1 0 0 0 OA ネイチャー・テクノロジー事始

- 著者

- 石田 秀輝

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.48, no.4, pp.156-159, 2009 (Released:2012-09-21)

- 参考文献数

- 16

1 0 0 0 OA 高強度 Ag シース Bi-2223線材の開発

- 著者

- 長部 吾郎

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.80, no.7, pp.396-405, 2016 (Released:2016-06-25)

- 参考文献数

- 24

- 被引用文献数

- 5

By using the CT-OP (Controlled Over-Pressure) sintering furnace, Sumitomo Electric (SEI) succeeded in improving various characteristics such as critical current and mechanical properties of Ag sheath Bi-2223 wire commercialized as DI-BSCCO. Recently, SEI has developed and commercialized high strength DI-BSCCO Type HT-NX wire reinforced with the Ni alloy tapes and has applied the residual axial compression after lamination. The critical tensile stress of Type HT-NX has reached 400 MPa at 77 K. For high field magnetic application such as NMR using Bi-2223 based superconducting wire reinforced with Ni alloy tapes is highly expected.

1 0 0 0 OA 鋼のベイナイトとその工業的重要性

- 著者

- 牧 正志

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.46, no.5, pp.321-326, 2007-05-01 (Released:2011-08-11)

- 参考文献数

- 20

- 被引用文献数

- 6 11

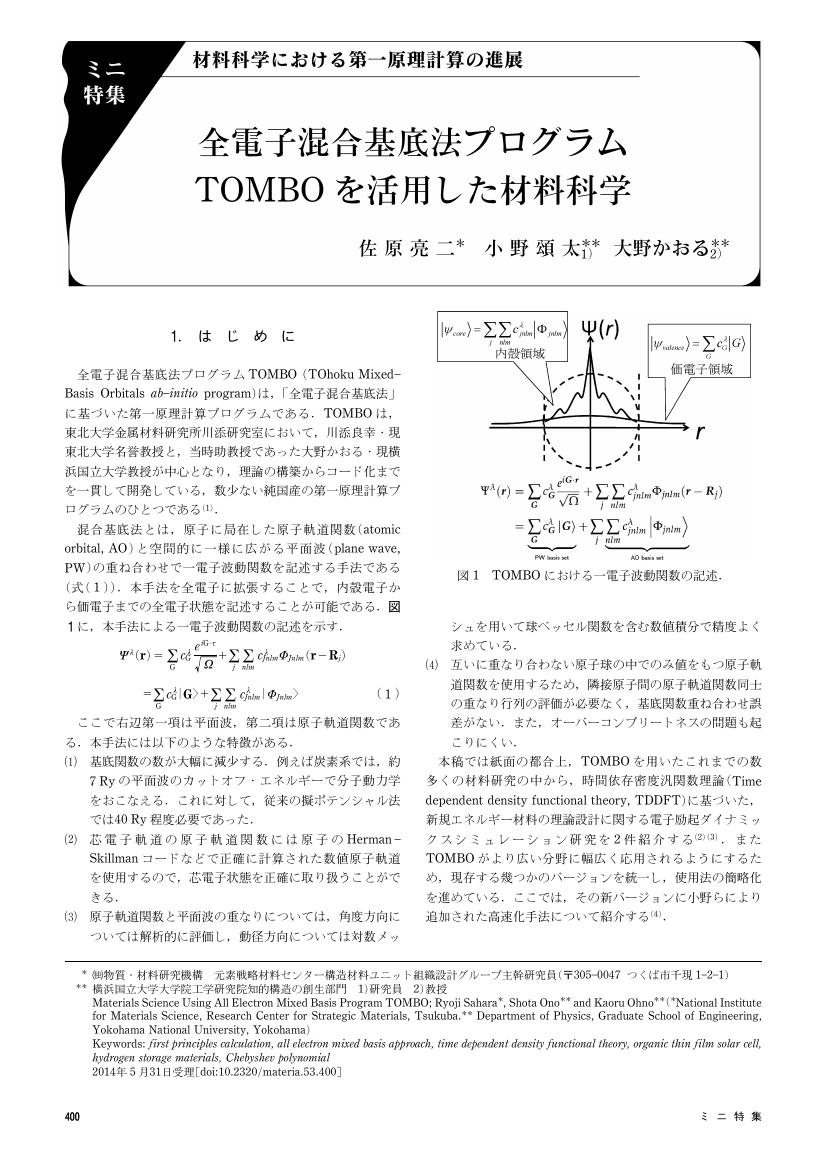

1 0 0 0 OA 全電子混合基底法プログラムTOMBO を活用した材料科学

- 著者

- 佐原 亮二 小野 頌太 大野 かおる

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.53, no.9, pp.400-404, 2014 (Released:2014-09-01)

- 参考文献数

- 22

1 0 0 0 OA 開発 Ni-Co 基鍛造超合金を用いた模擬タービンディスクの機械的特性

- 著者

- 横川 忠晴 谷 月峰 崔 傳勇 小泉 裕 藤岡 順三 原田 広史 福田 正 三橋 章

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.74, no.3, pp.221-225, 2010 (Released:2010-03-01)

- 参考文献数

- 18

- 被引用文献数

- 1 3

New kinds of cast and wrought (C & W) Ni-Co base superalloys (TMW alloys) have been developed based on the innovative concept of combining two kinds of γ-γ′ two-phase alloys, Ni-base and Co-base alloys, for the applications of turbine disks and high-pressure compressor blades. The results based on testing 20 kg ingots indicate that TMW alloys show excellent high temperature strength and formability, may provide 50°C temperature advantage in 630 MPa/100 h creep performance over C & W alloy U720Li. In this paper, we report our new results on the full-scale pancakes manufactured through the C & W process for real components. The results indicate that TMW alloys had good process-ability in the ingot making and forging into disk pancakes. Pancake disks with fine grain size of about 10 μm were successfully obtained for TMW alloys. TMW alloys provide 58°C to 76°C temperature advantages in 0.2% creep strain life under the 630 MPa condition, over alloy U720Li.

1 0 0 0 OA 江戸時代貨幣『豆板銀』に用いられた色揚げ処理技法における処理条件の検討

- 著者

- 田口 智子 桐野 文良

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.79, no.10, pp.485-490, 2015 (Released:2015-10-01)

- 参考文献数

- 10

Silver coins, such as mameitagin, which were used in the Edo period, were composed of a silver and copper alloy. In case the mameitagin casting was performed with low silver concentration, traditional metal works technique called iroage was performed on the coin to elute the copper from the alloy and produce an Ag-rich layer on the surface. In a previous study, we reproduced the iroage treatment on an Ag-Cu alloy using umezu (plum vinegar) as the treatment liquid and clarified that citric acid, malic acid and sodium chloride that are the main constituents of umezu, elute copper in the treatment liquid. In this study, the iroage treatment on Ag-Cu alloys was performed under various conditions to clarify the effect of different treatment conditions. The silver concentration of the Ag-Cu alloy samples used in this study were 75%, 45%, and 15%, and the color, surface structure, and silver concentration before and after treatment were investigated by spectrophotometry, scanning electron microscopy (SEM) and energy dispersive X-ray spectrometry (EDS), respectively. First, the iroage treatment was performed by varying the immersion time in the treatment liquid. The results show that the copper elution velocity differed depending on Ag concentration in the samples. The treatment liquid temperature affected the amount of copper eluted. The percentage of umezu in the treatment solution did not affect the elution amount of copper. The iroage treatment was performed several times in the samples, and the EDS analysis showed that Ag concentration widely varied after treatment. The results suggest that the surface conditions of the repeatedly treated samples affected the copper elution.

1 0 0 0 OA 飽和磁束密度が高く高周波鉄損の低い Si 傾斜磁性材料 JNSF の開発

1 0 0 0 OA 高松塚古墳石室の目地漆喰表面汚染層の微細構造

- 著者

- 北田 正弘 高妻 洋成 建石 徹

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.79, no.8, pp.404-412, 2015 (Released:2015-08-01)

- 参考文献数

- 15

- 被引用文献数

- 2 4

The Takamatsuzuka tumulus was constructed in the 7th to 8th centuries at Asuka in Nara prefecture. The mural and wall surfaces are soiled and deteriorated by rainwater, mold, and other causes. The mural is painted on the stone wall that is coated with stucco. The stone walls are jointed with masonry joint stucco. The purpose of this investigation is to clarify the composition, crystal structure, and other material factors of the surface contaminant layer on the joint stucco. An X-ray computer tomography, an X-ray diffractometer, a scanning electron microscope, and a transmission electron microscope are utilized to examine the microstructure. The contaminant layer thickness is 0.2-0.3 mm. Kaolinite, muscovite, montmorillonite, hematite and a few silicates are detected from the contaminant layer. The compounds detected are constituents of soil-like clay, and most of them contain Fe. By transmission electron microscopy observation, the contaminant layer is found to consist of fine mineral grains, as mentioned above, most of which are acicular. The acicular grain size is approximately 0.2-1 μm in length and 0.015-0.2 μm in width. The grains are in a row parallel to the layer surface. The hematite grains are circular with diameters of 15-250 nm. In addition, iron titanate is observed. The yellowish brown color of the stucco surface is mainly due to iron ions contained in the above-mentioned compounds. It is thought that the grains deposited on the stucco surface from colloidal-like water containing the above-mentioned fine grains.

- 著者

- Ikeda Masahiko Komatsu Shin-ya Nakamura Yuichiro

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- MATERIALS TRANSACTIONS

- 巻号頁・発行日

- vol.45, no.4, pp.1106-1112, 2004

- 被引用文献数

- 43

Using Ti-50Ta, Ti-50Ta-Sn and Ti-50Ta-Zr alloys, the effects of Sn and Zr additions on phase constitution in the solution treated and quenched state and aging behavior were studied by electrical resistivity and Vickers hardness measurements and X-ray diffactometry. All alloys were solution treated at 1173 K for 3.6 ks and then quenched into ice water (STQ). STQed specimens were isochronally aged at temperatures up to 1323 K in Ti-50Ta-Sn alloys and 1173 K in Ti-50Ta-Zr alloys. Shape recovery test was also performed in bent Ti-50Ta, Ti-50Ta-Sn and Ti-50Ta-Zr alloy specimens. In the STQed state, only reflections of orthorhombic α″ martensite were observed by XRD in Ti-50Ta and Ti-50Ta-4Sn alloys. In STQed Ti-50Ta-10Zr alloy, coexistence of α″ and β (bcc) phases were found by XRD. In STQed Ti-50Ta-8Sn and Ti-50Ta-20Zr alloys, only β phase was identified. In Ti-50Ta, Ti-50Ta-4Sn and Ti-50Ta-10Zr alloys, resistivity at liquid nitrogen temperature and resistivity ratio increased with isochronal aging up to a certain temperature. It is considered that these increases are due to reverse-transformation of α″ into metastable β phase. Shape-recovery test confirmed the shape memory effect of Ti-50Ta, 50Ta-4Sn and 50Ta-10Zr alloys.

1 0 0 0 OA 透過 EBSD 法の評価と材料ミクロ組織観察への応用

- 著者

- 鈴木 清一

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.77, no.7, pp.268-275, 2013 (Released:2013-07-01)

- 参考文献数

- 10

- 被引用文献数

- 4 6

Transmission-EBSD (t-EBSD) method is proposed as a new method for nano-scale microstructures analysis of materials. t-EBSD uses TEM thin foil specimen. Electrons transmitted through the specimen form EBSD patterns. A EBSD detector used for standard EBSD (s-EBSD) is used to acquire these t-EBSD patterns. The patterns are indexed in the same manner as s-EBSD to get crystal orientation. The conditions to get good t-EBSD patterns, formation of t-EBSD patterns and spatial resolution of this method are studied in this paper. Specimen thickness affects seriously to the results of orientation mapping by t-EBSD. It is confirmed that t-EBSD patterns are formed at the bottom layer of the specimen. If the specimen is very thin, the patterns become very weak and noisy. If the specimen becomes thicker, t-EBSD patterns lose its contrast and sometimes patterns become weak with reverse contrast bands. This means that total thickness of the specimen is important for t-EBSD method, but overlapped grains look not so big problem to get t-EBSD patterns. Electron beam spread in the specimen is reduced due to thin foil specimen, and it improves spatial resolution of EBSD orientation map. It is confirmed that it can achieve about 10 nm spatial resolution and about 30 nm size grains can be detected with reasonable thickness specimen.

1 0 0 0 OA 粒界工学 ―オーステナイト系ステンレス鋼への適用を例として(I) ~粒界の性格と挙動~

- 著者

- 粉川 博之

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.52, no.1, pp.10-13, 2013 (Released:2013-01-10)

- 参考文献数

- 24

- 被引用文献数

- 1

1 0 0 0 OA 高効率ガスタービン用高性能Ni基耐熱合金MGA1400の開発と実用化

- 著者

- 河合 久孝 岡田 郁生 高橋 孝二 佐平 健彰 三橋 章

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.36, no.6, pp.643-645, 1997-06-20 (Released:2011-08-11)

- 被引用文献数

- 1

1 0 0 0 OA 電子線エネルギー損失スペクトルの理論計算による解釈

- 著者

- 溝口 照康 田中 功 足立 裕彦

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.42, no.3, pp.207-213, 2003-03-20 (Released:2011-08-11)

- 参考文献数

- 18

- 被引用文献数

- 1 1

1 0 0 0 OA 高温酸化の研究最前線

- 著者

- 谷口 滋次

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.50, no.7, pp.287-292, 2011 (Released:2012-12-13)

- 参考文献数

- 60

1 0 0 0 OA タービンディスク用 Ni-Co 基鍛造超合金 ~ミクロ組織制御法と強化機構の解明~

- 著者

- 長田 俊郎

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.51, no.7, pp.327-330, 2012 (Released:2012-12-27)

- 参考文献数

- 11

1 0 0 0 OA 電子デバイス用 Cu 配線におけるCu 合金膜を用いた複数機能一体形成

- 著者

- 伊藤 和博

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.52, no.3, pp.108-115, 2013 (Released:2013-03-10)

- 参考文献数

- 19

1 0 0 0 OA 材料機能の電気化学I

- 著者

- 杉本 克久

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.46, no.8, pp.552-560, 2007-08-01 (Released:2011-08-11)

- 参考文献数

- 32

1 0 0 0 OA 新 α′マルテンサイト型 Ti 合金の組織制御と高機能化に関する紹介を中心として

- 著者

- 松本 洋明

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.48, no.10, pp.515-519, 2009 (Released:2012-10-20)

- 参考文献数

- 26

- 被引用文献数

- 1 1

- 著者

- 進藤 裕英 小堀 智之 堀口 勝三 山田 英一 中嶋 秀夫 辻 博史

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.59, no.8, pp.793-798, 1995 (Released:2008-04-04)

- 参考文献数

- 12

- 被引用文献数

- 2

This paper discusses fracture toughness and temperature rise for JJ1 austenitic stainless steel forged plate at liquid helium temperature for fusion reactor magnets of next generation. Elastic-plastic fracture toughness (JIC) testing was conducted in general accordance with ASTM standards E813-81 and E813-87, and unloading-compliance technique was applied using compact specimens 25.0 mm and 12.5 mm thick. Thermocouples were used to measure the temperature rise near the crack tip. The effects of specimen size and side-groove on the cryogenic fracture properties of this alloy are examined. Examination of the fracture surface of CT specimens by scanning electron microscopy showed ductile failure by microvoid coalescence. The effect of inclusion on fracture mechanics parameters (JQ, JIC) is also discussed using energy dispersive X-ray analyser.