1 0 0 0 OA 低質燃料油に起因する障害について

- 著者

- 乾 文雄

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.15, no.10, pp.825-830, 1980 (Released:2010-05-31)

Recently, marine fuel quality has been deteriorating. Consequently, many engine troubles due to low quality fuel have been increasing.In this article, the present writer describes only about troubles of oil heaters caused by low quality marine fuel. According to the investigation carbonaceous deposits on the fuel side of the heater and corrosion of heat transfer pins were remarkable.Our investigation revealed that clogging troubles caused by deposits on the fuel side surface have suddenly increased since around 1977. According to the recent data in case fuel additives were added to the bunker fuel, deposit troubles have remarkably decreased. As the original material of the Sun Rod oil heater pin had been copper, corrosion sometimes occurred on the copper pin. Since the maker changed the material to aluminum, very few corrosion has occurred.Marine fuel quality will gradually further deteriorate in future, as well. Accordingly, the troubles are likely to occur more frequently.The most important thing, among other things, for the maintenance of fuel oil heaters is to develop the chemical detergent capable of cleaning up carbonaceous deposits on the heating surface. Unfortunately at present no effective detergent solving the troubles are available on the market, therefore the development of such detergent for chemical cleaning are keenly desired.

1 0 0 0 ボイラ燃焼室の熱的諸特性の計測

- 著者

- 佐川 隆一 加藤 幸三 松田 裕昌 蔵田 親利 森 鋭和

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.8, no.9, pp.697-708, 1973

近年, 舶用主機の大容量化に伴い, ボイラ燃焼室の発熱負荷は大幅に増大している.これにより加熱管の局所過熱や熱計算法の再検討等の問題が起きている.これらの問題点に関する情報を得るために, 自然循環ボイラ (蒸発量30T/H) を用いて実験を行なった.<BR>本報告は, これらの問題に大きな関連を持つ燃焼ガスのフローパターン, 炉内温度分布, 熱流束分布等の実験結果について示す.<BR>まず, 炉内フローパターンの観察を5孔ピトー管, 発煙筒等を用いて行なった結果, 以下のことが判明した.<BR>(1) フロパターンは燃焼時でも非燃焼時でもほとんど同様である. (2) 火炎形状は卵形であり, 燃焼室の形状には無関係である. (3) 火炎と底面の間の狭い領域に強い逆流が存在している. (4) 上部空間には炎がなく, ガスは停滞している.<BR>次に, 吸引式温度計を用いて炉内温度分布を測定した結果, フローパターンの計測並びに火炎形状の観察結果と良い対応を示した.最高温度は火炎のバーナ寄り約1/3の所で記録された.燃焼室出口ガス温度は計算結果と大体一致した.<BR>最後に, 手製の熱流束計を用いて熱流束の分布を測定した.本装置は全熱流束だけでなく, ふく射成分のみの分離計測も可能である.最大熱流束は火炎の中央で記録され, その値は燃焼室平均値より67~84%大きかった.その結果, 各々の水冷管の熱吸収割合にはかなり大きな差が現われた.この差異はボイラの循環や安全性に大きな影響を持っているであろう.<BR>全熱流束に対するふく射成分は2/4負荷時に約84%であった.

- 著者

- 鈴木 清

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.34, no.5, pp.320-327, 1999-05-01

The ship have completed the docking survey at Singapore. After twenty hours in sailing for loading port, the main deisel engine occurred explosion in the scavenging air manifold. And then the main engine stopped by auto.device. But it was not re-start. Both of the aux. blowers damaged at impeller and casing. The ship was staying for a week at emergency anchorage. The aux, blowers changed completely with elect. Motors. It caused that much accumulated oily mist in the scavenging air manifold by the drain pipe be blockade was ignited.

- 著者

- 佐藤 準一

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.35, no.11, pp.743-750, 2000-11-01

- 参考文献数

- 33

- 被引用文献数

- 1

1 0 0 0 OA 舶用主機・発電用ガスタービンについて

- 著者

- 岩本 敏昭

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.23, no.9, pp.578-587, 1988-09-01 (Released:2010-05-31)

- 参考文献数

- 13

1 0 0 0 OA 主機潤滑油サンプタンク設計マニュアル

- 著者

- 機関第三研究委員会

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.28, no.12, pp.752-758, 1993-12-01 (Released:2010-05-31)

This paper shows the design manual of main engine lubricating oil sump tank.

1 0 0 0 OA 幕末期輸入船とその主機

- 著者

- 坂本 賢三

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.18, no.6, pp.456-464, 1983-06-01 (Released:2010-05-31)

- 参考文献数

- 27

A role of imported steamships and their main engines at the beginning of modern industry in Japan is scrutinized and examined in this paper.Before the first arrival of steamship to Japan in the year 1853, some of Japanese artisans had endeavoured to make up a side-lever engine only in dependence on a translation of a Dutch textbook. They successfully built up a steamship and it operated well in 1854, but these trials were suspended and many western steamships were imported, because it was so difficult to make up complicated marine engines such as an oscillating engine without machine-tools and related industry. In addition, there was no time to prepare for the foreign pressure. But the importation of steamships played a great part for the progress of Japanese marine engineering.At that time, in Europe the marine engine had been in the era of innovation, for example, the spread of oscillating engine or double-cylinder engine etc., and also the change from paddle wheel to screw in propeller. Steamships equipped new-type engines were imported successively, and Japan could keep up with the times. In 1862, excellent engineers went abroad for study and joined in construction of an ordered ship in the Netherlands, thus they could learn in practice. Using the imported ships, Japanese engineers grew accustomed to operation and repair of new machines. There was a rather good understanding of the necessity of dockyards for repair and such shipyards made a contribution to the development of marine engine in Japan.

1 0 0 0 OA ヨット型客船「おせあにっくぐれいす」

- 著者

- 北野 公夫

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.25, no.3, pp.195-202, 1990-03-01 (Released:2010-05-31)

1 0 0 0 OA ディーゼル噴霧の粒径に及ぼす燃料粘度の影響

- 著者

- 廣安 博之 新井 雅隆 田端 道彦

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.20, no.3, pp.194-202, 1985-03-01 (Released:2010-05-31)

- 参考文献数

- 11

- 被引用文献数

- 6

To study the effect of fuel viscosity, injection pressure and surface tension on the mean droplet size and spray angle, the diesel fuel spray droplets were measured by a Laser diffraction technique. Several kinds of glycerine solution with water and residual fuel oil were used. The tests were carried out over a wide range of injection pressure [3 to 90 MPa (30.6 to 917.7 kgf/cm2) ] and of kinematic viscosity of liquid [1×10-6 to 200×10-6 m2 /s (1 to 200 cSt) ] at ambient pressure of 3 MPa (30.6 kgf/cm2) .The main results obtained are as follows:(1) Sauter mean diameter increases with increasing kinematic viscosity of liquid, but decreases with increasing injection pressure. There are an upper limit of viscosity and a lower limit of the pressure to produce a fine spray.(2) At high injection pressure, the effect of viscosity on Sauter mean diameter still remains, but the viscosity has no effect on the spray angle.(3) When the viscosity is the same at low injection pressure, Sauter mean diameter of glycerine solution spray is larger than that of residual oil. Surface tension has no effect on the Sauter mean diameter at high injection pressure.

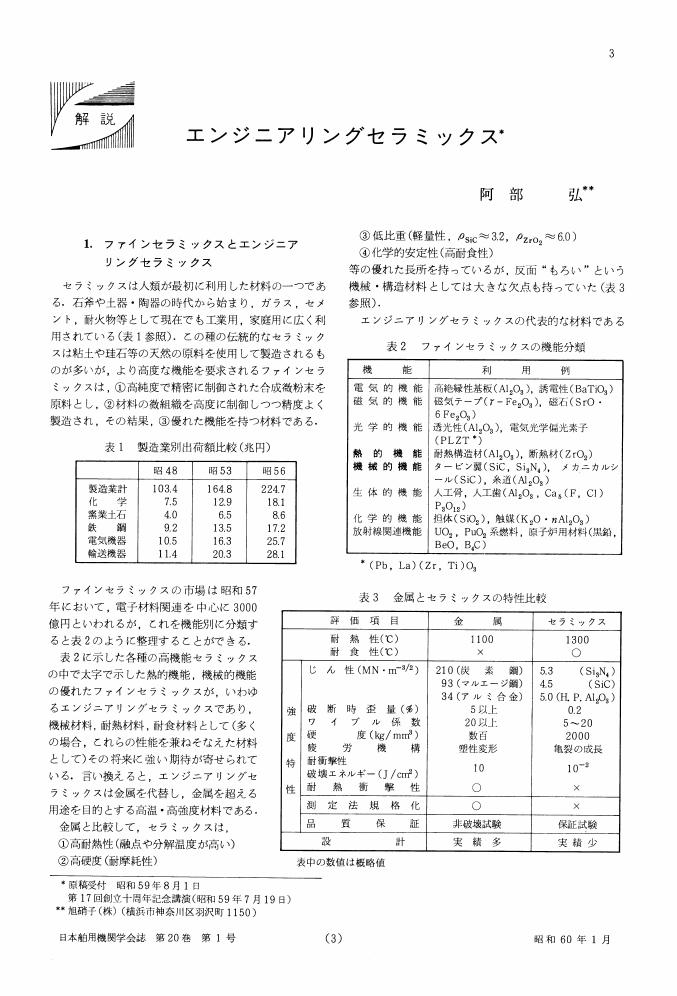

1 0 0 0 OA エンジニアリングセラミックス*

- 著者

- 阿部 弘

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.20, no.1, pp.3-7, 1985-01-01 (Released:2010-05-31)

1 0 0 0 OA ベイズの定理と信頼性への応用

- 著者

- 堀籠 教夫

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.25, no.2, pp.91-97, 1990-02-01 (Released:2010-05-31)

- 参考文献数

- 10

1 0 0 0 国鉄式投炭法の思い出 (蒸気プラント特集号)

- 著者

- 一色 尚次

- 出版者

- 日本舶用機関学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.14, no.9, pp.p682-683, 1979-09

1 0 0 0 海洋地球研究船「みらい」

- 著者

- 重松 祥三 三好 章夫

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.33, no.2, pp.111-117, 1998-02-01

1 0 0 0 大型測量船「昭洋」の電気推進システム

- 著者

- 西山 洋一郎

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.32, no.9, pp.684-690, 1997-09-01

- 被引用文献数

- 1

The new hydrographic surver ship "SHOYO" with capacity of 3, 200tons, is now under construction in the Japan Maritime Safety Agency as a replacement of the old ship "SHOYO" which was constructed in 1972.<BR>This new ship is expected to be completed in March, 1998.<BR>The electric propulsion system was first employed in the Japan Meritime Safety Agency. It is equipped with diesel engine generators as a power source for every application on sailing.<BR>The electric propulsion system is provided with 2 sets of 2, 800kW main-generators to drive the fixed pitch propellers at a motor output and speed of 2, 100kW/262-290rpm ahead.<BR>The thyristor motor system is applied to driving 2 sets (2 shafts of propellers.)<BR>In addition, one set of bow-thruster (800kW) is located at the stem for controling the ship with the Joy-stick conbined to the electric propulsion system during fixed point observation.

1 0 0 0 OA 戦前の舶用補機械発達史

- 著者

- 日本舶用機関史編集委員会補機専門委員会

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.21, no.6, pp.372-382, 1986-06-01 (Released:2010-05-31)

This paper is an excert from the manuscripts written by the marine auxiary equipment subcommittee of the marine Engineering history committee of the MESJ. The manuscript was completed after 10 years of hard wark. But has not yet been pubbished because of various aduerse conditions. This paper is one of the serial papers which will appear in this Journal twice a year to introduce the content of the manuscript to menbers of MESJ.This paper are consist of Deck machinery, Steering gear systems, and refrigerator and air conditioning systems.Marine machinery equipment developed according to ship building progress. They were almost imported from foreign country in Meiji and Taishou Era, but a some of large sized passenger vessels used the imported products on account of a lack of reliability in Japanese products.The marine machinery equipments developed rapidly own design and unique products by the World War II.

1 0 0 0 OA 1997年における舶用機関技術の進歩

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.33, no.7, pp.468-506, 1998-07-01 (Released:2010-05-31)

1 0 0 0 OA 日本の艦艇・商船の内燃機関技術史 (第2次世界大戦集結まで)

- 著者

- 藤田 秀雄 村田 正之 大原 信義 片岡 敏道

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.31, no.5, pp.267-285, 1996-05-01 (Released:2010-05-31)

- 参考文献数

- 13

1 0 0 0 OA 1987年における舶用機関技術の進歩

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.23, no.7, pp.389-424, 1988-07-01 (Released:2010-05-31)

1 0 0 0 SSC型海中作業実験船"かいよう"

- 著者

- 小沢 宏臣 宮田 紀隆

- 出版者

- The Japan Institute of Marine Engineering

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.21, no.2, pp.119-124, 1986

1 0 0 0 OA SSC型海中作業実験船“かいよう”

- 著者

- 小沢 宏臣 宮田 紀隆

- 出版者

- 公益社団法人 日本マリンエンジニアリング学会

- 雑誌

- 日本舶用機関学会誌 (ISSN:03883051)

- 巻号頁・発行日

- vol.21, no.2, pp.119-124, 1986 (Released:2010-05-31)