1 0 0 0 OA 各種チタン合金の破壊靱性におよぼす温度と加工誘起変態の影響

- 著者

- 小林 俊郎 新家 光雄 稲垣 育宏

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.75, no.3, pp.537-544, 1989-03-01 (Released:2010-01-18)

- 参考文献数

- 16

- 被引用文献数

- 1 1

It is highly expected that the ductility and toughness of titanium alloys bearing unstable β phase may be developed by the stress relaxation caused by strain-induced transformation. In this study, tensile test, Charpy impact test, static and dynamic fracture toughness tests were carried out at various temperatures on typical titanium alloys bearing unstable β phase. The strain-induced α″ martensitic transformation occurred in the (α+β) type Ti-6Al-2Sn-4Zr-6Mo alloy and the dynamic fracture toughness of this alloy increased considerably at 223 K. The strain-induced α' martensitic transformation occurred in the (α+β) type Ti-6Al-4V alloy, and the static and dynamic fracture toughness increased considerably at 123 and 223 K respectively and strength increased at low test temperatures in this alloy. The mechanical twin occurred in the β type Ti-15V-3Al-3Sn-3Cr alloy and the elongation of this alloy increased considerably at 123 K.

1 0 0 0 OA 溶銑予備処理技術の開発,発展の歴史と将来展望

- 著者

- 小川 雄司 丸岡 伸洋

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.100, no.4, pp.434-444, 2014 (Released:2014-03-31)

- 参考文献数

- 92

- 被引用文献数

- 8 15

Progress of hot metal treatment technology in Japan and scientific researches which supported the technology are outlined.To meet the increasingly severe customer requirements for steel properties, integrated steelmakers developed technologies for purifying molten steel, centering on the divided refining process, consisting of hot metal treatment, BOF decarburization and secondary refining. The hot metal treatment processes were put into practice at almost all steelworks in the 1980 s.Since the 1990 s, all companies have improved and restructured the hot metal treatment facilities, aiming at not only improvement of refining efficiency so as to achieve a higher degree of purity steel with higher productivity at lower cost, but also reduction in slag volume with the environmental problems taken into consideration.The directions in which hot metal treatment technology is to be pursued in the future are also commented briefly.

1 0 0 0 OA 韓国の鉄スクラップ需要予測

- 著者

- 玉城 わかな 五十嵐 佑馬 藤巻 大輔 林 誠一 友田 陽 松野 泰也 長坂 徹也

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.92, no.5, pp.340-345, 2006-05-01 (Released:2009-06-19)

- 参考文献数

- 20

- 被引用文献数

- 6 6

1.91 milliont of steel scrap was exported from Japan to Korea in 2003, which accounted for more than 30% of the total steel scrap exported to other countries from Japan. Change in steel scrap demand in Korea in the future will make a great influence on the amount of Japan's steel scrap domestic consumption and export. In this work, quantitative data about the steel production, steel scrap demand and consumption during 1977-2003 in Korea were collected to analyze the amounts of inhouse, industrial and obsolete scrap generation, and total steel accumulation in Korea. Then, the steel scrap demand in Korea in the future was estimated. The total accumulation of steel in Korea was estimated as 380 million t in 2003 and 548 million t in 2010, respectively. The amount of obsolete scrap generation in Korea was 7.1 million t in 1996 and 9.0 million t in 2003, which was about 3.0% and 2.4% of the total steel accumulation in each year. Supposing that the amount of crude steel production, scrap consumption percentages in B.O.F and E.A.F will be stable, the obsolete scrap generation in Korea in 2010 were estimated as 13-17 million t. This significant increase in obsolete scrap generation in Korea could exceed the current amount of the scrap import. So, self-sufficiency of steel scrap could be achieved in around 2010 in Korea.

1 0 0 0 OA ピアノ線に関する研究

- 著者

- 俵 信次 福地 浩

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.29, no.6, pp.518-533, 1943-06-25 (Released:2009-07-09)

- 参考文献数

- 4

Effect of the temperature of heat treatment on the wire-drawing operation and mechanical properties were examined, in view of obtaining fundamental data on the manufacture of the excellent piano wire. The result of the test on the effect of the copper content in the wire revealed a decrease of the twisting value in case of the copper content more than 0.15%.

1 0 0 0 OA 神戸第2高炉(3次)の吹き止め操業及びN2冷却保存

- 著者

- 西田 功 田中 孝三 上原 輝久 矢場田 武 高野 成

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.71, no.2, pp.189-196, 1985-02-01 (Released:2009-06-19)

- 参考文献数

- 14

- 被引用文献数

- 1

No. 2 blast furnace in Kobe Works was blown in on February 4, 1981 and because of the economic conditions it was blown out on April 22, 1983. Since its working period was very short (about 2.2 years), it was banked with the expectation of blowing in after several years.The methods employed were :(1) to lower the stock line down to just above the level of the SiC brick lining (lower shaft) with the burden being replaced by coke, (2) to cool the furnace by N2 gas, (3) to preserve the furnace brick under N2 atmosphere.Two samples of SiC brick at lower shaft part were collected just after and at 8 months after blowing out, and then they were investigated. It was found that there was no impairment in the SiC brick during this 8-month period.Hot stoves were cooled by the natural cooling method with keeping airtight and their cooling periods were about 3 months. After cooling them, the observations inside them were done and it was confirmed that the damage of the brick was very little, so the reoperation of them would be of no trouble.

1 0 0 0 OA 鉄鋼技術の進歩発展と将来展望

- 著者

- 三好 俊吉

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.81, no.11, pp.N534-N540, 1995-11-01 (Released:2009-06-19)

- 著者

- 横井 龍雄 首藤 洋志 池田 賢一 中田 伸生 土山 聡宏 大村 孝仁 峯 洋二 高島 和希

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.102, no.5, pp.244-252, 2016 (Released:2016-04-30)

- 参考文献数

- 38

Dual Phase (DP) steel is used in automotive body parts for weight saving and crashworthiness, however there is an issue of DP steel in low stretch flange ability evaluated by hole expanding tests. In order to improve stretch flange ability of DP steel, it is important to estimate the damage of punching quantitatively and to clarify the change of microstructure before and after punching because the hole expansion ratio is decided in the ductility remained after pre-strain equivalent to punching. Therefore we tried to measure the damage of punching by unique techniques of Electron Backscatter Diffraction (EBSD), nano-indentation and micro-tensile testing and to observe fracture surface by Scanning Transmission Electron Microscope (STEM). Average EBSD-Kernel Average Misorientation (KAM) value and pre-strain damage have strong correlation, thus average KAM value can become the index of the damage. The nanohardness and tensile strength using micrometer-sized specimens increased with increasing average KAM value in the ferritic phase as approaching the punching edge. A shear type fracture occurred without necking in the specimen cut out in the area of the edge. The ultrafine-grained ferritic microstructure was observed in the sample cut out in the same area with STEM. It seems that the ductility loss of the punched DP steel was probably attributed to localized strain into the ultrafine-grained ferritic microstructure.

1 0 0 0 OA 昭和35年を鉄鋼技術躍進の年とせよ

- 著者

- 絹川 虚舟

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.46, no.4, pp.453-454, 1960-04-01 (Released:2010-10-12)

1 0 0 0 OA 抄録

1 0 0 0 OA 高温におけるクリープおよび疲労

- 著者

- 大谷 隆一

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.66, no.14, pp.2106-2118, 1980-12-01 (Released:2009-06-19)

- 参考文献数

- 57

- 被引用文献数

- 3 5

1 0 0 0 OA ピアノ線に就て

- 著者

- 銅金 義一

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.18, no.3, pp.261-271, 1932-03-25 (Released:2009-07-09)

1 0 0 0 OA 複合サイクル腐食試験における有機複合被覆鋼板の腐食挙動

- 著者

- 筋田 成子 望月 一雄 森戸 延行

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.84, no.11, pp.777-784, 1998-11-01 (Released:2009-06-19)

- 参考文献数

- 26

- 被引用文献数

- 3 3

Organic composite coated steel sheets show their excellent corrosion resistance during cyclic corrosion tests (CCT). To clarify corrosion behavior of these sheets, changes in corrosion products and elements of plating, chromate and organic resin layers during CCT were examined. Formation of crystalline ZnCl2·4Zn(OH)2 and superficial amorphous zinc carbonate were detected by X-ray diffraction, fourier transform infrared spectroscopy and Raman spectroscopy. And besides it was found by electron probe micro analysis, chemical analysis and fourier transform infrared spectroscopy that the corrosion products formed on organic resin layer contained silicon as zinc silicate from silica in organic resin layer.Consequently, weight of zinc in plating layer and silica in organic resin layer decreased, while that of nickel in plating layer, chromium in chromate layer and carbon in organic resin layer remained constant, and the corrosion products formed on organic resin layer contained zinc and silicon dissolved from each layer during CCT.

- 著者

- 川上 正博 永田 和宏 山村 稔 坂田 直起 宮下 芳雄 後藤 和弘

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.63, no.13, pp.2162-2171, 1977

- 被引用文献数

- 16

Local temperature and voltage in the molten flux and metal pool beneath the electrode of ESR porcesses were measured directly by a bare hot junction of W-WRe thermocouple.<BR>The temperature in the flux during remelting was almost uniform at 1750±30°C. No temperature gradient was found at the metal pool-flux interface. The temperature in the metal pool decreased smoothly downward in the pool with a platea at 1500°C which was the liquidus temperature of the steel used.<BR>The iso-voltage line was densely distributed at the electrode-flux interface and broadened toward the metal pool-flux interface. Most of the “Joule heat” in the flux was generated very close to the electrode. However, Faradaic heat generation at the electrode-flux interface was hardly found.<BR>It is suggested from the experimental results that refining processes, not only slag-metal reaction but also inclusion removal take place mainly at the metal pool-flux interface. Because the temperature in the flux was uniform even with the localized heat generation, a violent convection should exist in the flux.<BR>One of the driving forces for the convertion, the pinch effect of the current, was calculated. The selection of the proper voltage and current in order to have a good shape of the metal pool was suggested on an I-V diagram.

1 0 0 0 OA 50年間大気暴露試験における溶融Alめっき鋼板の腐食挙動

- 著者

- 真木 純

- 出版者

- 一般社団法人 日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.105, no.7, pp.759-766, 2019 (Released:2019-06-30)

- 参考文献数

- 17

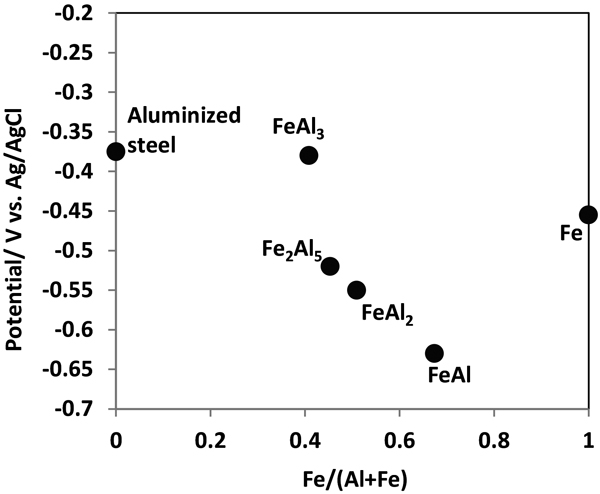

Aluminized steel sheets are very resistant to corrosion in the outdoor exposure environment. We evaluated the corrosion behavior of aluminized steel sheets with a Type1 coating containing around 10%Si but also a Type2 coating not containing Si in a 50-year outdoor exposure test. Both specimens had strong perforation resistance, but those with Type2 coating had superior perforation resistance. The Type2 aluminized steel sheets had two sublayers composed of Fe2Al5 and FeAl2 as the intermediate layer between the aluminized layer and the steel substrate. The FeAl2 phase has less noble potential than steel substrate and the Fe2Al5 phase in an artificial rain water environment. As a result, this layer provided sacrificial corrosion protection for the steel substrate. That was why the specimens with the Type2 coating had better perforation resistance than those with Type1 coating.

1 0 0 0 OA 円柱鋼材の冷却過程における熱応力の計算

- 著者

- 坂井 一男

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.60, no.12, pp.1591-1598, 1974-10-01 (Released:2010-10-12)

- 参考文献数

- 12

- 被引用文献数

- 3 4

The paper presented a calculation of thrmal stress in a cylindrical steel induced during cooling by introduction of strain-history into Hara's calculation method.Calculation was based on elastic-plastic theory and total strain was calculated by non-linear integral equation through a successive integration. Plastic strain was calculated by total strain theory and stress-strain diagram.A calculation was made for a cylindrical steel bar with 1500mm in diameter quenched in mist from 850°C, and the results are as follows.(1) Tensile stresses (δt, δz, ) at surface of bar are the largest, when temperature difference between surface and core was the largest.(2) Stresses (δt, δz) at starting point of transformation always show the maximum tensile values.(3) Reverse of stresses (δr, δt, δz) takes place after completion of transformation of core.(4) At final stage of cooling, core has tensile stresses (δr, δt, δz) and surface layer has compressive stresses (δt, δz) of characteristic pattern.

1 0 0 0 OA 知っておきたい金属凝固の基礎(II)

- 著者

- 郡司 好喜

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.80, no.5, pp.N208-N221, 1994-05-01 (Released:2009-06-19)

- 参考文献数

- 27

- 被引用文献数

- 2

1 0 0 0 OA 燃焼の基礎技術(II)

- 著者

- 水谷 幸夫

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.70, no.8, pp.774-784, 1984-06-01 (Released:2009-06-30)

- 参考文献数

- 11

- 被引用文献数

- 1 1

1 0 0 0 OA 日本鉄鋼業における計算機制御の進歩

- 著者

- 野坂 康雄

- 出版者

- The Iron and Steel Institute of Japan

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.59, no.5, pp.557-569, 1973-04-01 (Released:2010-10-12)

- 参考文献数

- 5

- 被引用文献数

- 1 1

1 0 0 0 高炉製銑法,直接製鉄-電気炉法,溶融還元法のエクセルギー解析

- 著者

- 秋山 友宏 八木 順一郎

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鉄と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.74, no.12, pp.2270-2277, 1988

- 被引用文献数

- 3 14

Exergy analysis was conducted on three ironmaking systems which were conventional ironmaking, direct reduction-electric furnace and smelting reduction systems. The exergy analysis is better than an enthalpy balance or a heat balance because exergy can express the quality of energy and evaluate different forms of energy like chemical, thermal, pressure and mixing energy by a unified measure.<BR>According to the calculated results for the specified conditions, the smelting reduction system was the lowest in net exergy loss, however, the highest in overall output exergy. The development of the efficient heat recovery process is therefore required for this system. The direct reduction-electric furnace system was the highest in net exergy loss. However, nonfired pellets were found to be effective to reduce net exergy loss. In the conventional ironmaking system, net exergy loss of its constituent processes significantly depended on the injection rate of pulverized coal and on the charging amount of nonfired pellets.

1 0 0 0 米國旅行記

- 著者

- 橋口 隆吉

- 出版者

- 社団法人日本鉄鋼協会

- 雑誌

- 鐵と鋼 (ISSN:00211575)

- 巻号頁・発行日

- vol.37, no.3, pp.169-178, 1951