1 0 0 0 OA 酸化物-金属界面原子層の光電子分光法による解析

- 著者

- 吉武 道子

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.78, no.11, pp.408-414, 2014 (Released:2014-11-01)

- 参考文献数

- 18

At metal oxide (AO)-metal (M) interfaces, metal (M) atoms can make bonds with metal oxide through either oxygen (O) atoms or metal (A) atoms that composed of the oxide. Examples of the identification of an element at the interface in atomic level using photoelectron spectroscopy have been demonstrated for alumina, zinc oxide and cerium oxide. Software, which predicts interface bonding according to a method developed by the author, and which is open to public, is presented. It is demonstrated that the difference in the interface bonding species has great influence on the band offset, the energy difference between the Fermi level and the valence band in the band energy diagram. The observations of such difference in band offset using photoelectron spectroscopy are also provided.

1 0 0 0 OA 相変態における界面現象

- 著者

- 古原 忠

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.43, no.2, pp.103-107, 2004-02-20 (Released:2011-08-11)

- 参考文献数

- 50

- 被引用文献数

- 2 3

1 0 0 0 OA 拡散変態における異相界面構造と変態機構

- 著者

- 古原 忠 牧 正志

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.36, no.5, pp.483-490, 1997-05-20 (Released:2011-08-11)

- 参考文献数

- 30

- 被引用文献数

- 5 6

1 0 0 0 偏光解析法による鉄表面不働態皮膜の研究

- 著者

- 野田 哲二 工藤 清勝 佐藤 教男

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.37, no.9, pp.951-957, 1973

- 被引用文献数

- 11

The anodic passivation film formed on iron in neutral borate-buffer solution has been studied by using ellipsometric, electrochemical, and gravimetrical techniques. The film can be dissolved from its outer surface by applying a cathodic current in borate-buffer solution at pH 6.35 in which the reductive dissolution,<BR>(This article is not displayable. Please see full text pdf.) <BR>\oindentproceeds at 100 per cent current efficiency. Ellipsometric measurements carried out during the galvanostatic-cathodic reduction of the film in this solution reveals that the film consists of two layers, an inner layer with the optical constant 3.0−0.5<I>i</I> and an outer layer with the constant 1.8−0.1<I>i</I>. It is also shown that the density of the inner layer is in agreement with that of γ-Fe<SUB>2</SUB>O<SUB>3</SUB>.<BR>The inner layer thickness increases linearly with the passivating potential, and the potential extrapolated at zero thickness of the inner layer corresponds to the equilibrium potential of the anodic formation of γ-Fe<SUB>2</SUB>O<SUB>3</SUB>,<BR>(This article is not displayable. Please see full text pdf.) <BR>\oindentThe outer layer, however, is not directly related to the anode potential. <BR>Thermo-gravimetrical measurements indicate that the film contains some amount of water which is concentrated in the outer layer. The average composition of the outer layer is estimated as Fe(OH)<SUB>3</SUB>.<BR>A film model is proposed in which the inner layer of anhydrous γ-Fe<SUB>2</SUB>O<SUB>3</SUB> is the cause of the potential drop in the film producing a field intensity of 5.6×10<SUP>6</SUP> V/cm and the outer layer of hydrous ferric oxide depends on the solution environment and passivation process.

- 著者

- 飯島 澄男 平原 佳織 末永 和知 坂東 俊治

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ : 日本金属学会会報 (ISSN:13402625)

- 巻号頁・発行日

- vol.40, no.12, 2001-12-20

- 参考文献数

- 2

- 著者

- 中島 篤之助 高橋 正雄 河口 広司

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.22, no.11, pp.564-568, 1958

- 被引用文献数

- 1

A method has been developed for the determination of rare earth elements including yttrium in uranium and its compounds. The greater portion of the uranium is separated from the rare earths by ether extraction. The rare earths are then precipitated as fluorides and subsequently purified as hydroxides. Lanthanum was used as the carrier. The efficiency of the above separation procedures was studied by means of the radioactive tracer Eu<SUP>152+154</SUP>. The final determination was carried out spectrographically by the copper-spark method. Five rare earth elements which showed extremely high neutron absorption were investigated, and their limits of detection (sensitivity) and recoveries from U<SUB>3</SUB>O<SUB>8</SUB> are reported.

1 0 0 0 OA チタンの高温水蒸気中における酸化挙動

- 著者

- 諸石 大司 志田 善明

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.42, no.3, pp.316-323, 1978 (Released:2008-04-04)

- 参考文献数

- 21

- 被引用文献数

- 1 1

The oxidation of pure titanium was studied in superheated steam at 400∼550°C. The effects of prior cold working and several heat treatment conditions on the oxidation were examined and also the effects of the addition of small amounts of iron and oxygen were investigated. The oxidation mechanism of pure titanium is discussed in relation to the scale structure and the oxidation kinetics. Hydrogen absorption rate was also measured. As a result, the following conclusions were drawn:(1) The oxidation of pure titanium in steam was faster than in air and breakaway oxidation was observed above 500°C after the specimen had gained a certain weight. Prior cold working and heat treatment conditions scarcely affected the oxidation rate, whereas the specimen containing small amounts of iron and oxygen showed a little more rapid oxidation.(2) At 500 and 550°C a dark grey inner scale and a yellow-brown outer scale were formed. The outer scae was apt to exfoliate after the occurrence of breakaway oxidation. At 400 and 450°C only a dark grey scale was observed. All of these oxides were identified as the rutile type, TiO2. Furthermore, the presence of a thin and uniform oxygen rich layer beneath the external scale was confirmed at all test temperatures.(3) The measured weight gain approximately followed the cubic rate law; this would be expected for the following reason; one component of the weight gain is due to the dissolved oxygen, the amount of which remains constant after the early stages of oxidation. The second component is due to the parabolic growth of the external TiO2 scale. When these contributions are added a pseudo-cubic weight gain curve results.(4) It was shown that 50 percent of the hydrogen generated during the oxidation was absorbed into the metal.

- 著者

- 松井 光彦

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.64, no.5, pp.403-406, 2000

Recently sodium ionic conductors such as NASICON (Na<SUB>3</SUB>Zr<SUB>2</SUB>Si<SUB>2</SUB>PO<SUB>12</SUB>) have been used as the solid electrolyte for EMF(electromotive force) type CO<SUB>2</SUB> sensors. However, it has been hard to obtain a sufficiently high quality in this type of sensor, partly due to the low humidity-resistance of NASICON and partly because of its poor initial response of EMF to CO<SUB>2</SUB> pressure.<BR>For the purpose of improving the humidity-resistance and the initial response of EMF of the solid electrolyte CO<SUB>2</SUB> sensors, Li<SUB>2</SUB>TiSiO<SUB>5</SUB> is employed as the sensing material instead of NASICON. It is composed of the following electrochemical cell:<BR>(This article is not displayable. Please see full text pdf.) <BR>The electrochemical reaction is in good agreement with the Nernst equation, and reacted electron is calculated as 2.04. The sensor fabricated with Li<SUB>2</SUB>TiSiO<SUB>5</SUB> shows good linearity when it is exposed to an atmosphere of 90% relative humidity at 60°C. The initial 90% response of EMF is steadied within 4 min. These experimental results make it possible to use the sensor in the environments.

1 0 0 0 OA 光触媒の材料開発と産業応用への展開

- 著者

- 峠田 博史

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.45, no.10, pp.738-744, 2006-10-20 (Released:2011-08-11)

- 参考文献数

- 12

1 0 0 0 OA スペクトル解析のための統計的機械学習

- 著者

- 志賀 元紀

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.58, no.1, pp.23-28, 2019-01-01 (Released:2019-01-01)

- 参考文献数

- 17

1 0 0 0 OA パルス電析によるFe-Ni系微粒子・多層膜の電気的および磁気的性質

- 著者

- 山田 昭弥 白田 光利 Rizal C. L. S. 宝賀 剛 上田 勇治

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.66, no.9, pp.869-872, 2002 (Released:2008-04-24)

- 参考文献数

- 13

- 被引用文献数

- 4 5

Pulse electrodepositon is a useful technique with which it is possible to achieve atomic-scale control of the layer composition, thickness of the multilayer and the grain size in ferromagnetic films by regulating the pulse amplitude and width. It is possible to fabricate ferromagnetic films with various magnetic properties from a single electrolytic solution containing more than two kinds of metallic ions, by changing the step pulse wave. Multilayer films composed of a Ni-rich layer with high coercive force, an Fe-Ni layer with low coercive force, and a nonmagnetic Cu layer were produced by controlling the step pulse potential from a single electrolytic solution containing Fe, Ni and Cu ions. Moreover, we are able to produce thinner ferromagnetic films consisting of multiple layers with magnetic characteristics such as a wide variation in coercive force, high susceptibility, and large magnetoresistance effect by controlling the time interval of the step pulse.In this study, we investigated the relationships between the magnetic field dependence of the magnetoresistance effect and the film preparation conditions for composition-modulated Fe-Cu-Ni alloy films produced by the pulse electrodeposition method. The MR ratio observed in the film has maximum values of 3.4% and 9% at 300 K and 5 K, respectively. A highly sensitive change of the electric resistance was obtained at a low magnetic field.

1 0 0 0 OA 金属博物館の展示品から

- 著者

- 今井 勇之進

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.34, no.10, pp.1158-1165, 1995-10-20 (Released:2011-08-11)

1 0 0 0 OA 燃料電池の特徴と技術動向

- 著者

- 本間 琢也

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.44, no.3, pp.197-201, 2005-03-20 (Released:2011-08-11)

- 参考文献数

- 4

1 0 0 0 OA 金相学の誕生と材料科学への発展

- 著者

- 小岩 昌宏

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.48, no.8, pp.412-419, 2009 (Released:2012-10-13)

- 参考文献数

- 12

- 被引用文献数

- 5 2

1 0 0 0 OA ホウ素と窒素を添加した18-8ステンレス鋼表面上への窒化ホウ素の析出挙動

- 著者

- 吉原 一紘 新居 和嘉

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.47, no.11, pp.941-949, 1983 (Released:2008-04-04)

- 参考文献数

- 12

- 被引用文献数

- 4 2

The surface composition of 18-8 stainless steel doped with boron and nitrogen at high temperatures was observed in vacuum with AES and XPS.The precipitation of boron nitride was found on the surface of the stainless steel. At the first stage of heating, a thin layer of boron nitride flowed out from grain boundaries and spread on the surface, replacing phosphorus and sulfur which segregated all over the surface. As the heating time was prolonged, parts of the thin layer of boron nitride increased in thickness. The thickness increased in proportion to the square root of heating time and became about 0.06 μm after heated at 1100 K for 432 ks. The precipitated boron nitride was not replaced by the most surface active element, sulfur, and remained stable on the surface. On the surface of the stainless steel, however, there existed areas not covered with boron nitride after prolonged heating. On these uncovered areas, sulfur segregated.The precipitated boron nitride layer was inert to the adsorption of gases. Therefore, this stainless steel is a superior candidate material for vacuum vessels.

1 0 0 0 OA エネルギー材料としての水素化物の研究開発

- 著者

- 折茂 慎一 中村 優美子 石川 和宏 西村 睦 亀川 厚則

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.56, no.3, pp.130-134, 2017 (Released:2017-03-01)

- 参考文献数

- 28

1 0 0 0 OA 固体の電子論V

- 著者

- 志賀 正幸

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.44, no.4, pp.315-323, 2005-04-20 (Released:2011-08-11)

- 参考文献数

- 5

1 0 0 0 OA 体内を透視する光断層イメージング

- 著者

- 山田 幸生

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.38, no.3, pp.189-193, 1999-03-20 (Released:2011-08-11)

- 参考文献数

- 17

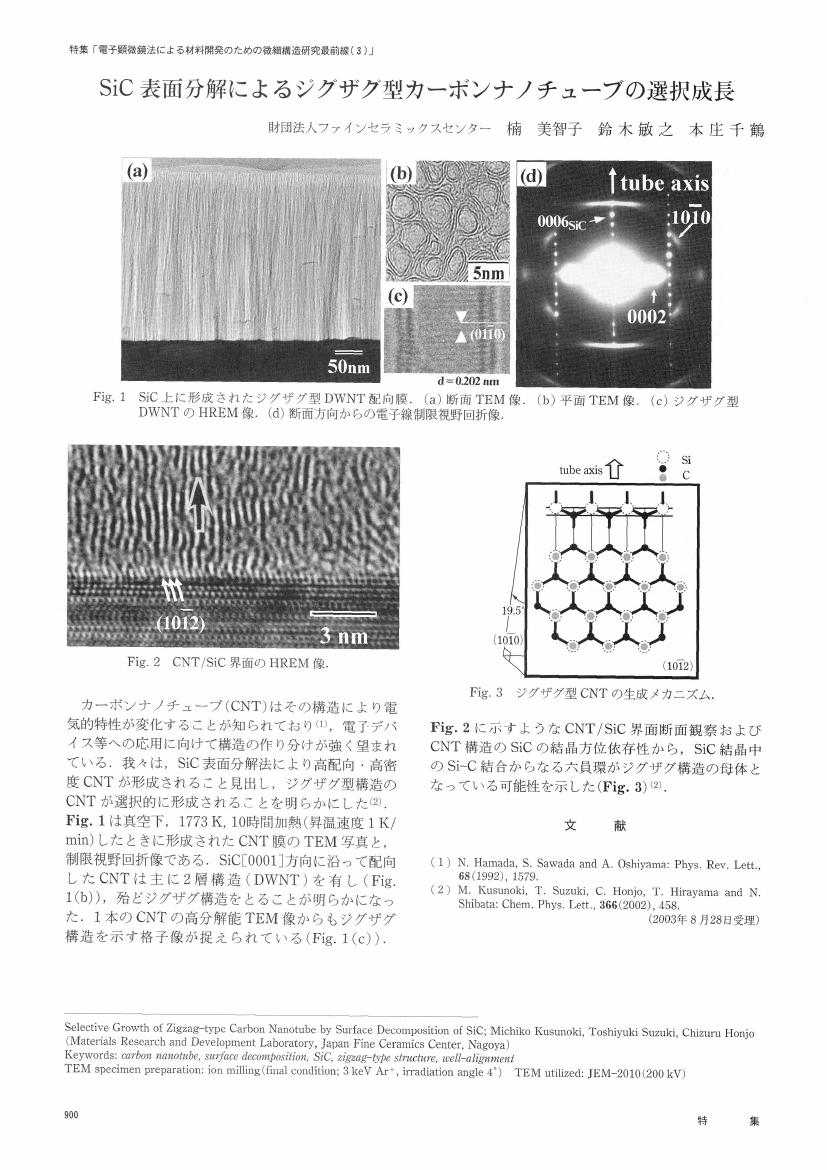

1 0 0 0 OA SiC表面分解によるジグザグ型カーボンナノチューブの選択成長

- 著者

- 楠 美智子 鈴木 敏之 本庄 千鶴

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.42, no.12, pp.900, 2003-12-20 (Released:2011-08-11)

- 参考文献数

- 2

1 0 0 0 OA 江戸時代に製造された火縄銃の金属組織

- 著者

- 田中 眞奈子 北田 正弘

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.73, no.10, pp.778-785, 2009 (Released:2009-10-01)

- 参考文献数

- 10

- 被引用文献数

- 5 6

The metallurgical microstructure and mechanical properties of the steel barrel of a Japanese matchlock gun fabricated in the Edo period have been investigated. The purpose of this work is to obtain modern materials-science data of the Japanese matchlock gun and to study the manufacturing technique of the steel barrel. Test pieces are cut from the center, the muzzle and the screw of the barrel. The carbon concentration is determined by chemical analysis. The metallurgical microstructure and nonmetallic inclusions of the barrel are observed using an optical microscope and a scanning electron microscope (SEM). Test pieces for measuring the mechanical properties are cut from the gun. To evaluate the hardness, Vickers hardness (Hv) is used. The stress-strain curve, tensile strength and elongation of the gun are obtained. The carbon concentration is 0.01∼0.1mass% for the center of the barrel, 0.04∼0.1 mass% for the muzzle of the barrel, 0.05∼0.5 mass% for the front sight (Saki-meate in Japanese) and 0.13∼0.3 mass% for the male screw. The distribution of nonmetallic inclusions in the center and in the muzzle of the barrel suggest that the barrel was fabricated by a manufacturing technique called Udonbari (in Japanese). The metallurgical microstructure of the specimen taken from the muzzle of the barrel in the vertical direction suggests that the barrel and a front sight were joined mechanically. Both male and female screws were made by a cutting technique. The tensile strength and elongation are 316∼366 MPa and 25.0∼31.4%, respectively.