1 0 0 0 OA γ'マルテンサイト型Ni・Al青銅焼結合金の音響特性

- 著者

- 鈴木 建次 三谷 裕康

- 出版者

- Japan Society of Powder and Powder Metallurgy

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.26, no.6, pp.228-231, 1979-08-25 (Released:2009-12-04)

- 参考文献数

- 3

- 被引用文献数

- 1 1

By using an acoustic method, the duration of reverberation of γ′-Ni·Al bronze sintered alloy was compared with those of Cu-10wt%Sn, Fe-10wt%Cu and α-Ni·Al bronze sintered alloys. The relationship between the duration of reverberation and internal friction was discussed. It was found that the duration of reverberation in this γ′-Ni·Al bronze sintered alloy is extremely shorter than those in other alloys, and decreases linearly with increasing internal friction.

1 0 0 0 OA 登り窯で焼成した備前焼表面に現れる茶褐色および黒色部の微構造と茶褐色の再現

- 著者

- 牧 涼介 彭 沢亮 福原 実 草野 圭弘

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.69, no.10, pp.409-414, 2022-10-15 (Released:2022-10-15)

- 参考文献数

- 11

- 被引用文献数

- 1

Bizen stoneware is produced by firing shaped green clay in a firewood kiln at around 1200°C. The brownish and blackish colors that appear on the stoneware surface in a firewood kiln do not appear on stoneware heated in an electric furnace. The brownish color was found to be caused by the formation of single crystalline, branched, dendritic, Al-substituted ε-Fe2O3 particles. Composite particles consisting of Al-substituted ε-Fe2O3 and Fe-substituted spinel solid solution also formed on the stoneware surface. In this study, we successfully prepared brownish samples that were similar in color to Bizen stoneware by annealing at 1200°C for 2 h in air after heating Bizen clay pellets with K2CO3 at 1230°C under a 10 vol% CO and 90 vol% Ar gas mixture in an electric furnace instead of firing in a firewood kiln. Dendritic hematite particles also formed on the reproduced samples. The blackish color on Bizen stoneware fired in a firewood kiln was caused by the formation of augite [(Ca,Mg,Fe)2Si2O6], which was produced by a reaction between the Bizen clay and firewood ash.

1 0 0 0 OA レーザ積層造形されたSUS316Lステンレス鋼の機械的性質と組織に及ぼす窒素雰囲気の影響

- 著者

- 宮内 創 横田 耕三

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.67, no.8, pp.441-446, 2020-08-15 (Released:2020-08-15)

- 参考文献数

- 14

- 被引用文献数

- 1

This research evaluated the effect of nitrogen absorption into austenitic stainless steel in selective laser melting (SLM) process. Microstructures and mechanical properties of SUS316 specimens fabricated by SLM in different atmosphere, nitrogen and argon, were investigated. The results of microscopy observation of as-built specimen fabricated in nitrogen showed a fine cellular microstructure. In contrast, coarse columnar grains grew up from melt pool boundaries were observed in the microstructure of as-built specimen fabricated in argon. The ultimate tensile strength, yield strength and hardness of as-built specimen in nitrogen were considerably higher than those of specimen in argon and conventionally processed material. These were considered to be the cause of the difference in microstructures and nitrogen absorption. Post-SLM solution heat treatment (SHT) reduced the tensile strength and hardness of both specimens and improved their ductility. However, the tensile strength and hardness of the specimen in nitrogen were still higher than those in argon.

1 0 0 0 OA 金属粉の着火・爆発危険性とその特徴

- 著者

- 榎本 兵治

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.66, no.11, pp.513-524, 2019-11-15 (Released:2019-11-15)

- 参考文献数

- 22

This paper describes characteristic profiles of explosibility and ignitability of metal powders as well as their possible hazards, in most cases, in comparison to those of organic dusts. Metals are mostly pure materials and their physical and thermochemical properties are well known, so that it was tried to explain their performances on the basis of their properties, which may help the estimation of explosibility and ignitability of metal powders that are not yet known.

1 0 0 0 TiC生成反応に及ぼすミリング方式の効果

- 著者

- 鰐川 周治 武田 徹

- 出版者

- Japan Society of Powder and Powder Metallurgy

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.39, no.12, pp.1145-1150, 1992

By using the planetary, screw disc and vibration type ball mills, mechanically activated states of Ti-C powders formed in milling were investigated with the change of their reaction temperature. The temperature decreased with increasing milling time, and its relation is characteristic of the milling methods. Especially, in case of the vibration mill, there is clear indication that the reaction temperature of milled powder was saturated at a constant value as the lapse of the milling time, and also the size of balls charged in mill influenced markedly to the reaction temperature.

1 0 0 0 OA 貴金属使用量低減化を目指したMn修飾六方晶YbFeO3触媒の創製

- 著者

- 細川 三郎 松本 祥吾 多田 稜平 芝野 卓也 田中 庸裕

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.64, no.11, pp.583-588, 2017-11-15 (Released:2017-11-29)

- 参考文献数

- 29

- 被引用文献数

- 1 2

Mn-modified hexagonal YbFeO3 (Mn-YFO) synthesized by a solvothemal method is found to have a higher catalytic activity for C3H8 or CO oxidation than noble metal catalyst, Pd/Al2O3. The catalytic activity is mainly due to amorphous MnOx species located on ab plane of the hexagonal lattice. A small amount of Pd loading on Mn-YFO drastically enhances the catalytic activity; that is, 0.5 wt% Pd/Mn-YFO shows excellent activity for CO oxidation that exceeds the activity of 2.0 wt% Pd/Al2O3. The Pd loading dramatically improves the reducibility of the MnOx species and also CO adsorption to Mn-YFO. Thus, we demonstrate that an extremely small amount of Pd species plays a role as a promoter for the catalytic and reduction functions of the MnOx species on Mn-YFO. It is expected that the establishment of such promoter effect will provide a novel guideline for reducing the use of precious metal resources.

1 0 0 0 Y系酸化物超伝導体および関連化合物の高圧合成

- 著者

- 鄂 剛 吉川 信一 金丸 文一 田中 功

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.38, no.2, pp.215-218, 1991

High pressure synthesis was performed on 123 and 124 phases in Y-Ba-Cu-O system under a pressure of 3GPa at 950°C. Lattice parameters and superconducting properties changed with an annealing duration under pressure in 123 phase with oxygen content X=7. The 123 product obtained from raw materials with X=8.5 had a tetragonal lattice with a=c/3=3.87A. Its real oxygen content could be estimated to be 7.3 from the lattice parameter, Raman spectroscopy, and also Rietveld analysis. The product seemed to be semiconductor containing a small amount of superconductor. 124 phase was obtained by a reaction at 950°C with its successive annealing at 700°C under 3GPa adjusting oxygen content of raw material to the exact composition of the product.

- 著者

- 宮城 加津也 深野 陽介

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.68, no.10, pp.409-414, 2021

<p>Verification of the manufacturing conditions for translucency ceramics are showed using powder forming and sintering method in order to establish the manufacturing technology for optical devices with arbitrary complex shape and shape retention, and high-optical excitation. However, this method is extremely difficult to obtain translucency ceramics because the combination of complex factors such as "the shape and particle size of the raw materials, forming conditions and sintering" adversely affect the translucency of the sintered material, which is caused by the transmitted light scattering of the sintered material. Therefore, we have succeeded in realizing translucent ceramics by examining these complicated factors (materials, molding, sintering conditions, crystallization) and specifying the amorphous sintering conditions and the densification-molding conditions necessary to eliminate the light scattering factors inherent in sintered materials. It is necessary to show the correlation of the volume change with respect to T<sub>g</sub>-temperature and T<sub>m</sub>-temperature, which are important regarding amorphization, considering the sintering treatment conditions that depend on the particle size of the raw material fine powder, and to specify the molding body-pressurization (pressure and time) conditions. These optimizations will make it possible to develop the expected high-functional-photoelectric optical devices with microstructures and, high-power laser light sources independent of materials.</p>

1 0 0 0 タイミングベルトプーリーの高機能化事例について

- 著者

- 佐藤 克明 坂 勉 酒井 純 高木 善昭

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.43, no.11, pp.1328-1332, 1996-11-15

- 参考文献数

- 1

The pulleys are used to be produced by powder metal due to cost performance and high productivity. Recently, the timing belt pulleys for automotive engine are required extra high functions which have sensor or light weight, and the complex shape pulleys are tend to increase. This report introduces the examples of the design and engineering of these pulleys as follows.<BR>1)The light weight pulleys with thin wall curtain shape rim are lighter than stamping pulleys.<BR>2)The cam shaft pulleys with sensing cam are manufactured as utilizing powder flow during compacting.<BR>3)The crank shaft pulleys with sensing cam at flange portion for miss fire detection have high accuracy of angle phase between key way and sensing cam.

- 著者

- 栗林 大樹 佐藤 知広 齋藤 賢一 宅間 正則 高橋 可昌

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.68, no.8, pp.317-323, 2021-08-15 (Released:2021-08-15)

- 参考文献数

- 16

In recent years, materials infomatics (MI), a technology that combines materials engineering and machine learning, has become popular and is used for discovering new materials. In this research, we aimed to verify whether MI can be applied to the problem of “development and maintenance of technology,” which is becoming more difficult due to the decrease in the number of engineers caused by the declining birthrate and aging population in Japan. We selected “discrimination of optical electron microscope images” as the verification target, and used Convolutional Neural Networks (CNNs) as the machine learning technology to discriminate between seven types of sintered metal objects under different sintering conditions, hoping for general applicability to the discrimination problem, and confirmed a discrimination accuracy of 98.5%. In addition, we verified the effectiveness of using pseudo-samples for the discrimination problem using Generative Adversarial Networks (GANs) in the hope of improving accuracy by increasing the number of samples, and confirmed the improvement of accuracy by adding pseudo-samples to the training data.

1 0 0 0 鋳鉄,黒鉛系自己潤滑複合材料の繊維冶金製法

- 著者

- 李 世欽 鈴木 清 中川 威雄

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.35, no.6, pp.552-557, 1988

For further development of the high performance self-lubrication materials being proof against vacuum or high temperature, cast iron fibre composites containing a large amount of graphite were investigated. The cast iron fibre of 20-40 μm in diameter and 1.2 mm in length, which was prepared by chatter-machining a ductile cast iron bar, was mixed with graphite powder and consolidated by compacting in a die, sintering and finally repressing. The optimum conditions for the processing were determined experimentally, and the composite of the almost same mechanical strength as grey iron was made with an addition of 28.8 vol% graphite. In conclusion the fibre metallurgical processing of the high performance self-lubrication composite materials of cast iron and graphite is feasible in the production.

1 0 0 0 連続粉末圧延法による簿板製造の研究

- 著者

- 木村 尚 平林 平八郎 徳吉 睦生

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.10, no.4, pp.172-180, 1963

A continuous method of producing iron strip from powder has been developed. Iron powder directly conversed to green strip by roll compacting, and which was continuously sintered, hot rolled and cooled in hydrogen atmosphere and coiled up. The effects of various continuous powder rolling factors, such as the sintering temperature, roll speed, and hot rolling lood on the properties of hot rolled strip were investigated with Husquvarna Star electrolytic iron powder and Höganäs sponge iron powder.<BR>In general, with increasing the sintering temperature and hot rolling lood the physical and mechanical properties of iron strip by powder rolling were improved, whereas the effect of roll speed was different, depending upon the sinterability of iron powder. These properties obtained were considerably well for the powder metallurgical product, although the sintering time was short. According to the repeated hot rolling or annealing and cold rolling, the pro. perties of the iron strip were equal to those of the conventional iron strip, especially the one made from Husquvarna Star iron powder showed superior magnetic properties.

1 0 0 0 OA 金属射出成形法によるチタンおよびチタン合金の製品化技術

- 著者

- 河野 富夫 洞田 亮 近藤 鉄也

- 出版者

- Japan Society of Powder and Powder Metallurgy

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.44, no.11, pp.985-992, 1997-11-15 (Released:2009-05-22)

- 参考文献数

- 27

- 被引用文献数

- 14 18

The properties of typical pure Ti and Ti-6Al-4V alloys produced by Metal Injection Molding (MIM) process have been investigated in detail after optimization of the powder characteristic, debinding and sintering conditions for the process.(1) Sintered pure Ti using the blended in equal amount of hydrided-dehydrided and gas-atomized powders has better tensile strength (640MPa) and elongation (21%), which properties are similar to the JIS 3 grade of wrought pure Ti.(2) Sintered Ti-6Al-4V alloys produced by both mixed elemental and prealloyed powders have good tensile strength (970MPa) and elongation (12%), which are almost comparable to those of wrought Ti-6Al-4V alloys.(3) Polishability of sintered pure Ti is generally poor. However, the specific heat treatment leads to fairly improved polishability because of the grain refining which is also favorable for the mechanical properties.

1 0 0 0 OA 放射光マルチスケールCTで見るセラミックスの3次元内部欠陥構造

- 著者

- 大熊 学 渡辺 修平 篠部 寛 西山 宣正 竹内 晃久 上杉 健太郎 田中 諭 若井 史博

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.66, no.12, pp.604-610, 2019-12-15 (Released:2019-12-15)

- 参考文献数

- 40

The characterization of the processing-induced defects is a significant step for developing defect-free processing, which is important to the assurance of the mechanical reliability of brittle ceramics. Recent advances in multiscale X-ray computed tomography which consists of micro-CT and nano-CT enables us to observe the three-dimensional (3D) internal structure non-destructively. Micro-CT reveals the distribution of defects in the entire body of a sample, while nano-CT reveals the shape of the identified defect. This powerful imaging tool was used to reveal the complicated 3D morphology of defects evolved during sintering of alumina. The hierarchical packing structure of granules was the origin of several types of strength-limiting defects, which could not be eliminated due to the differential sintering of heterogeneous microstructures. This imaging technique of internal defects provides a link between the processing and the fracture strength for the development of structural materials.

1 0 0 0 OA 光機能材料

- 著者

- 宮本 大樹

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.46, no.2, pp.174, 1999-02-15 (Released:2009-05-22)

1 0 0 0 OA 火花放電による微粉末の生成

- 著者

- 石橋 渡

- 出版者

- Japan Society of Powder and Powder Metallurgy

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.24, no.4, pp.107-112, 1977-06-05 (Released:2009-05-22)

- 参考文献数

- 8

- 被引用文献数

- 3 4

As an application of electrode erosion by electric discharge, a new method was developed in which fine powder was produced by the spark discharge.When metal pellets are dipped into the liquid medium, the contact points of each pellets form the spark points. The pellets repel momentarilly each other by the impulse of spark discharge, and maintain its steady spark discharge by shifting the contact points and inhibiting the conversion to arc discharge. Thus fine powder is produced at spark points.In spark discharge circuit, electrostatic capacity of condenser is set as small as possible, and enhances the condenser energy by higher charge voltage. In addition, the discharge voltage is brought to be higher by quenched spark gap.The powder quantity is increased with the higher discharge voltage (10-40 kV) and its particle size becomes smaller with increase of frequency (230-610 kHz). Discharge condition has been investigated for producing fine powder (0.05-5μm) from aluminum, copper and iron materials. Finally the theoretical description has been given with regard to the mechanism of producing the fine powder at spark points.

1 0 0 0 OA 遠心噴霧粉末製造法の水モデル解析

- 著者

- 原田 幸明 菅 広雄

- 出版者

- Japan Society of Powder and Powder Metallurgy

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.33, no.2, pp.63-68, 1986-02-25 (Released:2009-05-22)

- 参考文献数

- 16

- 被引用文献数

- 1 1

Some of the processing parameters for centrifugal atomization of molten metal were studied by means of a model-experiment using water.The shape and revolution velocity of the high speed rotating stages affected the size and the scattering distribution of disintigrated droplets. In the atomization using a flat stage, liquid disintegrated into smaller particles but sticked considerably to the wall of the apparatus. Conical type stages lessened the sticking and increased the portion of the larger drops slightly. Higher velocity revolution made finer particles and narrowed the scattering range of drops at the bottom of the chamber closely to the center. The wettability of the liquid on the stage surface was found to be an important factor for the disintegration of the liquid. Enhanced wettability brought direct drop formation, while poor wettability brought ligament disintegration.

1 0 0 0 2020年度春季大会研究発表講演募集

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.67, no.1, pp.Mtg1_2-Mtg1_5, 2020

1 0 0 0 OA タングステン酸化物の生成と還元の研究

- 著者

- 安永 弼

- 出版者

- Japan Society of Powder and Powder Metallurgy

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.8, no.6, pp.253-264, 1961-12-25 (Released:2009-05-22)

- 参考文献数

- 17

- 被引用文献数

- 4 3

The crystals of ammonium paratungstate were thermally decomposed in both air and vacuum, and the process of thermal decomposition of this salt and the formation of tungsten trioxide particles were studied by means of following measurements, (i) weight (ii) determination of the evolved ammonia gas, (iii) the differential thermal analysis, (iv) the X-ray analysis, (v) the surface area measurement and also (vi) the observation by electron microscope.The result obtained are as follows;(1) The dehydration of the crystal takes place completely below 250°C. The evolution of ammonia occurs in several stages extending to 420°C.(2) The a-tungsten trioxide are obtained at the temperatures above 420°C by the decomposipion in air. The particle of a-tungsten trioxide consists of small unit particles which are linked with each other, forming an aggregate whose shape are resemble that of the mother salt.(3) When the salts are decomposed in vacuum, 7-tungsten oxide are obtained at the temperature ranging from 400-500°C, and 8-tungsten oxide at the temperature higher than 500°C. The shape of the particle thus obtained was somewhat different from that of a-tungsten obtained in air.Experimental results, and the considerations on the mechanism of decomospition and also the formation of tungsten trioxide are described in detail.

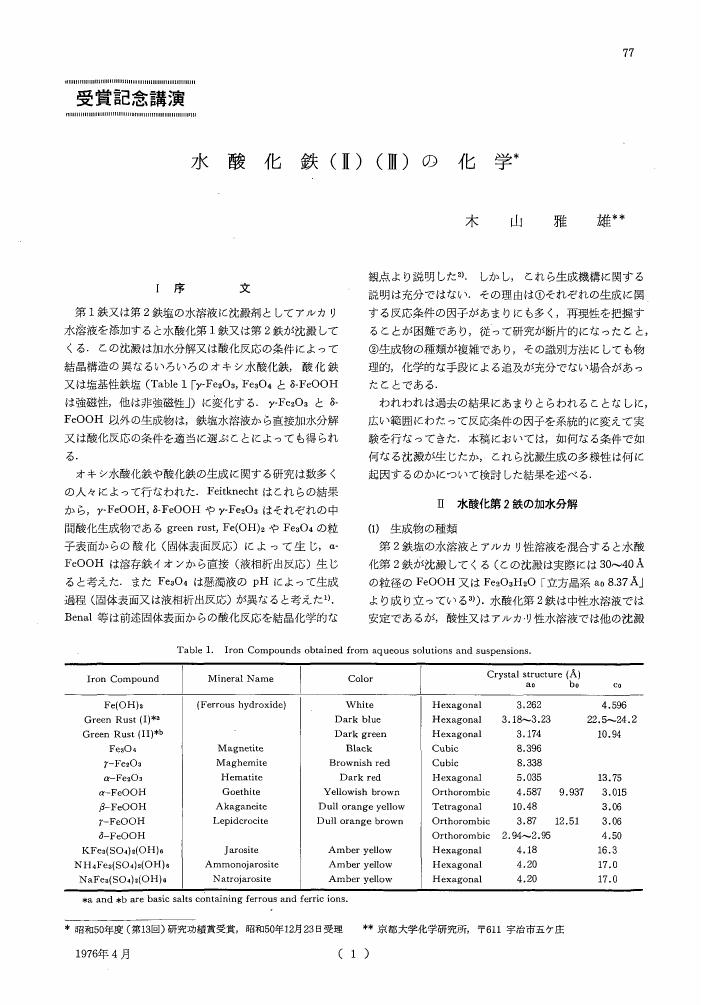

1 0 0 0 OA 水酸化鉄(II)(III)の化学

- 著者

- 木山 雅雄

- 出版者

- 一般社団法人 粉体粉末冶金協会

- 雑誌

- 粉体および粉末冶金 (ISSN:05328799)

- 巻号頁・発行日

- vol.23, no.3, pp.77-84, 1976-04-05 (Released:2009-05-22)

- 参考文献数

- 30

- 被引用文献数

- 29 21