1 0 0 0 OA 複合サイクル腐食試験における有機複合被覆鋼板の腐食挙動

- 著者

- 筋田 成子 望月 一雄 森戸 延行

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.84, no.11, pp.777-784, 1998-11-01 (Released:2009-06-19)

- 参考文献数

- 26

- 被引用文献数

- 3 3

Organic composite coated steel sheets show their excellent corrosion resistance during cyclic corrosion tests (CCT). To clarify corrosion behavior of these sheets, changes in corrosion products and elements of plating, chromate and organic resin layers during CCT were examined. Formation of crystalline ZnCl2·4Zn(OH)2 and superficial amorphous zinc carbonate were detected by X-ray diffraction, fourier transform infrared spectroscopy and Raman spectroscopy. And besides it was found by electron probe micro analysis, chemical analysis and fourier transform infrared spectroscopy that the corrosion products formed on organic resin layer contained silicon as zinc silicate from silica in organic resin layer.Consequently, weight of zinc in plating layer and silica in organic resin layer decreased, while that of nickel in plating layer, chromium in chromate layer and carbon in organic resin layer remained constant, and the corrosion products formed on organic resin layer contained zinc and silicon dissolved from each layer during CCT.

1 0 0 0 OA 円柱鋼材の冷却過程における熱応力の計算

- 著者

- 坂井 一男

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.60, no.12, pp.1591-1598, 1974-10-01 (Released:2010-10-12)

- 参考文献数

- 12

- 被引用文献数

- 3 4

The paper presented a calculation of thrmal stress in a cylindrical steel induced during cooling by introduction of strain-history into Hara's calculation method.Calculation was based on elastic-plastic theory and total strain was calculated by non-linear integral equation through a successive integration. Plastic strain was calculated by total strain theory and stress-strain diagram.A calculation was made for a cylindrical steel bar with 1500mm in diameter quenched in mist from 850°C, and the results are as follows.(1) Tensile stresses (δt, δz, ) at surface of bar are the largest, when temperature difference between surface and core was the largest.(2) Stresses (δt, δz) at starting point of transformation always show the maximum tensile values.(3) Reverse of stresses (δr, δt, δz) takes place after completion of transformation of core.(4) At final stage of cooling, core has tensile stresses (δr, δt, δz) and surface layer has compressive stresses (δt, δz) of characteristic pattern.

- 著者

- Alya Naili Rozhan Mohd Hanafi Ani Hamzah Mohd Salleh Tomohiro Akiyama Hadi Purwanto

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.55, no.2, pp.436-440, 2015-02-15 (Released:2015-02-20)

- 参考文献数

- 44

- 被引用文献数

- 1 6

This paper presents a technology to utilize bio-char and bio-tar from the pyrolysis of oil palm empty fruit bunch, EFB. In this study, tar vapor from pyrolysis of EFB was infiltrated within porous bio-char and carbon deposition occurred on the pore surface by chemical vapor infiltration process. For preparation, EFB particles were made into pellets. In the first part of experiments, porous bio-char pellets were produced by slowly heating the EFB pellets in a tube furnace in argon atmosphere to terminal temperatures of 500–800°C. In the second part, the porous bio-char pellets were used as precursor for tar decomposition process to deposit carbon within the bio-char pores. Tar vapor was obtained from the pyrolysis of EFB at 400–500°C at a fast heating rate for tar decomposition to occur. The purpose of this research is to investigate the amount of carbon deposited within bio-char by this tar carbonization process as compared to carbon contents of metallurgical coke. We showed how EFB bio-char was used as the tar filter and in the process to produce carbon-infiltrated bio-char, a useful renewable energy source for ironmaking process.

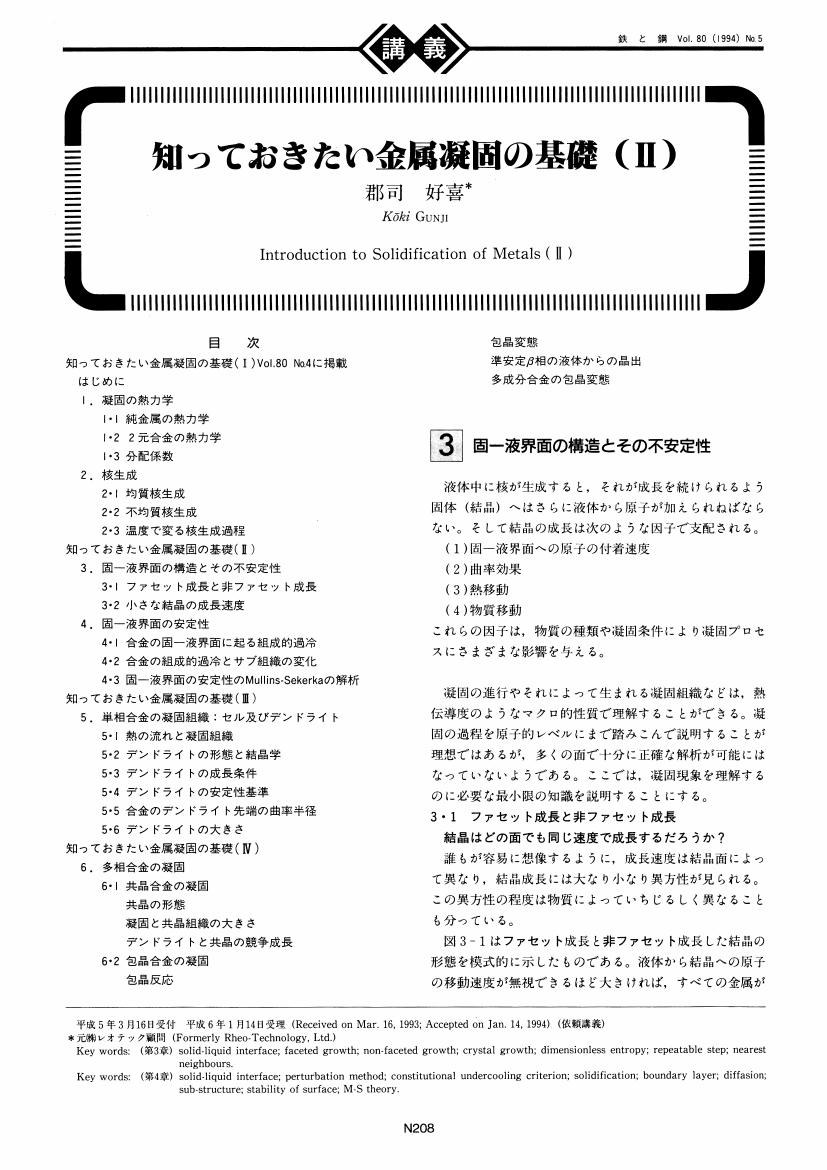

1 0 0 0 OA 知っておきたい金属凝固の基礎(II)

- 著者

- 郡司 好喜

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.80, no.5, pp.N208-N221, 1994-05-01 (Released:2009-06-19)

- 参考文献数

- 27

- 被引用文献数

- 2

1 0 0 0 OA 燃焼の基礎技術(II)

- 著者

- 水谷 幸夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.70, no.8, pp.774-784, 1984-06-01 (Released:2009-06-30)

- 参考文献数

- 11

- 被引用文献数

- 1 1

1 0 0 0 OA Understanding the Structure and Structural Effects on the Properties of Blast Furnace Slag (BFS)

- 著者

- Muhammad Sajid Chenguang Bai Muhammad Aamir Zhixiong You Zhiming Yan Xueming Lv

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.59, no.7, pp.1153-1166, 2019-07-15 (Released:2019-07-13)

- 参考文献数

- 96

- 被引用文献数

- 37

Evolving knowledge of the structure and physical properties of metallurgical slags is summarized in current review. Slag structure, compositional effects, role of cations in structural modifications, parameters used to represent the structure, structural analysis techniques and effects of structure on properties of blast furnace slag (BFS) studied in details. The basicity, polymerization (Q) or depolymerization (NBO/T), optical basicity, Qn values, concentrations of bridging O’s (Oo), non-bridging O’s (O−) and free O’s (O2−) in slag are useful to represent the structure of slag. Methods and techniques utilized to study the slags are also discussed. The BFS is characterized by using X-ray Diffraction and Spectroscopy, Raman Spectroscopy, Fourier Transform Infrared Spectroscopy (FTIR), X-Ray Photoelectron Spectroscopy (XPS) and Nuclear Magnetic Resonance (NMR) Spectroscopy. The physical properties such as surface tension, viscosity, density, thermal expansion and diffusion, electrical conductivity and resistivity of slags are reviewed thoroughly which are heavily dependent on structure of slag. Viscosity is affected by polymerization or depolymerization of slag structure and cation size; electrical resistivity depends on Q, size of cations and number of available cations; thermal expansion depends on Q and cation field strength (i.e. z/r2); thermal conductivity is linked with rigidity of slag network which is also dependent on Q and metal-oxygen (M–O) bond strength. Degree of polymerization or depolymerization of slag structure also effect the surface and interfacial tension, it decreases as metal-oxygen (M–O) bond strengths (i.e. z/r2, cation field strength) decrease.

1 0 0 0 OA 日本鉄鋼業における計算機制御の進歩

- 著者

- 野坂 康雄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.59, no.5, pp.557-569, 1973-04-01 (Released:2010-10-12)

- 参考文献数

- 5

- 被引用文献数

- 1 1

1 0 0 0 OA 自動車車体用薄鋼板とその成形技術の動向

- 著者

- 吉田 清太

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.63, no.9, pp.1588-1596, 1977-08-01 (Released:2010-03-15)

- 被引用文献数

- 2

1 0 0 0 OA 鐵の瓦斯吸收に於ける處女性に就て

- 著者

- 岩瀬 慶三 福島 政治 三井 三郎

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.22, no.10, pp.769-773, 1936-10-25 (Released:2009-07-09)

- 参考文献数

- 2

On the Irreversibility of Gas Absorption found in various kinds of Irons. Gas absorption experiment has been carried out with various kinds of iron and its alloys to investigate the effect of impurity and heat treatment. The result of experiment show that virgin iron, when it contains no other metallic element, behaves toward gas reversibly, while impure iron behaves toward gas irreversibly. That is, pure iron absorbs the same quantity of gas whether it is once heated in the gas or not while impure iron absorbs the gas in less amount when it is once heated in the gas in comparison with the virgin iron.

1 0 0 0 OA わが国のばね鋼の進歩発展について

- 著者

- 阿部 芳平

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.76, no.12, pp.2059-2064, 1990-12-01 (Released:2009-06-30)

The report discusses the recent development of spring steel in Japan during last 40 years. There has been a great increase in this steel production with the increase of production of automobiles. The technical trends of spring steel and springs are discussed in connection with hardenability, fatigue, high-stressed design and productivity. Especially, ways of improvement of performance of springs for suspention of automobiles were studied in respect to chemical composition, heat-treatment and manufacturing process.

1 0 0 0 OA 流れにおける渦の生成

- 著者

- 亀本 喬司

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.76, no.3, pp.320-328, 1990-03-01 (Released:2009-06-30)

- 参考文献数

- 26

- 被引用文献数

- 2 2

流れの中に渦が発生するメカニズムは,流れの初期条件や境界条件によってかなり相違があるが,本質的には渦度がどのように供給され,それらがどのように流れるかによっていることは本文に説明したとおりである. 自然界における空気や水の流れを見ても,渦を伴わないものはほとんど無いと言っても過言ではない.技術の粋を集めて作られた航空機でもひとたび設計条件からはずれると,Fig.7に示したような流れの剥離により失速状態に陥ることもあり,渦とはこれほど発生しやすいものと考えたほうが良さそうである.流れにおける渦の生成を,さまざまな条件下で意のままにコントロールできたとすれば,それは正に人間にとって夢の実現に値するものである.鳥や魚のように,渦無しの流れと渦放出を巧みに使い分けることもできるし,台風やたつ巻の,発生や進路を自由に制御することもできるようになる.流れにおける渦の生成に関する研究を行っていると,流体が時として生き物のように感じられ,「流れは, 自身の姿を自由に変え,常に流れやすいように流れている」ように見えてくる.要は,「流れの気持ち」が理解できるようになることであろうか.溶けた鉄の流れがどのような性質を持つ生き物なのかについては,ご専門の技術者や研究者の方々が解き明かしてくださるものと楽しみにしている.この分野の方々にとって,本文が多少なりともご参考になれば幸いである.

- 著者

- 植森 龍治 向井 俊夫 谷野 満

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.77, no.11, pp.2060-2067, 1991-11-01 (Released:2009-06-19)

- 参考文献数

- 20

- 被引用文献数

- 1 1

Partition of alloying elements between spinodally-decomposed phases in Fe-Cr-Co-Si alloys was examined by Atom-Probe Field-Ion Microscope (AP-FIM). The results showed that the ferromagnetic particle (α1) is rich in Fe and Co, and the weak-ferromagnetic matrix (α2) rich in Cr and Si. The enrichment of Si in the α2 phase was explained through thermodynamical considerations. Si is more strongly bonded to Cr than to Fe. The improvement of hard magnetic properties by Si additions was found and discussed in terms of the changes in saturation magnetization of the α1 and α2 phases. The increase in coercive force may be mainly attributed to the reduction of saturation magnetization of the α2 phase by the addition of Si.

1 0 0 0 OA 二相ステンレス鋼のσ相析出挙動

- 著者

- 前原 泰裕 小池 正夫 藤野 允克 邦武 立郎

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.3, pp.577-586, 1981-03-01 (Released:2010-01-18)

- 参考文献数

- 33

- 被引用文献数

- 11 27

Precipitation of σ phase in an Fe-25Cr-7Ni-3Mo alloy with a duplex structure of α and γ phases, has been studied systematically by means of optical microscopy, X-ray diffraction, hardness measurement, tensile test, SEM observation and dilatometric measurement. The results obtained in this study are as follows: (1) TTT diagram for the precipitation of σ phase was a C-type with a nose at about 820°C and 2030 min. (2) σ phase nucleated on the α/γ boundaries and grew into α grains, and thereafter the nucleation of σ and new γ phases began also in α grains. Volume fraction of α phase decreased and that of γ phase increased with increasing σ phase. Precipitation of σ phase occurred by the reaction, α→σ+γ. It was found that Cr, Mo and W were concentrated into α phase. (3) Increase of hardness with precipitation of α phase was not so large, on the contrary, impact value decreased drastically even at a few percent precipitation of α phase. α phase was also found to be harmful for hot ductility. (4) The precipitation range during cooling were about 700900°C and a phase precipitation could be avoided if cooling rate were larger than about 20°C/min after solution treatment. It was clarified from the above results that α embrittlement during production of duplex phase stainless steels could be avoided by selecting adequate manufacturing conditions.

- 著者

- Masato Yamashita Hiroo Nagano Toshihei Misawa Herb E. Townsend

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.38, no.3, pp.285-290, 1998-03-15 (Released:2007-05-31)

- 参考文献数

- 23

- 被引用文献数

- 37 68

A protective and adherent rust layer develops on weathering steels during outdoor exposure. This layer acts as a barrier which slows further corrosion, thus enabling weathering steel to be used in structural applications without painting. To aid in understanding the mechanism of protective rust formation, studies have been made on the composition and microstructure of these layers. The present study was jointly conducted on Japanese weathering steel exposed in the industrial environment of Amagasaki, and US weathering steel exposed in the industrial environment of Bethlehem. The rust layers were studied by use of optical microscopy, electron microscopy with X-ray fluorescence, X-ray diffraction, and micro-Raman spectroscopy. The results of this collaboration show that, in general, the rust layers formed during long-term exposure are composed of one or more alternating layers of goethite and lepidocrocite, with scattered patches of maghemite and/or magnetite.

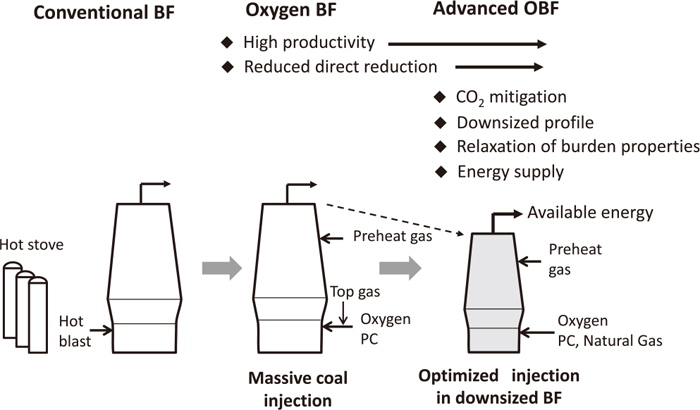

- 著者

- Tatsuro Ariyama Michitaka Sato Taihei Nouchi Koichi Takahashi

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.56, no.10, pp.1681-1696, 2016-10-15 (Released:2016-10-15)

- 参考文献数

- 59

- 被引用文献数

- 4 46

Blast furnace has been regarded as a highly optimized process as a result of various technological improvements over its long history. However, from the viewpoints of resources, energy and global warming, continuing evolution toward reductant flexibility and CO2 mitigation is desired. This review focuses on the progressive design of an ambitious blast furnace for the future.First, the history of techniques for reducing coke rate and reducing agent in the blast furnace are reviewed. Pulverized coal injection is currently common; however a more innovative process is desired in order to address the global warming issue. The low temperature blast furnace based on charging of high reactivity coke is a realistic process. The combination of the oxygen blast furnace with top gas recycling is also attractive. Although the top gas recycling process based on the oxygen blast furnace is very effective for reducing CO2 emissions, a total evaluation considering the role of the blast furnace to keep the energy self-sufficiency in the integrated steel works is necessary. The oxygen blast furnace enables injection of a large amount of natural gas, and optimized injection of natural gas and pulverized coal makes it possible to mitigate CO2 emissions while maintaining the energy supply to downstream processes. Moreover, owing to the high productivity of the oxygen blast furnace, the blast furnace profile can be downsized. The characteristics of several processes are quantitatively examined, and the concept of the advanced oxygen blast furnace as a next-generation process toward carbon dioxide mitigation is discussed.

1 0 0 0 OA アーク放電とその利用

- 著者

- 牛尾 誠夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.73, no.10, pp.1309-1315, 1987-08-01 (Released:2009-06-19)

- 参考文献数

- 23

- 被引用文献数

- 1 2

1 0 0 0 OA 塗装後の鮮映性に及ぼす鋼板表面粗度の影響

- 著者

- 角山 浩三 今中 誠 古川 九州男 岸田 朗 山田 恭裕

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.75, no.11, pp.2090-2097, 1989-11-01 (Released:2009-06-19)

- 参考文献数

- 5

- 被引用文献数

- 4 4

The influence of base metal surface roughness parameters on the clarity of painted automotive cold rolled sheet steels was investigated. The sheet steels were dull finished by shot blasting, electro-discharge texturing or laser dull texturing. It was found that the painted clarity improved with decreasing of Ra, while it scarcely depended on PPI. Characteristic of the surface profiles of base metal was the waviness with wavelength of hundreds micron. Whose trace remained after coating and deteriorated the clarity. In shot blasting, the dendritic microstructure and the statistical fluctuation of grit collision generated the waviness and made it difficult to control its wavelength. And, in electro-discharge texturing, it is suggested, controlling the waviness is difficult similarly. In laser dull texturing, it was possible to reduce the wavelength of waviness to less than hundreds micron and then to improve the clarity without deteriorating the press formability. A larger fraction of flat portion in laser dull texture was also responsible for the improvement of clarity.

- 著者

- OH Jin Taek JUNG Bong Bu PARK Hyun Chul

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ international (ISSN:09151559)

- 巻号頁・発行日

- vol.49, no.8, pp.1167-1173, 2009-08-15

- 参考文献数

- 15

Rollers are used widely in the transfer of the steel plate in steel mills. This method causes very loud impact noise because of the deflection of the steel plate and causes noise pollution in the labor environment. In this paper, the relationship between the impact noise and the impact force was examined. Also, a method for reducing the impact force was implemented in order to reduce the impact noise. The noise index was introduced to quantify the relation between impact noise and impact force. Dynamic and impact analyses were carried out using the finite element method. Experiments on impact were also carried out in order to validate the results.

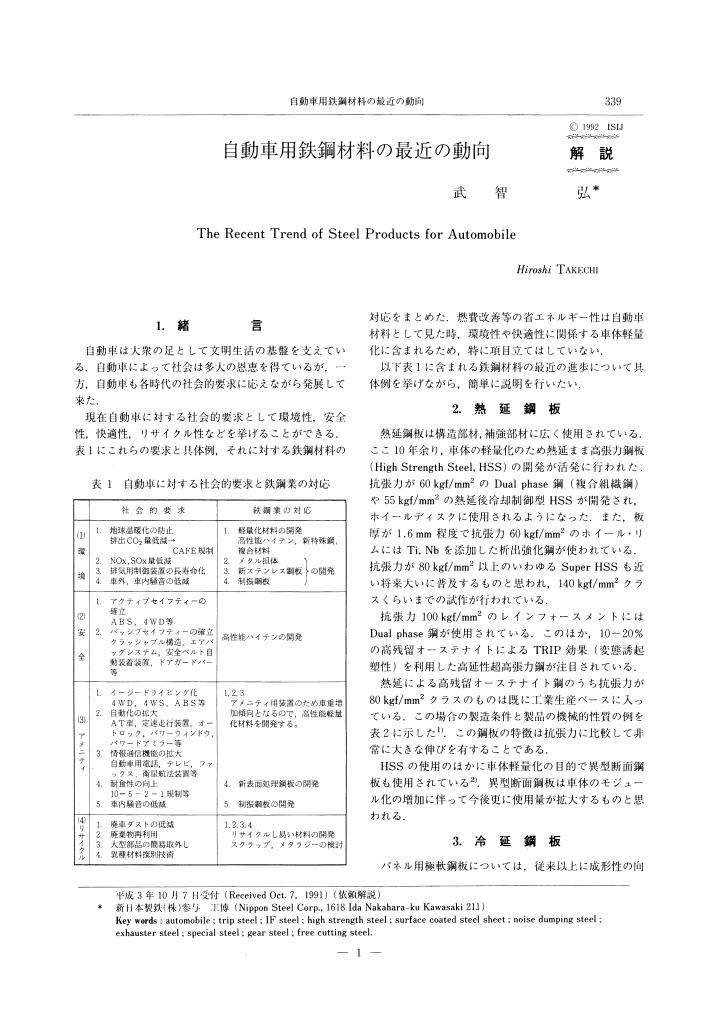

1 0 0 0 OA 自動車用鉄鋼材料の最近の動向

- 著者

- 武智 弘

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.78, no.3, pp.339-345, 1992-03-01 (Released:2009-05-29)

- 参考文献数

- 15

- 被引用文献数

- 1

1 0 0 0 OA 溶融FetO-SiO2系スラグの生成熱測定

- 著者

- 萬谷 志郎 井口 泰孝 本多 弘 石塚 晴彦

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.71, no.7, pp.846-852, 1985-05-01 (Released:2010-01-19)

- 参考文献数

- 18

- 被引用文献数

- 2 3

The heat of mixing of silica(β-cristobalite) with liquid wustite melted in an iron vessel has been directly measured at 1420°C by the modified isoperibol calorimeter(iso-thermal jacket type). Mixing of solid silica with liquid wustite is an exothermic reaction and the measured heat, ΔHFetO(l)-SiO2(β-cristobalite), is about-900cal/mol at the fayalite composition. Heats of mixing of liquid silica with liquid wustite, ΔHMFetO(l)-SiO2(l), are obtained by the combination of this direct measured results and heat of fusion of SiO2 in the reference. This result is discussed in comparison with the estimated values by the thermochemical data and by the assumption of the regular solution.