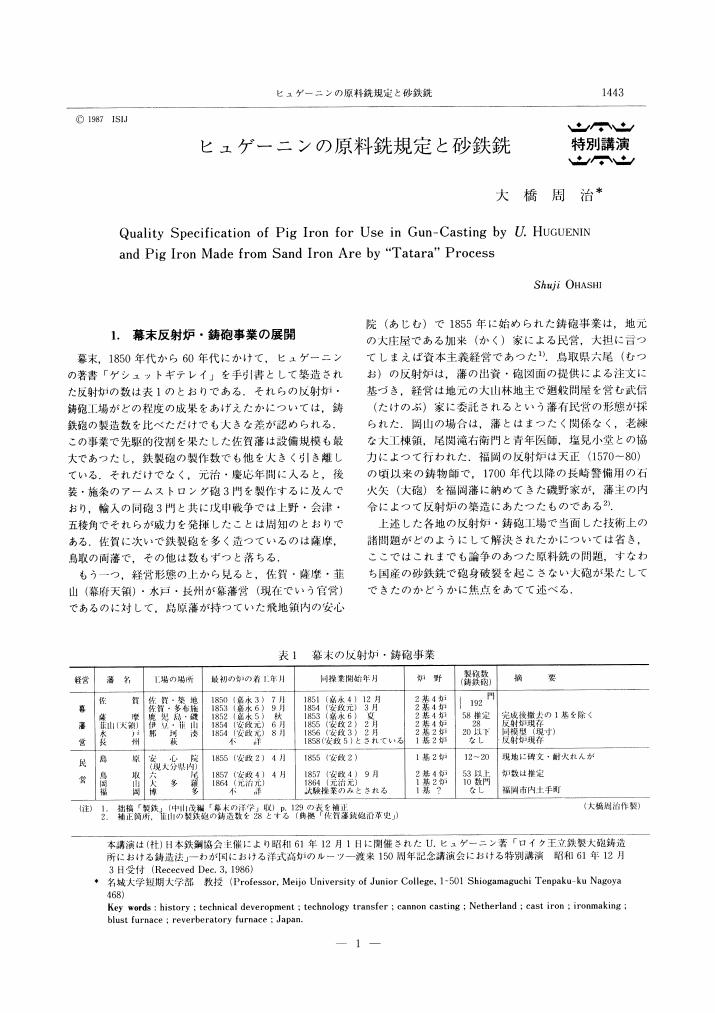

1 0 0 0 OA ヒュゲーニンの原料銑規定と砂鉄銑

- 著者

- 大橋 周治

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.73, no.11, pp.1443-1452, 1987-09-01 (Released:2009-06-19)

- 参考文献数

- 12

1 0 0 0 OA 2. 設備(鉄鋼技術共同研究会鋼材部会分塊分科会報告書)

- 著者

- 記載無し

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.48, no.10, pp.1125-1226, 1962-08-25

1 0 0 0 第44回国際溶接学会ハーグ大会出席報告

- 著者

- 粉川 博之

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.77, no.12, 1991-12-01

- 著者

- 山中 啓充 福島 克治 森脇 三郎 守脇 広治 桜谷 敏和 大沼 啓明

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.68, no.4, 1982-03-05

1 0 0 0 OA 最近のチタンの溶解技術およびチタンインゴットの品質問題とその解決法

- 著者

- 小泉 昌明

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.74, no.2, pp.215-223, 1988-02-01 (Released:2009-05-29)

- 参考文献数

- 38

- 被引用文献数

- 3

1 0 0 0 OA 鉄鉱石の還元速度式

- 著者

- 森 一美

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.50, no.13, pp.2259-2260, 1964-11-01

A rate equation has been derived for the gaseous reduction of iron ore pellets on the assumption that both chemical reaction and diffusion contribute to the overall reduction rate. It was assumed that there is no resistance of diffusion through the boundary layer outside the pellet and chemical reaction takes place only at the interface between reduced and unreduced layers. Under these conditions the rate equation is given as follows : (1/k)[1-(1-R)^<1/3>]+(r_o/D)[1/2-R/3-(1-R)^<2/3>/2]=(C_o-C_e)t/r_od_o where R : fractional reduction k : chemical reaction rate constant t : time D : effective diffusion coefficient r_o : radius of pellet C_o : gas concenration in the bulk gas phase d_o : density of pellet C_e : equilibrium gas concentration The two terms on the left side of the equation show the relative contribution by chemical reaction and by diffusion of the reducing gas through the reduced metal layer. It was found that the equation agrees with experimental data except towards the completion of reduction. Equation for the reduction controlled either by chemical reaction or by diffusion could be derived as the limitimg cases of the above-mentioned equation.

1 0 0 0 OA セルモデルによる溶融スラグのハイドロオキシルキャパシティーの定式化

- 著者

- 渡辺 雅俊 井口 〓孝

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.81, no.6, pp.613-618, 1995-06-01

A statistical thermodynamic model, cell model, has been attempted to represent the hydroxyl capacities of some molten silicates and molten aluminates. The slag systems discussed were CaO-SiO_2, CaO-Al_2O_3 binaries and CaO-SiO_2-MgO, CaO-Al_2O_3-MgO and CaO-SiO_2-Al_2O_3 ternaries. The cell model is based on the description of the liquid in terms of cells composed of an oxygen anion surrounded by two cations (i, j). In addition to binary parameters, W_<ij> and E<ij> a new parameter, W′_<Hi> was introduced into the cell model for representing the hydroxyl capacity. Here, W′<Hi> is free energy of formation of dilute H-O-i cell. The hydroxyl capacities calculated by the model agreed with the experimental data over the wide range of slag composition and temperature. A good correlation between W′<Hi> and free energy of formation of hydroxide was confirmed. Therefore, the cell model with the new parameter W′<Hi> is considered to be applicable to predict the hydroxyl capacities of multicomponent slags.

- 著者

- 太宰 武生 大久保 尚武 大浜 光正 広田 惣一 伊福 享 貞方 良文

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.13, 1981-09-10

- 著者

- 石田 次雄 高藤 英生 江藤 哲雄

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.67, no.13, 1981-09-10

1 0 0 0 OA 軟鋼の低温における降伏応力の温度および歪速度依存性と延性-脆性遷移について

- 著者

- 西野 知良 本間 浩夫

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.56, no.7, pp.859-868, 1970-06-01

The dependence of the yield stress of mild steel at low temperatures on grain size, strain rate and temperature was studied mainly by compressive deformation test. (1) The following equation relating strain rate (ε), temprature (T) and frictional stress (σ_t) of Petch equation was obtained ; ε=Cσ^n_t exp(-E/RT) This is applicable when σ_t is in the range of 8.7 to 28.2kg/mm^2. Strain rate exponent n and activation energy E are constant, both being independent on temperature, strain rate or stress. Above this stress level, n becomes larger but E is substantially invariable. (2) According to the study on BCC metals, it can be said that they behave in a similar manner to mild steel. That is, n is in the range of 7 to 9, being constant and specific to BCC metals, and in addition, E is approximately proportional to an energy of μb^3, where μ is the shear modulus and b the Burgers vector. (3) The relations between strain rate, grain size and ductile-brittle transition temperature were studied by using the above equation, and the calculated temperatures are generally in accordance with the measured values.

1 0 0 0 OA フェライト・ステンレス鋼の遷移温度と475℃脆性におよぼす不純物元素の影響

- 著者

- 長谷川 正義 武田 克彦 竹下 一彦

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.60, no.9, pp.1353-1362, 1974-08-01 (Released:2010-10-12)

- 参考文献数

- 10

- 被引用文献数

- 2 2

The brittle-to-ductile transition curves of a series of ferritic stainless steels containing carbon, nitrogen, silicon or manganese, respectively, were determined, and also the effect of aging at 475°C on the transition curves of high purity ferritic stainless steels was discussed.The main results obtained were as follows:(1) In 18% chromium steels, at the 0.002% carbon and 0.004% nitrogen levels, the indicated transition temperature is found to be 85°C However, there is a remarkable increase in transition temperature and a decrease in upper shelf energy, as carbon or nitrogen content increases. The effect on transition temperature and upper shelf energy is attributed to the exsistence of solute carbon or nitrogen atoms and the dispersed carbide or nitride precipitates.(2) Addition of aluminium as stabilizer is effective in lowering transition temperature.(3) Silicon and manganese additions tend to raise transition temperature.(4) In high purity 18% chromium steel aged at 475°C the upper shelf energy decreases, but the transition temperature has little change.(5) In 0.05% nitrogen-18% chromium steel aged at 475°C, the upper shelf energy decreases, and the transition temperature is shifted toward higher temperatures.(6) The hardness increase with the aging time for high purity 18% chromium steel is less than for 0.05% nitrogen-18% chromium steel.(7) These phenomena caused by aging at 475°C must be depended on the precipitation of chromium rich bcc phase and chromium nitrides.

1 0 0 0 OA 鉄鋼材料の結晶粒超微細化

- 著者

- 辻 伸泰

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.88, no.7, pp.359-369, 2002-07

- 被引用文献数

- 9

Recent progress in grain refinement of steels was overviewed. After energetic research works since middle 1990's including big national projects in Japan, ultrafine grained steels whose mean grain size is smaller than 1 μm have been realized. There are principally two ways to obtain ultrafine grained structure in steels: the ultimate thermomechanical processing using various kinds of phase transformation in steels and the intense straining using a kind of recovery and recrystallization phenomena. Large amount of plastic strain is the key factor in both case. Microstructural characteristics and mechanical properties ofthe ultrafine grained steels were summarized. Future advance and prospect in the ultrafine grained steels was discussed.

1 0 0 0 OA ニオブ, バナジウム添加による微粒処理鋼(<特集>非調質高張力鋼の研究と開発)

- 著者

- 梶 晴男 木下 修司 林 登

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.58, no.13, pp.1759-1774, 1972-11-01

1 0 0 0 OA 圧力容器用鋼の応力除去焼なまし処理に伴う機械的性質の変化

- 著者

- 勝亦 正昭 小出 憲司 梶 晴男

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.75, no.2, pp.353-360, 1989-02-01 (Released:2009-06-19)

- 参考文献数

- 15

- 被引用文献数

- 2

Prolonging annealing treatment below the critical temperature is carried in order to relieve residual stress due to welding and to improve toughness of weld heat affected zone in the fabrication of pressure vessels. It has been known that this treatment named stress relief (SR) annealing decreases strength and toughness of base metals. Thus, the effects of microstructure and alloying elements on this decrease in mechanical properties were investigated in carbon-manganese, manganese-molybdenum and chromium-molybdenum steels for pressure vessels.The decreasing amount of strength and toughness due to SR annealing was the largest in martensite structure and next in bainite structure. These was little change in strength and toughness in ferrite-pear-lite structure. Good toughness was obtained by SR treatment at high temperature and for short time in comparison with that of low temperature and long time at a certain strength. The start of decreasing toughness was delayed by an increase in {1/5 (Mn(%)+ Cr(%))+Mo(%)} content.Applied stress equivalent to residual stress level in SR treatment did not affect mechanical properties. The amount of temper embrittlement due to slow cooling in SR treatment decreased with prolonging SR treatment.

1 0 0 0 OA 高張力鋼の破壊靱性および冶金的要因について(<特集>非調質高張力鋼の研究と開発)

- 著者

- 三村 宏

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.58, no.13, pp.1822-1831, 1972-11-01

1 0 0 0 OA 非調質高張力鋼の冶金技術研究の概観(<特集>非調質高張力鋼の研究と開発)

- 著者

- 荒木 透

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.58, no.13, pp.1753-1758, 1972-11-01

1 0 0 0 OA 連続冷却途中での冷却速度変更にともなうパーライト変態挙動

- 著者

- 清水 信善 田村 今男

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.61, no.10, pp.2375-2390, 1975-08-01 (Released:2010-10-12)

- 参考文献数

- 13

- 被引用文献数

- 4

In this investigation, the pearlitic transformation behaviour of steel with the cooling rate discontinuously altered during continious cooling was studied in relation to the CCT diagram of the steel. The main results are as follows:(1) The pea litic transformation behaviour with the cooling rate discontinuously altered during continuous cooling was diffe-ent from the transformation behaviour illustrated by usual CCT diagram.(2) The pearlitic transformation behaviour and the critical cooling rate with the cooling rate altered at a point during continuous cooling were observed to be related to the incubation period consumed before changing the cooling rate.(3) Including the degree of consumed incubation period in usual CCT diagram as a parameter, the transformation behaviour and the critical cooling rate can be estimated from a conventional CCT diagram.(4) If the same amount of the incubation period was consumed by either continuous cooling or isothermal holding, the transformation behaviour was virtually the same in subsequent cooling when the cooling started from the same temperature.

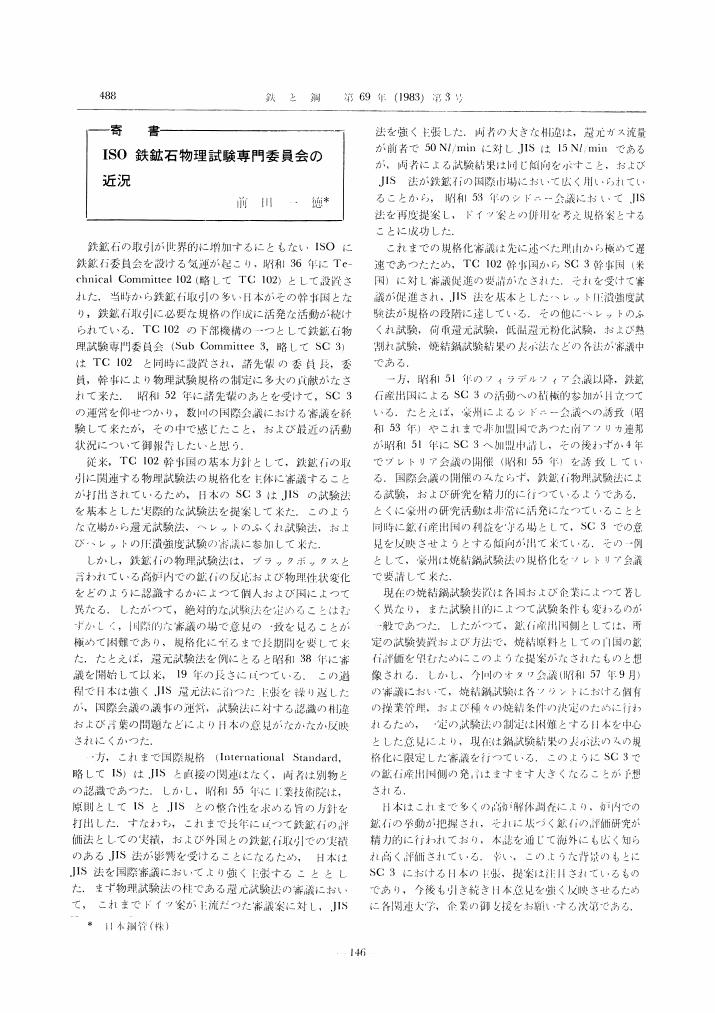

1 0 0 0 OA ISO鉄鉱石物理試験専門委員会の近況/第二次世界大戦中における製鋼技術の開発研究

- 著者

- 前田 一徳 堀川 一男

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.69, no.3, pp.488-491, 1983-03-01 (Released:2009-06-30)

1 0 0 0 OA 着色亜鉛鉄板 25 年の歩みと展望(有機被覆鋼板)(<特集>鋼材の表面処理)

- 著者

- 高村 久雄 近藤 登

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 : 日本鐡鋼協會々誌 (ISSN:00211575)

- 巻号頁・発行日

- vol.66, no.7, pp.875-881, 1980-06-01

1 0 0 0 OA シリコン結晶中の酸素の挙動

- 著者

- 井上 直久 和田 一実

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.73, no.8, pp.947-955, 1987-06-01 (Released:2009-06-19)

- 参考文献数

- 40