- 著者

- 正橋 直哉

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.59, no.2, pp.84-91, 2020-02-01 (Released:2020-02-01)

- 参考文献数

- 60

1 0 0 0 OA フロッピーディスクセンターコア用フェライト-マルテンサイト複合組織ステンレス鋼板の開発

- 著者

- 宮楠 克久 藤本 廣

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.34, no.5, pp.617-619, 1995-05-20 (Released:2011-08-11)

- 参考文献数

- 6

1 0 0 0 OA 軟磁性材料の開発動向と展望

- 著者

- 吉沢 克仁

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.56, no.3, pp.186-189, 2017 (Released:2017-03-01)

- 参考文献数

- 29

- 被引用文献数

- 6

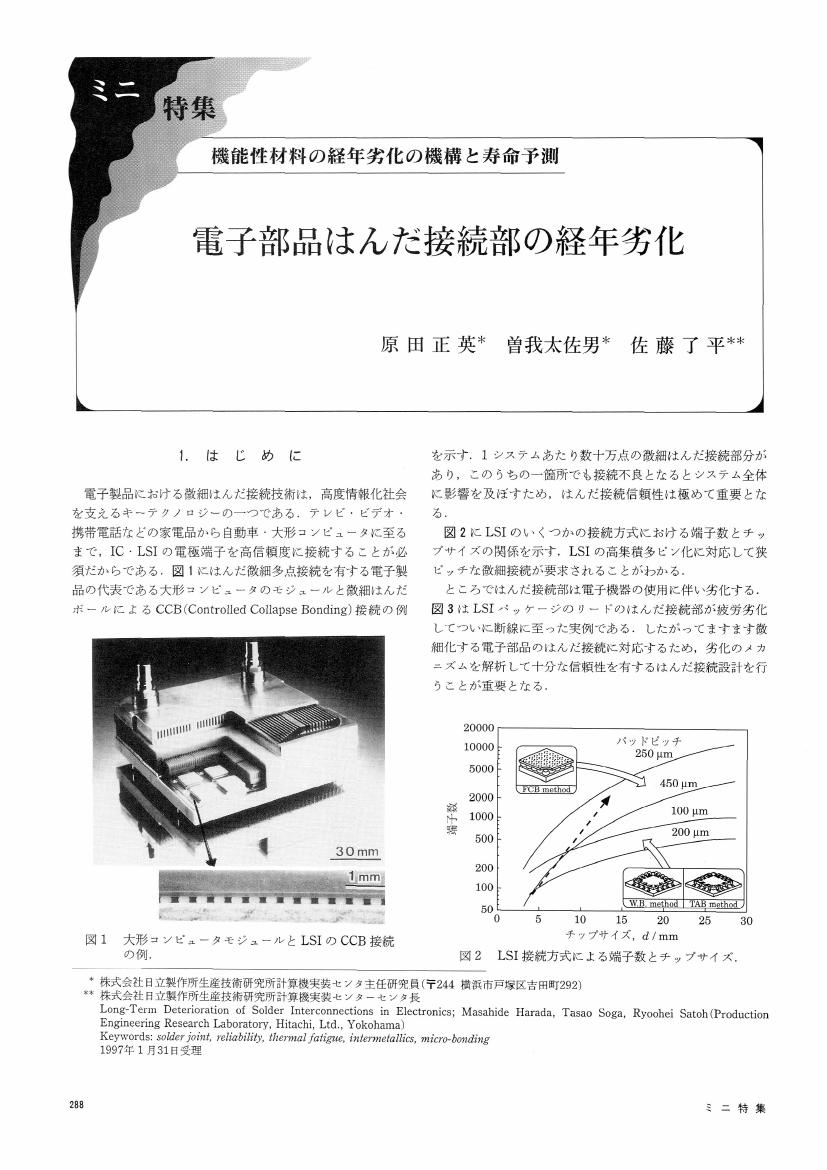

1 0 0 0 OA 電子部品はんだ接続部の経年劣化

- 著者

- 原田 正英 曽我 太佐男 佐藤 了平

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.36, no.4, pp.288-292, 1997-04-20 (Released:2011-08-11)

- 参考文献数

- 7

1 0 0 0 OA 脆性材料のモードI-II混合モード破壊のクライテリオン

- 著者

- 淡路 英夫 加藤 稔也

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.62, no.8, pp.735-741, 1998 (Released:2008-04-24)

- 参考文献数

- 21

- 被引用文献数

- 4 5

The Griffith energy criterion for brittle fracture is extended to mode II and combined mode I-II fracture by postulating that crack extension occurs when the maximum energy release rate in non-coplanar crack extension is equal to the fracture energy rate required for the mode II or the combined mode crack extension. The fracture energy rate is considered to be proportional to the critical magnitude of the area of a frontal process zone at a crack tip for brittle materials. The area of the frontal process zone is simply assessed here from the area enclosed in the iso-stress contours of both the maximum principal stress and the maximum shear stress around a crack tip. The anticipated ratio of mode II and mode I fracture toughness, KIIC⁄KIC, is 1.20. The value of the ratio, KIIC⁄KIC, is also estimated experimentally for float glass using a disk test. The result shows that the value of KIIC⁄KIC is 1.28 which agrees quite well with the anticipated one.

1 0 0 0 OA 白金を塩酸で溶解する新技術開発の裏話

- 著者

- 岡部 徹

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.53, no.3, pp.115-116, 2014 (Released:2014-03-01)

- 参考文献数

- 4

- 著者

- 梅原 佳那 松野 泰也

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.80, no.4, pp.247-252, 2016 (Released:2016-03-25)

- 参考文献数

- 16

- 被引用文献数

- 1

Previously we studied a novel process for recycling gold from secondary sources: the leaching of gold using dimethyl sulfoxide solutions containing copper bromide and precipitation with water, which could offer a number of advantages, including eco-friendliness, ease of operation and low cost. In this study, we have further investigated a more environmentally benign solvent, Propylene Carbonate (PC), with CuBr2 and KBr for the leaching and recovery of precious and rare metals. The mechanism of dissolution was investigated using electrochemical measurements. Metal wires were dissolved in a PC solution with 0.2 M of CuBr2 and 0.2 M of KBr at 343 K. Next, 10 ml of dilute sulfuric acid aqueous solution at pH 1 was added to the solution at ambient temperature and shaken to biphasically separate the dissolved metals. The contents of each element in the sulfuric acid and PC phases were measured by ICP-OES. The results of the electrochemical measurements indicated that the anodic dissolution of sample metals in the PC containing CuBr2 occurred at relatively negative potentials and was paired with the cathodic reduction of Cu2+ to Cu+. It was found that Au, Pd, Cu, Sn, Co, Ni and Zn could be dissolved at relatively fast rate, while Ag, Ta, Ti and W could not be dissolved. In addition, 98% of Au and 94% of Pd remained in the PC phase, while most other dissolved metals migrated to the sulfuric acid phase. This indicated that the dissolved Au and Pd could be effectively separated from other metals via biphasic separation with sulfuric acid. Next, the gold in the PC phase was recovered by the reduction of ascorbic acid or calcination. The cost analysis for recovering gold by this system resulted in 0.34 USD/g-Au.

- 著者

- 市川 裕士 所 竜太郎 亀山 雄高

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- pp.J2019033, (Released:2019-11-15)

- 参考文献数

- 17

- 被引用文献数

- 1

Fine particle peening (FPP) is a surface modification process in which fine hard metallic particles project onto the substrate. During this process, shot particles that remain transfer to the substrate and form a complex and multi-layered lamellar structure in which transferred fragments are distributed in the depth direction and several tens of micrometers from the surface. Because the bond strength at each interface of this structure and its generation mechanism are unclear, the local bond strength of the laminated interface was evaluated in this study by a microscale tensile test conducted by focus ion beam facilities. In the transferred lamellar modified region, the hardness was considerably higher than that of as-received materials, and the microscopic bonding strength between the transferred copper or iron and the aluminum matrix was 300 MPa or greater. When steel particles were used with FPP, iron oxide was mainly transferred to the aluminum matrix. However, copper plating on the particles suppressed the oxidation of the steel composing the particles and, as a result, the metallic steel was transferred. The bonding strength was improved by oxidation-controlled steel particles.

1 0 0 0 OA 科学技術史は何の役にたつか

- 著者

- 杉山 滋郎

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.37, no.8, pp.647-650, 1998-08-20 (Released:2011-08-11)

- 参考文献数

- 10

1 0 0 0 OA 箔打ちによる金属箔製造に関する力学的検討

- 著者

- 吾郷 真司 田中 照剛 横手 達夫 東田 賢二 小野寺 龍太

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会誌 (ISSN:00214876)

- 巻号頁・発行日

- vol.67, no.1, pp.34-39, 2003 (Released:2008-04-24)

- 参考文献数

- 1

This study aims to give a mechanical explanation to manufacturing of metal (silver) foil in a traditional Japanese way in which the foils are put between Japanese papers and forged. It was clarified by forging tests carried out at various forging pressures that the forging pressure necessary for manufacturing silver foil is about 30 MPa, which is equal to one-tenth of the yield stress in a 90% rolled specimen. The test also showed that the plastic elongation of foil is of the order of 0.1% per forging (pressure is 30 MPa). This result suggests that the foil is not stretched by forging pressure, but by frictional tensile stress applied to the foil by the Japanese paper. Another test to measure the elastic property of paper showed that the Japanese paper was elongated by 0.5∼0.6% in the paper plane when it was compressed in the vertical direction at the pressure of 30 MPa. Considering the elastic strain of foil, the value of 0.5∼0.6% agreed well with the plastic elongation of foil of 0.1%. The forging tests also showed that the lower limit of foil thickness is dominated by the ability of paper not to adhere to the silver foil (removability); for example, it was 1 μm for some papers, but 0.4 μm for others.

1 0 0 0 OA ストラティファイド光触媒による硫化水素からの水素製造

- 著者

- 田路 和幸 高橋 英志 松本 高利

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.46, no.3, pp.162-165, 2007-03-01 (Released:2011-08-11)

- 参考文献数

- 16

1 0 0 0 金属薄膜における電気化学的水素付加による内部応力制御法の検討

- 著者

- 山口 健吾 神谷 柾人 常盤 蓮 源馬 龍太 内田 ヘルムート 貴大 松村 義人

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- 日本金属学会 2019年秋期(第165回)講演大会

- 巻号頁・発行日

- 2019-08-01

1 0 0 0 OA 「NPO ものづくり教育たたら」の活動事例

- 著者

- 渡邊 玄

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.54, no.4, pp.152-156, 2015 (Released:2015-04-01)

- 参考文献数

- 2

1 0 0 0 OA 2ピース飲料缶の軽量化を実現する極薄容器用鋼板の開発

- 著者

- 村上 英邦 橋本 浩二 田中 聖市 竹下 哲郎 横矢 博一

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.38, no.3, pp.245-247, 1999-03-20 (Released:2011-08-11)

- 参考文献数

- 8

1 0 0 0 OA 耐熱用オーステナイト系ステンレス鋼 “NAR-AH-4” の開発

- 著者

- 西山 佳孝 椹木 義淳 宇野 秀樹 木原 重光 梶谷 一郎

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.36, no.4, pp.352-354, 1997-04-20 (Released:2011-08-11)

- 参考文献数

- 5

1 0 0 0 OA 自動車におけるLCA実施例

- 著者

- 山戸 昌子

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.40, no.8, pp.715-719, 2001-08-20 (Released:2011-08-11)

- 被引用文献数

- 1

1 0 0 0 OA コンクリートの代替が可能な環境にやさしい製鋼スラグ塊成化技術の開発

- 著者

- 高木 正人 松永 久宏 小菊 史男 谷敷 多穂 相川 真紀子

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.41, no.1, pp.45-47, 2002-01-20 (Released:2011-08-11)

- 参考文献数

- 3

1 0 0 0 OA 開発裏話~合金鉄溶解炉による資源循環システムプロセスの開発

- 著者

- 加藤 勝彦

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.57, no.5, pp.230-231, 2018 (Released:2018-05-01)

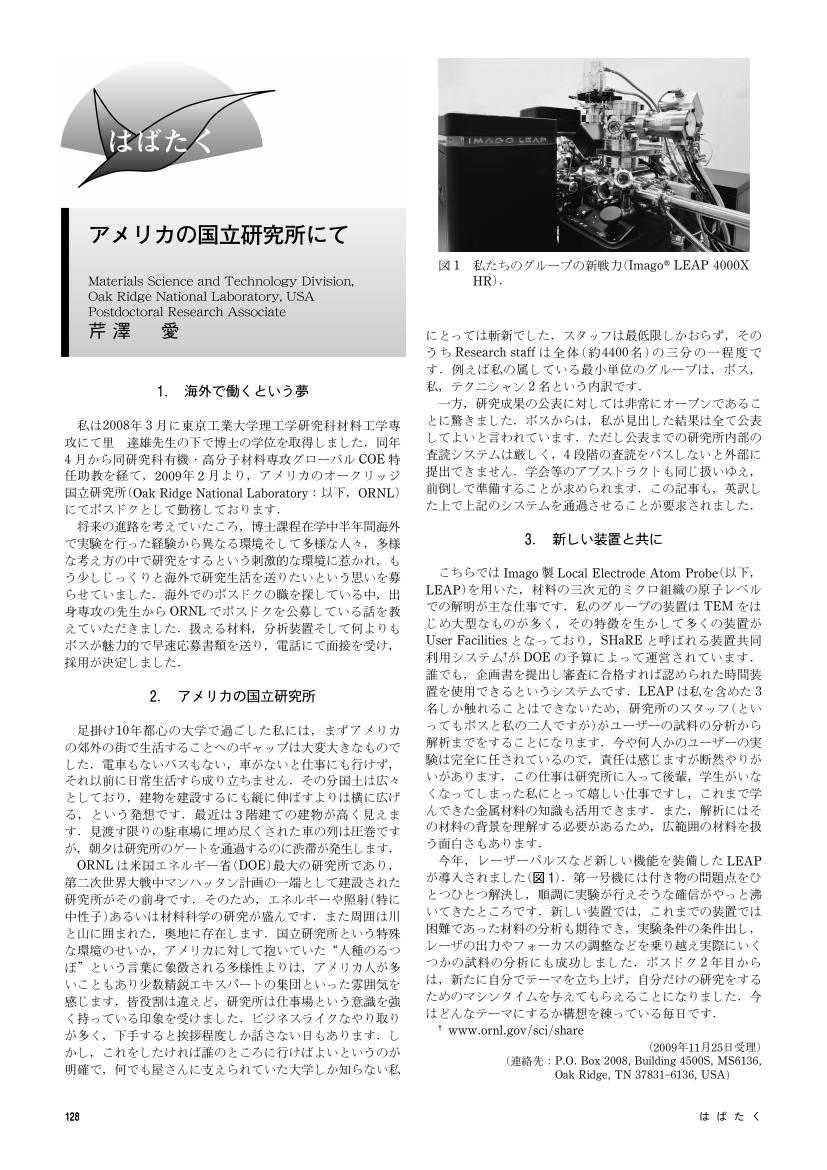

1 0 0 0 OA アメリカの国立研究所にて

- 著者

- 芹澤 愛

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.49, no.3, pp.128, 2010 (Released:2012-11-01)

1 0 0 0 OA 超高純度鉄の特性

- 著者

- 高木 清一

- 出版者

- 公益社団法人 日本金属学会

- 雑誌

- まてりあ (ISSN:13402625)

- 巻号頁・発行日

- vol.33, no.1, pp.6-10, 1994-01-20 (Released:2011-08-11)

- 参考文献数

- 33

- 被引用文献数

- 3 2