1 0 0 0 OA 八戸工業高等専門学校

- 著者

- 齊藤 貴之

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.63, no.7, pp.416, 2012-07-01 (Released:2013-01-29)

1 0 0 0 OA チタン建材とその表面処理

- 著者

- 佐藤 廣士

- 出版者

- The Surface Finishing Society of Japan

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.43, no.11, pp.1014-1019, 1992-11-01 (Released:2009-10-30)

- 参考文献数

- 15

- 被引用文献数

- 3 4

1 0 0 0 OA ゾル-ゲル法による光触媒の作製と応用

- 著者

- 垰田 博史

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.57, no.6, pp.406, 2006 (Released:2006-12-18)

- 参考文献数

- 10

1 0 0 0 OA 光触媒の固定化法

- 著者

- 吉本 哲夫

- 出版者

- The Surface Finishing Society of Japan

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.50, no.3, pp.242-246, 1999-03-01 (Released:2009-10-30)

- 参考文献数

- 15

- 被引用文献数

- 7 4

1 0 0 0 OA 界面インピーダンス法による銅とはんだの接合界面評価

- 著者

- 佐藤 有紀 大山 昌憲 興戸 正純

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.63, no.2, pp.108, 2012-02-01 (Released:2012-10-05)

- 参考文献数

- 5

Interfacial impedance method was applied to evaluate the interface stability of solder joints. Results showed that the surface treatment on rolled copper strongly influenced the solder joint interface structure. The composition and interfacial impedance between rolled copper and solder were also influenced by the surface treatment of the copper. Especially, a correlation was found between the surface treatment and time dependence of the interfacial impedance value. The admittance spectra of interfacial impedance between as-rolled copper and solder showed strain from the semicircular shape, although the plasma ashed copper or thermally oxidized copper showed no such strain over time. The strain probably represents solder joint instability. The interfacial impedance method can be useful for evaluation of the solid metal interface, not only the interface between the liquid and solid.

1 0 0 0 OA 振動エネルギーによる環境発電(振動発電)

- 著者

- 神野 伊策

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.67, no.7, pp.348-352, 2016-07-01 (Released:2017-07-01)

- 参考文献数

- 19

- 被引用文献数

- 3 5

1 0 0 0 OA DLCバリアボトルとその諸特性

- 著者

- 柳原 英人

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.65, no.4, pp.158-161, 2014-04-01 (Released:2015-04-01)

- 参考文献数

- 8

- 被引用文献数

- 1

1 0 0 0 OA 日本刀の伝統的作刀技術と美術的価値

- 著者

- 水木 良光

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.70, no.5, pp.270-275, 2019-05-01 (Released:2019-11-01)

- 参考文献数

- 9

1 0 0 0 OA 表面処理における光技術

- 著者

- 吉原 啓太

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.69, no.2, pp.80-84, 2018-02-01 (Released:2018-11-01)

- 被引用文献数

- 1 2

1 0 0 0 OA アルカリ性電解水による金属表面の洗浄

- 著者

- 竹ノ内 敏一 田中 博志 若林 信一

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.54, no.11, pp.818-822, 2003 (Released:2004-11-19)

- 参考文献数

- 6

- 被引用文献数

- 8 8

Electrolyzed alkaline water, obtained by the electrolysis of a dilute NaCl solution in a cathode compartment shows high pH (alkalinity), low ORP (Oxidation Reduction Potential), and moderate reducibility and oil-emulsification. By utilizing the characteristics of the alkalinity and the oil-emulsification of the electrolyzed alkaline water, metals and lead frames stamped with oil were washed and cleaned, then the cleanness of metals and lead frames for electronic products was evaluated. The surface analysis and quantitative data on remaining residual oils and ionic contamination, AES (Auger Electron Spectroscopy) analysis on metals, and wire-bond pull strength on the lead frames which were washed and cleaned by the electrolyzed alkaline water, showed the same level of cleanness compared to that of the conventional cleaning method by chemicals.

1 0 0 0 OA 抗菌性めっき皮膜とその応用

- 著者

- 福崎 智司 平松 実

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.58, no.12, pp.739, 2007 (Released:2008-08-01)

- 参考文献数

- 20

- 被引用文献数

- 2 2

1 0 0 0 OA アルミニウムのアルカリ性化学研磨液における浴組成と光沢度, 表面構造との関係について

- 著者

- 新藤 恵美 吉田 明 松本 誠臣

- 出版者

- The Surface Finishing Society of Japan

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.51, no.6, pp.633-639, 2000-06-01 (Released:2009-10-30)

- 参考文献数

- 8

Chemical polishing solutions for aluminum based on mixtures of phosphoric and nitric acid cause air pollution with hazardous gaseous emissions, such as NOx, during the chemical polishing process, and cause water pollution due to the effluent of wastewater that contains phosphates and nitrates. Hence, the authors attempted to polish aluminum in an alkaline solution containing sodium hydroxide as an alkaline agent and sodium persulfate as an oxidizing agent. In this process, exceptionally bright surfaces of aluminum were obtained; that is, the brightness of the surface polished in the alkaline solution was comparable with that of the surface polished in an acid chemical polishing solution. The composition of the alkaline solution that had the least polishing effect had a concentration of sodium hydroxide in a range of 0.5 to 1.5% by weight for pure aluminum and a range of 1.0 to 2.0% by weight for commercially pure aluminum, while the concentration of sodium persulfate was 35% by weight. At with a high magnification on a scanning electron microscope (SEM), network patterns were observed over the entire polished surface of the aluminum polished in the alkaline solution and that in the acid chemical polishing solution. On the surface of the commercially pure aluminum polished in the alkaline solution, very small projections were observed by SEM, that were identified by electron probe microanalysis (EPMA) as insoluble phases that included foreign elements such as Fe and Si in the aluminum. On the other hand, on the surface of the aluminum polished in the acid chemical polishing solution, very small pits were observed, formed by dissolution of the phases in the acid solution. Also, use of x-ray photoelectron spectroscopy (XPS) and fourier transform infrared spectroscopy (FT-IR) indicated that the oxide films formed on the surface of the aluminum polished in the alkaline solution were thicker and contained a larger amount of hydroxyl radicals than those on the surface polished in the acid chemical solution.

1 0 0 0 OA アルミニウムの表面処理における前処理

- 著者

- 原 健二

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.69, no.9, pp.380-383, 2018-09-01 (Released:2019-03-01)

- 参考文献数

- 7

- 被引用文献数

- 2

1 0 0 0 OA 溶液中STMによる有機分子の吸着観測

- 著者

- 山田 太郎

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.59, no.12, pp.825, 2008 (Released:2009-09-29)

- 参考文献数

- 11

1 0 0 0 OA 自動車塗装工程の概要とその課題への対応

- 著者

- 柴田 浩行 飯田 達也 那須 礼学

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.69, no.7, pp.290-295, 2018-07-01 (Released:2019-01-01)

- 参考文献数

- 4

- 被引用文献数

- 1

1 0 0 0 OA フォトリソグラフィ (1)

- 著者

- 駒野 博司

- 出版者

- The Surface Finishing Society of Japan

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.46, no.9, pp.778-783, 1995-09-01 (Released:2009-10-30)

- 参考文献数

- 19

- 被引用文献数

- 1

1 0 0 0 OA 信頼性と信頼性管理

- 著者

- 鈴木 和幸

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.70, no.6, pp.290-296, 2019-06-01 (Released:2019-12-01)

- 参考文献数

- 6

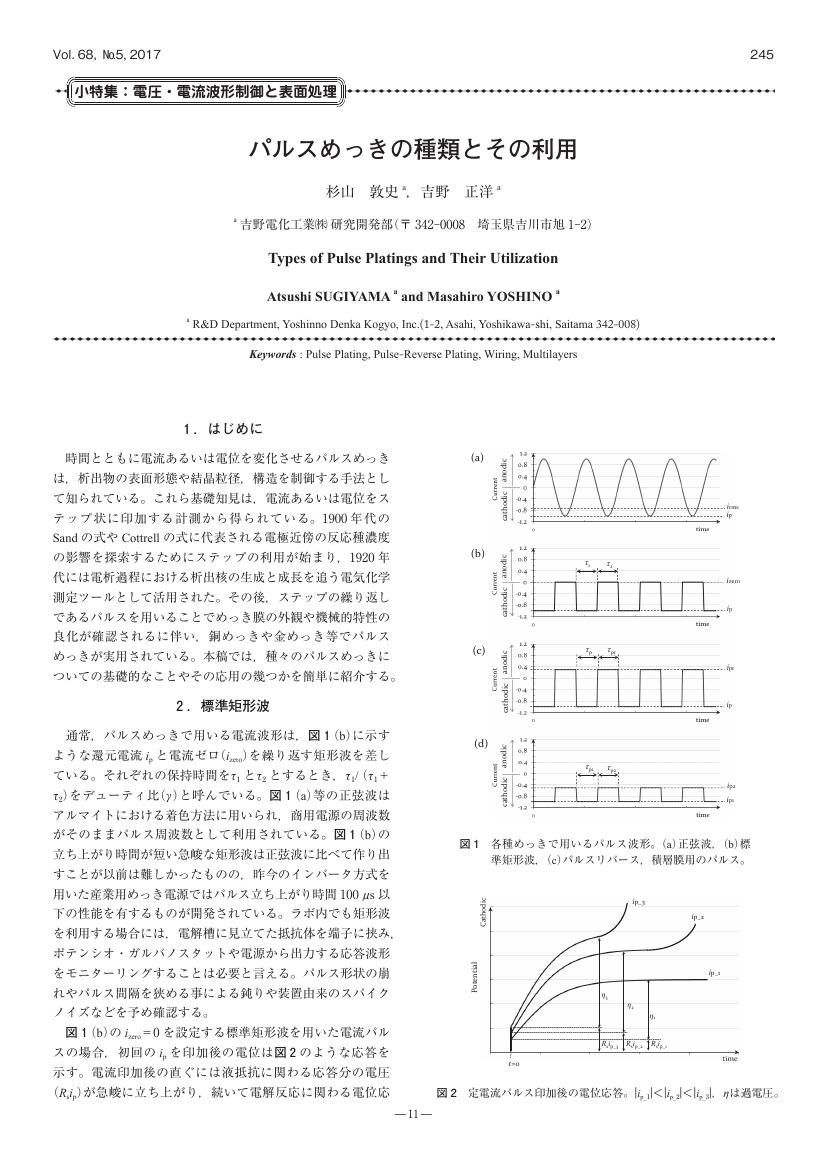

1 0 0 0 OA パルスめっきの種類とその利用

- 著者

- 杉山 敦史 吉野 正洋

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.68, no.5, pp.245-248, 2017-05-01 (Released:2018-05-01)

- 参考文献数

- 20

1 0 0 0 OA ヘテロエピタキシャルダイヤモンド基板の開発とそのデバイス応用

1 0 0 0 OA 結晶シリコン薄膜太陽電池の技術動向

- 著者

- 坂田 功

- 出版者

- 一般社団法人 表面技術協会

- 雑誌

- 表面技術 (ISSN:09151869)

- 巻号頁・発行日

- vol.56, no.1, pp.3, 2005 (Released:2005-10-15)

- 参考文献数

- 18