110-115, 2021-11-30 (Released:2021-11-30)

- 参考文献数

- 27

- 被引用文献数

- 2

A stabilized zirconia oxygen probe was used to measure the oxygen partial pressure (OPP) at an electrode submerged in a copper slag melt at 1300 ℃. The OPP was controlled in the range of 10−10–10−5 atm owing to the presence or absence of a powdered carbon layer on the slag melt using a high-purity alumina crucible in argon (Ar) gas flow. Under suppression of magnetite formation at an OPP of approximately 10−10 atm, the viscosities of the copper slag and FeO-Fe2O3-SiO2-Al2O3 slag melts were measured between 1200 ℃ and 1300 ℃. The obtained values were in the range of 1.0×102–7.8×102 mPa・s. The dependences of total Fe/SiO2 mass ratio and Al2O3 concentration on viscosity were qualitatively interpreted from the aluminosilicate network structure viewpoint.

1 0 0 0 OA 濃厚塩化カルシウム水溶液からの鉛電析

- 著者

- 宮本 真之 北田 敦 安達 謙 深見 一弘 邑瀬 邦明

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.137, no.11, pp.103-109, 2021-11-30 (Released:2021-11-30)

- 参考文献数

- 25

- 被引用文献数

- 2

CaCl2 is a low-toxic, inexpensive reagent that dissolves in large amounts in water to form highly concentrated aqueous solutions, or hydrate melts electrolyte. In this work, it was investigated that the concentrated CaCl2 aqueous solutions (aq) as novel lead (Pb) electrodeposition baths. While PbCl2 is poorly soluble in water at room temperature, PbCl2 dissolved up to 0.452 mol kg−1 ([Pb(II)] = 93.7 g kg−1) by the formation of PbCl42− complexes in the concentrated CaCl2 aq due to its high Cl− activity. Electrochemical measurements confirmed that the apparent exchange current density and the limiting current density of Pb electrodeposition decreased with increasing CaCl2 concentration. Since the diffusion of Pb(II) species was limited due to the high viscosity and ionic strength of the solution, agitation was effective in improving ion transport and electrodeposition rate. The presence of chloride ions in Pb electrolysis is usually detrimental due to the low solubility of PbCl2, however, the highly concentrated CaCl2 solution can be a potential candidate electrolyte for PbCl2-based electrolytic processes.

1 0 0 0 OA 馬鞍山鉱山概況

- 著者

- 西脇 三樹雄

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.81, no.931, pp.981-988, 1965-11-25 (Released:2011-07-13)

- 被引用文献数

- 1

The Ma On Shan Mine, the metamorphic contact iron are deposit, located in Kowloon peninsula, has been operated since 1906. However, in 1952 as the grade of the are was getting gradually low, the Japanese mills refused to take it successively unless the, grade up operations were under control of our company. In 1953 the Mutual Trust Co. Ltd. which is the ownner of the mine asked our company to operate the mine as the joint venture, and the agreement was concluded in that year. The first processing plant having the capacity 120, 000 tons of concentrate per annum, was completed and started its production in 1954. In 1959 the open cast was mined out and the mining site had to be removed into the under ground. At the same time the processing plant was capacitied up partially. In 1963 the 110M adit was driven through. In 1965 the production was raised up to 150, 000 tons of concentrate per annum, and the facilities and equipments of the plant have been increased accordingly.

1 0 0 0 OA 廃LIB由来成分のスラグ熔融温度への影響

- 著者

- 山下 雄 高橋 純一

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.137, no.10, pp.98-102, 2021-10-29 (Released:2021-10-29)

- 参考文献数

- 10

A pyrometallurgical process of metal recycling from waste lithium-ion batteries (LIB) has been developed. Basic process is that Co, Ni oxides which are from cathode materials of LIB and Cu which is from anode current collector are smelted and are reduced to metal, and the metal is refined in a next hydrometallurgical process. Since Al and Li contained in LIB are distributed to slag as oxides in the melting process, it is important to know the influence of these elements on the melting temperature of slag in determining the operating conditions. Therefore, the effects on the slag melting temperature when these elements and the amount of flux are changed are investigated and compared with the calculation results in FactSage (thermodynamic calculation software). In addition, based on the obtained melting temperature, waste LIB and flux were mixed and melted, and it was confirmed whether the metal and slag could be separated.

1 0 0 0 OA 多孔質中にトラップされたCO2 の他のガス種と比較して特異な溶解挙動

- 著者

- アニンディティヨ パトモノアジ ムハンマド ナシル ムハンマド アジス マハルディカ 雲 佘 末包 哲也

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ (ISSN:18816118)

- 巻号頁・発行日

- vol.137, no.9, pp.91-97, 2021-09-30 (Released:2021-09-30)

- 参考文献数

- 23

- 被引用文献数

- 2

多孔質内にトラップされているガスの流動している水相への溶解は二酸化炭素地下貯留(GCS)などの様々な水理学的分野において重要な過程である。GCS では,CO2 の溶解により,貯留層圧力変化や浮力によるリークリスクの低減につながるため溶解速度は安全性評価において重要な観点になる。本研究ではCO2, O2, N2, と Ar の4種のガスの多孔質中での溶解プロセスの違いを比較検討した。CO2 は他のガスに比べて極めて特徴的な溶解挙動を示すことを見出した。CO2 は他のガスに比べて溶解度が一桁程度大きいため,初期の溶解が非常に速く,トラップされたCO2 気 泡の周りに飽和水の膜が形成される。この飽和膜の存在がCO2 の物質輸送係数を低下させていると考えられる。

1 0 0 0 OA ポーランドの鉱業について 訪ポ鉱業研修団の報告

- 著者

- 岡村 宏

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.95, no.1101, pp.829-832, 1979-11-25 (Released:2011-07-13)

1 0 0 0 幌別鑛山の現況

- 著者

- 三崎 復造

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.53, no.625, pp.278-281, 1937

- 著者

- 下川 公博 手塚 大輔 鹿田 慧 邑瀬 邦明 杉村 博之 粟倉 泰弘

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- Journal of MMIJ : journal of the Mining and Materials Processing Institute of Japan (ISSN:18816118)

- 巻号頁・発行日

- vol.129, no.2, pp.72-77, 2013-02-01

- 参考文献数

- 28

- 被引用文献数

- 4

The surface smoothness, S and Ag content of electrodeposited copper were investigated to clarify the influence of chloride ions on electrorefining using hydrochloric acid and SbCl<SUB>3</SUB>. The surface smoothness of electrodeposited copper was improved with increasing amounts of hydrochloric acid and SbCl<SUB>3</SUB> as well as lower S and Ag content. The tensile strength and elongation of the electrodeposited copper were also studied to determine if they could be used as criteria for evaluating the cathode strippability in the permanent cathode process. The tensile strength and elongation increased when the total concentration of chloride ions released from hydrochloric acid and SbCl<SUB>3</SUB> was 20 mg/L. Metallographic observations indicated that lower rate of twin crystal formation resulted in higher tensile strength and elongation at approximately 20 mg/L of chloride ion concentration.

1 0 0 0 佐賀関製錬所における自溶炉リニューアルと生産性向上

- 著者

- 安田 豊 千田 裕史 本村 竜也

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 資源・素材学会誌 (ISSN:18816118)

- 巻号頁・発行日

- vol.136, no.8, pp.88-98, 2020

- 被引用文献数

- 3

<p>Flash smelting furnace at Saganoseki was build 1973 and its capacity increased to 3.5 times the original during 40 years. The degradation progressed in that process, so it was replaced to higher potential furnace in the long-term shutdown at 2017 for further capacity improvement. In addition, gas treatment facility for FSF off gas and other related facilities were modified in order to accommodate the increased FSF capacity. As a result, FSF capacity increased to 4 times the original after the long-term shutdown at 2019 and the competitiveness of Saganoseki smelter and refinery was improved.</p>

1 0 0 0 異種金属接触による銅電解精製時のAg溶解抑制

- 著者

- 糟野 貴史 北田 敦 下川 公博 邑瀬 邦明

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鑛業會誌 (ISSN:18816118)

- 巻号頁・発行日

- vol.130, no.2, pp.65-69, 2014

- 被引用文献数

- 6

Electrolytic copper contains, on average, 10 ppm silver as impurity, which leads to a loss of silver as a cashcow product for copper smelters.Most of silver included in blister copper anodes passes into anode slime when electrolyzed, keeping the elemental state. However, once a part of elemental silver dissolves from the anode or from anode slime for some reason, then silver can co-deposit with electrolytic copper cathode, since silver is nobler than copper. In the present work, the dissolution behavior of silver from anode slime was examined by using granular silver as a model of the slime.We have shown that the silver dissolution is caused by dissolved oxygen in the electrolyte, and that thiourea and/or chloride ions as usual additives play a role to suppress the silver dissolution approximately to two thirds.Moreover, it was found that the dissolution of silver was suppressed to less than 1ppm by galvanic contacting of the granular silver with less noble metals (Pb or Cu) immersed in the same electrolyte. This indicates that the use of Pb or Cu lining at the bottom of electrolytic cells can suppress silver dissolution from the anode slime settled to the bottom, reducing the silver loss to electrolytic copper.

1 0 0 0 OA 鉱物粒子による材料の摩耗

- 著者

- 橋本 建次

- 出版者

- 一般社団法人 資源・素材学会

- 雑誌

- 日本鉱業会誌 (ISSN:03694194)

- 巻号頁・発行日

- vol.98, no.1134, pp.733-740, 1982-08-25 (Released:2011-07-13)

- 参考文献数

- 100

- 被引用文献数

- 2 1

A number of studies have recently been carried out in which the abrasive and erosive wear rate of the materials by the mineral grains was determined. In this paper the effects of various variables on these wear are summarized.M ain contents are as follows:1) Introduction: Difinition of wear, Classification of wear testing methods- three-body sliding friction between loose mineral grains and materials (flat-flat plate and flat-circle plate), two-body sliding friction between materials and minerals (fixed and loose abrasive), rolling and impacting between materials and loose mineral grains (ball or rod mills), rotating of materials in loose mineral grains, impacting of loose mineral grains against materials and impacting of materials against loose mineral grains-, Relations between different testing methods.2) Factors influencing abrasive and erosive wear: Knoop and micro Vickers hardness of minerals and materials, Correlationsbetween wear rate W and hardness ratio (material hardness Hm/mineral hardness Ha)-W∝(Hm/Ha) n-, Wear-resistant factors except hardness- Youngs modulas, tensile strength, fatigue strength, impact strength, etc.-, Effect of mineral grains size while the wear rate are proportional to the grain size, after the critical size (about 10-300 pm) it is almost constant-.3) Wear characteristics: Initial and steady wear processes-in steady wear the wear rate are proportional to sliding distance or impact time-, Influence of velocity V-W∝ Vn, where n value are 0-0.5 in two and three-body sliding friction testing methods, 0.8-1.3 in ball mill, 2-6.5 in testing methods of impacting of loosegrains against materials (metal: 2-3 and non-metal: 3-6.5)-, Influence of impact angle in erosive wear-the ductile materials exhibits maximum wear rate at low impact angle, but the brittle materials produces its maximum at high angle (for example, rubber: 0°, steel: 15-25°, castiron: 40-50°, glass: 90°).