2193 0 0 0 OA 缶詰の内面腐食

- 著者

- 宮崎 俊三

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.73, no.3, pp.427-436, 1987-03-01 (Released:2010-01-18)

- 参考文献数

- 87

- 被引用文献数

- 2 1

229 0 0 0 OA 日本刀刃先部の強度と破壊抵抗に及ぼす不均一組織の影響

- 著者

- 郭 光植 山室 賢輝 峯 洋二 森戸 茂一 高島 和希

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- pp.TETSU-2023-076, (Released:2023-11-25)

- 参考文献数

- 24

Microtensile and microfracture tests were performed on the sharp-edge regions of Japanese swords fabricated in the Muromachi and Showa periods, which are called old sword (OS) and modern sword (MS), respectively, to correlate the mechanical properties with the inhomogeneous microstructures. The hardness of the sharp-edge regions was characterised by the distribution of fine pearlite mixed in martensite microstructures. The OS containing a large fraction of fine pearlite exhibited a low hardness compared to the MS. Microtensile tests using sharp-edge specimens revealed a positive correlation between their tensile strength and strain-to-failure, as opposed to the common tendency in conventional carbon steels made by modern iron-making technology. The fracture surfaces of the sharp-edge specimens were composed of intergranular and dimple fracture features. The tensile strength and dimple fracture area fraction were higher in the OS than in the MS. These findings suggest that the fine pearlite microstructure contributes to increased strength in the sharp-edge region through inhibiting the linkage of intergranular cracking owing to local plastic deformation. Microfracture tests using the sharp-edge specimens revealed that the intrinsic fracture resistance of both OS and MS was determined by the intergranular fracture, whereas the fine pearlite microstructure increased the resistance to crack propagation. The micromechanical testing study indicates that in the sharp-edge regions, their strength and fracture toughness are simultaneously enhanced by the presence of fine pearlite although depending on its distribution.

75 0 0 0 OA 航空發動機用曲軸鋼の撰定竝に其將來に就て

- 著者

- 高瀬 孝次

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.22, no.2, pp.107-120, 1936-02-25 (Released:2009-07-09)

Owing to the marked increase of aero-engine power, number of revolution, compression ratio, etc., crankshaft should inevitably biar the vibrational and duplicated over-stresses. The crankshaft should, therefore, not only be of the best chemical composition, most properly heat-treated, the latest metallurgical procedure being applied, but also of the most perfect design, in addition to the minimum weight and size.The writer has published a part of this investigation in the "Tetsu To Hagane" Vol. XIX, No.4 In this paper, in order to select the most suitable steel for the future, the notch effect in regard to the endurance properties and the influence of heat-treatment of these steels have been investigated.An investigation of crankshaft steel on the relation between the mechanical test results and the endurance properties by fatigue test have also been executed, and the writer has introduced a new method for determing the endurance limit in stead of laborious fatigue test.As a conclusion, the writer has suggested future requirements for the aero-engine crankshaft steel, considering all the facts above mentioned.

34 0 0 0 OA 過去 10 年間に於ける本邦鐵鋼事業の發達と將來の對策

- 著者

- 河村 驍

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.21, no.6, pp.373-383, 1935-06-25

The development and progress of the iron and steel industry during last ten years is reviewed, giving frank criticism upon the policies carried during the period and concluding with future prospect of the industry. The statistical review of production, Consumption and import of finished as well as raw materials is also given.

31 0 0 0 OA 小型たたら炉による鋼製錬機構

- 著者

- 永田 和宏

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.84, no.10, pp.715-720, 1998 (Released:2009-06-19)

- 参考文献数

- 7

- 被引用文献数

- 8 9

Tatara was used to be a traditional process to produce solid steel, so called "Kera", and/or liquid pig iron, so called "Zuku", from iron sand and charcoal using the box type furnace with blowing cold air intermittently. A modified Tatara furnace has been examined on the production mechanisms of "Kera". Temeratures and oxygen partial pressures in the furnace were measured by means of thermocouples and oxygen sensors with solid electrolyte of zirconia. Iron sand and a piece of "Kera" produced in the bottom of furnace were sampled and analyzed chemically or by a electron probe micro analyser. Iron sand is reduced above tuyere and absorbs carbon on fired charcoals in front of the tuyere at about 1350°C. Many small balls of liquid steel with different carbon content were found in molten slag pool of FeO-saturated silica, so-called "Noro", and cohere each other to grow into a bloom. The characteristics of Tatara steelmaking process are low temperature for carbon absorption of steel at about 1350°C, high oxygen potential in the molten slag of FeO-saturated silica and hypo-eutectic carbon content in steel.

- 著者

- 佐野 幸吉

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.76, no.2, 1990-02-01

21 0 0 0 OA 製銑技術の100年 −技術導入から先進技術への展開,そして次世代技術へ−

- 著者

- 内藤 誠章 武田 幹治 松井 良行

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.1, pp.2-30, 2014 (Released:2013-12-31)

- 参考文献数

- 218

- 被引用文献数

- 9 14

The modern blast furnace operation at integrated steel works in Japan has started in 1901 by the first blown-in of Higashida No. 1 blast furnace in Yawata Works, while a 150 years history of Japanese steel industry has dated back to the first western blast furnace built by T. Ohashi in 1857. The steel industry has been supporting the Japanese economy as a key industry which supplies base materials for social infrastructure and developments throughout the pre and post war periods.After the recovery period from the war destruction, Chiba Works of Kawasaki Steel Corp., were built and started its operation in 1953 as the first integrated steel works in Keiyo Industrial Region after the war. During the rapid growth period, many coastal steel works equipped with a large blast furnace more than 3000m3 and some of 5000m3 were built for the efficient marine transportation of raw materials and steel products. Most advanced technologies, high pressure equipment, stave cooler system and bell-less charging system etc., were introduced, improved and has risen to the top level in the world with low reducing agent ratio (RAR), energy saving and long service life of a blast furnace and coke ovens.Energy shift from oil to coal by the oil crisis, cost oriented operation design and technology were tackled and the hot metal of about 80 million tons is manufactured with 27 blast furnaces including over 5000m3 large scale blast furnaces in 2012. During this period, our industry has faced many economical and social pressures of high exchange rate of yen, oligopoly of mining market, global warming problem, and surge of iron ore and coal prices by the rapid growth of the BRICs. We have kept our competitive positions by developing advanced technologies on pulverized coal injection, extended use of low cost iron resources, recycling for environment and CO2 mitigation technologies.Prospects of ironmaking technologies for other decades are discussed by reviewing various papers published and looking back the history of ironmaking developments during the last 100 years.

18 0 0 0 OA AMS-炭素14年代測定法が明らかにした日本の鉄の歴史

- 著者

- 藤尾 慎一郎

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.91, no.1, pp.11-15, 2005-01-01 (Released:2009-06-19)

- 参考文献数

- 12

- 被引用文献数

- 3 2

This paper focuses on the influence what the AMS-carbon 14 age method attains to the history of the iron in the Japanese Islands.The research team in National Museum of Japanese History makes a clear that the Yayoi period began in 10 Cen. cal BC. However, there was a problem in this.It is iron. If the Yayoi period has started in the 10th Cen. BC, it means that the ironware in Japanese Islands had spread early rather than it spreads in China.The research team reexamined the ironware excavated from Magarita site in the Fukuoka Pref. considered to be the oldest ironware in Japan. Consequently, the excavation situation was indefinite and it turned out that we cannot specify the time to belong.Furthermore, 36 ironwares in the initial and early Yayoi were also already found by that time cannot be specified except for two points. Therefore, it turned out that Japanese ironware appeared in the 3rd century of B.C. What does this mean?Although it had been thought that the beginning of agriculture in Japan and the appearance of ironware were simultaneous, it turned out that agriculture has appeared early about in 700 years. Therefore, it became clear that agriculture of Japan started at the Stone Age.

17 0 0 0 OA 装甲鈑製造についての回顧録

- 著者

- 佐々川 清

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.53, no.9, pp.1119-1129, 1967-08-01 (Released:2010-10-12)

14 0 0 0 OA 日本刀の鍛錬性に及ぼす南蛮鉄のリン含有量の影響

- 著者

- 鈴木 卓夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.90, no.1, pp.43-47, 2004-01-01 (Released:2009-05-29)

- 参考文献数

- 10

- 被引用文献数

- 2 2

Nanban-tetsu is a steel which was imported into Japan by Portuguese or Spanish merchant ships in the end of Muromachi period (1392-1573). The steel was produced in India and called "Wootz steel". Nanban-tetsu steel was shaped in some forms of a gourd called "Hyotan", a oval called "Koban", a square timber called "Saijo", a semi-cylinder called "Tajo" and others. In 1613, one of the Japanese sword smith, Echizen Yasutsugu 1, first produced a sword using Nanban-tetsu steel. Since then, many sword smiths who lived in Echizen area (Fukui Prefecture) had used Nanban-tetsu steel as a material of Japanese swords. The steels produced using the "Nittoho-Tatara" furnace in Shimane prefecture has been examined by forge-welding as a function of phosphor content in the steels. It is concluded that "Hyotan" shaped Nanban-tetsu steel is not good for forging, "Saijo" shaped Nanban-tetsu steel is good for forging, "Koban"-shaped one is difficult to forgeweld and "Tajo"-shaped one is intermediate.

14 0 0 0 OA 歐米に於ける平爐製鋼の管見

- 著者

- 絹川 武良司

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.25, no.3, pp.163-174, 1939-03-25

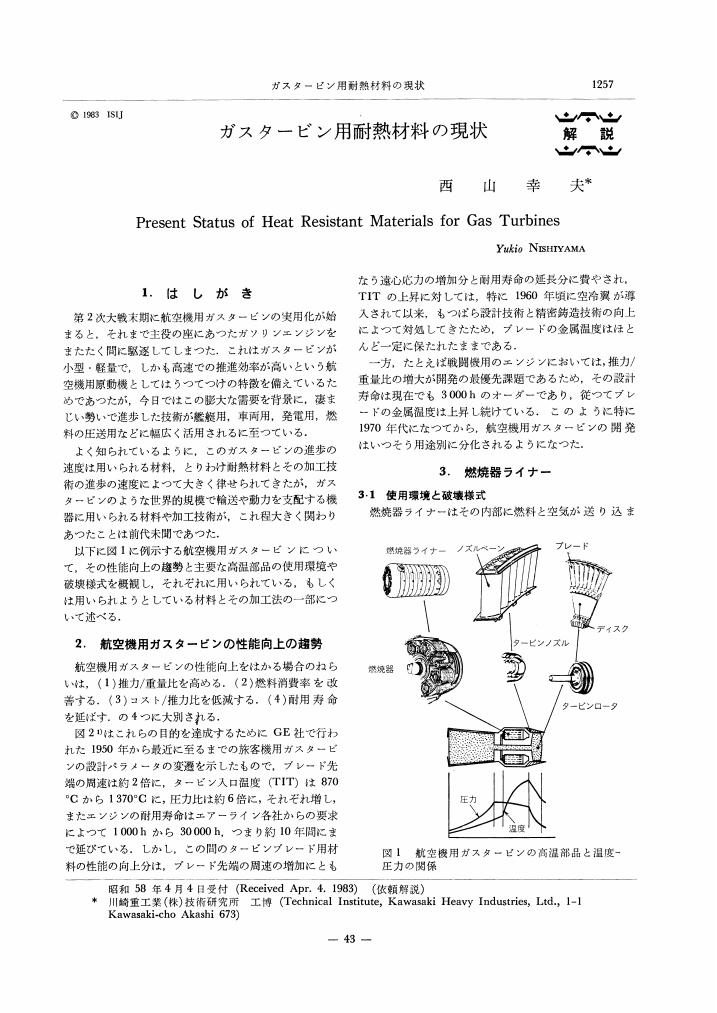

11 0 0 0 OA ガスタービン用耐熱材料の現状

- 著者

- 西山 幸夫

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.69, no.10, pp.1257-1265, 1983-08-01 (Released:2009-06-30)

- 参考文献数

- 27

- 被引用文献数

- 1

10 0 0 0 OA 日本刀の冶金学的研究 : 日本刀は複合的金属材料の精粋である

- 著者

- 谷村 熈

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.3, pp.497-507, 1981-03-01

10 0 0 0 OA 日本における構造用高張力鋼の発達と溶接上の問題点

- 著者

- 木原 博

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.58, no.13, pp.1903-1912, 1972-11-01 (Released:2010-10-12)

- 参考文献数

- 26

10 0 0 0 OA 日本刀の強度-靭性バランスと刃金用玉鋼の折返し鍛錬による炭素量,焼入れ硬さの変化

- 著者

- 佐々木 直彦 堀井 胤匡 藤原 幹男 斎藤 英之 三澤 俊平

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.86, no.1, pp.45-50, 2000-01-01 (Released:2009-06-19)

- 参考文献数

- 13

- 被引用文献数

- 7

Micro-strucure, micro-hardness and micro-absorbed impact energy in the Japanese sword have been investigated to clarify excellent mechanical properties of the Japanese sword. The Japanese sword specimen used in the present research has been made by using TSUKURIKOMI process which combines four kinds of steels; HAGANE (edge), SHINGANE (core), MUNEGANE (back) and KAWAGANE (side) steels, with different carbon contents. By this process, HASAKI (edge) side becomes high carbon steel and MUNE (back) side possesses low carbon steel. The cooling velocity in quenching of the Japanese sword is controlled by TSUCHIOKI treatment which coats the clay thinner in the HASAKI side and thicker in the MUNE side. The HASAKI side is quickly cooled and the MUNE side is slowly cooled. The micro-structure in the HASAKI side shows martensite while the MUNE side shows the coexist structure of ferrite and pearlite. The HASAKI side has a lower value while the MUNE side shows a higher value in the micro absorbed impact energies obtained with the 1.0 and 0.7 mm square miniaturized specimens. It has been shown clearly that the TSUKURIKOMI and the TSUCHIOKI processes give the excellent gradated balance of strength-toughness to the Japanese sword.The ORIKAESHI (folding) forging has an effect both on the carbon content and as quenched hardness in HAGANE steel. The most suitable times of ORIKAESHI cycles which adjust to the carbon content of 0.55-0.60 mass% and hardness of 800HV1 have been determined to be thirteen times. These times of ORIKAESHI cycles correspond to the optimum traditional cycles lying between twelve and fifteen times. The present research from the viewpoint of the metallurgy sheds light on the empirical rule in the traditional Japanese sword processing.

9 0 0 0 OA ラジオアイソトープによる高炉炉壁の侵蝕調査(I)

- 著者

- 富永 在寛 八塚 健夫 庄野 四朗

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.46, no.1, pp.7-11, 1960 (Released:2012-07-12)

- 参考文献数

- 5

To measure the wearing state of a blast-furnace brick-work during its operation, a test method using a radioactive isotope (Co60) was investigated. In this report, some basic investigations which include the measurement of absorption coefficients of the blast furnace construction materials, determination of the burying amounts of Co60, and experiments with a brick-work model are described.

9 0 0 0 OA 鉄鋼生産技術の展望

- 著者

- 山岡 武

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.53, no.1, pp.3-10, 1967-01-01 (Released:2010-10-12)

8 0 0 0 OA New Materials for High Speed Railway Vehicle

- 著者

- Yasufumi SUZUKI

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- Tetsu-to-Hagane (ISSN:00211575)

- 巻号頁・発行日

- vol.79, no.8, pp.N568-N575, 1993-08-01 (Released:2009-06-30)

- 参考文献数

- 13

- 被引用文献数

- 4

8 0 0 0 戦時中のジェット・エンジン事始め

- 著者

- 永野 治

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.64, no.5, pp.659-663, 1978-04-01

- 被引用文献数

- 4

7 0 0 0 OA 加速器質量分析による日本刀の14C年代と暦年代

- 著者

- 永田 和宏 松原 章浩 國分(齋藤) 陽子 中村 俊夫

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.102, no.12, pp.736-741, 2016 (Released:2016-11-30)

- 参考文献数

- 15

- 被引用文献数

- 2 2

Steel of Japanese swords has been produced with Tatara process from iron sand and charcoal. Carbon dissolved in steel was absorbed from wooden charcoal fuel during the production of the steel. From the decay of 14C activity in the steel, the 14C age of Japanese sword can be determined. The 14C ages of 4 Japanese swords were measured with accelerator mass spectrometry and calibrated to calendar years. Each 14C age provided plural calendar year periods with definite probabilities, and one of the periods agreed with the production year of each sword that was determined from the sword master’s name cut in the grip of his sword after taking the age range of charcoal used for steel production and usage for several generations of the same names of sword masters into account.