1 0 0 0 OA クリーニングのCO2排出量の算定

- 著者

- 山口 庸子 清井 えり子 永山 升三

- 出版者

- 日本LCA学会

- 雑誌

- 日本LCA学会誌 (ISSN:18802761)

- 巻号頁・発行日

- vol.6, no.3, pp.209-216, 2010 (Released:2012-08-24)

- 参考文献数

- 17

Objective. The most common professional cleaning services available today are professional dry cleaning, laundry, and wet cleaning. Many of the organic solvents used in dry-cleaning have been identified as factors contributing to global warming, destruction of the ozone layer, and groundwater contamination, among other problems, and are subject to legal restrictions and controls. Dry-cleaning remains an essential process, since it causes less damage to clothing than water-based cleaning. Requirements for clothing cleaning have grown increasingly restrictive as exemplified by the launch of the Carbon Footprint Pilot Project. Given these circumstances, this study seeks to estimate greenhouse gas emissions (in terms of GWP100) based on LCI analysis of each step of the cleaning processes and discusses methods for reducing emissions. Cleaning is an essential aspect of the usage stage of clothing and its life cycle. To help create a system for establishing carbon footprints for clothing products, this study also examines a wide range of public information sources related to CO2 emissions, based on cleaning site data collected in fiscal 2009.Results and Discussion. In the dry cleaning process, the electric power consumed by the various activities at cleaning agencies, the steam required for solvent recovery, steam required for pressing, and packing materials, including hangers and carrier bags, contribute significantly to overall CO2 emissions. At 0.369 kg-CO2eq per clothing, the CO2 emissions associated with the steam required for tetrachloroethylene recovery accounts for the highest fraction of CO2 generated. The results suggest CO2 emissions generated by tetrachloroethylene which used as the dry-cleaning solvent exceed those of petroleum-derived solvents. The results also show CO2 emissions from solvents can be suppressed by reducing the solvent consumption rate to 4% or 20%, which also reduces the generation of photochemical oxidants. In laundry processes, steam for pressing and drying in the finishing processes contributes significantly to CO2 emissions, followed by heating boilers, detergents, and cardboard use.Conclusions. The CO2 emissions generated by the dry cleaning process depend significantly on the types of solvents used. The steam required for solvent recovery contributes a large portion of these emissions, followed by the steam used in finishing processes. Improving boiler efficiency is a key factor in reducing CO2 emissions in both dry cleaning and ordinary laundry processes. This paper also proposes a flexible method for estimating cleaning-related CO2 emissions per clothing, based on a conversion proportional to weight, by accounting for differences in washing methods, finishing processes, and solvents.

1 0 0 0 OA エチレンオキシド付加非イオン界面活性剤の化学と現状

- 著者

- 永山 升三 伊佐 弘

- 出版者

- Japan Oil Chemists' Society

- 雑誌

- 油化学 (ISSN:18842003)

- 巻号頁・発行日

- vol.28, no.12, pp.881-889, 1979-12-20 (Released:2009-11-10)

- 参考文献数

- 107

- 被引用文献数

- 1 1

- 著者

- 戸張 真臣 石田 多美江 田中 丈三 渡辺 真郎 永山 升三

- 出版者

- 一般社団法人 日本繊維製品消費科学会

- 雑誌

- 繊維製品消費科学 (ISSN:00372072)

- 巻号頁・発行日

- vol.22, no.9, pp.397-402, 1981

家庭洗たくにおける各種衣料用洗剤のウール製品の収縮に与える影響の度合いを明らかにすることを目的とし, このウール製品の収縮がいかなる原因によって生じるのかを, 主にウールの物性面から検討した.その結果, ウール製品を洗たく機・ソフト水流で洗浄すると, 弱アルカリ性合成洗剤や粉石けんは, 中性洗剤に比べ収縮小の傾向にあり, これは, 弱アルカリ性合成洗剤や粉石けんのようなpHの高い洗剤系では, ウール表面のスケールがアルカリで侵されることや, さらに, 粉石けんの場合, カルシウム石けんなどの付着により, 摩擦係数の異方性 (Differencial Frictional Fffect; D.F.E.) が低下することも一因していることがわかった.このD.F.E.の考え方は, 近年の防縮加工技術に応用されているが, 本実験により, 実際の洗浄系においても, この考え方の適用されることが明らかとなった.

1 0 0 0 OA 家庭洗濯における衣類乾燥の環境負荷低減のための評価

- 著者

- 山口 庸子 土屋 みさと 永山 升三

- 出版者

- 日本LCA学会

- 雑誌

- 日本LCA学会誌 (ISSN:18802761)

- 巻号頁・発行日

- vol.3, no.4, pp.221-231, 2007 (Released:2012-05-19)

- 参考文献数

- 22

- 被引用文献数

- 4 3

Sales of household machines combining both washing and drying functions have increased rapidly in recent years due to an increasing number of women working, an increasing number of single-person households, and the appeal of these machines in terms of reducing the burden of housework. In this study, we examined ways to reduce environmental and economic effects by applying social LCA to the entire life cycle, including clothing-related factors, by comparing the new type of washer-dryer incorporating a heat-pump unit with traditional type of washer-dryer and separate gas dryer. The mechanical action of washer-dryers was evaluated by measuring the unraveling of MA test pieces and the rate of shrinkage of shirt collars as an indication of the effects on clothing. Electric power and water consumption were measured for each washer-dryer cycle. The unit prices for washer-dryers, detergent, and clothes were obtained via market research. The social LCA results indicated that CO2 emissions were higher for machine usage than for manufacture, for all types of washer-dryer. The results also showed that greater damage to clothing was caused during the drying process compared to washing alone, and the drying process also greatly increased overall CO2 emissions. The study also showed that heat-pump washer-dryers with short, low-temperature drying cycles were effective in reducing CO2 emissions by approximately half due to their lower energy consumption and mechanical power compared to conventional washer-dryers. The Life cycle costing (LCC) results showed that using heat-pump washer-dryers for both washing and drying reduced costs compared to conventional washer-dryer or gas dryer.

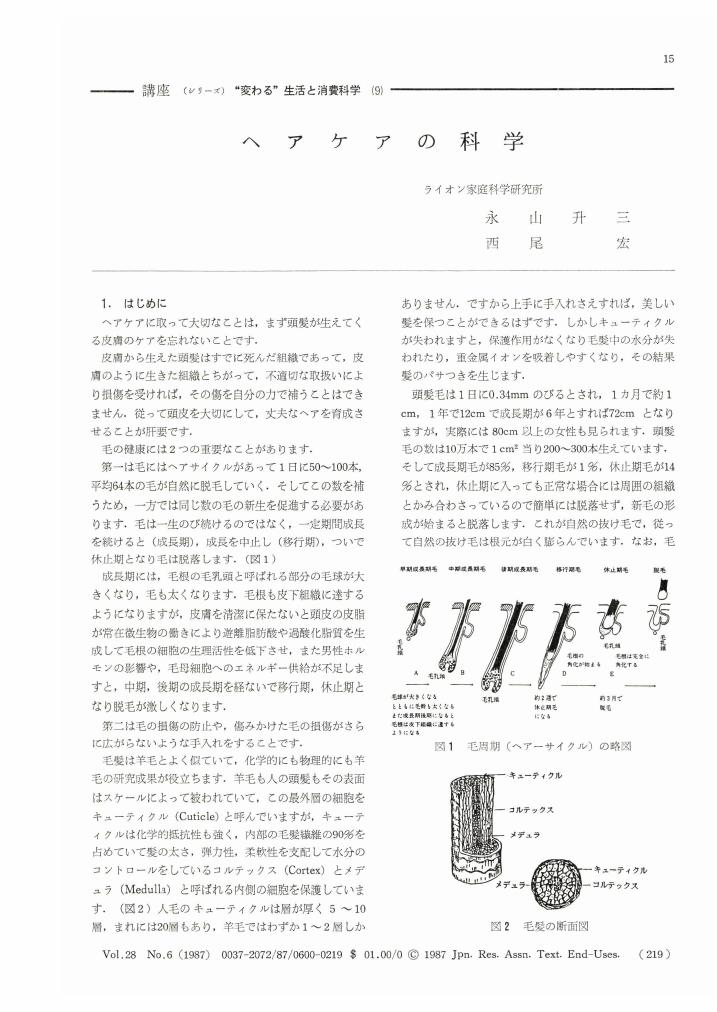

1 0 0 0 OA ヘアケアの科学

- 著者

- 永山 升三 西尾 宏

- 出版者

- 一般社団法人 日本繊維製品消費科学会

- 雑誌

- 繊維製品消費科学 (ISSN:00372072)

- 巻号頁・発行日

- vol.28, no.6, pp.219-226, 1987-06-25 (Released:2010-09-30)

1 0 0 0 OA 洗濯及び柔軟剤処理によるおむつカバーの耐水性変化について

- 著者

- 田中 丈三 関根 和子 戸張 真臣 永山 升三

- 出版者

- 一般社団法人 日本繊維製品消費科学会

- 雑誌

- 繊維製品消費科学 (ISSN:00372072)

- 巻号頁・発行日

- vol.27, no.4, pp.164-169, 1986-04-25 (Released:2010-09-30)

- 参考文献数

- 9

- 著者

- 永山 升三

- 出版者

- 社団法人日本化学会

- 雑誌

- 化学教育 (ISSN:03862151)

- 巻号頁・発行日

- vol.31, no.1, 1983-02-20