- 著者

- Itsuki Iwamoto Ade Kurniawan Hiroki Hasegawa Yoshiaki Kashiwaya Takahiro Nomura Tomohiro Akiyama

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.62, no.12, pp.2483-2490, 2022-12-15 (Released:2022-12-15)

- 参考文献数

- 38

- 被引用文献数

- 2

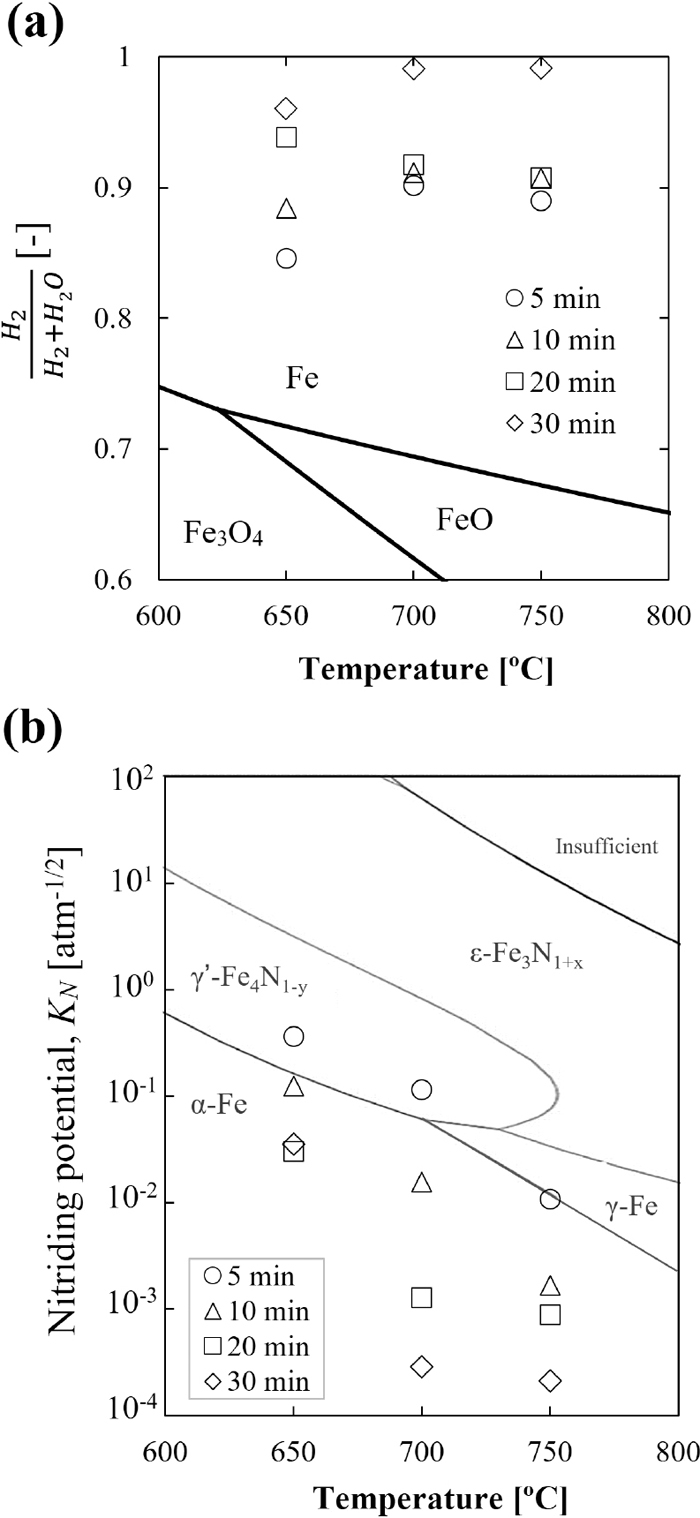

As one of the hydrogen carriers, ammonia has become one promising candidate as a reducing agent for implementing hydrogen-based ironmaking to reduce CO2 emissions. On the other hand, the abundant high combined water (CW) iron ore has recently been investigated as a raw material for ironmaking. Goethite (FeOOH), the main component of high-CW iron ore, can change to porous hematite (Fe2O3) by dehydration, enhancing its reactivity. This paper describes the fundamental study of the ore reduction behavior using ammonia as reducing agent. The effects of different ore types (i.e., high- and low-CW ores), reduction temperatures (i.e., 650, 700, and 750°C), and conditions of post-reduction treatments (i.e., quenching by NH3, fast- and slow- quenching by inert gas) on ore reduction behavior. The results reveal that the dehydrated high-CW one exhibits a higher ammonia utilization rate and is reduced faster due to the high specific surface area of the pores generated from the ore dehydration. The reduction degree of the sample increased at a higher temperature. However, in contrast, the nitriding degree decreases since the decomposition of nitrides occur highly at elevated temperatures. During quenching at temperatures lower than 700°C, the metallic Fe in the sample was nitrided in the presence of NH3. In contrast, the nitrides were easily decomposed into metallic Fe in the absence of NH3 at 700°C. This finding suggests that the quenching conditions significantly affect the generated phases. Thus, the generated phases of the reduced ore could be easily controlled in the post-reduction process.

1 0 0 0 OA Natural Convection on Dendrite Morphology: A High–performance Phase–field Lattice Boltzmann Study

- 著者

- Tomohiro Takaki Shinji Sakane Takayuki Aoki

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.63, no.1, pp.83-90, 2023-01-15 (Released:2023-01-21)

- 参考文献数

- 50

- 被引用文献数

- 3

Numerical study on the effect of liquid flow on three-dimensional dendrite growth is still a challenging topic. Herein, high-performance phase–field lattice Boltzmann (PF-LB) simulations were performed to investigate the effect of natural convection on dendrite morphology and the possibility for causing fragmentation. Parallel computing in multiple graphics processing units (GPUs) with dynamic load balancing for the block-structured adaptive mesh refinement (AMR) scheme (parallel-GPU AMR) was applied to the PF-LB simulations as a high-performance computing tool in a GPU supercomputer. Parallel-GPU AMR PF-LB simulations showed that the growth of dendrites with natural convection in two and three dimensions were quite different. The dendrite tip velocity increased in the following order: upward buoyancy, no gravity, and downward buoyancy. Downward and upward buoyancy enhanced and restricted the growth of the secondary arms, respectively. The root size of the secondary arms growing from the bottom was drastically affected by the flow direction. However, the dendrite fragmentations were not observed in the present simulations.

1 0 0 0 OA 表面錆からみた稲荷山鉄剣の材質

- 著者

- 村田 朋美 佐々木 稔 田口 勇

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.69, no.16, pp.2087-2092, 1983-12-01 (Released:2009-06-30)

- 参考文献数

- 13

- 被引用文献数

- 1

- 著者

- Takuya Kiyozumi Shinji Kudo Aska Mori Riku Mizoguchi Atsushi Tahara Shusaku Asano Jun-ichiro Hayashi

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.62, no.12, pp.2476-2482, 2022-12-15 (Released:2022-12-15)

- 参考文献数

- 26

Oxalic acid is an attractive chemical platform potentially available from CO2 due to its established applications and chemical characteristics enabling it to serve as a mediator in hydrometallurgy including iron-making. However, a method for synthesizing oxalic acid from CO2 has yet to be established. In the present work, the formation of oxalate scaffold during heating of cesium carbonate (Cs2CO3) in the presence of CO2 and H2 as reactants was experimentally investigated with a particular focus on the influence of supporting Cs2CO3 over porous materials. Among the support materials examined, activated carbon (AC) had a notable effect in improving the reaction rate and yield of total carboxylates (formate and oxalate) during experiments with an autoclave. An important problem was the dominant presence of formate, the intermediate between carbonate and oxalate, accounting for over 90% of the carboxylates. Changing the reaction conditions, including temperature, reaction time, partial pressure of gas components, and amount of loaded Cs2CO3, did not alter the situation. Alternatively, re-heating of the formate-rich salts over AC under CO and CO2 enhanced the oxalate fraction while maintaining the total carboxylates yield. Benefiting from the employment of support material, the two-step conversion was carried out using a gas-flow type reactor with a packed bed of Cs2CO3 supported over AC. In this reaction system, because water, acting as a promoter, was absent, the total carboxylates yield was lower than that in the autoclave, while the oxalate fraction was higher, being 71.8% with a yield of 43.2% on a Cs2CO3-carbon basis.

1 0 0 0 OA 薄鋼板におけるα→γ→α変態による集合組織形成

- 著者

- 橋本 修 佐藤 進 田中 智夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.66, no.1, pp.102-111, 1980-01-01 (Released:2010-01-18)

- 参考文献数

- 40

- 被引用文献数

- 19 15

For the purpose of investigating the formation mechanism of the texture which is developed by ferrite (α)→austenite (γ)→ferrite (α) transformation, the effects of heating and cooling rates during phase transformation and specimen thickness on the transformation texture have been studied by using extra low carbon sheet steel with the initial texture of {111}. The results obtained are summarized in the following: (1) Rapid heating and rapid cooling produced weak {100} and {111} texture. (2) Rapid heating and slow cooling exhibited both {110} texture and the orientation shifted 2030 degrees away from {100}. (3) Slow heating and slow cooling produced distinct {100} texture. (4) There was much difference in texture between surface and midsection of thick specimen: In the midsection, the texture similar to (1) was formed, independent of heating and cooling rates. While, specimen surface exhibited such textures as (1) to (3). (5) Those results were reasonably and consistently explained on the assumptions that the orientation relationship between bcc and fcc follows the Kurdjumov-Sachs relation, and that during α→γ→α transformation with slow rate such variants preferentially operate that undergo larger elastic work in normal direction of sheet.

- 著者

- Keita Tanahashi Yusei Omura Hidekazu Naya Yuji Kunisada Norihito Sakaguchi Ade Kurniawan Takahiro Nomura

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.62, no.12, pp.2578-2586, 2022-12-15 (Released:2022-12-15)

- 参考文献数

- 30

- 被引用文献数

- 1

High-temperature pressure swing adsorption (HT-PSA) is a promising energy-saving approach for oxygen production from air. Ca2AlMnO5+δ, a Brownmillerite-type perovskite, is a promising sorbent for HT-PSA because of its remarkably high oxygen storage capacity (up to 3.3 wt%). In this study, we investigated the redox thermodynamics of Ca2AlMnO5+δ by pressure–composition–temperature (PCT) measurements and investigated the HT-PSA performance of Ca2AlMnO5+δ pellets in a 100 g-scale packed-bed-type reactor. PCT measurements revealed that Ca2AlMnO5+δ can reversibly separate 2.2 wt% of oxygen per cycle under equilibrium conditions between ambient oxygen partial pressure and 5×10−4 MPa at 525°C. However, in a 5 min switching HT-PSA test, Ca2AlMnO5+δ pellets were able to reversibly separate less than 1 wt% oxygen per cycle, which is significantly lower than that estimated from the thermodynamic properties of Ca2AlMnO5+δ. On the other hand, the exothermic oxygen storage and endothermic oxygen release reactions cause significant temperature variation of the packed bed. This study clarifies that, in order to increase the energy efficiency of oxygen separation by HT-PSA, there is a need to compensate for the heat of reaction, which changes the reactor temperature in a direction that interferes with the reaction.

1 0 0 0 OA 軸受鋼の寿命におよぼす熱処理組織の影響

- 著者

- 仕幸 三郎 岡本 一生 渡辺 章三

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.54, no.13, pp.1353-1366, 1968-11-01 (Released:2010-10-12)

- 参考文献数

- 21

- 被引用文献数

- 22 21

Effect of metallographical factors on the rolling fatigue life of 1%C-1.5%Cr bearing steel was investigated, and the most profitable component for the bearing life was discussed.The results obtained are as follows:(1) Metallographical factors affected on the rolling fatigue life of bearing steel were not amount and size of residual cementite but the chemical compositions soluted in fhe matrix.(2) The most effective factor affected on the rolling fatigue life was carbon content soluted in the matrix and the most desirable carbon content in the matrix was about 0.5 percent.(3) It was recognized that the mechanism of flaking was related to the third stage of the tempering of martensite. This was deduced from the observation of the micro-structure of cyclic stressed area by the transmission electron microscopy and the result of bearing life test of a new type steel with higher silicon of which the starting temperature of the third stage was rised by silicon.

- 著者

- Yushi Takenouchi Shuhei Wada Takuro Masumura Toshihiro Tsuchiyama Hiroshi Okano Shusaku Takagi

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.62, no.10, pp.2000-2007, 2022-10-15 (Released:2022-10-19)

- 参考文献数

- 23

- 被引用文献数

- 2

Stress relaxation tests were conducted in the elastic region of an ultralow carbon martensitic steel (Fe–18%Ni alloy) to quantitatively analyze the effect of mobile dislocations on the low elastic limit of the steel. The elastic limit of the as-quenched material was measured at 255 MPa, although its tensile strength was as high as 720 MPa. The stress relaxation tests, which were performed at 255 MPa, revealed a remarkable stress reduction due to the movement of the mobile dislocations present in the as-quenched material. The total dislocation density barely changed during the test, while the distribution parameter (M-value) decreased significantly, indicating that the mobile dislocations exhibited stable arrangements. The 5% cold rolling before the relaxation tests suppressed the relaxation and simultaneously increased the elastic limit to a maximum, 435 MPa. By estimating the mobile dislocation density by relating the stress reduction in the stress relaxation tests to the distance of the dislocation movement evaluated via transmission electron microscopy (TEM) observations, it was estimated that the mobile dislocation density of the 5%-cold-rolled material was lowered to ~1/10 of that of the as-quenched material.

- 著者

- Yuki Tampa Kosuke Takagi Shohei Ueki Motoki Ohta Yoji Mine Kazuki Takashima

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.62, no.8, pp.1741-1749, 2022-08-15 (Released:2022-08-18)

- 参考文献数

- 27

- 被引用文献数

- 3

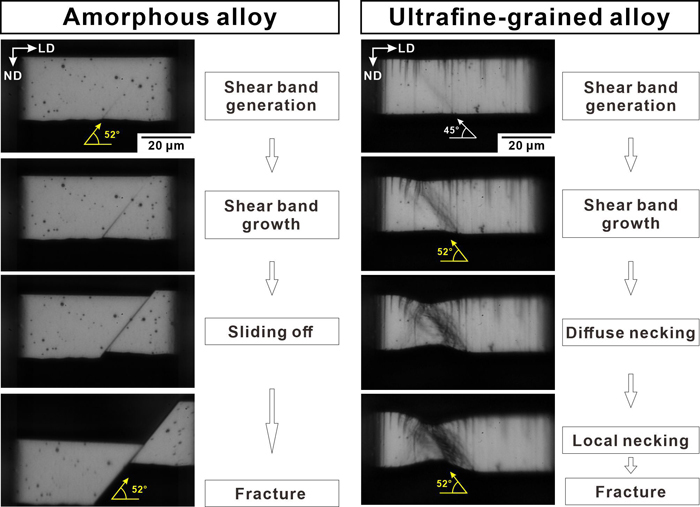

Micro-tensile tests were employed to clarify the post-plastic-instability behavior in the shear fractures of specimens with the dimensions of 18×25×50 µm3 made from iron-based amorphous (AM) and ultrafine-grained (UFG) alloys. The AM specimen yielded by localized shear bands with an inclination angle of ~52° with respect to the loading axis, followed by sliding off almost throughout the entire specimen thickness. Micro-tensile and micro-shearing tests revealed that the Mohr failure envelope of the AM specimens could be described by a quadratic equation rather than a linear equation. Therefore, the sliding-off process is assisted by the applied normal stress, which suggests that it is caused by free-volume coalescence. For the UFG specimen, yielding set in by shear band formation with an inclination angle of ~45° with respect to the loading axis, following the Tresca criterion. Necking after shear band diffusion formed a triaxial stress state, which resulted in a final shear fracture plane via void coalescence in the UFG specimens. Voids formed along the intersection of the primary shear bands with secondary shear bands during the necking process. This indicates that the deviation of the shear fracture plane in the UFG specimen was determined by the strain development process. A comparison of the post-plastic-instability behavior between the AM and UFG specimens suggests that the external control of triaxial stress conditions is key to improving the formability of AM specimens.

1 0 0 0 OA 高炉スラグ中単体硫黄の吸光光度分析法

- 著者

- 小野 昭紘 山口 直治

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.70, no.10, pp.1377-1384, 1984-08-01 (Released:2009-06-30)

- 参考文献数

- 6

- 被引用文献数

- 7 5

A new spectrophotometric method for determination of elemental sulfur in blast furnace slag has been developed. The outline of the procedure is as follows. A slag sample is powdered with n-hexane using a disk mill and elemental sulfur in the sample is extracted into n-hexane at the same time. The ultraviolet absorption of the n-hexane layer is measured at 275 nm to determine the quantity of elemental sulfur.By using this method elemental sulfur can be determined with high accuracy, provided the amount is higher than 0.002%. The coefficient of variations at the 0.05 and 0.2% levels of elemental sulfur are 2.3 and 1.4%, respectively. The time required for analysis of one sample is less than 10 min. There is no interference effect for sulfur compounds in the slag sample such as sulfate, thiosulfate, sulfite, sulfide and poly-sulfides.When a slag sample is powdered under the dry condition before the n-hexane extraction, lower analytical values are obtained, because elemental sulfur changes into poly-sulfides by the reaction with Ca components of the slag sample. This chemical change is found to be suppressed by simultaneous performance of powdering and extraction. Based on this technique, an analytical method is proposed and successfully applied to determine elemental sulfur in a slag sample.

1 0 0 0 OA ベイナイトの等温変態挙動とその連続冷却変態への適用

- 著者

- 梅本 実 堀内 一也 田村 今男

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.68, no.3, pp.461-470, 1982-03-01 (Released:2009-06-19)

- 参考文献数

- 23

- 被引用文献数

- 22 25

To obtain a general cooling transformation kinetics of steels from its isothermal transformation kinetic data, a bainite transformation has been investigated in present study. The main results obtained are as follows:(1) The isothermal transformation behaviour of bainite for the steel used in present investigation (JIS, SUJ2) can be expressed by the Johnson-Mehl type equation.(2) The bainite trasformation is retarded with an increase in the austenite grain size. The nucleation site of bainite is mainly on austenite grain surface but some homogeneous nucleations in the matrix are also found.(3) The equation expressing the transformation bahaviour of bainite during continuous cooling has been derived from the experimentally obtained isothermal transformation kinetics. It is examined that this equation well expresses the actual continuous cooling transformation behaviour.(4) The above result showing that additivity rule for transformed fraction is hold for bainite transformation during continuous cooling and cooling transformation behaviour can weell be predicted using the isothermal transformation kinetics.

1 0 0 0 OA 電磁熱流体力学の基礎と応用(II)

- 著者

- 棚橋 隆彦

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.79, no.4, pp.N263-N281, 1993-04-01 (Released:2009-06-30)

- 被引用文献数

- 1 2

1 0 0 0 OA 耐熱軸受鋼および耐食軸受鋼

- 著者

- 小柳 明

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.62, no.3, pp.414-423, 1976-03-01 (Released:2010-02-22)

- 参考文献数

- 35

- 被引用文献数

- 1

1 0 0 0 OA 二相混合組織をもつ鉄合金の強度と延性について

- 著者

- 田村 今男 友田 陽 山岡 幸男 金谷 三郎 小沢 正俊 赤尾 明

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.59, no.3, pp.454-468, 1973-03-01 (Released:2010-10-12)

- 参考文献数

- 21

- 被引用文献数

- 40 15

The strength and ductility of two-phase iron alloys with a ductile second phase were studied. The alloys used in this investigation were classified in three groups, that is, Fe-Cr-Ni alloys composed of austenite and ferrite, Fe-Ni-C alloys composed of austenite and martensite, and Fe-C alloys composed of ferrite and martensite; these phases had various volume fractions.The main results obtained are as follows:(1) In case of Fe-Cr-Ni alloys having different volume fractions of phases, when the same heat treatment was given, the better combination of strength and elongation was obtained in two-phase alloys than in single-phase alloys of austenite or ferrite. The main cause of this behavior was the difference in grain size. The coarsening of grains in two-phase alloys was much slower than that in single-phase alloys.(2) The effects of grain size on strength were shown by Petch type relations even in two-phase alloys as well as in single phase ones.(3) The effect of the volume fraction of phases on tensile properties with nearly the same grain size depended on the difference between the tensile properties of the second phase and the matrix. As the ratio of the 0.2% proof stress of the second phase to that of the matrix became larger than about 3, the relationb etween 0.2% proof stress and the volume fraction became to deviate from a linear relationship; this is known as the law of mixture. This may be caused by the difference of strains in the second phase and the matrix which becomes larger with an increase of the ratio.

1 0 0 0 OA 冷延鋼板のリン酸塩処理性に及ぼすCuとSnの影響

- 著者

- 大澤 紘一 濱田 紘一 峯 恭一 冨田 邦和 土谷 康夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.90, no.7, pp.494-501, 2004-07-01 (Released:2009-05-29)

- 参考文献数

- 15

- 被引用文献数

- 2 3

低C-Alキルド鋼をベースとして,Cu含有量を0.52mass%,Sn含有量を0.052mass%の範囲内で変化させた鋼種を用い,N,-3%H,雰囲気および1.3×10-2Pa以下の真空中で焼鈍した冷延鋼板におけるディップタイプのリン酸亜鉛化成処理性へのCuおよびSnの影響を調査し,つぎの結論を得た.(1)N2-H2雰囲気で焼鈍した冷延鋼板においては,052mass%まではCu含有量が増加しても化成処理性は若干低下する程度であるが,翫含有量の増加にともなって著しく化成処理性が低下する.(2)真空中で焼鈍した冷延鋼板においては,Cu,Sn共含有量の増加により著しく化成処理性が低下する.(3)焼鈍雰囲気が異なる場合の冷延鋼板の化成処理性へのCu,Snの影響に対して,焼鈍によるCu,Sn,Mn,Cなどの元素の表面濃化の寄与が大きいものと推察される.(4)スクラップの再利用により冷延鋼板を製造するに当たっては,Cu含有量に加えて,化成処理性を著しく低下させるSn含有量の上限管理が重要である.

1 0 0 0 OA シャルピー衝撃試験における試験片巾の影響

- 著者

- 作井 誠太 中村 正久 布村 成具 藤原 達雄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.49, no.4, pp.672-679, 1963-04-01 (Released:2010-10-12)

- 参考文献数

- 7

- 被引用文献数

- 3

The effect of the specimen width on the Charpy test was studied with specimens of hotrolled mild steel and quenched-and-tempered medium carbon steel, by recording the load-time relations under impact bending. Results obtained were summarized as follows:(1) The energy absorption in the ductile range was influenced by the specimen-width smaller than 4mm-the smaller the width, the lower the energy absorption per unit sectional area and it was found that the law of similarity was not satisfied in this case. On the contrary the maximum fiber fracture strength was almost constant for all the specimens, showing the applicability of the law of similarity.(2) Maximum fiber bending stress in fracture was the largest in the temperature range where the absorption energy was decreased almost to minimum value and the load-time curve of type I designated by the authors in the previous papers was obtained. (Tetsu-to-Haganeé 46 (1960) p. 141, 1538; Tetsu-to-Haganeé Overseas, 1 (1961) p. 38).(3) The brittle specimens tempered at a rather lower temperature after quenching, showed the type I or 11 load-time curves over all the testing temperature, and thus fractured thoroughly with only a crack, once started. It was found that in these tests the fracture strength scattered considerably.(4) The notch shape had an influence on the absorption energy for ductile fracture of the less ductile specimens with tempered martensite. It was concluded that the above effect was mainly due to the difference of the amount of deformation produced until the crack formation.(5) The transition temperature showed the same tendency to the changes of specimenwidth under any definition, rising as the width increased. However, the change of the transition temperature for the specimen-witdh larger than 6mm showed the considerablly different tendency from that of the specimen smaller than 4mm. Therefore, in the application of subsize specimen, it is desirable to use the specimen-width larger than 6mm. The effect of specimen-width on transition temperature was affected markedly by the types of the steels and their microstructures.

1 0 0 0 OA Solidification Behavior of Ti-6Al-4V Alloy

- 著者

- Hideo Mizukami Yoshihisa Shirai Akira Kawakami Alec Mitchell

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.60, no.11, pp.2455-2461, 2020-11-15 (Released:2020-11-17)

- 参考文献数

- 23

- 被引用文献数

- 5 12

It is important to understand the solidification behavior of titanium alloys for optimizing the casting conditions. In this study, to evaluate the solidification behavior of the Ti-6Al-4V alloy, an experiment was conducted using a lab-scale electron beam furnace. After melting the surface layer of the ingot through electron beam heating, the surface layer was allowed to solidify. Based on the measurement results of the cooling curve of the surface of the ingots, it was observed that the solid was subject to undercooling during its formation. The cooling rate of the ingot could be predicted through numerical simulation, for the melting and solidification of the ingot. The primary and the secondary dendrite arm spacing were examined with respect to the cooling rate. The concentrations of Al and V in the dendritic region were analyzed using electron probe microanalysis (EPMA). It is clarified that the Al is segregated into the dendrite core during solidification, and that V is segregated into the interdendritic region.

1 0 0 0 OA 真空脱ガス炉における脱炭反応モデル

- 著者

- 北村 信也 矢野 正孝 原島 和海 堤 直人

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.80, no.3, pp.213-218, 1994-03-01 (Released:2009-06-19)

- 参考文献数

- 10

- 被引用文献数

- 25 25

A new decarburization model for the vacuum degasser was constructed. In this model, the mass transfer of carbon andoxygen in the liquid phase, the mass transfer of CO in the gas phase and the chemical reaction rate at the interface were taken into account for the rate controlling steps. Also, as the decarburization sites, the Ar bubble surface, bath surface, and the CO bubble formation at inner sites were considered. This model was verified by the correspondence of the calculation results with the experimental results of the small scale tests and applied to the various RH degassers. The following results were clarified :1) Decarburization at inner sites mainly occurs in the initial stage of the decarburization process (Stage I ), and decarburization at the bath surface becomes predominant in the final stage of the decarburization process (Stage II).2) The reaction in Stage I is mainly governed by the circulation rate and evacuation rate.3) The evacuation rate has a smaller influence on the reaction in Stage II. In this stage, it is essential to increase the circulation rate and to increase the effective reaction area for the decarburization at the bath surface by inducing violent surface agitation.

1 0 0 0 OA 木炭銑の性質に就て

- 著者

- 宮下 格之助

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.21, no.1, pp.5-13, 1935-01-25 (Released:2009-07-09)

- 参考文献数

- 7

- 被引用文献数

- 1

It is a well-known fact that cold blast charcoal pig iron has the far more superior qualities than that of coke pig iron, but is not yet clear that causes. The author studied the relation between the strength and the melting con, ditions, and finally determined the nitrogen content in the above test pieces. The nitrogen obtained from these test pieces are, in cold blast charcoal pig 0.0008-0.0010%, in hot blast charcoal pig 0.0012-0.0020%, in electric arc furnace iron 0.0015-0.0035%, in. coke pig 0.0017-0.0025%, The strength of cast iron is almost inverse oroportional to the nitrogen content in the materials. From these facts, the author concludes that the small contents of the nitrogen in cold blast charcoal pig iron is one of the main couses giving rise to its superior qualities.

- 著者

- Ko-ichiro Ohno Yoshiki Kitamura Sohei Sukenaga Sungo Natsui Takayuki Maeda Kazuya Kunitomo

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- ISIJ International (ISSN:09151559)

- 巻号頁・発行日

- vol.60, no.7, pp.1512-1519, 2020-07-15 (Released:2020-07-16)

- 参考文献数

- 11

- 被引用文献数

- 5 8

Negative effect from low coke rate operation at cohesive zone is obvious because it makes thinning of coke slit thickness. Correct knowledge about gas permeability of cohesive layer is becoming more and more important. In order to precisely understand cohesive behaviour, a softening and melting simulator under rapid heating and quenching conditions was applied for clarify a determinant factor of gas permeability behaviour. To focus on softening and melting behaviour, granulated slag particle bed layer without iron oxide was prepared as packed bed sample layer can show softening and melting. The packed bed slag samples in graphite crucible were rapidly heated up to 1200°C, and then gradually heated up to 1500°C with 10°C/min under inert gas atmosphere and 0.1 MPa load. Gas pressure drop and shrinkage degree of the sample layer were measured during the softening and melting test, and quenched sample was made at certain temperature when the maximum gas pressure drop was measured. The CT observation of the quenched sample provided 3D shape information of gas path shape in sample packed bed. Gas pressure drop was estimated with fanning’s equation with the gas path information. The estimation values were shown positive correlation with measured maximum pressure drop. The CT observation also gave triple line length among molten slag, graphite, and gas. Combination the triple line length and molten slag surface tension could use for evaluation of static force balance when maximum pressure drop obtained.